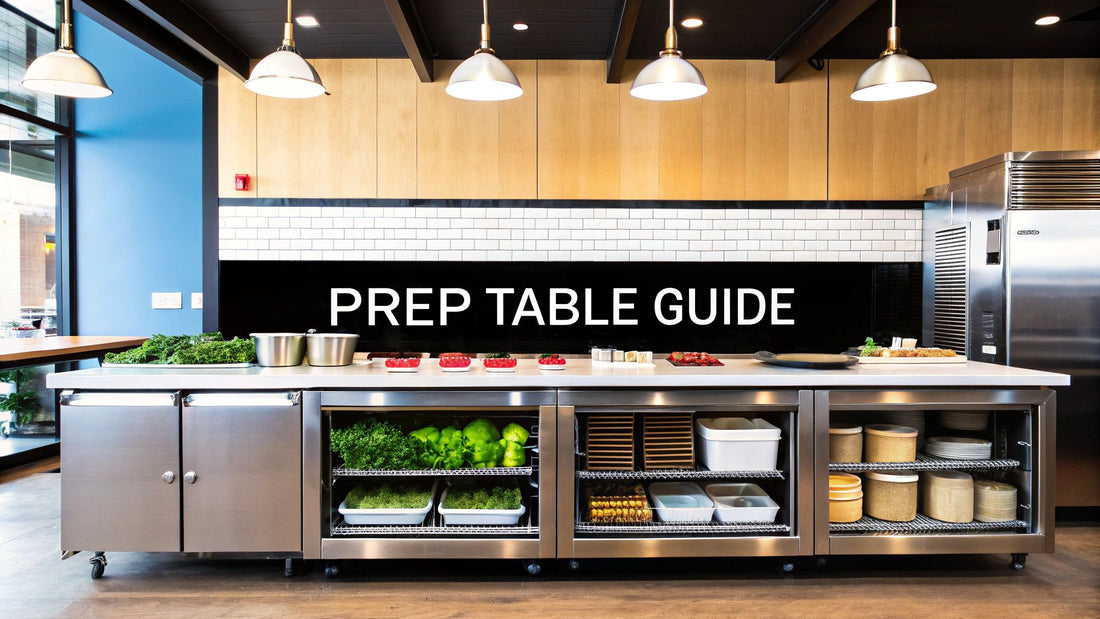

A Guide to Commercial Refrigerated Prep Tables

Share

Think of a commercial refrigerated prep table as the command center of any busy kitchen. It's the perfect bridge between your big walk-in cooler and the hot cooking line, keeping everything you need chilled and right at your fingertips for quick assembly.

This guide will walk you through exactly why these units are so crucial and how to pick the perfect one for your menu and space.

Why Your Kitchen Needs a Refrigerated Prep Table

In any professional kitchen, it all comes down to three things: speed, consistency, and safety. A good refrigerated prep table is a game-changer that hits all three. It’s so much more than just a stainless steel table with a fridge underneath; it's a workstation specifically engineered to make the most critical part of your service—building the dish—as smooth as possible.

Let's picture making a sandwich without one. Your cook walks to the cooler for meat, then shuffles over to another spot for cheese, and finally to a third for veggies. Each step adds precious seconds to the ticket time and opens the door for mistakes or even cross-contamination.

Now, imagine that same cook with a refrigerated prep table. Every single ingredient is neatly organized in chilled pans directly in front of them. This integrated setup slashes wasted movement and keeps the line humming along efficiently.

Unlocking Efficiency and Safety

The biggest win with these units is the seamless workflow they create. By having chilled storage and a prep surface in one spot, your staff can put together dishes way faster and with fewer mistakes. This is absolutely essential for businesses built on speed, like delis, pizzerias, and fast-casual spots.

Investing in the right unit isn't just about buying equipment; it's a strategic decision that boosts efficiency, ensures consistency, and directly impacts your bottom line.

Beyond just speed, these tables are your first line of defense for food safety. They hold ingredients in that critical temperature "safe zone" of 33°F to 41°F (0.5°C to 5°C), which stops harmful bacteria from growing. This makes sure every salad, sandwich, or pizza you send out is not only fresh but completely safe to eat.

Here are the key benefits you'll see right away:

- Enhanced Workflow: It keeps your staff planted in one spot by putting all the ingredients they need within arm's reach. This seriously cuts down on order fulfillment times.

- Improved Food Safety: By holding a consistent, safe temperature for your perishable items, you lower the risk of foodborne illness and stay on the right side of the health inspector.

- Optimized Space: You're basically getting two pieces of essential kitchen equipment—a prep area and a refrigerator—in one compact footprint. This is a lifesaver in tight kitchens.

- Ingredient Consistency: It protects the quality, texture, and flavor of your ingredients, making sure every dish that leaves the kitchen is up to your standards.

When you get right down to it, a well-chosen prep table becomes the heart of your production line. It empowers your crew, protects your customers, and builds your reputation for quality.

Decoding the Different Types of Prep Tables

Choosing a commercial refrigerated prep table isn’t as simple as just picking a stainless steel surface with a cooler attached. The right unit is built to support a specific workflow, becoming a critical part of your kitchen's rhythm. Picking the wrong one is like trying to chop onions with a butter knife—you might get the job done, but it’s going to be slow, messy, and frustrating.

The small differences between models can be the deciding factor between lightning-fast service and a major bottleneck. Understanding these core types is your first step toward finding a unit that feels like it was made just for your team. This decision is more important than ever, as the global market for food prep tables was valued at USD 1.18 billion in 2023 and is expected to hit USD 1.62 billion by 2029. This growth shows just how vital these stations are for any modern kitchen.

Sandwich and Salad Prep Tables

The undisputed workhorse in countless kitchens is the sandwich/salad prep table. Picture a busy deli at the height of the lunch rush. The secret to that speed is having every single topping, spread, and protein perfectly organized and within arm's reach. That's exactly what these tables are designed for.

They come with a raised, refrigerated pan rail that holds a lineup of food pans, keeping ingredients like tomatoes, lettuce, deli meats, and cheeses chilled and ready to go. The cutting board on these models is typically on the narrower side—usually 8 to 12 inches deep—because the main job is assembly, not heavy-duty prep work.

- Key Design: A raised refrigerated rail designed to hold multiple food pans.

- Best For: Delis, cafes, and any spot with a high volume of sandwich and salad orders.

- Workflow Advantage: Keeps all your ingredients right in front of the chef, cutting down on movement and speeding up every single order.

Pizza Prep Tables

While they look similar at first glance, pizza prep tables are engineered for a totally different task. Building a great pizza requires a wide, flat space for stretching out dough, spreading sauce, and layering on a mountain of toppings. A skinny little cutting board just isn't going to work.

That's why pizza prep tables have a much deeper work surface, often 16 to 24 inches deep, giving you plenty of room for a full-size pizza. The refrigerated rail is also built differently; it's usually raised higher to accommodate larger food pans for bulky items like shredded cheese, pepperoni, and heaps of veggie toppings.

A pizza prep table is built entirely around the dough. Its deep cutting board and roomy topping rail give a pizzaiolo the perfect, efficient station to craft pies without compromise. Trying to make a pizza on a standard sandwich table is a recipe for a slow, messy disaster.

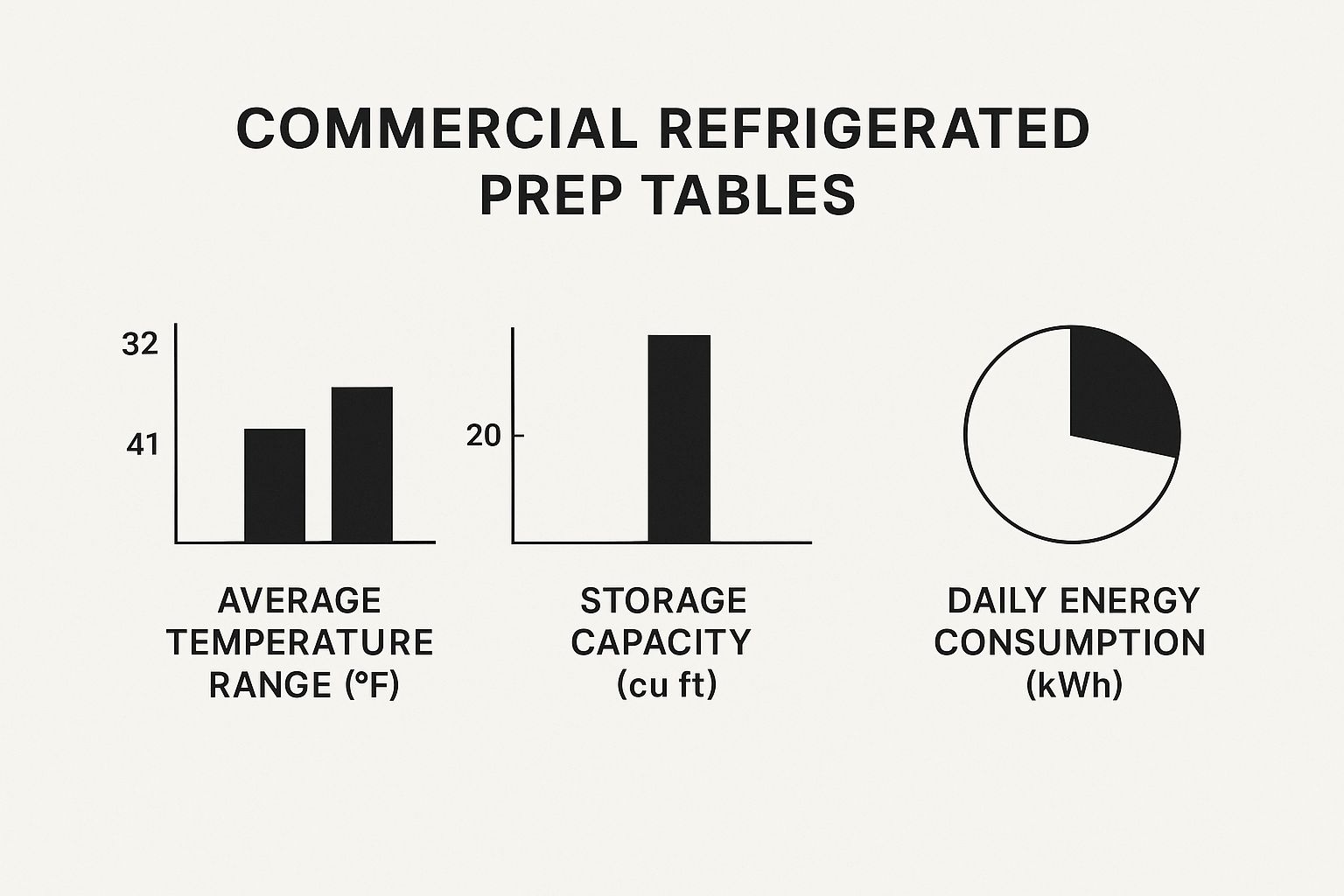

This infographic gives you a quick visual breakdown of the key metrics for different commercial refrigerated prep tables.

As you can see, different models are engineered to balance storage capacity, energy consumption, and temperature consistency to fit specific kitchen needs.

To make the choice even clearer, let's compare these common models side-by-side.

Comparing Key Refrigerated Prep Table Models

| Table Type | Primary Use | Key Feature | Cutting Board Depth |

|---|---|---|---|

| Sandwich/Salad Table | Assembling sandwiches, wraps, salads | Raised rail with multiple small pans | 8" - 12" |

| Pizza Prep Table | Making pizzas from scratch | Extra-deep work surface | 16" - 24" |

| Mega-Top Table | High-volume sandwich/salad assembly | Extra row of pans for more ingredients | 10" - 12" |

| Standard Worktop | General food preparation | Flat, uninterrupted work surface | N/A (Full surface) |

This table should help you quickly identify which style is the best fit for the primary tasks in your kitchen.

Standard Worktops and Mega Tops

Beyond these two highly specialized units, you'll run into a couple of other common types of stainless steel prep tables. A standard worktop refrigerator is the jack-of-all-trades, offering a simple, flat stainless steel surface on top of refrigerated storage. It's a great all-around choice for general prep that doesn't need a dedicated topping rail.

For those high-volume kitchens that need more ingredient options than a standard sandwich table can provide, there’s the mega-top prep table. Think of it as a sandwich table on steroids. It features an extra row of pan capacity in the refrigerated rail, giving you space for a wider variety of ingredients. This is perfect for kitchens with complex menus or those that face insane rushes. You can dive deeper into all the different setups in our complete guide on the types of stainless prep tables.

Essential Features That Define Performance

Once you've settled on the basic type of prep table you need, the real magic—or misery—is in the details. The underlying technology and design features are what separate a true kitchen workhorse from a unit that's a constant headache. Learning what to look for helps you see past the sales pitch and judge a table on its real-world performance.

This isn't just about bells and whistles. The right features can seriously cut your energy bills, slash food waste, and make your team’s life a whole lot easier during a chaotic dinner rush. Let's dig into the features that really matter.

Refrigeration Airflow and Placement

One of the first big decisions you'll make is about airflow: does the unit "breathe" from the front or the back? This choice dictates exactly where you can put the table in your kitchen, so it's a critical first step.

- Front-Breathing Units: These are the most flexible. They pull air in and push it out through a grille on the front. This means you can slide the unit right up against a wall or nestle it between other pieces of equipment without choking its airflow.

- Rear-Breathing Units: These models need space to breathe. You have to leave several inches of clearance around the back and sides for them to work correctly. While they can be a bit easier on the wallet, that upfront saving means less freedom in your kitchen layout.

Shoving a rear-breathing unit against a wall is a classic mistake. It forces the compressor to work way too hard, driving up your energy bills and leading to a much shorter lifespan for the equipment. Always measure your space carefully and account for that clearance.

Storage Configuration Doors vs. Drawers

The choice between doors and drawers in the base seems simple, but it has a huge effect on how organized and fast your line can be. Each one is built for a different kind of workflow.

Doors are your go-to for bulk storage. They’re perfect for stashing large Cambros of prepped sauce, backup pans of ingredients, or any oversized items that just won’t squeeze into a drawer. If you need maximum flexibility for different-sized containers, doors are the way to go.

Drawers, on the other hand, are the champions of organization. They let you neatly separate every ingredient, so your staff can grab exactly what they need in a split second without digging around. For a high-volume sandwich or salad station where speed is everything, drawers are a game-changer.

The Rise of Smart and Efficient Technology

Today’s prep tables are smarter than ever, packing in features that improve both performance and food safety. The market is shifting towards units with energy-saving compressors and better temperature controls, a trend confirmed by a detailed market forecast. These aren't just fancy add-ons; they're designed to lower your operating costs.

A digital temperature controller is non-negotiable these days. It gives you a precise, easy-to-read display, ensuring your ingredients stay in that critical food-safe zone of 33°F to 41°F.

Some of the newer systems even have remote monitoring. They can send an alert straight to your phone if the temperature starts creeping up, which can be the difference between a quick fix and a dumpster full of spoiled product. Likewise, energy-efficient compressors use far less power to stay cold, and those savings really add up on your utility bill over time.

Finally, don’t ignore the little things. High-quality magnetic door gaskets are crucial for creating a tight seal that traps cold air inside, keeping the compressor from running constantly. A clean, well-maintained condenser coil is just as important for efficiency. By paying attention to these core features, you're not just buying a piece of equipment—you're investing in a strategic asset for your kitchen.

Picking the right commercial refrigerated prep table is about more than just finding a unit that slots into an empty space. Get the size or configuration wrong, and you can unknowingly create a major bottleneck in your kitchen. This can bog down service and leave your staff feeling the heat. But when you get it right? The table becomes a seamless part of your kitchen's natural rhythm.

The first, non-negotiable step is to measure everything. And I don't just mean the floor space. You have to account for the clearance needed on the back and sides for proper airflow—this is often several inches. If you skip this, a rear-breathing unit can easily overheat, which is a fast track to costly repairs and a much shorter lifespan for your equipment.

From Footprint to Workflow

Once you have your physical dimensions locked down, it's time to think about how that footprint translates to your kitchen's output. Commercial refrigerated prep tables generally come in standard widths, most commonly 48, 60, and 72 inches.

- A smaller 48-inch unit is often the perfect solution for tight kitchens, bustling food trucks, or cafes with a more focused menu. It gives you a dedicated prep zone without hogging precious real estate.

- The 60-inch model is a fantastic all-rounder. It strikes a balance, offering more refrigerated storage and a bigger work surface for kitchens dealing with a steady, moderate flow of orders.

- A big 72-inch unit (or even larger) is a true workhorse. These are built for high-volume operations that need to run multiple assembly lines at once or require a massive amount of cold ingredient storage right at their fingertips.

Think about your peak service hours. Can your team work side-by-side without constantly bumping elbows? A table that's too small will breed chaos during a rush. On the flip side, one that's too big is just a waste of valuable kitchen space and electricity.

Calculating Your Pan Capacity

Beyond the physical width, the most important configuration detail is the pan capacity. This is all about how many food pans the refrigerated rail up top can hold. Nailing this is the secret to making sure your team isn't constantly breaking their flow to restock ingredients in the middle of a service.

To figure out your ideal capacity, take a hard look at your menu.

- List Every Ingredient: Jot down every single cold ingredient that goes into the sandwiches, salads, pizzas, or whatever else you're assembling at that station.

- Estimate Peak Volume: How many of your top-selling items fly out of the kitchen during your busiest hour? This helps you understand how fast you’ll burn through things like lettuce, cheese, or your signature sauce.

- Factor in Variety: A complex menu with tons of different toppings will naturally need more individual pans than a simpler, more streamlined one.

A classic mistake is underestimating your pan needs. Running out of a core ingredient during the dinner rush doesn't just slow down the line; it can also tank food quality as your crew scrambles to refill pans. It's always better to plan for a little more capacity than you think you'll need.

For instance, a busy sandwich shop might find a "mega-top" unit with an extra row of pans is a lifesaver for holding all its various meats, cheeses, and veggies. A small pizzeria, however, might get by with a standard rail but opt for deeper pans to hold bulkier items like pepperoni and mounds of shredded mozzarella.

Choosing the right size and pan layout isn't just about logistics—it’s a strategic move. It has a direct line to your kitchen’s speed, organization, and your ability to serve up consistently great food when it counts. For a more detailed walkthrough, you can explore more options in this comprehensive prep tables buying guide.

Why Material Quality Matters for Longevity

When you're investing in a commercial refrigerated prep table, you're really investing in its bones. The materials it's built from are the foundation for its durability, how safe it is for food, and ultimately, how long it will last in your kitchen. It's a lot like building a house—you wouldn't frame it with cheap, flimsy wood and expect it to survive a storm. It's the same principle here. The kind of stainless steel and cutting board you choose will make or break how well your unit holds up to the daily grind.

When it comes to the steel, you have to understand that not all stainless is created equal. The real difference comes down to the "grade," which tells you how tough the metal is against rust, corrosion, and general wear and tear. Getting this right is the key to making a smart investment that won't let you down.

The Gold Standard: 304-Grade Stainless Steel

For any part of the table that actually touches food—think the inside of the refrigerated base or the topping rail—304-grade stainless steel is the undisputed champion. There’s a good reason for this. It has more chromium and nickel in its makeup, which gives it superior protection against rust and corrosion. This is a huge deal in a kitchen where the unit is constantly bombarded with acidic foods like tomato sauce and vinaigrettes, not to mention heavy-duty cleaning chemicals.

Sure, tables with 304-grade steel might cost a bit more upfront, but they absolutely pay for themselves over time. This material is far less likely to pit or degrade, which means no tiny cracks for bacteria to hide and grow in.

The Workhorse: 430-Grade Stainless Steel

You’ll often find 430-grade stainless steel used for the exterior of a prep table—the sides, back, and sometimes the top. This grade has less nickel, making it a more budget-friendly option, but it's also a bit more vulnerable to corrosion down the road. Since these surfaces aren’t usually in direct contact with food, using 430-grade here is a common way manufacturers keep costs down without sacrificing food safety.

But if you're looking for a top-of-the-line unit built to last a lifetime, an all-304 construction is the way to go. It offers the best possible defense against the humid, demanding reality of a commercial kitchen.

Choosing a unit with 304-grade steel for food-contact zones isn't just a recommendation; it's a critical food safety decision. It ensures your prep surfaces remain non-porous and easy to sanitize, protecting both your customers and your reputation.

More Than Just Steel: The Cutting Board

Don't forget about the cutting board—its material is just as vital as the steel. Most modern prep tables come standard with removable boards made from high-density polyethylene (HDPE). This stuff is a food safety hero. It’s non-porous, meaning it won’t soak up liquids or let bacteria set up camp like a wooden board can.

Here’s why the cutting board material is so critical:

- Sanitation: HDPE boards are NSF-certified and can be pulled right off for a deep clean in a commercial dishwasher.

- Durability: They’re tough enough to handle constant chopping but won't dull your knives too quickly.

- Maintenance: Unlike wood, you don't have to worry about oiling them or special treatments to stop them from cracking or warping.

Getting these material choices right is a crucial decision for any kitchen manager. For a deeper look at all the options, our guide to restaurant stainless steel tables has even more detailed insights to help you pick equipment that’s built to last.

Simple Maintenance for Peak Performance

Think of your commercial refrigerated prep table as the engine of your service line. It's a major investment, and just like any engine, it needs a little routine care to keep running smoothly. A consistent maintenance schedule is your best defense against costly, service-stopping breakdowns.

Sticking to a maintenance plan isn't just about dodging repair bills—it's about getting the best performance every single day. A well-maintained unit is more energy-efficient, holds its temperature precisely, and keeps you compliant with food safety rules. The daily, weekly, and monthly checks below are simple but incredibly effective at protecting your equipment.

Daily and Weekly Checks for Success

Small, consistent actions are the foundation of a healthy unit. These are quick tasks your kitchen staff can handle that will catch little problems before they become big, expensive ones.

- Clean All Surfaces: At the end of every shift, wipe down the interior and exterior with a food-safe cleaner. This keeps residue from building up and maintains a sanitary space.

- Inspect and Wipe Gaskets: Once a week, check the rubber door gaskets for any tears or cracks. A quick wipe with a damp cloth removes grime and ensures a tight seal, which saves energy by locking in the cold.

- Monitor Temperatures: Your team should check the digital thermometer at the start of every shift. You want to see it holding steady between 33°F and 41°F—that's the sweet spot for food safety.

- Listen for Odd Noises: Get your staff in the habit of listening for any unusual grinding, rattling, or humming. These sounds are often the first sign that a compressor or fan motor is on its way out.

"When PM companies aren’t there, it falls on the restaurant to clean and do routine maintenance," explains one industry expert. "It’s like having a maid who comes to your home once a month. That’s not the only time it gets cleaned. It has to be done in between too."

Essential Monthly Maintenance

The single most important thing you can do to prevent a catastrophic failure is to clean the condenser coil. Over time, this part gets clogged with all the dust, grease, and gunk floating around in a busy kitchen. This blockage forces the compressor to work way too hard just to release heat.

An overworked compressor will eventually overheat and fail, leading to one of the most expensive repairs you can imagine.

Here’s how to tackle this crucial monthly task:

- Disconnect Power: Safety first. Always unplug the unit from the wall before you start.

- Locate and Access the Coil: Find the condenser coil. It's usually behind a removable grille on the front or back of the unit.

- Clean Gently: Use a stiff-bristled brush to knock off any caked-on dust and grime from the coil fins. Follow up with a vacuum and its brush attachment to suck away all the loose debris.

This one monthly habit can add years to the life of your prep table, lower your energy bills, and save you from the headache of an emergency breakdown.

Got Prep Table Questions? We've Got Answers.

Even with the perfect refrigerated prep table in your kitchen, you're bound to have questions about how to use and care for it day-to-day. Nailing the details on temperature, cleaning, and using it for the right job is how you get the most out of your investment. Here are the answers to the questions we hear most often.

How Often Should I Clean the Condenser Coil?

As a solid rule of thumb, plan on cleaning your unit's condenser coil every 90 days. Think of that coil as the radiator for your fridge—if it’s clogged with dust and grease, it can't breathe. When it can't breathe, it can't get rid of heat, forcing your compressor to work overtime. That means higher energy bills and a much greater risk of a very expensive breakdown.

Of course, not every kitchen is the same.

If your kitchen is full of airborne grease from charbroilers, griddles, or fryers, you'll need to be more aggressive. In those tougher environments, a monthly cleaning is non-negotiable. It’s the only way to prevent poor performance and keep the unit from failing early.

What's the Right Temperature for a Prep Table?

Getting the temperature right is all about food safety—there's no room for error here. The FDA requires that all cold ingredients be kept in the "safe zone," which is between 33°F and 41°F (that's 0.5°C to 5°C). Sticking to this range is what slows down bacteria and keeps your food fresh and safe to eat.

A prep table that reliably holds this temperature means every sandwich, salad, or pizza you make is up to code and safe for your customers. Thankfully, most modern units have a digital thermostat, so checking the temperature is as simple as a quick glance.

Can I Use a Sandwich Prep Table for Pizza?

While it might seem like a clever shortcut, using a sandwich table to make pizza is a surefire way to create a frustrating bottleneck in your kitchen. These two pieces of equipment are designed for completely different jobs. Trying to swap them just doesn't work.

The biggest problem is the cutting board. Sandwich tables have a narrow board, usually just 8 to 12 inches deep. That’s nowhere near enough space to properly stretch and top a large pizza crust. Your cooks will be forced to work in a cramped, awkward position.

On top of that, the refrigerated rail on a sandwich table is made for smaller pans of deli meats and sliced veggies. It just can't handle the sheer volume of bulky pizza toppings like shredded cheese, pepperoni, and sauces. You'll end up with a disorganized mess. For pizza, you really need a dedicated pizza prep table with its deeper workspace and bigger rail.

Ready to find the refrigerated prep table that’s a perfect fit for your kitchen? Take a look at our huge collection at PrepTables.com. We have all the sizes and setups you need to boost your kitchen's speed and keep your food safe. Find your new unit today at https://preptables.com.