Refrigerator with Glass Doors: Your Ultimate Buying Guide

Share

Think of a refrigerator that does more than just keep things cold—one that actively helps you sell. That’s the real power behind a refrigerator with glass doors. It’s a piece of equipment that turns simple storage into a dynamic, profit-driving display. By making your best products impossible to ignore, it becomes a silent salesperson working for you 24/7.

Why a Glass Door Refrigerator Is Your Silent Salesperson

In a busy cafe, convenience store, or grab-and-go spot, customers make buying decisions in the blink of an eye. A standard solid-door refrigerator keeps your products chilled but completely hidden, forcing customers to open it up and poke around. That tiny bit of effort can be the difference between a sale and a missed opportunity.

A glass door refrigerator eliminates that barrier. It transforms your cold storage into a bright, inviting showcase, putting your most tempting and profitable items directly in the customer’s line of sight.

Driving Sales Through Visibility

It’s a simple but incredibly effective concept. A solid door is a closed book; a glass door is the enticing cover that makes you want to see what's inside. The clear view invites customers to browse with their eyes, sparking curiosity and encouraging those lucrative impulse buys.

When people can see colorful craft sodas, fresh-made salads, or decadent desserts right there, they're far more likely to grab one. The visual appeal does all the hard work for you. This is a game-changer for:

- Highlighting high-margin items: Place your most profitable products right at eye level to get the biggest return.

- Promoting new or seasonal products: Let your new offerings sell themselves without needing extra signs or promotions.

- Reducing decision time: Customers can spot what they want instantly, which keeps lines moving and everyone happy during peak hours.

By making your inventory the main attraction, you create an environment where the products essentially sell themselves. This turns a functional appliance into a powerful merchandising tool that directly contributes to your bottom line.

To give you a quick snapshot, here’s a look at the major advantages a glass door unit brings to your business.

Key Benefits of Glass Door Refrigerators at a Glance

| Benefit | Impact on Your Business | Best For |

|---|---|---|

| Increased Impulse Buys | Boosts average transaction value by showcasing tempting items. | Convenience stores, cafes, bakeries, grab-and-go spots. |

| Enhanced Product Appeal | Bright, clean presentation makes products look more attractive. | Displaying gourmet foods, craft beverages, fresh juices. |

| Improved Staff Efficiency | Staff can see inventory at a glance for faster restocking. | High-turnover environments like supermarkets and busy kitchens. |

| Better Customer Experience | Customers find what they want quickly without searching. | Any customer-facing business aiming for smooth traffic flow. |

Ultimately, investing in a glass door refrigerator streamlines operations from the front of the house to the back.

A Boost in Efficiency Beyond Sales

The perks aren't just for your customers. For your staff, a quick look is all it takes to know what’s running low. This visual stock-taking saves a ton of time during ordering and restocking, helping you avoid frustrating out-of-stocks or wasteful over-ordering.

The market certainly reflects this powerful blend of function and aesthetics. The global demand for these units is climbing fast; valued at about US$13.7 billion in 2024, the market is expected to hit around US$19.8 billion by 2030. This growth is all about new strides in energy efficiency and the simple fact that businesses need refrigerators that both work hard and look great. You can learn more about the market growth for glass door refrigerators and the technology behind them.

Choosing the Right Type for Your Space

Picking the right refrigerator with glass doors is a lot like choosing a specific tool from your toolbox. The best one always comes down to the job at hand. A massive supermarket has completely different needs than a cozy corner cafe, and your refrigerator choice has to reflect that reality. It’s all about matching the unit’s size, capacity, and features to how your business actually works.

You wouldn’t use a sledgehammer to hang a picture, right? In the same way, putting a giant three-door merchandiser in a small coffee shop just creates a bottleneck. A tiny undercounter unit in a busy convenience store would be just as useless, emptied out in minutes. The goal is to find a model that feels like a natural part of your space, not a clumsy obstacle.

The Workhorses: Full-Size Reach-In Merchandisers

For any business with decent floor space and a high volume of product sales, the full-size reach-in merchandiser is the undisputed champ. These are the workhorses of the industry, built for maximum capacity and visibility. They’re designed to show off a ton of product in a clean, appealing way.

They generally come in three configurations:

- One-Door Models: These are perfect if you have a focused product line, like a small deli showing off craft sodas or a bakery displaying chilled cakes. They give you great visibility without eating up your whole floor plan.

- Two-Door Models: This is the sweet spot for most businesses, from convenience stores to small grocery markets. They strike a great balance between storage capacity and a manageable footprint, letting you display a wider variety of items.

- Three-Door Models: Built for pure capacity, these are the giants of the glass door world. You’ll see them in supermarkets, big beverage stores, and other high-traffic spots. They let you organize extensively, dedicating whole sections to sodas, juices, dairy, and more.

Deciding between them really just boils down to your sales volume and your square footage. The more you sell and the more space you have, the bigger the unit you’ll need to keep up with customer demand and avoid constantly restocking.

Think of your glass door refrigerator as prime retail real estate. Every inch of glass is your "storefront," advertising products to browsing customers. A bigger unit isn't just more storage; it's more opportunity to make a sale.

Compact and Convenient: Undercounter and Countertop Models

When floor space is tight, you need a solution that works smarter, not just harder. That’s exactly where undercounter and countertop glass door refrigerators come in, tucking neatly into spots that would otherwise be wasted.

Undercounter refrigerators are designed to slide right under standard-height counters. This makes them a perfect fit for bars, coffee shop service areas, and busy restaurant kitchens. They keep essentials like milk, drink mixers, or garnishes perfectly chilled and right where you need them, which is a huge time-saver during a rush. A well-organized station is key, and pairing refrigeration with the right work surface can make all the difference. For more on that, our guide on different restaurant stainless steel tables can help you build the perfect setup.

Countertop refrigerators, on the other hand, are the ultimate impulse-buy machines. These small, eye-level units sit directly on your checkout counter. They’re perfect for showing off bottled drinks, energy shots, or small desserts right where customers are paying. Their placement makes it incredibly easy for someone to add one last item to their purchase.

Specialty Refrigerators for Niche Products

Sometimes, you need more than just a standard cooler. There are also specialized glass door units built for specific products that demand very precise conditions. These models really show how versatile a glass door refrigerator can be.

Two common examples are:

- Wine Coolers: These units don’t just control temperature; they also maintain specific humidity levels, which is absolutely critical for preserving the quality of wine. The glass is also usually UV-protected to stop sunlight from ruining the product.

- Floral Merchandisers: Designed just for florists, these refrigerators keep humidity high and use gentle air circulation. This keeps delicate flowers looking fresh and vibrant for as long as possible.

By getting to know these different types, you can find a refrigerator that does more than just keep things cold. You can choose a unit that actively supports your business goals, whether that means boosting sales in a big retail space or streamlining the workflow in a tight kitchen.

Features That Boost Performance and Profit

A great commercial refrigerator is about much more than just a clear view of your inventory. The real moneymakers are the features working behind the scenes—the engineering that drives reliability, efficiency, and a smoother workflow day in and day out. While looks matter, your actual return on investment comes from smart operational choices.

One of the best ways to get more out of your cooler is to pair it with the right work surface, creating a dedicated productivity zone. This is where you see the magic happen in a professional kitchen. A well-designed station cuts down on wasted steps, keeps staff from bumping into each other, and speeds up service time. The undisputed champion of this setup is the stainless steel prep table.

The Foundation of Efficiency: Stainless Steel Prep Tables

Think of a stainless steel prep table as the perfect partner for your refrigerator with glass doors. Its surface is non-porous, which makes it incredibly hygienic, a breeze to clean, and naturally resistant to rust and corrosion. It's the industry standard for a reason.

By placing a sturdy prep table right next to your glass door unit, you create a seamless path from cold storage to active prep. Your team can grab what they need and get to work instantly, eliminating wasted time and motion. The most common types you'll find are:

- Standard Work Tables: These are the versatile workhorses of the kitchen. With simple flat tops, they give you a solid surface for just about anything—chopping produce, portioning out ingredients, or plating dishes. Many also come with a handy undershelf for storing dry goods or small appliances.

- Tables with Backsplashes: If you're dealing with liquids or messy prep work, a table with a raised backsplash is a lifesaver. It keeps splashes and spills off your walls, which simplifies cleanup and helps maintain a cleaner, more sanitary kitchen.

The right prep table isn't just a surface; it's a strategic tool that bridges the gap between your refrigerated inventory and the final product. By choosing the correct type, you build an ergonomic and efficient workflow right into your kitchen's layout.

Specialized Tables for High-Volume Tasks

When your business is built around churning out dozens of sandwiches or pizzas, a standard table just won't cut it. This is where specialized prep tables step in. They integrate refrigeration directly into the workspace to create a powerhouse assembly line.

Sandwich prep tables are built for pure speed and organization. They combine a refrigerated base for meats and cheeses with a cutting board top and refrigerated pans or "rails" up top. These rails keep all your toppings perfectly chilled and right at your fingertips, making assembly lightning-fast.

Pizza prep tables work on the same concept but are scaled up for pizza making. They typically feature a much wider and deeper cutting board to handle large doughs and a refrigerated rail designed to hold standard-sized pans of sauce, cheese, and toppings. This all-in-one setup means a chef can build an entire pizza without taking a single step.

Choosing the Right Table for Your Operation

So, how do you pick the right one? It all comes down to your menu, your sales volume, and the layout of your kitchen. A small café could do perfectly well with a standard stainless steel table parked next to an undercounter glass door fridge. But a busy pizzeria? They’d see a huge return on a dedicated pizza prep table.

Keep these factors in mind when you're deciding:

- Material Gauge: This refers to the thickness of the stainless steel. A lower gauge number means thicker, tougher steel that can take a beating.

- Size and Configuration: Measure your space! Make sure the table not only fits but also leaves enough room for your staff to move comfortably. Think about whether an undershelf or cabinet could add valuable storage.

- Specialization: Here’s a good rule of thumb: if more than 30% of your orders are for a specific item like sandwiches or salads, a specialized prep table is a smart investment that will pay for itself in labor savings alone.

By carefully pairing your refrigerator with the right stainless steel prep table, you’re not just buying equipment—you’re designing a highly optimized work cell that boosts productivity, ensures food safety, and adds directly to your bottom line.

Pairing Your Fridge with the Perfect Prep Table

A profitable kitchen is an efficient kitchen. And real efficiency isn’t just about having great equipment; it's about creating a seamless workflow where every task flows logically into the next. One of the most fundamental ways to do this is by placing your refrigerator with glass doors right next to a prep table.

This simple pairing creates a high-performance work zone that can transform how your team gets food from cold storage to the service line. Think about it: a cook grabs fresh ingredients from the fridge and, without taking a single extra step, turns to start prepping. That’s the foundation of a faster, less chaotic, and more productive kitchen.

There’s a reason the market for these refrigerators is booming. In 2023, the global glass door refrigerator market hit a value of around USD 3.5 billion, with projections showing it could climb to USD 5.8 billion by 2032. This growth shows just how much businesses are realizing that visibility and accessibility are critical for both sales and kitchen efficiency. You can explore more on this trend and its market impact in the global glass door refrigerators market report.

The Versatile Champion: Stainless Steel Tables

The most common—and for good reason, most effective—partner for a commercial refrigerator is the classic stainless steel prep table. Its non-porous surface is incredibly hygienic and easy to sanitize. Plus, it's famously durable, standing up to the dents, dings, and corrosion that are just part of life in a busy kitchen.

You'll find them in a couple of key styles:

- Flat Top Work Tables: These are the workhorses. They offer a simple, open surface perfect for everything from chopping produce to portioning out ingredients. Many come with an undershelf, which is a lifesaver for storing small appliances or dry goods and keeping your main workspace clear.

- Tables with a Backsplash: If you’re dealing with messier tasks involving liquids or powders, a table with a built-in backsplash is a must. That little raised edge keeps splashes off the wall, which makes cleanup so much easier and helps maintain higher sanitation standards.

Specialized Tables for High-Volume Assembly

Sometimes, a standard flat-top table just creates a bottleneck, especially if a huge part of your menu involves assembling items like sandwiches or pizzas at high speed. This is where specialized prep tables really shine. They integrate refrigeration right into the workspace, creating a powerful, self-contained assembly line.

A well-designed station can dramatically boost your output. Take sandwich prep tables, for instance. Also known as salad prep tables, these units are built for pure speed and organization. They combine a refrigerated base for bulk ingredients with a cutting board work surface. Right above the board sits a refrigerated "rail" that holds pans of toppings—lettuce, tomatoes, onions—all perfectly chilled and right at the chef's fingertips.

Think of it as a cockpit for sandwich making. Everything the creator needs is right in front of them, eliminating the need to walk back and forth to the main refrigerator. This condensed workflow can cut assembly time by more than half during a busy lunch rush.

Pizza prep tables work on the same principle but are built to handle the unique demands of pizza making. They feature a much wider and deeper cutting board to accommodate large pizza doughs. The refrigerated rail above is designed to hold standard-sized food pans filled with sauce, cheese, pepperoni, and all the other essentials. An entire pizza can be built from start to finish without ever leaving that single, compact station. If you're looking at this kind of setup, you can learn more about how they supercharge a kitchen in our comprehensive guide to commercial refrigerated prep tables.

By carefully matching a prep table to your menu's demands and pairing it with a glass door refrigerator, you're not just buying equipment—you're engineering a more efficient kitchen. This smart combination streamlines your entire operation, cuts down on labor, and ultimately gets food to your customers faster.

Making Sense of Energy Use and Operating Costs

A refrigerator with glass doors is one of the few things in your business that never gets a day off. It runs 24/7, silently adding to your monthly operating budget. Getting a handle on its energy consumption isn't just about being green; it's a critical financial decision that will affect your bottom line for years.

Think of it like buying a delivery van. One might have a lower sticker price but drinks gas like it's going out of style. Another costs more upfront but saves you a fortune at the pump. An energy-efficient refrigerator is no different. It turns a necessary expense into a smart investment that pays you back every single month on your utility bill.

What Energy Efficiency Really Means

When you see a label like ENERGY STAR on a refrigerator, it’s not just a feel-good sticker. It’s a promise—a guarantee that the unit meets tough energy performance standards set by the U.S. Environmental Protection Agency. An ENERGY STAR certified commercial refrigerator is, on average, 20% more energy-efficient than a standard model. That translates directly into lower operating costs.

This efficiency doesn’t happen by accident. It's the result of key technological upgrades designed to cut power use without compromising on cooling power. The industry has been moving fast, with a huge focus on these green technologies. In fact, the glass door merchandiser market is expected to more than double from USD 9.8 billion in 2025 to over USD 20 billion by 2035, mostly because of these energy-saving innovations. You can read the full research on these market trends to get a deeper look at how technology is changing the game.

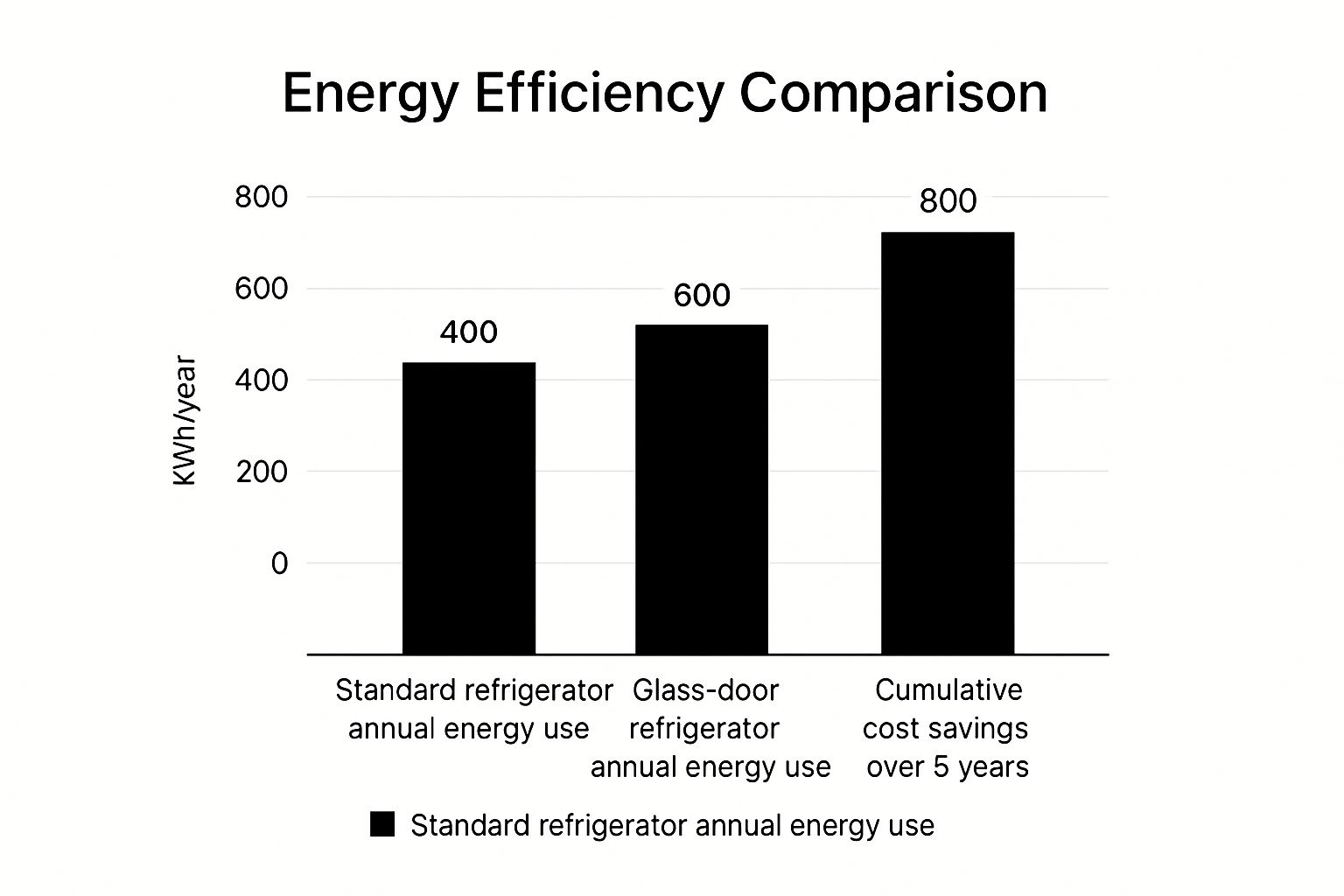

The chart below lays out the financial argument perfectly, showing the benefits of an energy-efficient model versus a standard one.

As you can see, the higher initial cost of an efficient unit is quickly offset by the real-world savings you'll see on your energy bills over just a few years.

Key Technologies That Cut Your Costs

So, what’s the secret sauce that makes a modern refrigerator with glass doors so much more efficient? It boils down to a few key pieces of hardware working in harmony to do more with less.

Here’s a look at the features that make the biggest impact on your wallet:

- Advanced Compressors: Think of a modern inverter compressor like the cruise control in your car. Instead of just lurching on and off at full power, it adjusts its speed to match the cooling demand. This smart adjustment uses way less energy.

- Eco-Friendly Refrigerants: Old refrigerants were bad news for the environment and have been phased out. The new gold standard is R290 (propane), a natural refrigerant that’s not only incredibly efficient but also has a very low global warming potential.

- Low-Emissivity (Low-E) Glass: This is a special, invisible coating on the glass that acts like a bouncer, reflecting heat away. It keeps the cold air in and the warm air out, so the compressor doesn't have to work nearly as hard.

- LED Lighting: LED lights give you that bright, appealing glow that makes products pop. Better yet, they generate very little heat and use up to 75% less energy than old-school fluorescent bulbs.

These features aren't just bells and whistles; they're core to the machine's performance and your long-term savings. The following table breaks down exactly how each piece of tech contributes to a more efficient, cost-effective unit.

Energy-Saving Features Comparison

| Technology Feature | How It Works | Primary Benefit |

|---|---|---|

| Inverter Compressor | Varies its running speed based on real-time cooling needs instead of just switching on/off. | Drastically reduces energy consumption and component wear-and-tear. |

| R290 Refrigerant | A natural hydrocarbon that absorbs and releases heat more efficiently than older chemical refrigerants. | Lower energy bills and minimal environmental impact (low GWP). |

| Low-E Glass Doors | A microscopic metallic coating on the glass reflects infrared and UV heat waves. | Keeps the cold inside, reducing the compressor's workload and preventing condensation. |

| LED Lighting | Produces bright light with very little heat output and minimal electricity usage. | Lower energy costs and reduces the heat load inside the cooler. |

By choosing a refrigerator equipped with these modern technologies, you’re not just buying a box to keep things cold. You’re investing in an asset engineered for peak financial performance, with the initial cost often recovered in energy savings within the first 18-24 months.

Essential Maintenance to Protect Your Investment

Think of your glass door refrigerator like a high-performance car. You wouldn't skip its oil changes and expect it to run forever, right? The same logic applies here. A little bit of routine care goes a long way in keeping your unit running efficiently, extending its lifespan, and most importantly, keeping your food safe.

Most major refrigerator meltdowns don't just happen out of the blue. They’re usually the result of small, neglected tasks that eventually snowball into a costly emergency. A simple, consistent maintenance plan is your best defense against unexpected breakdowns.

The Simple Maintenance Schedule

Trust me, preventative care is far easier—and cheaper—than scrambling to fix a broken-down unit during a busy service. This schedule hits the high points that are easy to forget but make all the difference for your refrigerator's long-term health.

-

Weekly Tasks:

- Wipe Down Interior Surfaces: Spills happen. Clean them up right away with a food-safe cleaner and give the inside a quick wipe-down. This simple step is huge for preventing funky odors and bacteria from taking hold.

- Check Temperature Readings: Just a quick glance at the thermometer is all it takes. You want to see a stable, safe temperature. If it's jumping around, that’s an early warning sign something might be wrong.

-

Monthly Tasks:

- Clean Condenser Coils: Your refrigerator’s condenser coils are a magnet for dust and grease, and that’s their worst enemy. When they get dirty, the compressor has to work overtime, which burns more energy and can lead to a burnout. A quick vacuum or gentle brushing once a month keeps them breathing easy.

- Inspect Door Gaskets: That rubber seal around the door—the gasket—is critical. Feel it for any cracks, tears, or stiff, brittle spots. A bad gasket leaks cold air, which means your unit is constantly fighting to stay cool and wasting a ton of energy.

Here's a pro tip: try the dollar bill test. Close the door on a dollar bill. If you can slide it out with zero resistance, your seal is weak. It's probably time to order a new gasket.

Troubleshooting Common Problems

Even the best-maintained equipment can hit a snag. When it comes to a refrigerator with glass doors, here’s how to tackle two of the most frequent headaches you’ll run into.

Problem 1: Condensation on the Glass

If your glass doors are constantly "sweating," it does more than just block the view of your products—it can signal a bigger problem. This happens when the warm, humid air in your kitchen hits the cold glass. Wiping it down is just a temporary fix.

The real solution is often in your environment. Try lowering the room's humidity or improving the airflow around the unit. And definitely check those door gaskets again, as warm air seeping in is a huge culprit. Keeping your entire work area in top shape matters, too. For instance, using the right surfaces nearby can help maintain a more stable environment. Our guide on choosing a stainless steel prep table has some great tips on that front.

Problem 2: Frost Buildup Inside

A thin, delicate layer of frost can be normal, but if you're seeing thick sheets of ice, that’s a major red flag. Ice acts like an insulator, forcing your refrigerator to work much harder to stay cold.

This is almost always caused by one of three things: a bad door seal, a blocked drain line, or staff holding the door open for too long. Make sure the door always closes completely and that no boxes or products are blocking it from sealing shut.

Frequently Asked Questions

It's completely normal to have a few questions when you're looking into commercial refrigeration. Whether this is your first time buying or you're an old hand at running a kitchen, getting straight answers is the best way to feel good about your purchase. Let's tackle some of the most common things people ask about refrigerators with glass doors.

How Do I Choose the Right Size?

Finding the right size is all about striking a balance between the physical space you have and how quickly you sell your products. You'll want to start by measuring the spot where the unit will go, but don't stop there. Think hard about your inventory turnover. A busy convenience store that needs to avoid constant restocking during peak hours will require a much bigger unit than a small café.

A good rule of thumb is to figure out your peak daily sales for refrigerated items, then pick a unit with at least 25% more capacity than you think you'll need. This extra room gives you a buffer for sales growth and, just as importantly, prevents you from stuffing it too full. Over-stuffing is a classic mistake that blocks airflow and makes the refrigerator struggle to stay cool.

What Is the Difference Between a Standard and an Energy-Efficient Model?

The real difference comes down to the technology inside and what it costs you to run it over the long haul. A standard model might have a lower sticker price, but an energy-efficient unit, especially one with an ENERGY STAR certification, is built to put money back in your pocket every single month.

These upgraded models use more advanced parts like variable-speed compressors, environmentally friendly R290 refrigerant, and Low-E coated glass. The initial investment might be a bit higher, sure, but these features can slash your refrigerator's energy use by 20-40%. You'll often make back the price difference in just a couple of years through lower utility bills.

How Often Should I Clean My Refrigerator?

Staying on top of cleaning is non-negotiable for both food safety and keeping your equipment running for years. A quick daily wipe-down of any spills is a must, along with a weekly cleaning of all interior surfaces using a food-safe solution.

The most important maintenance task, though, is cleaning the condenser coils. This needs to be done at least every 90 days—and even more often if your unit is in a greasy environment like a busy kitchen. When dust and grease build up on the coils, they force the compressor to work overtime, driving up your energy bills and putting you on the fast track to a costly breakdown. A simple brushing or vacuuming is all it takes to prevent this.

Keeping the inside clean stops bad smells and bacteria from taking hold. Keeping the outside parts like the coils clean makes sure the machine runs like a top for years. It's a simple discipline that protects your investment.

At PrepTables.com, we're all about providing the durable, high-performance equipment you need to build an efficient and profitable operation. Dive into our huge collection of commercial refrigerators and prep tables to find the perfect fit for your business.

Find your ideal refrigeration solution at PrepTables.com.