Top Prep Tables for Restaurant: Find Your Perfect Match

Share

Restaurant prep tables are the unsung heroes of any commercial kitchen. They provide the essential workspace for everything from chopping vegetables to plating the final dish. A well-chosen table isn't just furniture; it’s a critical investment in your kitchen's productivity, safety, and overall flow. The right surface can truly transform a chaotic space into an efficient culinary powerhouse.

The Foundation of an Efficient Kitchen

Every great meal starts on a prep table. Think of it as the central hub of your kitchen—the main stage where culinary creativity meets operational efficiency. The quality and type of table you choose directly impact how smoothly your team operates, especially during the intense pressure of a dinner rush.

A well-organized prep station dramatically cuts down on preparation time. When chefs have a dedicated, clean, and accessible surface, their movements become more fluid and purposeful. This seemingly simple piece of equipment is fundamental to creating a seamless production line, from raw ingredient to plated perfection.

Impact on Safety and Workflow

Beyond just speed, the right prep table is a cornerstone of food safety. A durable, non-porous surface like stainless steel is easy to clean and sanitize, which is non-negotiable for preventing cross-contamination and meeting strict health codes. A messy or inadequate prep area, on the other hand, can quickly become a liability.

The impact on your team's morale and physical well-being is also huge. An ergonomic and well-placed table reduces unnecessary strain and movement, making the demanding work of a kitchen professional more manageable and less taxing.

A thoughtfully chosen prep table is more than just a surface; it's a strategic tool that enhances workflow, ensures food safety, and supports your culinary team's performance every single shift.

Exploring Your Options

As we dive deeper, we'll look at the different kinds of prep tables out there. We'll start with the industry standard: stainless steel prep tables, the versatile workhorses you'll find in almost every professional kitchen. From there, we'll check out specialized units built for specific jobs:

- Pizza Prep Tables: These are engineered with wider cutting boards and refrigerated rails, perfect for holding all your different toppings.

- Sandwich and Salad Prep Tables: Optimized for quick assembly, they feature multiple small pans for ingredients, keeping everything chilled and within arm's reach.

Understanding these distinctions is the first step toward buying a table that truly serves your restaurant's needs and sets you up for long-term success.

Understanding Stainless Steel Prep Tables

Picture the heart of any bustling commercial kitchen. What do you see? I'd bet a gleaming stainless steel prep table is front and center. These tables are the unsung heroes, the foundational workhorses that provide the space and durability for almost every task on the prep list. But not all stainless steel is the same, and knowing the difference is what separates a smart purchase from a future headache.

The first thing to get a handle on is the steel grade. Think of this like the steel's recipe—different ingredients mean different levels of performance. The two you'll run into most often are 304 and 430.

- 304 Grade Stainless Steel: This is the premium stuff. It has a higher nickel content, which makes a huge difference in its ability to fight off rust and corrosion. It’s the perfect choice for any table that’s going to see a lot of water, acidic foods like tomatoes or lemons, or strong cleaning chemicals.

- 430 Grade Stainless Steel: This is your more budget-friendly option. It's still a solid, durable material, but it's more likely to show signs of corrosion over time, especially in humid kitchens or if it's constantly in contact with salt and acids. It's a fine choice for dry storage areas or very light-duty prep work.

Honestly, investing in 304 grade steel right from the start is almost always the smart move. Its superior durability means it will last longer and keep you on the right side of health and safety codes.

Strength and Stability

Beyond the grade of the steel, you have the steel gauge. This tells you how thick and strong the table is. It can feel a bit backward at first: a lower gauge number actually means thicker, stronger steel. Think of it like a golf handicap; a lower number means a better, more solid performer. A heavy-duty 14-gauge table can handle the weight of big equipment like commercial mixers or meat slicers without breaking a sweat, while a standard 18-gauge table is perfect for general chopping and assembly.

How the table is built is just as important. Look for features like gussets—those triangular metal braces that connect the legs to the tabletop. They add critical stability and stop the table from wobbling when your team is working hard. An undershelf is another key feature. It doesn't just give you extra storage space; it also braces the legs, making the whole unit sturdier and increasing its load capacity.

A table's true value isn't just its surface; it's in the combination of its steel grade, gauge, and structural reinforcements. These elements work together to create a reliable and long-lasting workspace.

Specialized Prep Tables for Unique Menus

While the classic flat-top stainless steel table is a kitchen staple, many kitchens can boost their efficiency with specialized units. These tables smartly combine workspace with refrigeration, creating a self-contained station where ingredients stay fresh and are always within arm's reach.

Pizza Prep Tables

A pizza prep table is built from the ground up for making pies. It has a deep, refrigerated rail designed to hold big pans of sauce, cheese, and all your toppings. The cutting board is usually extra-wide and deep, giving you plenty of room to stretch dough without flour flying everywhere. This design keeps everything organized and chilled, creating a fast, smooth assembly line from dough to oven.

Sandwich and Salad Prep Tables

A sandwich or salad prep table, on the other hand, is all about speed and customization. These units have a refrigerated top rail made to hold lots of smaller food pans—perfect for a wide array of fresh veggies, meats, cheeses, and dressings. This setup lets staff build complex salads and sandwiches in a flash, ensuring every single ingredient is fresh and held at a food-safe temperature.

While both are refrigerated, their layouts are tailored for very different workflows. To see a wider selection and really understand the nuances, check out the comprehensive guide on our restaurant stainless steel tables. It will help you pinpoint the exact style that fits your kitchen's needs.

The Guide to Refrigerated Prep Tables

While any basic stainless steel table gives you a workspace, a refrigerated prep table is on a whole other level. It's a true game-changer for any serious kitchen, blending a tough work surface with built-in cold storage. This smart design creates a streamlined assembly line that keeps your most important ingredients perfectly chilled and right where you need them.

Picture this: it's the middle of a chaotic dinner rush. Your line cook is putting together a complex salad. Instead of running back and forth to a separate cooler, every single vegetable, dressing, and protein is laid out right in front of them, held at a consistently safe temperature. That kind of setup doesn't just speed up service—it slashes the risk of spoilage and foodborne illness.

The Power of Integrated Cold Storage

For any fast-paced kitchen dealing with perishables, refrigerated prep tables are absolutely essential. They are your first line of defense in keeping ingredients out of the temperature danger zone (41°F to 135°F). This makes them a crucial tool for nailing your food safety standards and passing health inspections without breaking a sweat.

You can see their value reflected in the market. The global market for these tables was pegged at around USD 7.67 billion in 2024 and is on track to hit USD 10.30 billion by 2031. Why the growth? It's simple: food safety rules are getting tighter, and kitchens need equipment that makes them more efficient. You can read the full research on the refrigerated prep tables market to see the numbers for yourself.

This combination of workspace and refrigeration is precisely why these tables are a top priority for restaurants, delis, and caterers all over the world. They tackle the critical need for temperature control head-on, preventing waste and making sure every dish you send out is fresh and safe.

Key Features to Evaluate

When you're shopping for a refrigerated unit, a few key features will make or break its usefulness in your kitchen.

First up is the compressor—it's the heart of the whole system. Its location is a big deal. A side-mounted compressor is usually much easier to get to for cleaning and maintenance. On the other hand, a rear-mounted compressor can be a real space-saver if your kitchen is on the narrow side.

The cutting board is another vital piece. Most tables will come with a durable, non-porous polyethylene board that’s easy to sanitize and won't dull your knives. Think about the size and depth of this board; it directly impacts how much room you have to work.

Finally, check out the food pan setup. The refrigerated rail on top generally comes in two main styles:

- Standard Top: The cutting board and ingredient pans sit flush, giving you a completely flat workspace.

- Mega Top: These units have a deeper rail, allowing you to hold more pans—sometimes in multiple rows—which is great if you need access to a wider variety of ingredients.

A well-chosen refrigerated prep table does more than just keep food cold—it creates an ergonomic, efficient, and safe workstation that pays for itself in reduced food waste and faster service times.

Pizza and Sandwich Tables: Specialized Units

Within the world of refrigerated prep tables, you'll find specialized models built for specific jobs. The two most common are pizza prep tables and sandwich/salad prep tables. While they both keep ingredients cold, they're engineered for very different workflows.

A pizza prep table is easy to spot. It has a raised, refrigerated rail designed to hold big, deep pans—perfect for bulky toppings like pepperoni, mushrooms, and piles of cheese. The cutting board is also typically extra-deep to give you plenty of room to stretch out dough.

In contrast, a sandwich prep table (often called a salad station) features a rail designed to hold lots of smaller food pans. This layout is all about quick access to a wide variety of sliced meats, cheeses, and fresh veggies, making it a breeze to assemble custom orders on the fly. To get a better feel for these different models, take a look at our guide to commercial refrigerated prep tables.

Knowing the difference between these purpose-built designs is key to picking a unit that truly supports your menu and your kitchen's rhythm.

Choosing Your Specialized Prep Station

When you start looking at refrigerated prep tables, you quickly realize it’s not a one-size-fits-all world. While they all keep ingredients cool and ready to go, the specialized units are built from the ground up to master specific kitchen tasks. Getting these differences is the key to picking a station that feels like a natural part of your kitchen's flow, not a roadblock.

The two big players you'll run into are pizza prep tables and sandwich/salad prep tables. Each one is engineered for a certain kind of menu, tweaking every inch of its design to make your team faster, keep food safe, and handle the rush. The right choice really comes down to what your menu demands.

This decision is more important than ever. The global market for food prep tables was valued at around USD 1.18 billion in 2023 and is expected to hit USD 1.62 billion by 2029. That growth tells a story: kitchens are investing in specialized gear to get more efficient and keep up with customers who want fresh, made-to-order meals.

The Pizza Prep Table: A Purpose-Built Powerhouse

A pizza prep table is built for one thing: creating the ultimate pizza-making assembly line. Its standout feature is a raised, deep refrigerated rail. This design is made to hold big, full-size food pans, perfect for stocking bulky ingredients like piles of shredded mozzarella, pepperoni, and sliced veggies.

The other game-changer is the extra-wide cutting board. It’s usually made from a tough polyethylene and gives a cook plenty of real estate to stretch out dough, spread sauce, and load on toppings without everything ending up on the floor. It's this all-in-one workspace that makes a pizza station so incredibly effective.

The magic is in the combination of a deep ingredient rail and a wide work surface. It lets one person handle the entire process, moving from a ball of dough to a fully topped pie that’s ready for the oven, all in one smooth motion.

The Sandwich and Salad Prep Table: Built for Speed and Customization

On the other hand, a sandwich or salad prep table is all about speed and custom orders. Instead of massive pans, its refrigerated rail is set up to hold a bunch of smaller food pans—think sixth-size or ninth-size pans. This layout is perfect for keeping a huge variety of ingredients organized, from different greens and sliced meats to various cheeses and dressings.

This setup lets a cook stand in one place and fly through complex, custom-built sandwiches and salads. The whole point is having immediate access to a wide array of fresh components, making sure every order is right and ready in a flash, all while keeping perishables safely chilled.

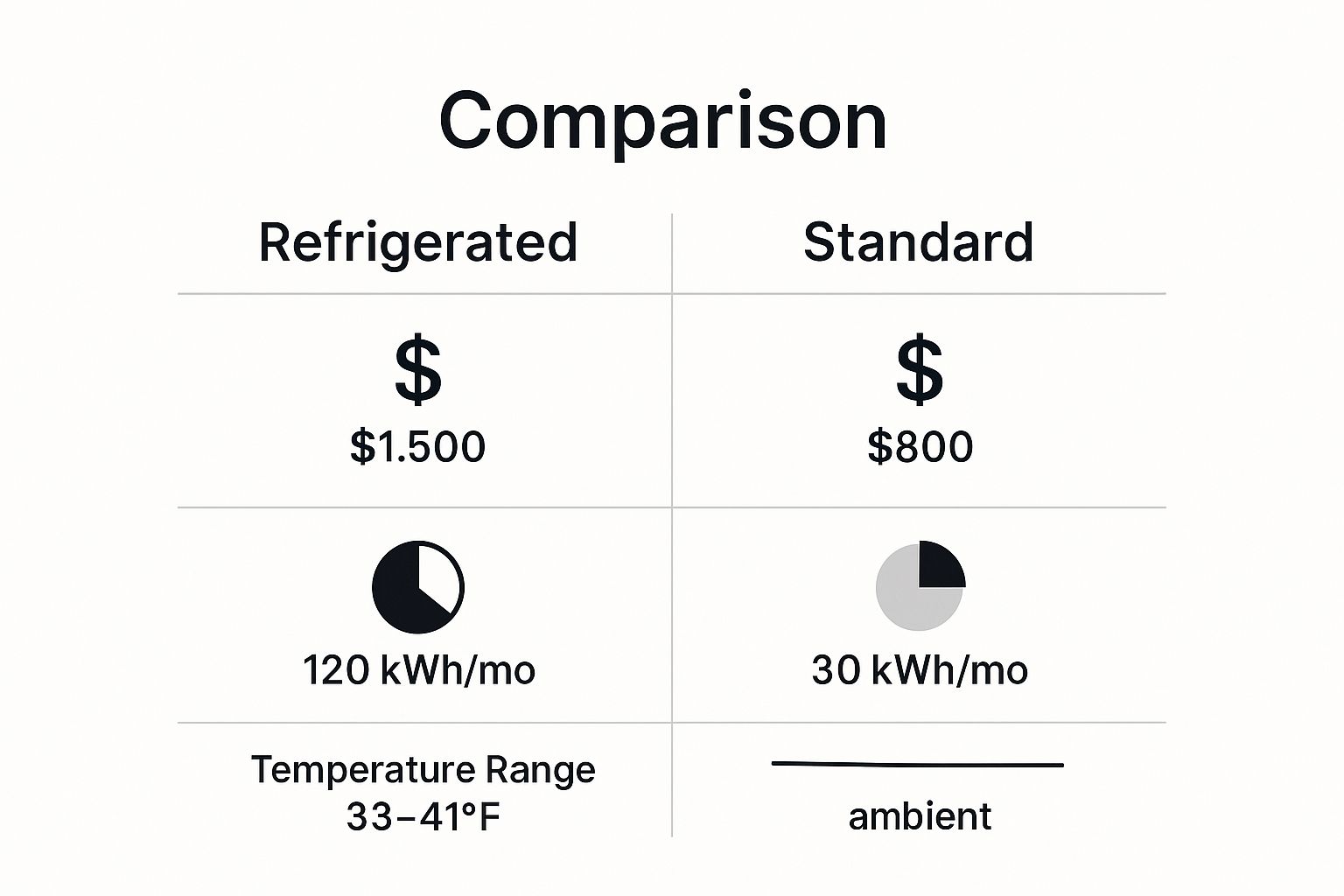

The image below breaks down the main differences between a standard table and its refrigerated cousin, showing you the trade-offs in cost and energy use.

As you can see, the refrigerated table costs more upfront and uses more power. But its ability to hold food at a safe 33–41°F is a non-negotiable benefit for most commercial kitchens.

Choosing between a pizza table and a sandwich/salad station is a critical decision that directly impacts how smoothly your kitchen runs. Let's make it simple with a direct comparison.

Pizza Prep Table vs Sandwich/Salad Prep Table

| Feature | Pizza Prep Table | Sandwich/Salad Prep Table |

|---|---|---|

| Refrigerated Rail | Raised and deep to hold full-size pans | Flush or slightly raised; holds multiple smaller pans |

| Cutting Board | Extra-deep (typically 19") for dough stretching | Standard depth (typically 10") for assembly |

| Primary Use | High-volume pizza production | Custom, made-to-order sandwiches and salads |

| Ingredient Focus | Fewer, bulkier ingredients (cheese, sauce) | Wide variety of smaller-portion ingredients |

Ultimately, the best prep table is the one designed for the food you actually make.

Making the Right Choice for Your Menu

Picking the right unit is a strategic move that will pay off in your kitchen's daily output.

- For Pizzerias: You absolutely need the deep pan capacity and large dough-stretching area of a pizza prep table.

- For Delis and Cafes: The multi-pan setup of a sandwich and salad station is a must-have for handling a diverse, customizable menu.

By matching the table's design to how you operate, you’re making an investment that directly boosts your kitchen's unique workflow. For an even deeper look into picking the right model, check out our complete guide to the essential food prep table.

Essential Features for Your Buying Checklist

Alright, you’ve decided between a standard stainless steel or a refrigerated prep table. Now comes the fun part: digging into the specific features that separate a good table from a great one. This is your final checklist before you buy. Skipping these details often leads to buyer's remorse, but getting them right means you'll have a workhorse station that your team can rely on for years to come.

First things first, look for an NSF certification. This is the single most important feature, and it’s non-negotiable. It’s not just a sticker; it’s proof that the table meets strict public health standards. An NSF-certified table is made from materials that are easy to clean, sanitize, and won't harbor bacteria. This is your ticket to passing health inspections and keeping your food safe.

Load Capacity and Stability

One of the biggest mistakes I see people make is buying a table that can't handle the heat—or in this case, the weight. A prep table's load capacity tells you exactly how much weight it can hold before it starts to buckle. This is absolutely critical if you plan on putting heavy equipment like a commercial mixer or a big slicer on top.

Pay close attention to how the table is built. Tables with lower-gauge steel (which is thicker) and gussets—those little triangular braces on the legs—are going to be much stronger. An undershelf also does wonders for structural support by spreading the weight out evenly. Always check the manufacturer's specified capacity and pick one that can handle more than you think you'll need.

Ergonomics for a Better Kitchen

A table that's uncomfortable for your staff is a recipe for disaster. It can cause fatigue, back pain, and slow down your whole line. Good ergonomics isn't a luxury; it's a must-have for a productive kitchen.

Most prep tables have a standard height of about 35 inches, which works for most people. But your team is made up of individuals of all different heights. That’s where adjustable legs become a game-changer, letting you customize the height so no one has to hunch over or strain themselves.

Mobility is another huge ergonomic win. Tables with casters (heavy-duty wheels) can be moved around for deep cleaning or to change your kitchen layout on the fly. Just make sure the casters lock firmly so the table is safe and stable when in use. This simple feature turns a piece of furniture into a truly versatile tool.

A table designed with ergonomics in mind is a direct investment in your team's well-being and efficiency. Features like adjustable height and casters reduce physical strain and create a more adaptable kitchen environment.

Practical Add-Ons That Make a Difference

Beyond the basic specs, a few add-ons can make a huge difference in how functional your table is and how clean your kitchen stays.

- Backsplashes: This is just a small raised edge at the back of the table, but it's incredibly useful. It stops food, liquids, and utensils from falling down the gap between the table and the wall, which makes cleanup so much easier.

- Undershelves: Whether solid or wire, an undershelf gives you crucial storage space for bins, appliances, or pans. Solid shelves are great for small items that could fall through, while wire shelves help with air circulation in humid kitchens.

- Marine Edges: You might also hear these called raised or anti-drip edges. They have a slightly raised perimeter that keeps spills and liquids contained on the tabletop. If you’re working with sauces or marinades, this feature is a lifesaver for keeping your floors clean and safe.

Getting the right mix of these features will make sure your new prep table for your restaurant isn’t just a surface, but a smart addition that makes your whole kitchen run better.

You've picked out the perfect prep table—now it's time to protect that investment. Good maintenance is what separates a table that lasts a few years from one that's a trusted part of your kitchen for a decade or more. A simple, consistent routine is all you need to keep your equipment in top shape, meet health codes, and avoid surprise repair bills.

For your standard stainless steel tables, daily cleaning is simple but absolutely essential. You're not just wiping away grime; you're preserving the passive chromium layer that shields the steel from rust and corrosion. Anything left sitting on the surface, from food scraps to grease, can slowly compromise this protective layer.

Think of the steel's surface like wood—it has a "grain." When you clean, always wipe and scrub in the direction of that grain. Going against it can create tiny, microscopic scratches that dull the finish over time and create hiding spots for bacteria. For most daily wipe-downs, a soft cloth with a bit of mild detergent and warm water is all you need.

Daily and Weekly Maintenance Routines

A solid cleaning schedule is your best defense against wear and tear. Breaking it down into daily and weekly tasks makes it easy to manage.

Daily Cleaning Checklist for All Tables:

- Wipe Up Spills Immediately: Don't let acidic foods like tomato sauce, vinegar, or citrus juices sit. They can start to eat away at the steel's protective finish. Wipe them up right away with a damp cloth.

- Clean and Sanitize Surfaces: At the end of every shift, give the entire surface a good wash with mild detergent. Rinse it thoroughly with clean water, then follow up with a food-safe sanitizer.

- Dry Completely: After rinsing, always wipe the table completely dry with a clean, soft cloth. This simple step prevents water spots, which are mineral deposits that can also damage the finish.

If you’re dealing with tough, caked-on gunk, a simple paste of baking soda and water works wonders as a gentle abrasive. Stay away from harsh, chlorine-based cleaners. They are the enemy of stainless steel and will break down that protective layer, inviting rust.

Special Care for Refrigerated Units

Refrigerated prep tables need all the surface care of a standard table, plus a little extra love for their cooling systems. Ignoring these components is a fast track to a failed compressor and a costly emergency service call right in the middle of a dinner rush.

Proper maintenance isn't just about what you can see. It's about preventative care. Regularly cleaning condenser coils and checking door gaskets can literally add years to the life of a refrigerated unit and save you from the headache of a sudden breakdown.

Be sure to add these tasks to your regular maintenance plan for any refrigerated prep table:

- Clean Condenser Coils: Dust and grease are magnets for the condenser coils, forcing the compressor to work overtime. This wastes energy and eventually leads to burnout. Use a stiff brush or a vacuum to clean them at least once a month.

- Inspect Door Gaskets: The rubber seal around the doors is what keeps the cold air in and the warm air out. Check them every week for any cracks, rips, or brittleness. A bad seal wastes energy and puts your food safety at risk.

- Monitor Temperature: Don't just trust the built-in display. Use a separate, calibrated thermometer to double-check that the unit is holding its temperature. It needs to consistently keep food at or below 41°F to stay in line with health department regulations.

Frequently Asked Questions

When you're outfitting a new kitchen or upgrading an old one, a ton of practical questions pop up around prep tables. Getting solid answers is the key to making sure the table you pick is a perfect fit for your space, your workflow, and your budget. Let’s walk through some of the most common questions we get from restaurant owners just like you.

What Size Prep Table Do I Need for My Restaurant?

The right size prep table really comes down to two things: your kitchen's layout and your menu. The first step is always to pull out the tape measure. Figure out the floor space you have to work with, but remember to leave at least a 3-foot clearance around it. You need clear, safe walkways for your team to move efficiently.

Next, think about what you'll be doing on that table every day. For general chopping and putting dishes together, a standard 48-inch table is often a great workhorse. But if you’re running a busy pizzeria, you’ll probably want a 72-inch or even larger pizza prep table to give your crew enough elbow room for stretching dough and arranging toppings. Don't forget to consider what's going on the table, too—if it needs to hold heavy mixers or other equipment, you'll want a larger model with a higher capacity.

Is a 304 Grade Stainless Steel Table Worth the Extra Cost?

For almost any commercial kitchen, the answer here is a resounding yes. It all comes down to the metal itself. 304 grade stainless steel has more nickel in its composition, which gives it a major advantage in fighting off corrosion and rust compared to the less expensive 430 grade.

Just picture your daily grind. Your tables get hit with water, acidic ingredients like tomatoes and citrus, and all sorts of cleaning chemicals. The higher upfront cost for 304 grade steel is really an investment in the future. It's going to last longer and stand up to that daily abuse, paying for itself over time.

Choosing a refrigerated table isn't just about cold storage; it's a strategic decision to boost efficiency. It keeps perishable ingredients safely at arm's reach, streamlining assembly for cold dishes and reducing costly food waste.

When Should I Choose a Refrigerated Table Over a Standard One?

A refrigerated prep table is a game-changer if your kitchen is constantly churning out cold items like salads, sandwiches, desserts, or pizzas. These units are built to keep perishable ingredients at a food-safe temperature, right where the prep work is happening.

By combining your workspace with cold storage, you seriously speed up your workflow, make it easier to nail food safety standards, and dramatically cut down on spoilage. But for tasks like butchering meat or chopping veggies that are heading straight to the stove, a standard stainless steel table does the job perfectly and is the more budget-friendly choice.

Ready to find the perfect foundation for your kitchen's workflow? At PrepTables.com, we offer a huge selection of durable, NSF-certified stainless steel and refrigerated prep tables designed for any professional setting. Explore our models and build a more efficient kitchen today at https://preptables.com.