Choosing Your Perfect Food Prep Table

Share

Think of any great kitchen, whether it’s in a bustling restaurant or a serious home setup. There's always a central command post, a dedicated spot where the magic begins. That's your food prep table. It's far more than just a surface to put things on; it’s a purpose-built workstation designed for efficiency, cleanliness, and a smooth workflow.

The Unsung Hero of Every Efficient Kitchen

Every kitchen needs a command center, and the food prep table is it. This isn't just a place to chop vegetables. It's the workbench where your entire operation comes together—where speed, safety, and productivity meet. Imagine a surgeon's tray before an operation; everything has its place, ready for seamless action.

A dedicated prep table is truly a non-negotiable piece of equipment. It gives you a clean, durable area to handle raw ingredients, keeping them separate from other kitchen activities. This separation is fundamental for preventing cross-contamination and upholding food safety standards. In a busy commercial kitchen, this single piece of furniture can slash preparation times and dramatically improve the flow of service.

Exploring the Core Types of Prep Tables

The world of food prep tables is surprisingly diverse, with models engineered for just about any culinary task you can think of. It's a growing market, too. The global demand for these tables was valued at around USD 1.18 billion in 2023 and is expected to climb to USD 1.62 billion by 2029. You can learn more about the food prep table market growth and see the full analysis.

To help you get started, here's a quick breakdown of the main categories of food prep tables and what they're best used for.

Quick Guide to Food Prep Table Types

| Table Type | Primary Material | Key Feature | Best For | | :--- | :--- | :--- | | Standard Stainless Steel | Stainless Steel | Durability, easy to sanitize, optional features | General purpose chopping, mixing, and prep | | Pizza Prep | Steel, Marble | Refrigerated rail for toppings | Pizzerias and high-volume pizza making | | Sandwich/Salad | Stainless Steel | Built-in refrigerated wells/pans | Delis, cafes, and assembly-line sandwich/salad making |

Each type serves a very specific role, turning a simple surface into an integrated system for particular jobs.

Understanding these main types is the first step to finding the perfect match for your kitchen. Let's dig a little deeper into what makes each one unique.

-

Stainless Steel Prep Tables: These are the undisputed workhorses of the industry. Prized for their durability and non-porous surface, you'll find them in almost every professional kitchen. They are available with different features like undershelves for storage, backsplashes to protect walls, or casters for mobility, making them highly versatile for any task from light dicing to heavy butchering.

-

Pizza Prep Tables: Built specifically for pizzerias, these units are genius. They typically feature a wide work surface—often made of marble or refrigerated steel—for stretching dough, plus a raised, refrigerated rail on top. This keeps toppings like cheese, pepperoni, and veggies perfectly chilled and right at your fingertips.

-

Sandwich and Salad Prep Tables: These are all about assembly-line speed. They are refrigerated tables that come with built-in cutting boards and chilled wells designed to hold standard-sized food pans. This keeps all your sandwich fillings, salad greens, and condiments at a safe temperature while making the assembly process fast and methodical.

A well-chosen food prep table acts as the central nervous system of your kitchen's workflow. It dictates how ingredients move, how quickly dishes are assembled, and ultimately, how efficiently your entire operation runs.

Whether you just need a basic, bulletproof workbench or a complex refrigerated unit, there’s a food prep table out there designed to make your kitchen safer, cleaner, and way more productive.

Decoding Stainless Steel: The Industry Standard

When you walk into almost any professional kitchen, one of the first things you'll notice is the gleam of stainless steel. It’s the undisputed champion of the food service world, and for very good reason. A stainless steel food prep table is the go-to choice because it nails the trifecta of strength, longevity, and hygiene.

Think about the alternatives. Wood is porous, a perfect hiding spot for bacteria. Plastic scratches easily, creating tiny crevices that are tough to sanitize. Stainless steel, on the other hand, is non-porous. This means liquids and food particles can't seep in, making it incredibly simple to clean and keep safe—a non-negotiable for preventing cross-contamination. Plus, it naturally resists rust and corrosion, so it can take the daily abuse of a busy, high-moisture kitchen without breaking a sweat.

Understanding Steel Grades: 304 vs. 430

Now, not all stainless steel is created equal. The "grade" of the steel tells you about its chemical makeup, which in turn dictates its performance and price tag. For food prep tables, you’ll mainly run into two grades: 304 and 430.

-

430 Grade Stainless Steel: This is your more budget-conscious option. It’s got chromium and is magnetic, but it's lower in nickel. While it's still plenty durable, it’s a bit more vulnerable to corrosion from the salts and acids found in a lot of common foods. This makes it a better fit for dry storage or prep areas that don't see a lot of action.

-

304 Grade Stainless Steel: Often called "18/8" because it's made of 18% chromium and 8% nickel, this is the gold standard for any surface that touches food. That extra nickel gives it superior resistance to rust and corrosion, even when it’s constantly doused in acidic ingredients like lemon juice or tomato sauce. For any table that's a primary workhorse for food prep, 304 grade is always the recommended choice.

Choosing between them is a classic cost-versus-investment scenario. A 430-grade table might save you a few bucks today, but a 304-grade table is a far smarter long-term investment for the heart of a busy kitchen.

The Importance of Steel Gauge

Beyond the grade, you also need to pay attention to the "gauge." This is simply a measure of the steel's thickness. Here's the slightly confusing part: a lower gauge number means thicker, stronger steel. A heavier-gauge table is built to last and can handle more weight.

Think of a table's gauge as its backbone. It determines how much weight it can hold—from heavy mixers to giant tubs of ingredients—without bending or buckling under pressure.

Here’s a quick rundown of common gauges and what they’re used for:

- 14-Gauge: This is the big kahuna—the thickest, toughest option you can get. It’s usually reserved for heavy-duty butcher tables or surfaces that need to support incredibly heavy equipment. It can handle constant, heavy impact without denting.

- 16-Gauge: A fantastic all-rounder. 16-gauge steel hits that sweet spot between strength and cost, making it perfect for most general prep work. It can comfortably hold most countertop appliances without any issues.

- 18-Gauge: This is the lightest and most economical choice. While it's perfectly fine for lighter tasks like tossing salads or plating desserts, it isn't built to handle heavy equipment or aggressive chopping.

If you want to go deeper into the nitty-gritty, it's worth exploring the different types of stainless prep tables to find the perfect match for your kitchen's unique needs. Getting a handle on these details—from grade to gauge—is what empowers you to pick a table that won't just fit your space, but will stand up to the challenge for years to come.

Mastering Workflow With Specialized Prep Tables

While a standard stainless steel prep table is a fantastic all-rounder, some kitchens have needs that go way beyond basic. When you're pumping out high volumes of the same type of food, you need more than just a surface—you need a system. This is where specialized, refrigerated prep tables become an absolute necessity.

Think of it this way: you can build a house with a basic hammer and saw, but a professional carpenter shows up with a nail gun and a power miter saw. The specialized tools don't just make the job possible; they make it faster, more precise, and a whole lot less stressful. That’s exactly what a purpose-built prep table does for a busy kitchen making pizzas, sandwiches, or salads.

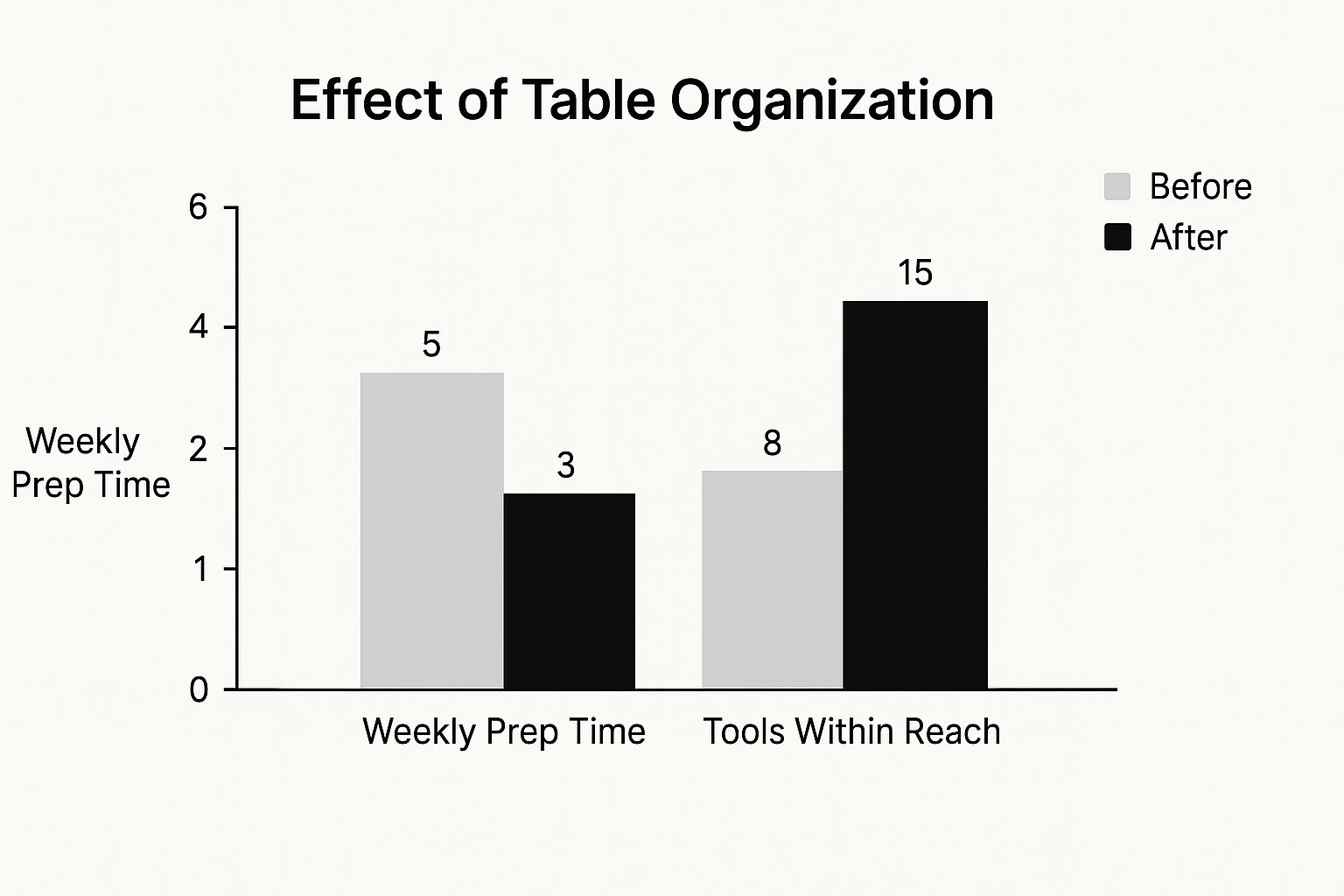

The impact on efficiency is massive. When every tool and ingredient has its place, your team can fly. The data below shows just how much a dedicated prep station can streamline your operation.

As you can see, a well-organized station can slash prep time by almost half and nearly double the immediate accessibility of ingredients. That’s a huge win in any kitchen.

The Two Most Common Types of Refrigerated Prep Tables

When you dive into the world of refrigerated prep tables, you’ll find that two types dominate the market: pizza prep tables and sandwich/salad prep tables. While they both keep ingredients cold, they're designed for very different workflows.

Choosing between them comes down to what you’re making. The table below breaks down the key differences to help you see which one fits your menu.

| Feature | Pizza Prep Table | Sandwich/Salad Prep Table |

|---|---|---|

| Ingredient Rail | Raised rail to fit deep pans for bulky toppings (cheese, pepperoni). | Flush, recessed wells for standard pans of sliced meats, veggies, etc. |

| Work Surface | Extra-deep (often 19"+) to handle large pizza doughs. | Standard depth with an integrated cutting board running the full length. |

| Primary Workflow | Spreading dough and adding toppings from the raised rail above. | Assembling sandwiches or salads by sliding them along the line of ingredients. |

| Best For | Pizzerias, Italian restaurants. | Delis, cafes, sub shops, salad bars. |

Ultimately, both are engineered for speed. They turn a simple prep station into a highly efficient, ergonomic cockpit for your line cooks.

Pizza Prep Tables: The Pizzeria Powerhouse

For any shop that takes its pizza seriously, a dedicated pizza prep table is non-negotiable. These units are built from the ground up to make the pizza-building process seamless.

The star of the show is the raised, refrigerated rail at the back. It’s designed to hold a battery of food pans, keeping cheese, sauce, and toppings perfectly chilled and right at the chef's fingertips. No more turning around or walking to a different cooler—every second saved adds up during a dinner rush.

The workspace itself is also thoughtfully designed. It’s much deeper than a standard table, giving you plenty of room to stretch and work with large pizza skins. Many even come with a marble or granite surface, which stays cool and helps keep the dough from sticking. It’s a small touch that makes a world of difference.

Sandwich and Salad Prep Tables: The Assembly Line Experts

In a bustling deli, cafe, or sandwich shop, it’s all about speed and consistency. A sandwich and salad prep table is designed to function like a mini assembly line, helping staff build orders with lightning-fast precision.

Instead of a raised rail, these tables have recessed, refrigerated wells that hold food pans flush with the work surface. This creates a smooth, uninterrupted workflow. An employee can start with bread on the built-in cutting board and slide it right down the line, adding ingredients from the chilled pans without missing a beat.

A specialized food prep table transforms a station from a simple surface into an ergonomic cockpit. Every ingredient and tool is placed for maximum efficiency, minimizing wasted motion and keeping food at safe temperatures even during the busiest service.

Everything from sliced turkey and provolone to lettuce and dressings stays at a food-safe temperature, right where you need it. This not only boosts your kitchen’s output but also ensures you’re meeting health codes and serving the freshest product possible.

Making the right choice is key to getting these benefits. To help you decide, check out our guide on buying the right prep table to compare all the features and find the perfect match for your business. An investment in the right equipment is an investment in a smoother, faster, and safer kitchen.

Exploring Different Types of Food Prep Tables

Let's be clear: not all food prep tables are created equal. While they all give you a surface to work on, the right table for your kitchen depends entirely on what you're doing day in and day out. Choosing the right one—whether it's a trusty stainless steel workhorse or a high-tech refrigerated unit—can actively boost your workflow, not just fill an empty spot on the floor.

The decision really boils down to your menu and your process. A simple, sturdy surface is great for general prep, but if you're slinging pizzas or building sandwiches all day, you need a more specialized tool for the job. Let’s break down the main types you’ll come across.

The All-Purpose Stainless Steel Prep Table

Think of the stainless steel prep table as the undisputed champion of the commercial kitchen. It's like a classic, reliable pickup truck—it's not flashy, but it's built tough and can handle anything you throw at it. Its non-porous surface is a massive win for food safety, stopping bacteria from finding a place to hide and making sanitation a breeze.

These versatile tables come in many configurations to suit specific needs:

- Open Base Tables: The most basic and common design, offering a flat worktop and four legs. They provide maximum under-table clearance, perfect for storing large containers or rolling equipment underneath.

- Tables with Undershelves: These add a fixed or adjustable lower shelf, providing crucial storage space for small appliances, ingredient bins, and cookware, keeping your workspace organized.

- Cabinet Base Tables: These feature enclosed cabinets with sliding or hinged doors. They're ideal for storing items you want to keep protected from dust and debris while maintaining a clean, streamlined look in your kitchen.

- Work Tables with Backsplashes: A backsplash is a raised lip along the back of the table that prevents ingredients and liquids from splashing onto the wall, making cleanup much easier and more hygienic.

- Mobile/Portable Tables: Outfitted with casters (wheels), these tables can be easily moved around the kitchen, offering flexibility to reconfigure your workspace on the fly.

Because it plays such a central role in keeping your kitchen clean and efficient, the stainless steel prep table is an investment you want to get right.

Specialized Pizza Prep Tables

For any spot that takes pride in its pizza, a dedicated pizza prep table isn't a luxury—it's a game-changer. These things are engineered from the ground up to streamline the entire pizza-making process, turning what could be a chaotic, multi-station mess into one smooth, fluid operation.

The design is brilliant. The key feature is a raised, refrigerated rail running along the back. It holds all your toppings—cheese, pepperoni, veggies—in food pans, perfectly chilled and right at your fingertips. No more turning around or walking to the cooler a hundred times a night. Those saved seconds add up fast during a dinner rush.

A specialized prep table transforms a workstation from a passive surface into an active system. It’s an ergonomic cockpit designed for a specific mission, whether that’s building a perfect pizza or assembling a sandwich in record time.

The work surface itself is also designed with purpose. It’s usually much deeper than a standard table, giving you plenty of room to stretch dough without feeling boxed in. Some models even come with marble or granite tops, which stay naturally cool and help keep the dough from sticking—a small detail that makes a massive difference in a high-volume pizzeria.

Efficient Sandwich and Salad Prep Tables

Speed and consistency are everything in a busy deli, café, or sandwich shop. That's exactly what a sandwich and salad prep table is built for. It functions like a compact, highly efficient assembly line, letting your team build orders quickly and accurately.

Instead of the raised rail you see on pizza tables, these units have recessed, refrigerated wells. The wells are made to hold standard food pans so they sit flush with the countertop, creating a totally smooth workflow. A cook can slide a sandwich right down the line, adding meats, cheeses, and veggies from the chilled pans without ever breaking their rhythm.

This setup keeps every single ingredient, from sliced turkey to crisp lettuce, at a constant, food-safe temperature. It’s not just about speed; it's about guaranteeing you're meeting health codes and serving the freshest possible product to every single customer.

Protecting Your Investment Through Proper Maintenance

A solid food prep table is a real workhorse and a significant investment, something that should last you for years, maybe even decades. But just like a great chef's knife, it won't stay in prime condition on its own. If you don't care for it, it'll degrade.

Consistent care is what protects your investment. It also ensures you’re always meeting food safety standards and staying on the right side of the health inspector. This isn’t about some huge deep clean once a month; it's about building small, simple habits into your kitchen's daily rhythm.

Daily and Weekly Cleaning Routines

The absolute foundation of good maintenance is a daily cleaning routine that is non-negotiable. At the close of every single shift, your prep table needs to be cleared, washed, and sanitized. It's that simple.

- Remove Debris: Use a soft cloth or a squeegee to get all the food scraps and particles off the surface.

- Wash the Surface: Clean the whole table with warm, soapy water or a gentle detergent. A pro tip: always wipe in the same direction as the steel's grain to prevent streaks.

- Rinse Thoroughly: Use clean water to wash away all the soap. Any leftover detergent can mess with your sanitizer, making it less effective.

- Sanitize and Air Dry: Apply a food-safe sanitizing solution, following the directions for how much to use and how long it needs to sit. Then, just let it air dry.

If you have a refrigerated prep table, add a quick weekly check to your list. Gently wipe down the gaskets on the doors and drawers with some mild soap and water. This simple step clears out grime that can break the seal, keeping your unit cold and efficient.

Monthly Deep Maintenance Checks

Once a month, it’s time for a more detailed look. For a standard stainless steel table, inspect it for any early signs of pitting or rust and double-check that the legs and shelves are still tight and secure.

For refrigerated models, the single most important monthly task is cleaning the condenser coil.

A dirty condenser coil is like trying to run a marathon while breathing through a straw. It forces the compressor to work overtime, wasting energy and leading to premature system failure.

Gently brush the dust and grease off the coils. Doing this one thing can make a massive difference in the unit's efficiency and how long it lasts, saving you a headache and money on energy and repair bills.

Finally, a quick word on what not to do. Never, ever use abrasive cleaners, steel wool, or anything with chlorine (like bleach) on your stainless steel. These will scratch the surface and strip away its protective layer. This creates tiny spots for bacteria to hide and invites rust to move in. Stick with mild detergents and approved sanitizers, and your table will serve you well for years to come.

Answering Your Final Food Prep Table Questions

Even after you've narrowed down your choices, a few nagging questions can pop up. Getting those last details ironed out is what separates a good purchase from a great one. Let's tackle some of the most common questions we hear, so you can buy with total confidence.

What Is the Best Grade of Stainless Steel for a Food Prep Table?

For almost any real-world kitchen scenario, 304-grade stainless steel is the gold standard. It contains a good bit more nickel than its budget-friendly cousin, 430-grade, which makes it far more resistant to corrosion from things like salt, citrus juices, and other acidic foods.

You can get away with 430-grade steel if the table will only ever be used in a dry area for non-corrosive storage. But if food is going to touch that surface or it's going in a humid part of the kitchen, spending a little more on 304-grade is a smart investment in the table's lifespan and safety.

Do I Really Need a Refrigerated Prep Table?

You might think a simple ice bath can do the job, but for any commercial kitchen that takes food safety and efficiency seriously, a refrigerated prep table is non-negotiable. These units are built to hold a steady, food-safe temperature, usually between 33-41°F (0.5-5°C). That's not just a nice-to-have; it's a critical defense against bacterial growth and a cornerstone of passing health inspections.

Think of it this way: a refrigerated unit isn't just a table with a mini-fridge attached. It's a fully integrated system that frees your staff from the constant, messy work of managing ice. That alone smooths out your workflow and pays for itself during a chaotic dinner rush.

How Do I Know What Size Food Prep Table to Get?

Getting the size right is a balancing act between the space you have and the work you do. First things first, get out a tape measure. Figure out exactly where the table will go and make sure you leave at least 36 to 48 inches of open space around it for your staff to move safely and without bumping into each other.

Next, think about what you'll actually be doing on it. A small station for chopping vegetables might only need to be 30-48 inches long. But if you're plating multiple entrees at once or doing huge batches of dough, you'll want to look at tables that are 72 inches or even longer. When you're on the fence, it's almost always better to go with the biggest size your kitchen and budget can comfortably handle.

What Does NSF Certified Mean and Why Is It Important?

When you see that NSF (National Sanitation Foundation) logo, it means the table has been put through its paces and meets tough standards for public health. It’s not just a sticker; it's a guarantee. For a prep table, NSF certification confirms a few key things:

- Safe Materials: The steel and other components are non-toxic and won't leach anything harmful into your food.

- Easy to Clean: The surface is smooth and non-porous, so it doesn't have tiny holes or cracks where bacteria can hide.

- Hygienic Design: The table is built without crevices or hard-to-reach corners that can trap food particles and become breeding grounds for germs.

Most health departments require commercial kitchens to use NSF-certified equipment. So, this isn't just a feature—it's essential for compliance and keeping your customers safe.

Ready to find the perfect workhorse for your kitchen? At PrepTables.com, we offer a wide selection of NSF-certified stainless steel and refrigerated prep tables designed for durability and efficiency. Explore our collection and find the ideal food prep table for your needs at https://preptables.com.