A Guide to Steam Table Pans Sizes and Materials

Share

Walk into any busy professional kitchen, and you’ll see them everywhere: the simple, workhorse steam table pans that are the real backbone of the food service industry. These are the unsung heroes, critical for keeping food perfectly hot or cold, from the prep line all the way to the buffet.

The Unsung Heroes of Your Commercial Kitchen

Think of steam table pans as the universal adapter for your kitchen. They're the standardized containers that travel seamlessly from the walk-in, to the prep station, into the oven, and finally, right onto the steam table for serving. This modular design is what makes them so vital. It allows chefs to cook, hold, and display food all in the same vessel, which is a massive time-saver that cuts down on cleanup and speeds up service.

This guide isn't just a basic overview; it treats these tools with the respect they've earned. We'll go beyond simple definitions to give you a real, practical understanding of how to pick the right materials, master the sizing system, and use the best practices for handling and cleaning. You’ll learn how to get the most out of your entire food holding and serving setup.

Why Steam Table Pans Are Essential

You can see just how important these pans are by looking at their market growth. The global steam table pans market was valued at around USD 1.20 billion in 2024 and is expected to climb to about USD 1.90 billion by 2030. This boom is all thanks to the ever-expanding foodservice sector, which absolutely depends on these pans for efficiency and food safety. You can find more details on this trend over at deepmarketinsights.com.

At their core, the benefits of using standardized steam table pans boil down to a few key things:

- Efficiency: They create a straight line from cooking to serving, cutting out the need to transfer food between a bunch of different containers.

- Consistency: Standard sizes mean a perfect, snug fit in steam tables and cold wells, which gives you that even, consistent heating or cooling you need.

- Versatility: You can use them for just about anything—from baking casseroles and roasting vegetables to holding soups, sauces, and everything in between.

Think of this guide as your complete playbook for optimizing your entire food holding and serving workflow, ensuring every dish is served exactly as you intended.

By truly understanding what your steam table pans are capable of, you can boost your food quality, cut down on waste, and run a much more organized, effective kitchen. Let's dive into how you can make these humble pans work a lot harder for you.

Decoding Steam Table Pan Sizes and Depths

Walk into just about any commercial kitchen, and you'll see a sea of stainless steel. But not all of those surfaces are created equal. The world of prep tables is surprisingly diverse, with specialized designs built to make different kitchen workflows faster and more efficient.

Figuring out these variations is the first step to creating a workspace where your steam table pans can move seamlessly from prep to the service line. Each type of table really does have a distinct job to do.

At the heart of it all are the standard flat-top prep tables. These are the indestructible workhorses you see everywhere. They give you a simple, durable surface for everything from chopping and mixing to plating and general assembly. Most come with an undershelf for stashing equipment and supplies, making them the foundation of any good kitchen layout.

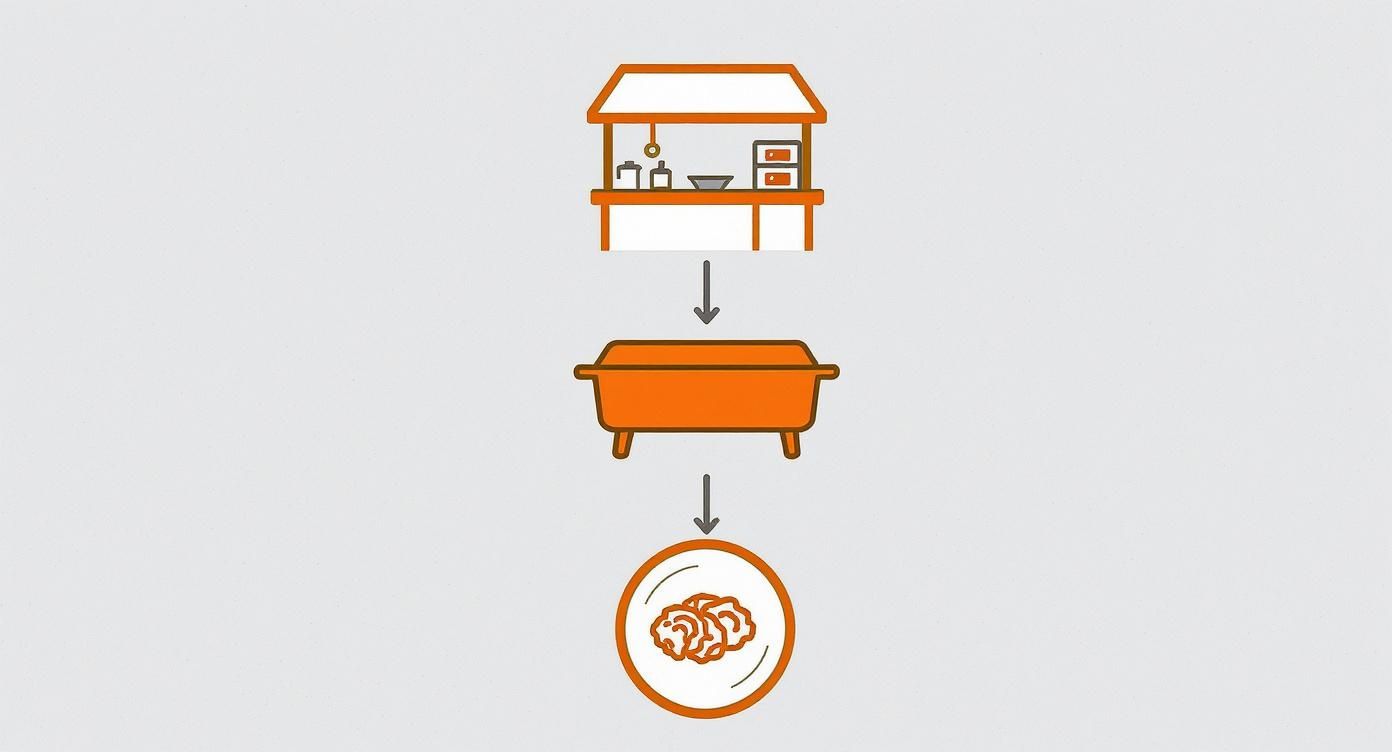

This infographic shows just how central steam table pans are, connecting everything that happens in the back of the house with the final plate of food.

You can see how the pan acts as the essential link between the kitchen's entire operational flow and the food being served. It’s a pretty critical role when you think about it.

Specialized Prep Tables for High-Speed Service

Once you move beyond the basics, you get into prep tables designed for the fast-paced, assembly-line style of food production. These units are game-changers because they integrate refrigeration right into the workspace. This is a massive win for both food safety and speed.

These tables are specifically set up to hold fractional steam table pans, keeping all your ingredients perfectly chilled and right where you need them. No more running back and forth to the walk-in.

Two of the most common specialized tables you'll find are:

- Sandwich Prep Tables: These tables have refrigerated wells on top, sized perfectly for holding third-size or sixth-size pans filled with sliced meats, cheeses, and veggies. Underneath the cutting board, you'll usually find a refrigerated cabinet for backup storage.

- Pizza Prep Tables: Working on the same idea, pizza prep tables have a much wider and deeper refrigerated rail to hold a bigger variety of toppings in different pan sizes. They often feature a heavy-duty stone or marble top, which is the perfect cold surface for working with dough.

When you match the type of prep table to your menu, you create a workflow that just makes sense. It’s more ergonomic for your staff, which not only speeds up service but also helps maintain the strict temperature control that is the absolute cornerstone of food safety.

Other Stainless Steel Table Variations

Beyond those main categories, a few other stainless steel tables play important supporting roles in a busy kitchen.

You’ll find tables with built-in sinks that combine prep space with cleaning capabilities, cutting down on how much your staff has to move around the kitchen. You'll also see heavy-duty equipment stands, which are tough-as-nails tables designed to hold bulky appliances like mixers or griddles at a comfortable working height.

Ultimately, the goal is to create a logical flow. A well-designed kitchen might have a flat-top table for breaking down produce, which then flows to a refrigerated sandwich station for assembly, and finally over to the steam table for hot holding. Each table is a crucial station in a bigger, more efficient system. Picking the right combination of prep tables is fundamental to maximizing your kitchen’s output.

Choosing the Right Material for Your Pans

When you're outfitting a kitchen, picking the right steam table pans is one of those decisions that directly impacts your daily grind. It's about durability, how well your food holds temperature, and, of course, safety. Not all pans are created equal, and knowing the difference is what separates a smart investment from a future headache. For almost any commercial kitchen, stainless steel is the undisputed champion.

This isn't just about what's always been done. Stainless steel brings a powerhouse combination of strength, corrosion resistance, and simple sanitation that other materials just can't touch. Its surface is non-porous, which means it won’t hold onto bacteria or soak up flavors and smells. You'll never have to worry about yesterday's garlic sauce making an unwelcome appearance in today's fruit cobbler.

This focus on tough, cleanable gear is a big deal in the industry. As kitchens everywhere get serious about health and safety, the demand for pans that can take a beating and be easily sanitized has shot up. With customers wanting quality food fast, the whole steam table pan market is set to keep growing. You can dive deeper into this trend over at Verified Market Reports.

Understanding Stainless Steel Gauge

As you shop for stainless steel pans, you'll see the term "gauge" pop up. It's just a way of talking about how thick the metal is. It can be a little counterintuitive, but remember this: a lower gauge number means thicker, tougher steel.

- 22-Gauge: This is your heavy-hitter. It’s thick, strong, and highly resistant to dents, dings, and the kind of warping that happens from constant heating and cooling. If you're running a high-volume kitchen where pans are in constant rotation, this is the way to go.

- 24-Gauge: This is a bit thinner and more budget-friendly. It’s still a solid choice, but it's more likely to show wear and tear over time. Think of it as a better fit for lighter-duty work.

For most busy restaurants, spending a little more on 22-gauge pans pays for itself in the long run. They simply last longer. That thicker build also helps spread heat more evenly, which means fewer hot spots burning your food. This kind of durability is just as important for the surfaces they sit on; you can check out our guide on restaurant stainless steel tables to learn more about setting up a truly robust workspace.

Other Material Options

While stainless steel really runs the show, a few other materials have their own specific uses:

- Polycarbonate: You've seen these clear plastic pans in salad bars and cold wells. They're perfect for cold applications and storage because you can see exactly what's inside. Just remember, they must never be used for hot holding or put in an oven.

- Aluminum: Aluminum is a fantastic heat conductor, meaning it heats up in a flash. That makes it great for some baking tasks, but it's not as durable as stainless steel and can react with acidic foods like tomato sauce.

One of the most critical things to look for on any pan is the NSF certification. This isn't just a sticker—it's your guarantee from an independent third party that the pan's design, material, and overall construction meet strict public health and safety standards. Always, always look for that NSF logo to ensure your gear is food-safe and built for the pros.

Pairing Your Pans with the Perfect Prep Table

Your steam table pans are only half the battle for a truly humming kitchen. The surface where all the action happens—the prep table—is just as critical. It's the launchpad for every single dish. The right table does more than just give you space; it sharpens your entire workflow, creating a smooth path from ingredient storage to the service line. The key is to match the type of stainless steel table to the job at hand.

Common Types of Stainless Steel Prep Tables

The foundation of any kitchen is the classic stainless steel work table. These are the simple, tough workhorses used for everything from dicing onions to assembling plates. They typically come with a flat top, an undershelf for storage, and sometimes a backsplash to protect walls. Their versatility makes them the heart of any prep area.

From this basic design, several specialized variations have emerged to tackle specific kitchen tasks more efficiently:

- Sandwich and Salad Prep Tables: These refrigerated units are a game-changer for high-speed assembly. They feature refrigerated wells on top, perfectly sized to hold fractional steam table pans filled with ingredients like sliced meats, cheeses, and fresh vegetables. This keeps everything chilled, organized, and within arm's reach of the integrated cutting board work surface.

- Pizza Prep Tables: Built on the same concept, these tables offer a much wider and deeper refrigerated rail to accommodate the large variety of toppings needed for a busy pizzeria. They often feature a heavy-duty marble or stone top that stays naturally cool, providing the ideal surface for working with dough.

- Work Tables with Sinks: Combining prep space with a built-in sink, these tables streamline the workflow by reducing the need for staff to move between stations for rinsing produce or washing hands and equipment. This consolidation saves valuable time and floor space.

- Equipment Stands: These are not your average tables. They are heavy-duty, reinforced stands designed to safely hold bulky and heavy appliances like commercial mixers, slicers, or griddles at an ergonomic working height. They provide a stable, dedicated base for essential machinery.

By matching your prep table to your menu's specific demands, you create a more logical and ergonomic station. This not only accelerates service but also reinforces the strict temperature control that is fundamental to food safety.

Integrating Refrigeration for Maximum Efficiency

The real magic of specialized units like sandwich and pizza prep tables is their built-in refrigeration. These tables are engineered to hold a consistent cold temperature, even when the lids are being opened constantly during a chaotic service. This ensures every ingredient stays safely in the cold zone, from the first ticket of the day to the very last.

To get an even better sense of how these units can completely change your kitchen's rhythm, you can learn more about the benefits of commercial refrigerated prep tables and how they work hand-in-hand with steam table pans.

At the end of the day, picking the right table is about building a cohesive system. A well-designed kitchen might have a standard stainless steel table for initial prep, which then flows to a refrigerated sandwich station for assembly, and finally over to the steam table for hot holding. Each table is a critical link in an efficient chain, and choosing the right one is a key step in optimizing your entire operation.

Proven Methods for Cleaning and Maintenance

The difference between a steam table pan that lasts for years and one that warps and stains in a few months often comes down to one thing: proper care. A solid cleaning routine isn't just about extending the life of your investment; it's a non-negotiable part of upholding food safety standards in your kitchen.

Great cleaning habits start the second a pan is empty. Instead of letting food residue turn into concrete, give the pan an immediate rinse with hot water. For those really stubborn, baked-on messes like burnt cheese or thick, sticky sauces, a pre-soak in warm, soapy water is your best friend. It does most of the hard work for you, loosening up the grime and making scrubbing a breeze.

Daily Cleaning Best Practices

The secret to keeping that pristine finish on your pans is using the right tools for the job. If you grab harsh, abrasive materials, you're essentially creating microscopic scratches on the steel's surface. Those tiny grooves become a perfect hiding spot for bacteria and will cause food to stick even more in the future.

Just follow these simple steps for your daily wash-up:

- Use Non-Abrasive Cleaners: Stick with mild detergents and a soft cloth or a gentle nylon scrubber. You'll want to avoid things like steel wool, scouring powders, or harsh chemicals like bleach. These can strip away the protective chromium oxide layer that makes stainless steel "stainless."

- Rinse Thoroughly: Once you're done washing, give each pan a good rinse with clean, hot water to wash away any soap residue. Skipping this step is what often leads to that cloudy film you sometimes see on steel.

- Air-Dry Completely: This is a surprisingly critical step. Stack your pans so that air can circulate freely around every single surface. Trapping moisture by stacking wet pans is a recipe for water spots and can create a damp environment where bacteria can thrive.

Tackling Common Cleaning Challenges

Even if you're doing everything right, stainless steel can sometimes throw you a curveball. One common issue is a faint, rainbow-like discoloration called "heat tint," which happens when a pan gets overheated. Another is the appearance of stubborn white spots, which are usually just mineral deposits left behind by hard water.

The good news is that most of these cosmetic issues are reversible. A simple paste made from baking soda and water, or a gentle wipe-down with white vinegar, can often restore the steel's original shine without causing any damage.

For a deeper look at keeping all your kitchen equipment in top shape, our guide offers detailed advice on how to clean stainless steel and keep it looking brand new. And for those times when you need a top-to-bottom clean, looking into professional restaurant cleaning services can ensure your entire commercial kitchen stays consistently hygienic. By making these habits part of your daily routine, you’ll ensure your steam table pans remain a reliable workhorse for years to come.

Strategies for Optimizing Your Steam Table Setup

Owning a steam table is one thing; mastering its performance is a whole different ball game. It's easy to just plug it in and get started, but the real magic happens when you dial in the details. Getting peak performance out of your setup can dramatically improve your food quality and make service way more efficient.

It all starts with the water in the wells. Think of that water as a gentle buffer, the thing that evenly transfers heat to your pans without ever scorching the food. Nailing the right water level and keeping the temperature steady is absolutely non-negotiable for gentle, consistent heating. Too little water, and you'll burn your product. The wrong temp, and you're risking food safety.

Transforming Your Setup with Key Accessories

Once you’ve got the water sorted, a few essential accessories can take your serving line from just functional to truly exceptional. These tools are designed to fix common serving headaches, make your food look better, and give you way more control.

- Pan Risers: These simple gadgets are a lifesaver. They lift shallower pans up closer to the top of the well, so guests can actually see what's inside and serve themselves without a struggle.

- False Bottoms: If you’re serving delicate items like steamed fish or veggies, you need these. A false bottom is just a perforated insert that sits inside the pan, elevating food so it doesn’t sit in its own juices and get soggy.

- Lids in Various Styles: Lids are your best friend for controlling heat and moisture. A solid lid traps all that steam for things you want to keep moist. A hinged lid is great for easy access during a rush, and a slotted lid gives you a perfect spot to rest a serving spoon.

By thoughtfully combining these accessories, you can create a customized setup that maintains the ideal texture and temperature for each specific dish you serve. This level of control is what separates an average buffet from a professional one.

While the market for steam table pans keeps growing, they're just one piece of a much larger commercial kitchen equipment puzzle. Seeing them as part of a market segment worth tens of billions really drives home how vital they are and why we keep seeing new innovations.

Getting these strategies right is a big step toward a more efficient kitchen. For more ideas on how to streamline restaurant operations, you can find some great information here.

Your Questions, Answered

Working with kitchen equipment always brings up a few questions. Here are some quick, clear answers to the most common things we hear from foodservice pros about steam table pans, helping you sort out those practical challenges right when they pop up.

Can You Use Steam Table Pans In An Oven?

Yes, you absolutely can. Standard stainless steel steam table pans are built for this kind of versatility, making them perfect for cooking, holding, and then sliding right into a serving line.

That said, it’s always a good idea to check the manufacturer’s guidelines first. And remember, this only applies to stainless steel—plastic or polycarbonate pans must never go in an oven. They will melt.

What Is The Difference Between Stainless Steel Gauges?

The gauge tells you how thick the metal is, but the numbering system can feel a bit backward at first: a lower number means thicker, more durable metal.

Think of it this way: a 22-gauge pan is noticeably heavier and way more resistant to dents and warping than a flimsy 24-gauge pan. For the daily grind of a busy commercial kitchen, choosing lower-gauge (thicker) pans is a smart move for long-term durability.

How Do You Prevent Food From Sticking To Pans?

While they aren’t non-stick like a Teflon skillet, you can definitely make them a lot slicker. The best first step? Make sure your steam table well has hot water in it before you place your pans of hot food inside.

If you’re cooking in them, a light coat of oil or cooking spray creates a helpful barrier. Most importantly, try to avoid using abrasive metal utensils. Those forks and spoons can create tiny scratches on the surface, and those little grooves are the perfect place for food to grab on and stick.

For a complete selection of durable steam table pans and the professional prep tables to match, explore the full range at PrepTables.com. Find the perfect equipment to optimize your kitchen's workflow today at https://preptables.com.