Choosing Restaurant Stainless Steel Tables

Share

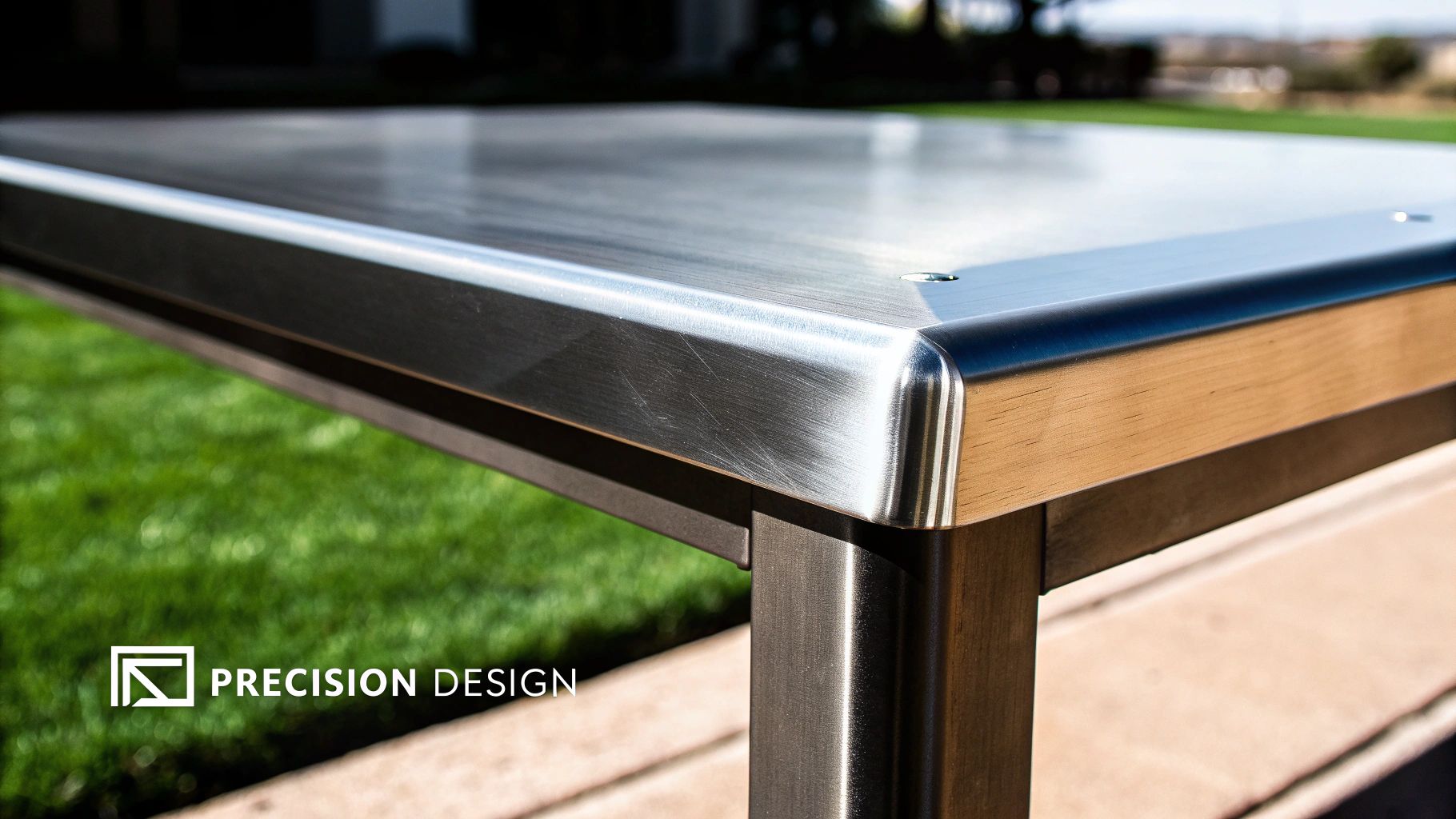

Walk into any thriving commercial kitchen, and you'll immediately notice the gleaming surfaces that form its backbone: restaurant stainless steel tables. These aren't just pieces of furniture; they're the hardworking, reliable stages where culinary magic happens. Every chop, every mix, every perfectly arranged plate starts here. Investing in the right table is a foundational step toward a safer, more efficient, and longer-lasting kitchen.

The Unsung Hero of Your Commercial Kitchen

Picture a high-octane workshop. A master woodworker wouldn’t dream of using a flimsy, unreliable workbench, and a chef is no different. They need a surface that can take a beating day in and day out. That's where materials like wood and plastic fall short in a professional setting.

Wood, for all its rustic charm, is porous. It’s like a sponge, soaking up moisture, food juices, and, unfortunately, bacteria. This creates a serious sanitation hazard that’s almost impossible to truly get rid of. Plastic surfaces don't fare much better; they scratch far too easily, and every one of those tiny grooves becomes a perfect hiding spot for germs, putting food safety at risk.

Why Stainless Steel Is the Industry Standard

So, why is stainless steel the go-to choice? It’s simple. The material is non-porous, meaning it won't absorb anything. This single quality makes it incredibly easy to clean and sanitize—an absolute must for passing health inspections and keeping your customers safe. Its tough, smooth surface shrugs off the dents, dings, and rust that are just part of life in a busy kitchen.

Let's take a look at the benefits in a nutshell.

| Attribute | Why It Matters for Your Restaurant |

|---|---|

| Durability | Resists dents, scratches, and heat, saving you money on replacements. |

| Hygienic | Non-porous surface prevents bacteria growth, ensuring food safety. |

| Corrosion-Resistant | Stands up to acidic foods, harsh cleaners, and moisture without rusting. |

| Easy to Maintain | A simple wipe-down is often all that's needed to keep it clean and sanitized. |

| Professional Look | Its clean, bright appearance contributes to a modern and well-managed kitchen aesthetic. |

These qualities are exactly why stainless steel is the undisputed champion for commercial food prep. In fact, the global market for these tables was valued at around USD 1.2 billion and is expected to climb to USD 1.8 billion. That growth is fueled by the very things that make them essential: durability, sanitation, and resistance to corrosion. You can find more insights on these market trends and what they mean for the industry.

Beyond just meeting health codes, these tables actively improve how your kitchen runs. Their reflective quality brightens up the workspace, making it easier for chefs to see what they're doing and spot any spills or debris right away. This helps maintain a cleaner, safer, and more organized station.

By choosing the right table, you’re investing in a core piece of equipment that will uphold your culinary standards for years to come.

Decoding Stainless Steel Grades and Gauges

When you're outfitting a commercial kitchen, choosing the right restaurant stainless steel table comes down to understanding the language of the metal itself. You'll see terms like "grade" and "gauge" thrown around, but these aren't just minor specs. They're the secret code that tells you how durable a table will be, where it belongs in your kitchen, and whether you're getting good value for your money.

Nailing these two factors from the start means you're investing in a piece of equipment that will stand up to the daily grind, not one that will fail you mid-service.

The Two Main Players: 304-Grade vs. 430-Grade Steel

In the world of kitchen tables, you'll almost always run into two main options: 304-grade and 430-grade stainless steel. The easiest way to think about them is like choosing a jacket for a specific kind of weather.

304-grade is your all-weather, rust-proof raincoat. It has more chromium and nickel mixed in, giving it top-tier protection against rust and corrosion. This makes it a no-brainer for any "wet" work—think prepping acidic foods like tomatoes and citrus, washing vegetables, or placing it in any area that gets hit with a lot of splashes and spills.

430-grade, on the other hand, is the sturdy, budget-friendly work coat. It's still tough and perfectly food-safe, but with less nickel in the mix, it's more likely to show rust if it's constantly wet or exposed to corrosive stuff. It’s an excellent, cost-effective choice for "dry" tasks like holding equipment, storing dry goods, or acting as a staging area for finished plates away from the chaos of the prep line.

Thickness Matters: Understanding The Gauge System

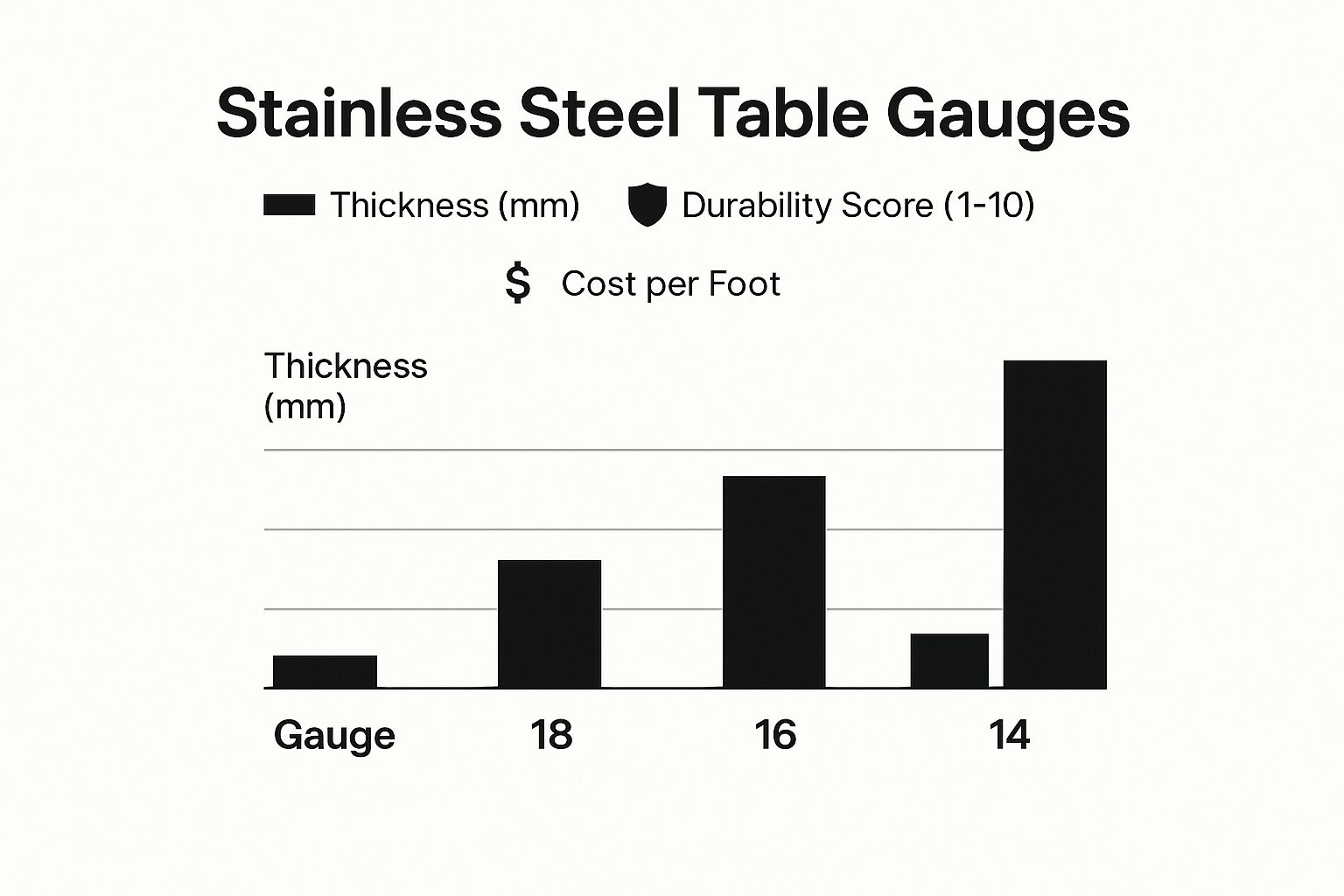

Right after the grade, the next critical detail is the gauge. This simply tells you how thick the steel is. Here’s the one quirky rule you need to remember: the lower the gauge number, the thicker and stronger the steel. A lower gauge number means you're getting a heavier, tougher table that can take a real beating and support more weight.

For most commercial kitchens, tables will land somewhere between 14-gauge and 18-gauge.

- 18-Gauge: This is the thinnest of the bunch and a very common choice for light-duty work. It's perfect for assembling salads, plating desserts, or general prep that doesn't involve heavy appliances or aggressive chopping.

- 16-Gauge: Here’s your workhorse. As the solid middle ground, it delivers a fantastic balance of durability and price. It’s versatile enough for most prep jobs and can easily handle medium-weight countertop equipment.

- 14-Gauge: This is the heavyweight champion, built for the most demanding tasks. If your kitchen does a lot of butchering, pounding out cutlets, or kneading huge batches of dense dough, the rock-solid stability of a 14-gauge table is what you need.

As you can see, dropping to a lower gauge like 14 gives you a massive jump in durability for a relatively small price increase. For high-impact work, it's an investment that pays for itself.

Matching Steel Specs to Your Kitchen's Needs

To make it even clearer, here’s a quick comparison to help you select the right grade and gauge based on your kitchen's specific demands and budget.

| Specification | 304-Grade (Premium Choice) | 430-Grade (Standard Choice) | Common Gauge and Use Case |

|---|---|---|---|

| Corrosion Resistance | Excellent. The high nickel content makes it highly resistant to rust from moisture and acids. | Good. It's durable but can be susceptible to rust with prolonged exposure to corrosive elements. |

18-Gauge: General prep, salad stations. 16-Gauge: All-purpose work, countertop appliances. 14-Gauge: Heavy butchering, dough prep. |

| Best For | "Wet" environments, food prep with acidic ingredients (citrus, tomatoes), fish filleting. | "Dry" environments, equipment stands, dry storage, plating stations away from sinks. | Your choice of gauge depends entirely on the intensity of the work performed on the table's surface. |

| Cost | Higher initial investment due to its superior composition and longevity. | More budget-friendly, making it a cost-effective solution for less demanding applications. | The price increases as the gauge number decreases (gets thicker). |

| Bottom Line | The go-to choice for durability and hygiene in demanding, high-moisture prep areas. | A smart, economical pick for storage and dry prep tasks where corrosion isn't a primary concern. | Match the thickness to the task to avoid a wobbly or dented table. |

Choosing the right combination ensures your table will last for years, providing a stable and safe work surface no matter what you throw at it.

Types of Stainless Steel Prep Tables for Your Kitchen

Alright, so you've nailed down the right grade and gauge of steel for your kitchen. That's a huge step. Now comes the fun part: matching the table's design to its actual job in your daily workflow.

Think of it this way: not all restaurant stainless steel tables are created equal. You wouldn't use a screwdriver to hammer a nail, right? The same logic applies here. Choosing the right types of tables is like casting the perfect actors for a play—each one needs to nail its specific role for the whole show to run without a hitch. A kitchen with the right mix of tables is a well-oiled machine, and understanding the various types of stainless steel prep tables available is key.

Let's walk through the most common types you’ll need to know.

The Foundation: Standard Work Tables

Every kitchen needs a solid foundation, and that's the standard flat-top work table. This is your all-purpose, go-to surface. It’s essentially a blank canvas, built strong and simple for just about any general task you can throw at it: chopping veggies, butchering proteins, mixing batters, or lining up plates for service. The clean, open top gives you maximum real estate to work with, which is why it's so incredibly versatile.

For most kitchens, especially those where space is at a premium, a table with an undershelf is an absolute lifesaver. This one feature practically doubles your storage without eating up another square foot of floor space. It's the perfect spot to stash frequently used pots, pans, mixing bowls, or even bins of dry goods, keeping them close by but off your primary work surface.

Another incredibly useful variation is the table with a backsplash. A backsplash is just a raised edge, usually 4 to 6 inches high, that runs along the back of the table. Its job is simple but critical: to stop liquids, food scraps, and general messes from splashing onto the wall behind it. This is a must-have for any table pushed against a wall, especially in a messy prep area. It makes cleanup faster and sanitation much easier to maintain.

A table with a backsplash does more than just protect your walls. It also acts as a safety net, stopping small tools or ingredients from rolling off the back and getting lost. It’s a small detail that pays huge dividends in cleanliness and organization.

Specialized Stations for a Streamlined Workflow

While standard tables are the trusty workhorses, specialized prep tables are the elite commandos of the kitchen. They are engineered to master a single, high-volume task, with features designed to make that job faster, safer, and more consistent. The two most common examples are for sandwiches and pizzas, two areas where speed and fresh ingredients are everything. To see how different designs fit specific roles, you can explore the different types of stainless prep tables available for today's busy kitchens.

Sandwich and Salad Prep Tables

Picture the chaos of a lunch rush. Trying to assemble 50 sandwiches with your ingredients spread all over a standard table is a recipe for disaster. This is exactly where a sandwich or salad prep table proves its worth. These units brilliantly combine three key functions into one hyper-efficient station:

- A Refrigerated Rail: The top of the unit has a series of chilled wells that hold all your go-to ingredients—lettuce, tomatoes, cheeses, deli meats—at a safe, food-cool temperature.

- A Cutting Board: Right in front of the ingredient rail, a durable cutting board runs the length of the table, giving you a dedicated spot to build sandwiches and salads.

- Refrigerated Storage: Underneath the work surface, you get a reach-in refrigerator, perfect for storing backup ingredient pans, sauces, and other essentials.

This all-in-one design means a cook can stand in one place and have everything they need to pump out orders quickly, without running all over the kitchen.

Pizza Prep Tables

Making great pizza comes with its own unique challenges, and a dedicated pizza prep table is built from the ground up to handle them. Just like a sandwich unit, it has a refrigerated rail up top to keep toppings like pepperoni, mushrooms, and cheese perfectly chilled and within easy reach.

The biggest difference, however, is often the work surface itself. While some have a stainless steel top, many of the best pizza tables feature a marble or stone surface. This isn't just for looks. Stone stays naturally cool, which is ideal for working with dough because it keeps it from getting too warm and sticky as you knead and shape it. The wide, flat surface also gives a pizzaiolo plenty of room to stretch dough to the perfect size before adding sauce and toppings.

By understanding these different table types, you can outfit your kitchen with purpose, creating a culinary ecosystem where every station is perfectly tuned for its task.

Essential Features That Make a Difference

The real difference between a good stainless steel table and a great one is in the details. Once you've nailed down the size, grade, and gauge, these smaller features are what turn a simple surface into a truly indispensable piece of kitchen equipment. Paying attention to them is like adding the right attachments to a power tool—they make it perfect for the job at hand.

These features might seem minor at first, but in the heat of service, they make a massive difference. They contain messes, keep the workspace stable, and make a busy kitchen run that much smoother. Your staff will thank you for them every single day.

Mastering the Edge Types

Not all table edges are created equal. In fact, the edge you choose directly impacts how clean your kitchen stays. The two main options you'll come across are the standard square edge and the marine edge.

A square edge is exactly what it sounds like: a clean, 90-degree corner. It’s straightforward, functional, and ideal for general prep. It's also the best choice when you need to butt multiple tables together to create one long, seamless work surface.

A marine edge, on the other hand, is all about mess control. It has a raised perimeter, creating a small lip around the entire tabletop. Think of it as a built-in containment wall. This single feature is a game-changer for any task involving liquids, sauces, or even fine powders like flour, as it traps spills and stops them from hitting the floor. It can save you countless hours of cleanup.

Stability and Mobility: The Feet of the Operation

A wobbly prep table isn't just annoying—it's a safety hazard. Since commercial kitchen floors are rarely perfectly flat, adjustable bullet feet are an absolute must. These small, threaded feet at the bottom of each leg let you tweak the height of each corner independently. This ensures your table is rock-solid and perfectly level, no matter how uneven the floor is.

For tables that need to be moved around, casters (wheels) are the answer. They transform a stationary workstation into a mobile unit, making it incredibly easy to rearrange your kitchen for deep cleaning or to adapt to a changing workflow. For the best of both worlds, look for locking casters that give you mobility when you want it and stability when you don’t.

Choosing the Right Undershelf

The space under your table is prime real estate, and the undershelf you select affects both storage and sanitation. The three main styles each have their own distinct advantages.

- Solid Undershelves: These provide a flat, stable surface that’s perfect for storing smaller items or equipment that might tip over on a wire shelf. They also do a great job of protecting whatever is stored below from drips from the work surface above.

- Wire Undershelves: The open design of a wire shelf promotes better airflow, which is fantastic for things that need to stay cool, like bins of produce. It also makes it easy to see what you've got stored and prevents dust and debris from building up.

- Louvered Undershelves: This style offers a happy medium. Louvered shelves have slats that allow for some air circulation while still offering more surface area than a wire shelf.

For a more detailed breakdown, our prep tables buying guide is a great resource for any commercial kitchen looking to optimize. The global market for stainless steel tableware is projected to grow steadily, hitting an estimated $28.9 billion by 2035. This reflects a wide-ranging demand for hygienic, long-lasting products in food service. You can get more insights on stainless steel market growth and see how consumer preferences are shaping the industry.

The Gold Standard: NSF Certification

Finally, and maybe most importantly, always look for the NSF certification mark. The National Sanitation Foundation (NSF) is an independent organization that tests products against strict public health and safety standards.

An NSF-certified table has been rigorously tested and verified to be non-porous, corrosion-resistant, and easy to sanitize, making it safe for direct contact with food. This isn't just a "nice-to-have" sticker; it's your guarantee that the table meets health code requirements and is built for the demands of a professional kitchen.

Keeping Your Stainless Steel Tables in Tip-Top Shape

Think of your restaurant stainless steel table as the workhorse of your kitchen. It's a serious investment designed to take a beating day in and day out. But even the toughest equipment needs a little care to go the distance. Proper maintenance isn't just a chore; it’s a professional habit that protects your investment, keeps you on the right side of the health inspector, and ensures your kitchen always looks sharp.

A gleaming, well-cared-for table says a lot about the standards you keep. The good news is, it only takes a few minutes each day to preserve its value and keep it performing beautifully for years to come.

Your Daily Cleaning Ritual

The secret to keeping stainless steel looking brand new is simple: clean it consistently and gently. After a long shift, the surface is covered in grease, food bits, and acidic splashes. If you let that sit overnight, you're giving it a chance to cause real problems like pitting or stubborn stains.

Make this your end-of-day routine:

- Clear the Decks: Get all the food scraps, cutting boards, and tools off the surface.

- Wash It Down: Grab a soft cloth or a microfiber towel, some warm water, and a mild, food-safe soap. A dedicated stainless steel cleaner works great, too.

- Rinse It Clean: Wipe the whole table down with a clean, damp cloth to get rid of any soap residue. If you leave cleaner on, it can dry into a dull, streaky film.

- Dry It Off: This is the step most people skip, but it's critical. Use a dry, soft cloth to wipe away every bit of moisture. Air-drying is what causes those annoying water spots, especially if you have hard water.

This whole process takes five minutes, tops. It’s easily the most important thing you can do to prevent long-term damage and keep your table sanitary.

The Pro Tip: Always Go With the Grain

Here’s a little trick that makes a huge difference: always clean in the direction of the grain. Look closely at your tabletop, and you'll notice faint, parallel lines. That’s the "grain," which comes from the finishing process when the table was made.

Think of it like sanding a piece of wood. You sand with the grain to get a smooth finish, not against it. Wiping against the grain of your steel table creates microscopic scratches that will eventually dull the surface and, worse, can trap tiny food particles.

Following the grain preserves that beautiful sheen and actually makes cleaning more effective. It's a small detail that pays off big time in the long run.

Busting Common Cleaning Myths

Stainless steel's non-porous surface is a sanitation dream, but it's not invincible. Some common cleaning habits can absolutely wreck it, turning a beautiful piece of equipment into a scratched-up, corroded eyesore.

Steer clear of these major mistakes:

- Steel Wool & Abrasive Pads: This is the number one sin of stainless steel care. Steel wool actually sheds tiny iron particles that dig into the surface and rust, making it look like your table is falling apart. Stick to soft cloths or non-abrasive scrub pads.

- Harsh Chemicals: Cleaners with chlorides (like bleach), abrasive powders, or oven cleaners are way too aggressive. They can eat away at the protective layer of the steel, leaving it vulnerable to permanent stains and corrosion. Use mild soap or a cleaner made specifically for stainless steel.

- Letting Spills Linger: Acidic stuff like tomato sauce, lemon juice, or vinegar can etch the surface if left sitting too long. Same goes for salty liquids like brine, which can cause pitting. Wipe up these kinds of spills right away.

Tackling Tougher Problems

Even with perfect daily care, you might run into stubborn issues like hard water stains or a bit of discoloration. Don't panic. For those chalky hard water spots, a mix of equal parts white vinegar and water usually does the trick. Just apply it with a soft cloth (moving with the grain!), rinse well, and dry completely.

If you see a small rust spot, it's almost always from contact with other metal tools, not the table itself. Make a paste with baking soda and water, and gently rub the spot with a soft cloth. Remember to rub in the direction of the grain, then rinse and dry. This gentle approach can lift the stain without scratching the finish.

Your Top Stainless Steel Table Questions, Answered

When you're investing in something as central to your kitchen as a stainless steel table, you're bound to have a few questions. Getting the right answers upfront can save you a world of frustration down the road. Let’s tackle some of the most common questions we hear from chefs and restaurant owners, drawing from years of real-world kitchen experience.

Think of this as the advice you'd get from a seasoned pro—the kind of know-how that helps you avoid common pitfalls and get the most out of your equipment from day one.

How Should I Assemble a New Table for Maximum Stability?

A wobbly prep table isn't just annoying; it's a safety hazard. The secret to a rock-solid table isn't about cranking down on the screws with all your might—it's about a smarter, more methodical approach.

First, loosely attach the legs and undershelf to the tabletop. Don't tighten anything fully just yet. Now, flip the table upright and place it exactly where you plan to use it. This is a critical step. Put a level on top and start adjusting the bullet feet on each leg. Tweak them one by one until that bubble is sitting perfectly in the middle.

The biggest mistake people make is tightening everything before leveling. Doing that just locks the wobble in. Once it's perfectly level, then you can go back and tighten every single set screw until it's secure. Grab a friend to help hold things steady; it makes the whole process faster and more precise.

Can I Put Sizzling Hot Pots Directly on My Table?

Even though stainless steel is famous for handling heat, you should think twice before slapping a screaming-hot pan straight from the burner onto its surface. That kind of sudden, extreme temperature shock can cause temporary discoloration. Over time, doing this repeatedly can even cause thinner gauge steel to warp.

The smart move? Always use a trivet or even a spare sheet pan to create a buffer. It’s a simple habit that protects your table's finish and helps it last a lifetime. If your workflow demands a dedicated spot for hot items, investing in a thicker 14-gauge table is a wise upgrade. Its extra mass is much better at absorbing and spreading out the heat.

Are Casters a Good Idea for a Prep Table?

Casters (wheels) can be a total game-changer, giving you the flexibility to move tables for deep cleaning or to quickly change your kitchen's layout. They're perfect for general-purpose tables, mobile equipment stands, or any workstation that needs to be moved around a lot. Think of a table used for receiving that can be rolled into place and then tucked away.

But for heavy-duty work, stationary legs are king.

- When to Use Casters: For light-to-medium tasks where mobility is the main goal. Great for general prep or holding lighter equipment.

- When to Use Stationary Legs: Absolutely essential for high-impact jobs like butchering, intense chopping, or kneading heavy dough. The fixed legs deliver the unshakeable stability you need for that kind of work.

If you go with casters, make sure at least two of them have solid locks. This gives you the best of both worlds—you can roll the table where you need it, then lock it down so it stays put.

How Do I Get Rid of Those Annoying Rust Spots?

Seeing a spot of rust on your gleaming stainless steel can be startling, but take a deep breath—your table isn't actually corroding. That "rust" is almost always surface contamination. It happens when something made of regular carbon steel, like a cheap can opener, some utensils, or (the worst culprit) steel wool, is left sitting on a wet surface.

To get rid of it, just make a simple paste with baking soda and water or grab a quality, chloride-free stainless steel cleaner.

Gently rub the paste onto the spot with a soft cloth, always moving with the grain of the steel to avoid any scratches. Once the spot vanishes, rinse the area well with clean water and dry it completely with a towel. The best way to prevent this is to never let carbon steel items linger on a wet table, and please, never use steel wool for cleaning.

At PrepTables.com, we know that great kitchens are built on a foundation of great equipment. From heavy-duty workbenches to specialized refrigerated prep stations, we're focused on providing durable, hygienic, and efficient solutions for culinary professionals. See our complete collection of NSF-certified tables and kitchen equipment to discover the perfect tools for your operation at PrepTables.com.