Your Expert Guide to Kitchen Work Tables

Share

Every great meal has an origin story, and in a busy professional kitchen, that story almost always starts on the work table. This isn't just a surface; the right kitchen work table is the command center for all things culinary. It sets the pace for your entire operation, influencing everything from workflow to sanitation.

This guide is about treating these tables not just as equipment, but as a strategic investment in your kitchen's success.

The Unsung Hero of Your Commercial Kitchen

It’s easy to overlook the humble work table, but it's the very foundation of your daily service. Think of it as the stage where your culinary team performs, shift after shift. A poorly chosen table can create frustrating bottlenecks and even safety hazards. But the right one? It can speed everything up and bring a sense of order to the chaos. It’s a game-changer.

We're going to break down how to pick a true workhorse that will anchor your kitchen for years. We'll get into the details of choosing the perfect material, size, and style—whether you need a standard stainless steel prep surface or a specialized refrigerated unit.

Why Your Choice Matters

Picking the right table is a core part of designing a kitchen that actually works. It’s a decision that fits into the bigger picture of your kitchen's layout and infrastructure. When you're looking at large-scale commercial kitchen tenant finish projects, the work tables are a key piece of that puzzle, ensuring the entire space is built for efficiency from the start.

A good work table choice pays off in a few key ways:

- Workflow Efficiency: The right size and placement create a natural, logical path from prep to cook to plate. No more bumping into each other.

- Food Safety: Non-porous materials like stainless steel are a breeze to sanitize, making it much easier to stay on the right side of the health inspector.

- Staff Ergonomics: A table at the correct height saves your team from the physical strain of bending over all day. That means fewer injuries and a happier, more productive crew.

Your work table isn't just a passive surface; it's an active tool. The right table enhances speed, ensures cleanliness, and supports your staff, making it one of the most important investments you can make in your kitchen's daily operations.

These tables are a big deal on a global scale, too. They're a huge part of the kitchen and dining furniture market, an industry that's expected to rocket past $66 billion worldwide by 2025. That number shows just how much kitchens everywhere—commercial and residential—are relying on durable, smart furniture. It's clear that investing in high-quality equipment is a globally recognized strategy for running a top-notch operation.

Navigating Your Stainless Steel Prep Table Options

When you start shopping for kitchen work tables, you'll quickly realize it's a bigger world than you might have expected. Not all stainless steel tables are made the same; they’re actually purpose-built tools, each designed for a specific job in a busy kitchen. Figuring out these differences is the first step to building a workspace that actually works for your team and boosts your kitchen's output.

Think of it like picking the right knife. You wouldn't grab a massive cleaver to mince garlic, right? It's the same logic here. You don't want a basic flat-top table where a specialized pizza prep station should be. Each type of table has its own strengths, built for different culinary needs and kitchen layouts.

The Foundational Flat-Top Table

The most common sight in just about any professional kitchen is the standard flat-top stainless steel table. This is your all-purpose workhorse, the blank canvas where all the magic starts. Its simple, open surface gives you the most room possible for everything from chopping vegetables and butchering meat to plating delicate desserts.

Its biggest strength is its versatility. In a tight kitchen, one flat-top might wear many hats throughout the day. In a larger operation, you’ll see them lined up to create dedicated stations, forming a smooth, efficient assembly line for different prep stages.

Adding a Backsplash for Cleanliness and Protection

A simple but incredibly useful upgrade is the prep table with a built-in backsplash. That small vertical lip at the back of the table does a huge job: it stops ingredients, liquids, and food scraps from falling behind the table or making a mess on your wall.

This isn't just about convenience—it's a huge win for sanitation and easy maintenance.

- Wall Protection: It shields walls from stains, moisture damage, and dents from equipment getting pushed back too far.

- Easier Cleanup: By keeping messes contained, it makes the end-of-night cleanup routine go so much faster.

- Improved Hygiene: It closes that annoying gap between the table and the wall, getting rid of a spot that's tough to clean and a magnet for bacteria.

Tables with a backsplash are the go-to choice anytime you're placing a table against a wall, which is how most kitchens are set up.

Undershelves Versus Cabinet Bases

That space under the tabletop is prime real estate, and how you use it comes down to your storage needs and workflow. The two main choices are tables with an open undershelf or those with an enclosed cabinet base.

An open undershelf, which is usually adjustable, gives you instant access to things you use all the time. We're talking big mixing bowls, stockpots, or cambros full of flour and sugar. This setup keeps your essentials right there, saving you steps and precious seconds during a chaotic service.

On the flip side, a cabinet base offers enclosed, protected storage. This is the spot for things that need to be kept free from dust, splashes, and general kitchen grime. It’s a great choice for stashing sensitive equipment, extra linens, or less-used tools in a much more organized, sanitary way.

The choice between an open shelf and a closed cabinet isn't just about storage; it's a strategic decision about workflow. Open shelves prioritize speed and access, while cabinet bases prioritize protection and organization.

Really thinking about how your crew moves and what they need to grab will point you to the right decision.

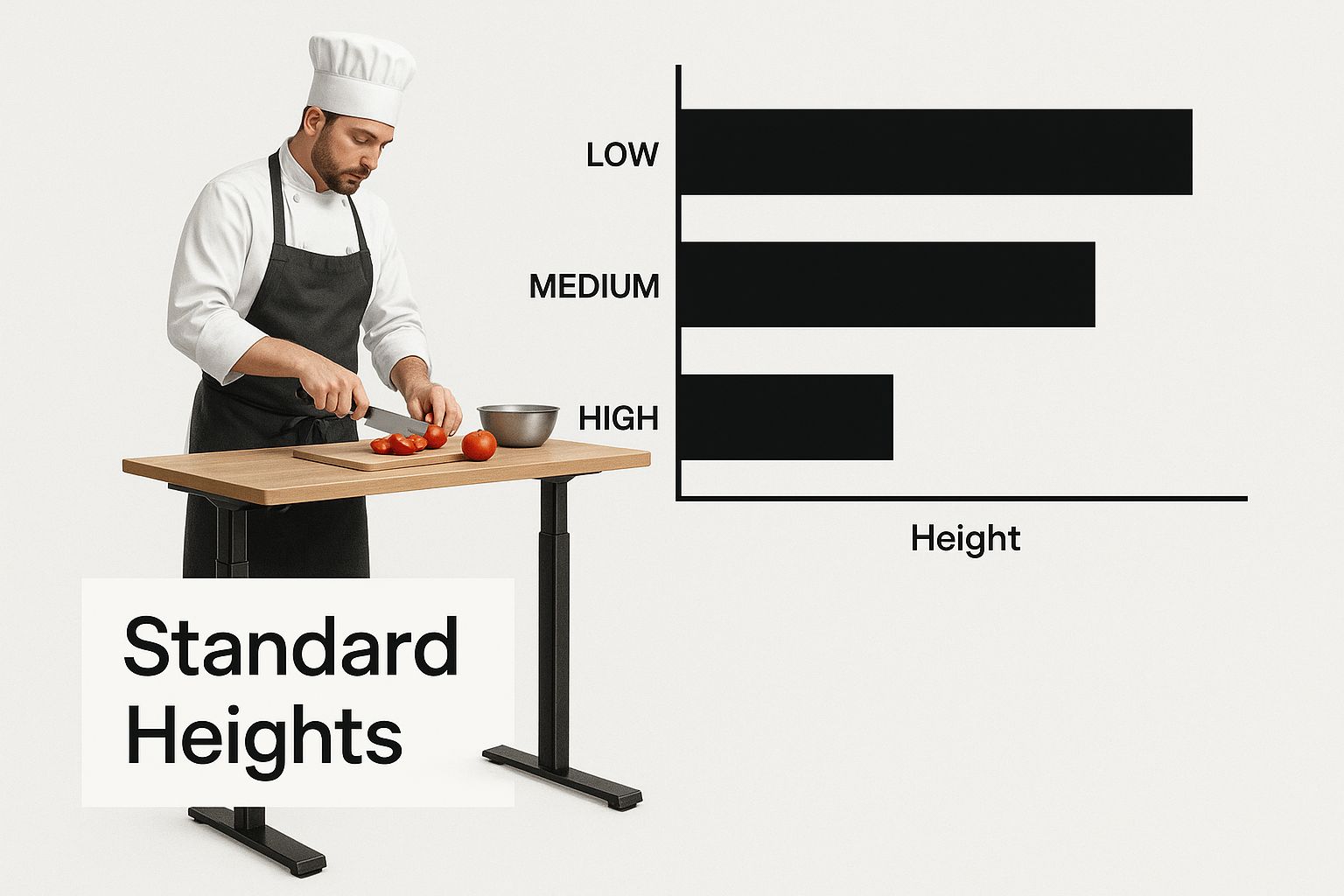

This infographic gives a great visual of common height ranges for kitchen work tables—a critical detail for keeping your staff comfortable and working efficiently.

As you can see, adjustable-height tables can be set to different levels, making sure everyone has an ergonomic setup for whatever task they're doing.

To help you visualize the options, let's break down the most common types of tables you'll encounter.

Comparing Common Commercial Kitchen Work Tables

This table gives a quick snapshot of the different work tables available, what they’re best for, and where they fit in a professional kitchen.

| Table Type | Primary Use | Key Features | Best For |

|---|---|---|---|

| Flat-Top Table | General-purpose prep, chopping, mixing, plating | Unobstructed, smooth surface; maximum workspace | Any kitchen needing versatile, multi-function prep space. |

| Table with Backsplash | Prep against a wall, messy tasks | Integrated vertical lip, contains spills, protects walls | Kitchens where tables are placed against walls to improve sanitation. |

| Table with Undershelf | Prep with frequent access to large items | Open, adjustable lower shelf for easy-to-grab storage | High-volume stations needing quick access to pots, pans, and bulk ingredients. |

| Table with Cabinet Base | Prep with protected storage needs | Enclosed base with doors, protects contents from debris | Storing sensitive equipment, clean linens, or less-used items securely. |

| Sandwich/Pizza Prep Table | Assembling sandwiches, salads, or pizzas | Refrigerated rails for pans, refrigerated base, cutting board surface | Delis, pizzerias, and quick-service spots that need an all-in-one station. |

Choosing the right table type from the get-go streamlines your kitchen's entire flow, making a noticeable difference in day-to-day operations.

Specialized Workstations: Sandwich and Pizza Prep Tables

Moving beyond the all-purpose tables, you get into specialized units designed to perfect one specific job. These aren't just tables—they're complete, self-contained workstations that merge prep space with refrigerated storage.

Sandwich prep tables are built for speed and efficiency in delis, cafes, and quick-service joints. They have a refrigerated rail at the back that holds an array of food pans filled with cold cuts, cheeses, veggies, and sauces. Right below the cutting surface, you'll find refrigerated cabinets or drawers for backup storage. This keeps everything for sandwich making chilled and literally at the chef's fingertips.

In the same vein, pizza prep tables are designed to make the pizza-making process seamless. They usually have a wider work surface, often made of marble or granite that stays cool—perfect for stretching dough. Just like their sandwich-making cousins, they have a refrigerated rail for all your toppings and a refrigerated base below for dough trays and extra ingredients. These all-in-one units cut down on the running around a chef has to do, keeping the whole operation tight and efficient.

Choosing the Right Materials and Construction

A kitchen work table's ability to handle the daily abuse of a commercial kitchen boils down to two things: what it’s made of and how it’s put together. When you’re shelling out for kitchen work tables, knowing the lingo of materials and construction is key to picking gear that lasts. The undisputed champ in pro kitchens is stainless steel, but you need to know that not all steel is created equal.

Making the right call means looking past the shiny surface and getting into the weeds of steel grades, thickness, and build quality. These are the details that separate a table that will serve you for a decade from one that starts to wobble and rust inside a year.

Decoding Stainless Steel Grades

The "grade" of stainless steel is all about its chemical makeup, which dictates how tough it is and how well it fights off rust. You'll mostly run into two common grades—304 and 430—and they each have their place in the kitchen.

304 Stainless Steel is the top-shelf choice for almost any food service job. It’s got more chromium and nickel in the mix, giving it superior resistance to corrosion from salt, acidic foods, and harsh cleaning chemicals. Think of it as the all-weather gear for your kitchen; it’s built to handle whatever you throw at it. For prep tables that see non-stop action with all kinds of ingredients, 304 is the gold standard for longevity.

On the flip side, 430 Stainless Steel is the more budget-friendly option. It's still plenty durable and totally food-safe, but it has less nickel. This makes it a bit more likely to corrode over time, especially if it's always wet or getting hit with acidic stuff. It's a solid pick for dry storage areas, equipment stands, or in kitchens with lighter prep needs where the price tag is a big factor.

Choosing between 304 and 430 steel is a balancing act between your budget and the table's job. For a primary, heavy-use prep surface, investing in 304-grade is a smart long-term move. For less demanding roles, 430-grade is a practical, cost-effective solution.

Understanding Steel Gauge

The gauge of the steel tells you its thickness, but here's where it gets a little counterintuitive: the lower the gauge number, the thicker and stronger the steel. A lower gauge means the table can hold more weight and won't get all dented and dinged up from heavy equipment and daily punishment.

Here’s a quick rundown of the common gauges:

- 14-Gauge: This is the heavyweight champion—the thickest and most durable option you'll usually find. It’s perfect for heavy-duty butchering, holding up massive mixers, or any task that involves a lot of impact.

- 16-Gauge: A very popular and reliable pick, 16-gauge steel hits that sweet spot between strength and cost. It’s ideal for most general-purpose prep work in a busy restaurant.

- 18-Gauge: This is the thinnest of the bunch, best saved for lighter-duty tasks, kitchens on a tight budget, or areas with less foot traffic. It's a functional choice, but it won’t take a beating like its lower-gauge cousins.

If you want to go deeper into how materials impact performance, you can learn more about the specifics of restaurant stainless steel tables to make sure you're getting exactly what you need.

Welded vs. Knock-Down Construction

How your table is put together is just as critical as the steel it's made from. You’ll typically have to choose between fully welded tables and knock-down (or bolt-together) models.

Welded construction means the table shows up as one solid piece, with the legs and shelves welded right to the top. This creates an incredibly sturdy and stable work surface that’s ready to go straight out of the box. The only real downside is that they are a beast to ship and can be pricier because of it.

Knock-down tables are shipped flat-packed and you have to assemble them on-site. This cuts shipping costs way down and makes it a breeze to get the table into tight spots or through narrow doorways. While modern knock-down tables are quite sturdy, you might need to re-tighten the bolts every so often to keep them from getting wobbly after years of use.

Choosing the Right Edge Profile

Last but not least, the edge of the table isn't just for looks—it’s a functional feature that affects both cleanliness and safety.

- Squared Edges: These are flat on all four sides. This lets you push tables right up against each other to create one long, seamless work area.

- Marine Edges: These have a raised lip all the way around the perimeter. It’s a simple but brilliant design that contains spills and stops liquids from dripping onto the floor, which makes cleanup faster and reduces slip hazards.

- Bullnose Edges: These have a rounded, smooth profile. They're more comfortable to lean on and a lot safer, since there are no sharp corners to bump into.

Sizing Your Table for a Perfect Kitchen Workflow

Even the best-built kitchen work table is a total bust if it doesn't fit your kitchen. A table that’s too big creates instant bottlenecks, crippling your kitchen’s flow. Go too small, and your team will be fighting for elbow room. This is all about getting the size right so your new table helps—not hurts—your kitchen’s natural rhythm.

It all starts with a tape measure and a good, honest look at how your team moves. A table’s dimensions aren't just numbers; they define the highways your staff travels all day long. Bad placement can turn a smooth operation into a frustrating obstacle course, slowing down service and creating safety hazards.

Measuring for Movement and Safety

Before you even think about buying, map out where the table will go. Measure the length and width you have available, but that's just step one. The most important part is accounting for clearance—the empty space around the table. You have to leave enough room for people to walk by, open oven doors, and pass each other without a collision, especially during a chaotic dinner rush.

A good rule of thumb is to keep at least 36 to 48 inches of clear space on all working sides of the table.

- 36 inches: This is the bare minimum for a one-person walkway. It’s a bit tight but can work in smaller kitchens.

- 48 inches: This is what you should aim for in a main path where two people might need to pass, or where you'll be rolling carts and other equipment.

Think of your kitchen aisles as actual roads. A single-lane road (36 inches) is fine for quiet side streets, but your main routes need to be multi-lane highways (48 inches or more) to keep traffic from grinding to a halt during peak hours.

Ergonomics and Table Height

Beyond the footprint, the height of your work tables is a huge deal for your staff's health and productivity. Most commercial prep tables are a standard 34 to 36 inches high. This range is designed to be comfortable for most people doing typical prep work like chopping and mixing.

If a table is too low or too high, staff will be forced to hunch over or strain their shoulders. That leads to fatigue, pain, and eventually, the risk of repetitive stress injuries. For kitchens where you have staff of different heights or very specific tasks, adjustable-height tables are a smart investment. They let everyone find their perfect ergonomic sweet spot, which makes a massive difference over a long shift.

The Kitchen Work Triangle Reimagined

You've probably heard of the classic "work triangle" that connects the sink, fridge, and stove. We can use that same idea when placing your kitchen work tables. Your prep table should sit in a logical spot that creates a seamless path between key stations. Think about its relationship to:

- Refrigeration: Put tables near your walk-ins or reach-in coolers. The fewer steps it takes to grab ingredients, the better.

- Sinks: Having a prep sink close by is a must for washing produce and keeping the workflow clean and efficient.

- Cooking Line: The table should offer a straight, clear shot to the ranges and ovens. No one wants to dodge obstacles while carrying a hot pan of prepped food.

This kind of strategic placement is a cornerstone of smart kitchen design. If you want to go deeper on optimizing your entire space, our guide on commercial kitchen layout planning is packed with insights for building a truly efficient kitchen.

Maximizing Your Space with Smart Add-Ons

Even in a perfectly measured space, there are always ways to squeeze out more efficiency. A few simple add-ons can turn a basic work table into a multi-functional beast.

- Casters (Wheels): Putting your table on wheels gives you incredible flexibility. You can easily reconfigure your layout for a special event or roll the table out of the way for deep cleaning.

- Over-shelves: These "double-decker" shelves use vertical space, keeping spices, tools, or holding trays right where you need them without cluttering up your main work surface.

These features help you get the most out of every square inch. It’s a trend we’re seeing everywhere—the global kitchen island market, which is closely related to work tables, was valued at around USD 11.41 billion. Its projected growth shows just how much demand there is for multi-functional tables that serve as the hub of a kitchen. You can discover more insights about the kitchen island market on maximizemarketresearch.com. By carefully planning your table's size and features, you’re not just buying furniture; you’re investing in a smarter, safer, and more productive kitchen.

Keeping Your Work Tables Clean and Safe

In any professional kitchen, your work tables are ground zero for food safety. A spotless prep surface isn't just a nice-to-have; it's a non-negotiable standard for preventing cross-contamination and staying on the right side of health codes. Proper daily care ensures your stainless steel kitchen work tables provide a safe, hygienic foundation for every dish that leaves your kitchen.

This goes way beyond a quick wipe-down at closing time. It’s about having a consistent, systematic routine for cleaning and sanitizing that gets rid of every trace of food debris, grease, and dangerous bacteria. Putting a clear, easy-to-follow process in place for your team is the first and most critical step.

The Daily Clean and Sanitize Routine

Think of your daily cleaning as a one-two punch: first, you clean to remove the gunk you can see, then you sanitize to kill the germs you can't. If you skip that first step, you're just wasting sanitizer. It's like trying to paint a dirty wall—the sanitizer can't do its job if it can't even reach the surface.

Here’s a simple, step-by-step process for daily table maintenance that gets it right every time:

- Clear and Scrape: Start by getting everything off the table—food scraps, containers, cutting boards, you name it. Use a plastic or rubber scraper to lift off any stubborn, stuck-on bits.

- Wash with Detergent: Mix a mild detergent with warm water. Grab a clean cloth or sponge and scrub the entire surface, making sure to hit the legs and undershelf. Pay extra attention to corners and edges where grime loves to hide.

- Rinse Thoroughly: Use a fresh cloth and clean, warm water to wipe away all the soap residue. Any leftover detergent can neutralize your sanitizer and even leave a funky chemical taste on food.

- Sanitize the Surface: Apply a food-safe sanitizer, following the manufacturer’s directions to the letter. Let it air dry completely. Wiping it dry can just spread germs right back onto your perfectly clean surface.

Choosing the Right Cleaners for Stainless Steel

Stainless steel is a workhorse, but it's not indestructible. Using the right cleaning products is absolutely crucial for preserving its protective layer and preventing damage like rust or pitting, which can become breeding grounds for bacteria.

For day-to-day cleaning, mild soap and water is usually all you need. If you’re dealing with something tougher, a non-abrasive, alkaline, or solvent-based cleaner is a safe bet. But there are a few things you should always avoid:

- Chlorine Bleach: Never let chlorine-based cleaners touch your stainless steel. The chlorides will attack the steel's passive layer, causing pitting and rust.

- Abrasive Powders: Harsh scouring powders will scratch the surface, creating tiny crevices where bacteria can hide and making the table even harder to clean in the future.

- Steel Wool: Using regular steel wool is a huge mistake. It will leave behind tiny iron particles that are guaranteed to rust and stain your table's surface.

For a deeper dive into best practices, our guide on how to properly clean stainless steel provides detailed techniques for handling tough stains and keeping your tables looking brand new.

Beyond Daily Cleaning: Deep Maintenance

While daily sanitizing is the baseline, periodic deep-cleaning and inspections are what guarantee the long-term safety and lifespan of your tables. Make it a weekly habit to inspect every inch of your tables. Look for signs of wear and tear, like deep scratches, loose bolts, or any developing rust spots.

A well-maintained kitchen work table is a silent partner in food safety. Regular inspections and deep cleaning are not just chores; they are critical practices that uphold your commitment to quality and protect your customers.

Keeping your work tables in top shape is a fundamental part of adhering to broader workplace safety guidelines in any commercial kitchen. By implementing a solid cleaning schedule and training your staff on the right techniques, you ensure your tables remain a reliable asset, helping you serve safe, high-quality food, day in and day out.

Think of It as an Investment, Not Just an Expense

Choosing a kitchen work table isn't like picking out just another piece of gear. It’s a genuine investment in the very heart of your kitchen's day-to-day grind. This one decision has a ripple effect, touching everything from your kitchen's efficiency and your staff's safety to the final quality of the food you serve. Nailing this choice from the get-go pays you back for years.

The whole process really just boils down to matching the table's features to what your kitchen actually needs. It's about picking the right type, the best material, and the perfect size to make your workflow feel effortless. A table that fits your space and process gets rid of those frustrating bottlenecks and becomes a solid foundation for your team's best work.

What to Look for in a Supplier

When you're ready to buy, you want to find suppliers who are serious about quality and aren't hiding anything. The first thing to look for is an NSF (National Sanitation Foundation) certification. This isn't just a fancy sticker; it's a guarantee that the table meets tough public health and safety standards and is safe for food to touch.

A solid warranty is another non-negotiable. It shows that the manufacturer believes in their own product and gives you the confidence that you're protected if something goes wrong. Any supplier worth their salt will stand behind their equipment, no questions asked.

A great kitchen work table is more than just furniture—it's an active, essential part of your business. It smooths out your processes, backs up your team, improves your product, and directly boosts your kitchen's bottom line.

This emphasis on quality isn't just our opinion; you can see it in global market trends. The entire kitchen and dining furniture category, which includes kitchen work tables, is constantly changing based on what people need in different parts of a world. For example, the global market for household furniture is expected to climb to over $407 billion. That’s a huge number, and it signals a strong, ongoing belief in buying quality kitchen gear.

You can read the full analysis of the kitchen furniture market on Statista.com. The data backs it up: investing in durable, high-quality tables is a smart, recognized strategy for long-term success in this industry.

Still Have Questions About Kitchen Work Tables?

Even after you've narrowed down the options, a few last-minute questions always seem to pop up. Getting these sorted out is often the final step before you can confidently choose the right table for your kitchen's unique rhythm and workflow.

Let's tackle some of the most common ones.

What Is the Real Difference Between 304 and 430 Stainless Steel?

Think of this as choosing between a heavy-duty, all-weather raincoat and a light windbreaker.

304 stainless steel is your top-of-the-line option, packed with more chromium and nickel. That extra nickel is the key, giving it fantastic resistance to rust and corrosion from things like salt, acidic foods, and tough cleaning chemicals. It’s the smart choice for any main prep surface that’s going to take a beating day in and day out.

430 stainless steel, on the other hand, is a bit more friendly on the wallet. It’s still strong and totally food-safe, but with less nickel, it's more likely to show rust over time if it's always wet or exposed to corrosive stuff. This makes it a great pick for equipment stands, dry storage shelves, or prep areas with lighter use.

It really boils down to this: for the workhorse table at the heart of your kitchen, you won't regret investing in 304-grade steel. For less critical roles or in drier spots, 430-grade gives you great value without sacrificing safety.

Should I Get a Table with a Backsplash?

If you're placing the table against a wall, the answer is almost always a resounding yes. That little lip on the back might seem minor, but it's a true lifesaver.

A backsplash does three critical things:

- It stops messes in their tracks: Spills, juices, and bits of food are blocked from falling into that awful, hard-to-clean gap between the table and the wall.

- It protects your walls: Think of it as a shield, preventing stains and moisture from damaging your drywall or tile over time.

- It boosts sanitation: By closing off that gap, you're eliminating a favorite hiding spot for bacteria and pests.

How Do I Choose the Right Table Height for My Staff?

Most commercial work tables stand between 34 and 36 inches high. This range is the sweet spot, designed to be ergonomically sound for most people doing typical prep work.

When a table is too low or too high, it forces your team to hunch over or strain their shoulders, which leads directly to fatigue and can even cause injuries down the road. If your staff has a wide range of heights or they're doing very specific tasks, an adjustable-height table is a fantastic solution to keep everyone working comfortably and safely.

Can I Place Hot Pans Directly on a Stainless Steel Surface?

Go for it. Stainless steel is incredibly heat resistant and won't be damaged by a hot pot or pan coming straight off the stove.

One small thing to keep in mind, though: extreme and repeated temperature changes (like putting a searing hot pan on an ice-cold table) can potentially cause very slight warping over a long time, especially with thinner steel. It's generally not an issue, but using a trivet for the hottest items is a good habit to keep your table looking perfect for years.

At PrepTables.com, we stock a full lineup of NSF-certified stainless steel work tables built for the real-world demands of a professional kitchen. You can explore our durable, high-quality options and find the perfect foundation for your culinary success at https://preptables.com.