Your Guide to Stainless Steel Prep Tables

Share

Walk into any serious kitchen—whether it’s the engine room of a busy restaurant or a passionate home cook's sanctuary—and you'll find a stainless steel prep table. It's the unsung hero of the culinary world. This isn't just a piece of furniture; it's the foundation for everything that follows, offering an unmatched combination of hygiene, durability, and pure, simple utility.

Why a Stainless Steel Prep Table Is Essential

Think of it as the stage where all the magic happens. It's where you chop vegetables, knead dough, and put the finishing touches on a perfect plate. The real genius lies in its non-porous surface. Unlike wood or other materials, it gives bacteria, germs, and stray food particles nowhere to hide, which is a massive win for food safety.

This is why you see them everywhere, not just in professional kitchens. They’re popping up in hospitals, labs, and even home kitchens as people catch on to their benefits. The demand is real—the global market for these tables was valued around USD 1.2 billion and is expected to climb to USD 1.8 billion by 2033. That’s a steady growth rate of about 5.5% a year, driven by a universal need for clean, long-lasting work surfaces. You can dig into the numbers and explore more about this market growth on Verified Market Reports.

More Than Just a Flat Surface

Here’s the thing, though: a prep table isn’t just a slab of steel. Its true value is in how it adapts to the job at hand. Kitchen workflows are all different, so the tables have evolved to match. There are several types of stainless steel prep tables, each designed for a specific purpose.

- Standard Work Tables: These are your classic, all-purpose tables. A flat top with either an open base or a handy undershelf for storage. They’re the reliable workhorses you can use for almost any prep task.

- Sandwich and Salad Prep Tables: Absolute game-changers for delis, cafes, and any spot churning out fresh salads or sandwiches. They have refrigerated wells built right into the top, keeping ingredients like lettuce, tomatoes, and meats perfectly chilled and right where you need them.

- Pizza Prep Tables: Built specifically for the art of pizza making. These tables often feature a wide work surface (sometimes marble) for stretching dough, paired with a refrigerated rail above it for all your toppings. It’s all about streamlining the process when the orders are flying in.

A stainless steel prep table is more than a purchase; it's an investment in your kitchen's efficiency, safety, and longevity. Choosing the right one can fundamentally improve how your space operates.

Ultimately, knowing these different types is the first step. It helps you zero in on a table that actually fits what you do. Whether you're running a high-volume pizzeria or just want a bulletproof surface for your home projects, there’s a stainless steel table designed to make your life easier. This guide is here to walk you through everything you need to know to make a smart investment.

Decoding the Different Types of Stainless Steel Prep Tables

When you're outfitting a kitchen, you quickly learn that not all prep tables are created equal. It’s a lot like choosing the right knife for a job; you wouldn't use a cleaver for delicate garnish work. The same idea applies here. The standard work table is your all-purpose chef's knife, but specialized models are what truly sharpen your kitchen's efficiency.

The most common starting point is the standard work table. This is your classic, flat-topped surface—a clean, durable workhorse for general prep like chopping vegetables, seasoning meats, or plating dishes. Many come with an open base for easy access or a simple undershelf to store containers and small appliances. Its beautiful simplicity is its greatest strength, making it an absolute must-have in any foodservice operation.

From this foundational design, the family of prep tables branches out to meet more specific, demanding workflows.

Work Tables With Backsplashes and Undershelves

Moving a step up from the basic model, you'll find tables with features that add a world of convenience. An undershelf, for example, is probably the most popular add-on. It instantly turns the empty space below the table into prime real estate for storage, keeping bulk ingredients, mixing bowls, or equipment off the floor but still right where you need them.

Another game-changing feature is the backsplash. This is simply a raised lip along the back of the table, but it serves two critical purposes. First, it stops food, liquids, and utensils from falling into that hard-to-clean gap between the table and the wall. Second, it protects the wall itself from splatters, helping you maintain a much more hygienic kitchen. For a deeper look at how these features pay off in a pro setting, you can check out our complete guide on restaurant stainless steel tables.

Specialized Prep Tables for High-Volume Kitchens

For kitchens that pump out a high volume of specific items, specialized tables are a necessity, not a luxury. These units are cleverly designed with built-in refrigeration and unique surfaces that streamline production when speed and consistency are everything.

Two of the best examples of this are:

- Sandwich Prep Tables: Absolutely essential for any deli, café, or sandwich shop. They have refrigerated pans or wells built right into the work surface, keeping cold cuts, cheeses, veggies, and condiments perfectly chilled and ready to go. This all-in-one design means a cook can assemble dozens of sandwiches without ever taking a step.

- Pizza Prep Tables: A pizzeria's best friend. These tables are engineered from the ground up for making pies. They usually feature a wide, flat workspace—often marble or stainless steel—that’s perfect for stretching dough. Right above it sits a refrigerated rail that holds every topping you can imagine. This setup dramatically cuts down the time from dough to oven.

Think of it like this: a standard table is a blank canvas, while a sandwich or pizza prep table is a pre-organized palette. Both are useful, but the specialized palette makes painting a specific picture far faster and more efficient.

The importance of these tables is reflected in the global demand for their core material. The stainless steel market was valued at 13.37 million tons and is on track to hit 16.85 million tons by 2030. That growth is powered by expanding foodservice sectors everywhere that depend on this tough, clean material.

Ultimately, understanding these different types lets you see beyond just a flat surface. You can choose a stainless steel prep table that actively supports your kitchen’s unique flow. Whether you need a simple workhorse for all-around use or a refrigerated unit for a signature product line, making the right choice will save you time, improve food safety, and boost your bottom line.

Finding the Right Prep Table for Your Workflow

Choosing a stainless steel prep table isn't just about finding a flat surface to work on. It’s about picking a partner that fits right into your kitchen's unique rhythm. The right table feels like a natural extension of your process, making every task smoother. Get it wrong, and you’re looking at frustrating bottlenecks that slow down your entire line.

The world of prep tables is surprisingly diverse. You'll find designs for everything from general-purpose dicing and mixing to highly specialized, high-volume production. Getting to know the different types is the first step to finding a perfect match and unlocking your kitchen's true potential.

The Foundation: Standard Work Tables

The most common model you'll see is the standard work table. This is the quintessential prep surface—a tough, hygienic platform for chopping, mixing, assembling, and plating. Think of it as the blank canvas of your kitchen, ready for whatever you throw at it.

These tables usually come in two main styles:

-

Open Base Tables: These are the simplest design, just a top supported by four legs. This leaves the space underneath totally open, which is perfect for stashing mobile equipment like ingredient bins or trash cans. The open design also makes mopping the floors a breeze.

-

Tables with Undershelves: Adding an undershelf is probably the most popular upgrade. This simple feature instantly turns that empty space under the table into valuable storage. It's the perfect spot to keep frequently used items—mixing bowls, small appliances, or stacked containers—organized and within reach, but up off the floor.

While these standard models are incredibly versatile, some kitchens have needs that go way beyond basic prep. That's where specialized tables really start to shine.

Specialized Units for Streamlined Production

When your menu is built around a specific item, like sandwiches or pizzas, a specialized stainless steel prep table can be a game-changer for speed and consistency. These units are designed with integrated refrigeration to create a true all-in-one workstation.

Imagine a busy deli trying to keep up with a lunch rush. If the sandwich maker has to constantly walk between a standard prep table and the walk-in cooler, they're wasting precious time and energy. A dedicated sandwich prep table solves this problem instantly.

A specialized prep table isn’t a luxury; it’s a strategic tool for efficiency. By placing everything a cook needs within arm's reach, it eliminates wasted motion and allows for a focused, assembly-line workflow that can double or even triple output.

This idea of integrated design is exactly what makes these tables so powerful. They are literally engineered to fix common operational headaches.

Sandwich and Pizza Prep Tables Explained

Sandwich prep tables are the workhorses of delis, cafes, and salad bars. Their key feature is a set of refrigerated wells, or "pans," built right into the work surface. These chilled compartments hold all your cold ingredients—meats, cheeses, veggies, dressings—at safe temperatures. A cutting board usually runs along the front, creating a seamless flow from grabbing ingredients to building the final product.

Pizza prep tables are built to handle the unique demands of a pizzeria. They combine a large, flat workspace (often stainless steel, but sometimes marble for its cool surface) with an overhead refrigerated rail. This rail holds all the toppings, from pepperoni and mushrooms to different cheeses. The pizza maker can stretch dough on the main surface and then grab every topping without taking a single step, making for a fast, fluid trip from dough to oven.

If you're thinking about investing in this kind of advanced equipment, it's smart to explore all the options available. You can dive deeper into the benefits and various models in our guide to commercial refrigerated prep tables.

Ultimately, whether you need a simple open-base table for general tasks or a fully loaded pizza station, choosing the right stainless steel prep table is a foundational decision. It will pay you back in efficiency, organization, and food quality for years to come.

Choosing the Right Size and Configuration

Picking a prep table that’s too big or too small is one of the easiest—and most aggravating—mistakes you can make in a kitchen. A table that’s too large clogs up walkways and creates frustrating choke points. On the other hand, a table that’s too small becomes an instant bottleneck, slowing down your entire workflow. Finding that "just right" fit isn't about just measuring an empty space; it's about landing on a size and setup that feels like it was made for your team and how they work.

Thankfully, these tables come in standard, predictable sizes, which makes finding a good match much easier. This standardization is a big reason they've become such a fixture in commercial kitchens and even homes. In fact, the market for stainless steel household goods, which includes these workhorse tables, is expected to hit 4.3 billion units sold, with a value climbing toward USD 28.9 billion by 2035. That kind of growth shows just how indispensable this type of durable, hygienic equipment has become. You can dig deeper into the numbers and learn more about the global market for stainless steel household articles on IndexBox.

This trend is powered by more and more people realizing the massive practical payoff of getting the setup right from day one.

Mastering Table Dimensions

When you're shopping for a stainless steel prep table, you'll see two measurements pop up again and again: length and depth. Nailing these two is the first step to building a truly efficient workspace.

- Common Lengths: Standard lengths usually run from 30 inches all the way up to 96 inches and sometimes even longer. A compact 48-inch table could be the perfect solution for a food truck or a dedicated plating station. A long 72-inch or 96-inch table, however, gives you a massive runway for multiple cooks to work together without bumping elbows in a high-volume kitchen.

- Standard Depths: The two most common depths you'll find are 24 inches and 30 inches. A 24-inch deep table is a space-saver, great for tighter spots or tasks that don’t require a huge surface. But that extra six inches on a 30-inch deep table provides a surprising amount of extra real estate, making it perfect for large-scale prep, rolling out dough, or holding bigger pieces of equipment.

Pro Tip: Before you commit, grab some painter's tape and outline the table's dimensions right on your floor. This simple trick lets you physically walk around the "table" and get a real feel for how it affects traffic, door clearances, and the overall flow of your kitchen.

It’s a foolproof way to see the table in your space before it arrives, helping you avoid that classic mistake of only looking at the empty floor and not the people who have to move around on it.

Key Configuration Choices

Beyond sheer size, a few key configuration choices can completely change how a table functions. The goal here is to match the features directly to what your kitchen crew does every single day.

Backsplash: Yes or No? A backsplash is that raised lip along the back of the table. It might seem like a small detail, but its impact is huge. If your table is going against a wall, a backsplash is a must-have. It stops food, liquids, and utensils from falling into that dreaded, impossible-to-clean gap. It also saves your wall from splatters, which makes cleanup and sanitation way easier. But if your table is going to be a freestanding island, a flat top without a backsplash is the way to go, allowing access from all sides.

Undershelves for Maximum Storage An undershelf is easily one of the most valuable add-ons you can get. It magically turns the dead space under the table into prime storage.

- Single Undershelf: This is the most common setup, giving you a sturdy shelf for stashing mixing bowls, tubs of ingredients, or small appliances.

- Double Undershelf: For kitchens that are serious about storage, a double undershelf offers two full levels of organization, perfect for keeping a high volume of dry goods or equipment neatly tucked away.

Casters vs. Stationary Legs The last big decision is about movement. Does your table need to be on the go?

- Stationary Legs: These provide rock-solid stability, which is non-negotiable for heavy-duty work like butchering or intense mixing. The legs are almost always adjustable, so you can get a perfectly level, wobble-free surface.

- Casters (Wheels): Casters give you total flexibility. You can effortlessly rearrange your kitchen layout on the fly or roll the table out of the way for deep cleaning. Just make sure you get good ones—quality casters have locking mechanisms to keep the table firmly in place when you're working.

Why NSF Certification Is A Must-Have

In any commercial kitchen, some things are simply non-negotiable. Food safety is right at the top of that list. Look closely at any professional-grade stainless steel prep table, and you'll find a small blue seal: the NSF Certification. This isn't just a fancy sticker. It's a critical stamp of approval that health inspectors actively look for.

Think of NSF International (formerly the National Sanitation Foundation) as the trusted, third-party referee for public health and safety. When a prep table earns that NSF seal, it means it's passed a battery of tests to meet incredibly strict standards for hygiene and cleanability.

The NSF seal is your guarantee that the table is built to promote food safety. It certifies that the materials are non-toxic, the surface is smooth and non-porous, and there are absolutely no cracks or crevices where dangerous bacteria could hide and multiply.

Trying to get by with non-certified equipment is a huge gamble. It’s not just about risking health code violations or fines; it’s about putting your customers' health on the line by creating a potential breeding ground for pathogens. In a professional kitchen, NSF certification isn't a "nice-to-have"—it's a must-have.

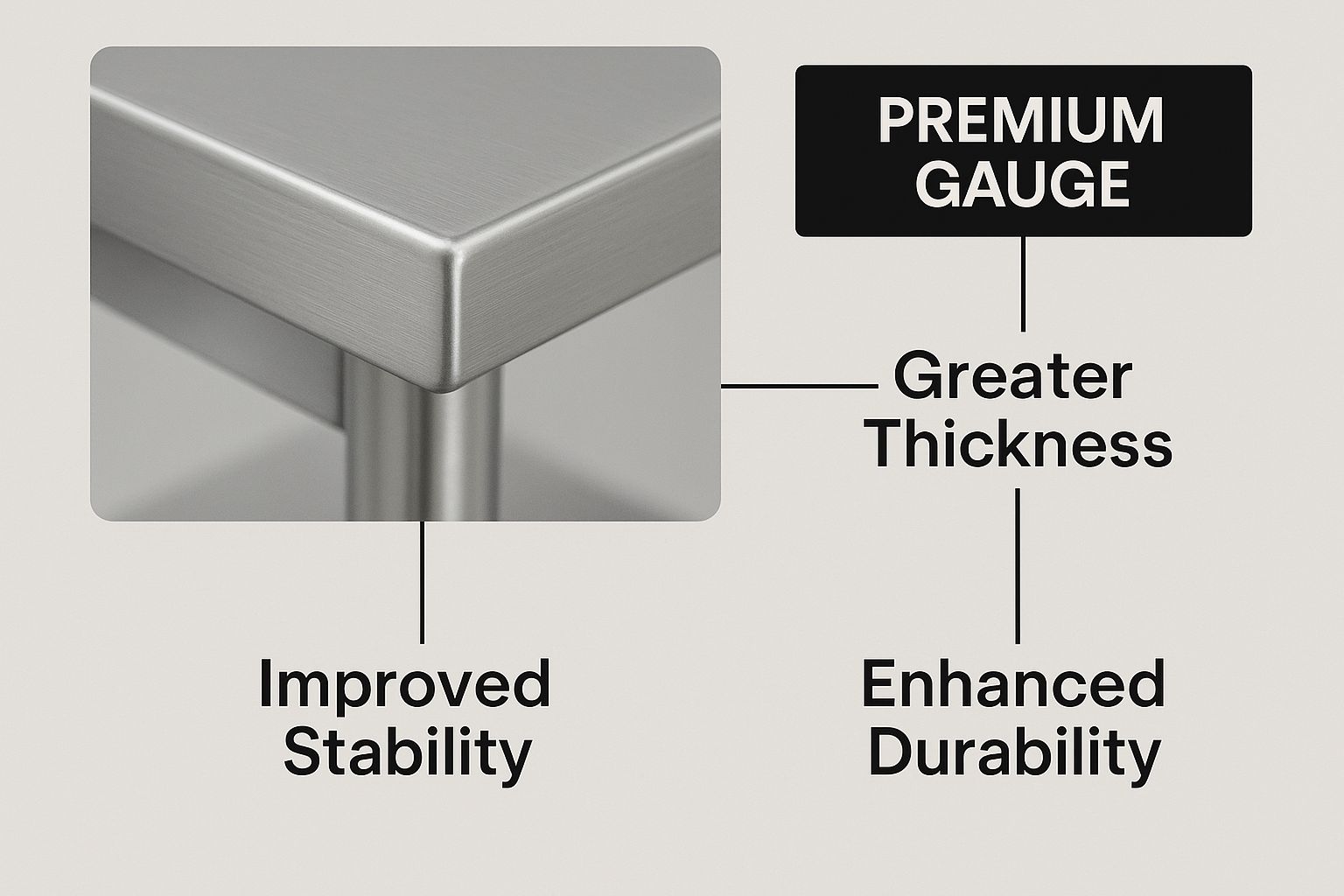

Understanding Steel Gauge: The Real Mark of Durability

Once you've confirmed a table is NSF certified, the next thing to look at is its steel gauge. This number tells you exactly how thick the stainless steel is, but it works in a way that might seem a little backward at first: the lower the gauge number, the thicker and stronger the steel.

It helps to think of it like sheets of paper. A single sheet is flimsy and bends easily (that's like a higher gauge). But a thick stack of paper is far more rigid and tough to damage (that's your lower gauge). Steel works the exact same way.

Here’s a quick rundown of what you'll typically find:

- 18-Gauge: This is your standard, budget-friendly option. It's perfectly fine for light-duty prep, simple storage, or as a landing spot in less busy areas. Think small cafes or even a serious home kitchen.

- 16-Gauge: This is where you hit the sweet spot for most commercial kitchens. A 16-gauge table is a significant step up in toughness, making it a fantastic all-rounder. It can handle daily chopping and the weight of countertop equipment without easily denting.

- 14-Gauge: Meet the undisputed heavyweight champion. A 14-gauge table is an absolute beast, built to take whatever you can throw at it. We're talking heavy equipment, constant pounding from meat tenderizers, and years of relentless use without warping or complaining.

Why Thicker Steel Is Worth The Investment

Choosing a lower gauge (thicker) steel is a direct investment in the longevity of your kitchen. Let's be honest, a busy kitchen is a battlefield. Heavy stockpots are slammed down, knives are used with force, and equipment gets dragged around constantly.

A thin, 18-gauge table might look fine on day one, but it will quickly start showing battle scars. Dents and dings aren't just ugly; they ruin the smooth, easy-to-clean surface that's so critical for sanitation.

On the other hand, a sturdier 16-gauge or 14-gauge table provides a rock-solid work surface that holds its ground for years. That durability doesn't just save you the cost of a replacement; it ensures your prep station stays hygienic and reliable, even in the chaos of a Saturday night dinner rush.

Exploring Different Types of Stainless Steel Prep Tables

While all stainless steel prep tables share that core of toughness and hygiene, they definitely aren't a one-size-fits-all solution. Think of it like a chef's knife set: you have your go-to chef's knife for most things, but you also need a nimble paring knife or a hefty cleaver for specific jobs. The world of prep tables works the same way, with different designs built to perfect a particular workflow.

The most common model you'll see is the standard work table. It's the versatile foundation of almost any kitchen—a simple, flat-topped surface built for general tasks like chopping vegetables, mixing ingredients, and plating dishes. You can easily find them with features like an undershelf for extra storage or a backsplash to keep your walls clean.

Specialized Tables for Peak Efficiency

For kitchens that really pump out a high volume of a specific item, specialized tables are game-changers. They can transform a clunky, multi-step process into a beautifully streamlined assembly line. These units often integrate features like refrigeration, putting everything a cook needs right at their fingertips and slashing the time wasted walking back and forth.

By eliminating the need to constantly move between a prep area and a separate cooler, a specialized table can dramatically boost a kitchen's output. It's not just a table; it's a complete, self-contained workstation.

This focus on targeted design leads to some incredibly efficient equipment.

Pizza and Sandwich Prep Tables

Two of the most popular specialized models are pizza prep tables and sandwich prep tables. Each one is a masterclass in workflow optimization, designed around a very specific set of tasks.

- Sandwich Prep Tables: An absolute must-have for delis, cafes, and sandwich shops. These tables have refrigerated pans or wells built directly into the work surface. This keeps all your cold cuts, cheeses, and veggies perfectly chilled and literally within arm's reach. A good cook can assemble dozens of sandwiches without ever taking a step.

- Pizza Prep Tables: Engineered specifically for pizzerias, these tables usually feature a large, flat workspace for stretching dough—some even have a marble top to help keep it cool. Directly above the work surface sits a refrigerated rail packed with all the essential toppings, allowing for rapid-fire pizza building from base to oven.

Choosing the right type of stainless steel prep table is a strategic decision that directly impacts your kitchen’s speed and organization. For a deeper dive into the features and benefits, learn more about what to look for in a high-quality stainless steel work table to ensure you make the best investment. Picking the right model ensures your workspace actively supports your team instead of slowing it down.

Still Have Questions? Let's Clear Things Up

Alright, we've walked through the nitty-gritty of materials, sizes, and care. But I know from experience that a few practical questions always pop up right when you're ready to make a choice. Let's tackle the most common ones I hear so you can feel completely confident in your decision.

What's the Best Grade of Stainless Steel for a Restaurant?

For just about any real-world restaurant kitchen, 304 grade stainless steel is the undisputed champion. Why? It has a higher mix of nickel and chromium, which is your best defense against corrosion from acidic foods like tomato sauce, aggressive cleaning chemicals, and the constant moisture of a busy kitchen. It's truly the go-to material for any surface where food is prepped.

You might see 430 grade tables out there, and yes, they are easier on the budget. But I'd only recommend them for dry applications or areas that aren't getting hammered with corrosive stuff—think equipment stands or dry storage shelving. Investing a little more in a 304 grade top from the start pays off big time in longevity and peace of mind with health codes.

Can I Put Hot Pans Right on the Table?

Yes, absolutely. This is one of the biggest perks of stainless steel over wood or laminate. That high heat resistance means you can generally slide a hot pot or pan right onto the surface without causing instant damage.

A word of caution, though. Extreme and repeated temperature shocks—like taking a pan straight from a 500°F oven and slapping it down—can potentially cause the metal to warp over time. This is especially true for thinner 18-gauge tables. The best practice? Keep a trivet handy for those screaming-hot items. It’s a small habit that will help keep your table perfectly flat for years to come.

How Do I Get Rid of Rust Spots on My Prep Table?

Seeing a rust spot on your "stainless" steel can be jarring, but don't panic! It's almost always fixable. This usually happens when the table comes into contact with other iron objects (like a stray piece of steel wool) or from residue left by harsh, chloride-based cleaners.

Here’s a simple, field-tested method to take care of it:

- Make a Paste: Mix some baking soda with a little water until you have a thick, spreadable paste.

- Apply and Let It Sit: Dab the paste directly onto the rust spot and just let it work its magic for about 20-30 minutes.

- Scrub Gently: Grab a soft-bristle brush or a non-abrasive sponge and scrub the area, but make sure you're moving in the direction of the steel's grain. Going against the grain is a surefire way to scratch the surface.

- Rinse and Dry: Give the spot a thorough rinse with clean water, then dry it completely with a soft cloth. This last step is key to preventing water spots and keeping new rust from forming.

If you have a really stubborn spot that won't budge, a specialized non-abrasive, non-chloride stainless steel cleaner is your next best bet. Honestly, consistent cleaning and avoiding those harsh chemicals is the best way to keep your stainless steel prep table looking brand new.

Ready to find the perfect foundation for your kitchen's workflow? Head over to PrepTables.com. You can explore our huge collection of NSF-certified tables, from heavy-duty workhorses to specialized refrigerated units—all built for a lifetime of durability and hygiene. Shop now at PrepTables.com and start building a more efficient, professional workspace.