Your Guide to Selecting a Kitchen Grease trap

Share

Ever wonder what that box is under the sink in a commercial kitchen? That's a kitchen grease trap, and it's one of the most critical pieces of equipment in any foodservice operation. It's a simple plumbing device with one crucial job: to intercept fats, oils, and grease (FOG) from your wastewater before they can wreak havoc on your pipes and the public sewer system.

Without one, you're looking at expensive blockages, nasty odors, and failing to comply with local health and environmental rules.

What Is a Kitchen Grease Trap and Why You Need One

Think of your restaurant’s plumbing like its arteries. Water needs to flow freely to keep everything running. Now, imagine pouring fats, oils, and grease—the stuff left over from cooking bacon, frying chicken, or making sauces—down the drain. When that FOG is hot, it’s liquid and seems to wash away just fine.

But as it travels down the pipes and cools, it solidifies. It's just like cholesterol building up in an artery, clinging to the inside and slowly narrowing the passage. Eventually, you get a complete blockage. For a restaurant, that means backed-up sinks, foul-smelling water flooding the floor, and a complete shutdown until an emergency plumber arrives.

The Science Behind a Simple Box

A grease trap isn't complicated; it works on basic physics. We all know oil and water don’t mix, and that's the principle a grease trap uses to its advantage. It's basically a box that your kitchen wastewater flows into. Inside, the water slows way down, giving everything time to separate naturally.

Here’s what happens inside:

- Fats, Oils, & Grease (FOG): Since FOG is lighter than water, it floats to the top, creating a layer of scum.

- Solid Food Particles: Heavier bits of food sink to the bottom and form a layer of sludge.

- Cleaner Water: The water trapped in the middle, now mostly free of grease and solids, can safely flow out of the trap and into the sewer lines.

This simple separation process stops the vast majority of grease from ever touching your main plumbing, protecting both your building and the city's sewer network.

Key Takeaway: A grease trap isn’t a filter; it's a separator. It uses gravity and density to isolate the harmful gunk, letting cleaner water pass through. It's your first and most important line of defense against a plumbing catastrophe.

Why a Grease Trap Is Non-Negotiable

Trying to run a commercial kitchen without a grease trap isn't just a bad business decision—it's usually against the law. Cities and counties have strict rules to keep FOG out of the public sewer system. When too much grease gets in, it creates massive blockages called "fatbergs" that can cause city-wide sewer backups and cost taxpayers a fortune to fix.

This is why having a properly functioning grease trap is so essential. It solves a whole host of problems before they can even start.

FOG Problems and Grease Trap Solutions

Take a look at how a grease trap directly tackles the biggest headaches caused by FOG.

| Problem Caused by FOG | How a Grease Trap Solves It |

|---|---|

| Costly Plumbing Emergencies | By capturing grease at the source, it prevents the buildup that leads to clogged pipes and expensive emergency calls. |

| Foul Odors and Pest Issues | A properly maintained trap contains decomposing grease and food, stopping odors from wafting up drains and attracting pests. |

| Health Code Violations and Fines | Nearly all jurisdictions mandate grease traps. Having one installed and maintained ensures compliance and avoids severe penalties. |

| Environmental Contamination | It prevents raw sewage overflows into local waterways, which can happen when municipal lines are blocked by FOG. |

At the end of the day, a kitchen grease trap is a fundamental part of running a responsible and successful restaurant. Think of it as an investment in your own stability, compliance, and the health of the community around you.

Exploring the Main Types of Grease Traps

Picking out a kitchen grease trap isn't a one-size-fits-all kind of deal. The right unit for you really boils down to the scale of your kitchen, how much wastewater you're generating, and what you've budgeted for both the initial setup and the ongoing upkeep. Getting to know the three main types is the first real step toward making a smart, compliant choice for your business.

While they all work on the same basic principle—separating fats, oils, and grease (FOG) from water—each type is engineered for a completely different scale of operation. From a small unit tucked under a sink to a massive tank buried outside, the technology you choose will have a big impact on your kitchen's daily rhythm and long-term expenses.

Hydromechanical Grease Traps (Point-of-Use)

You'll often hear these called manual grease traps. Hydromechanical units are the most common type you'll spot in smaller spots like cafes, delis, and food trucks. They're typically installed indoors, often right under a 3-compartment sink or next to a busy commercial dishwasher.

These units are nice and compact, and they won't break the bank upfront. They use a simple system of baffles to slow down the wastewater, which gives the lighter FOG a chance to float to the top while heavier food solids sink to the bottom. The catch? Their small size means they fill up fast and need to be cleaned out by hand, often weekly or even daily in a high-traffic kitchen.

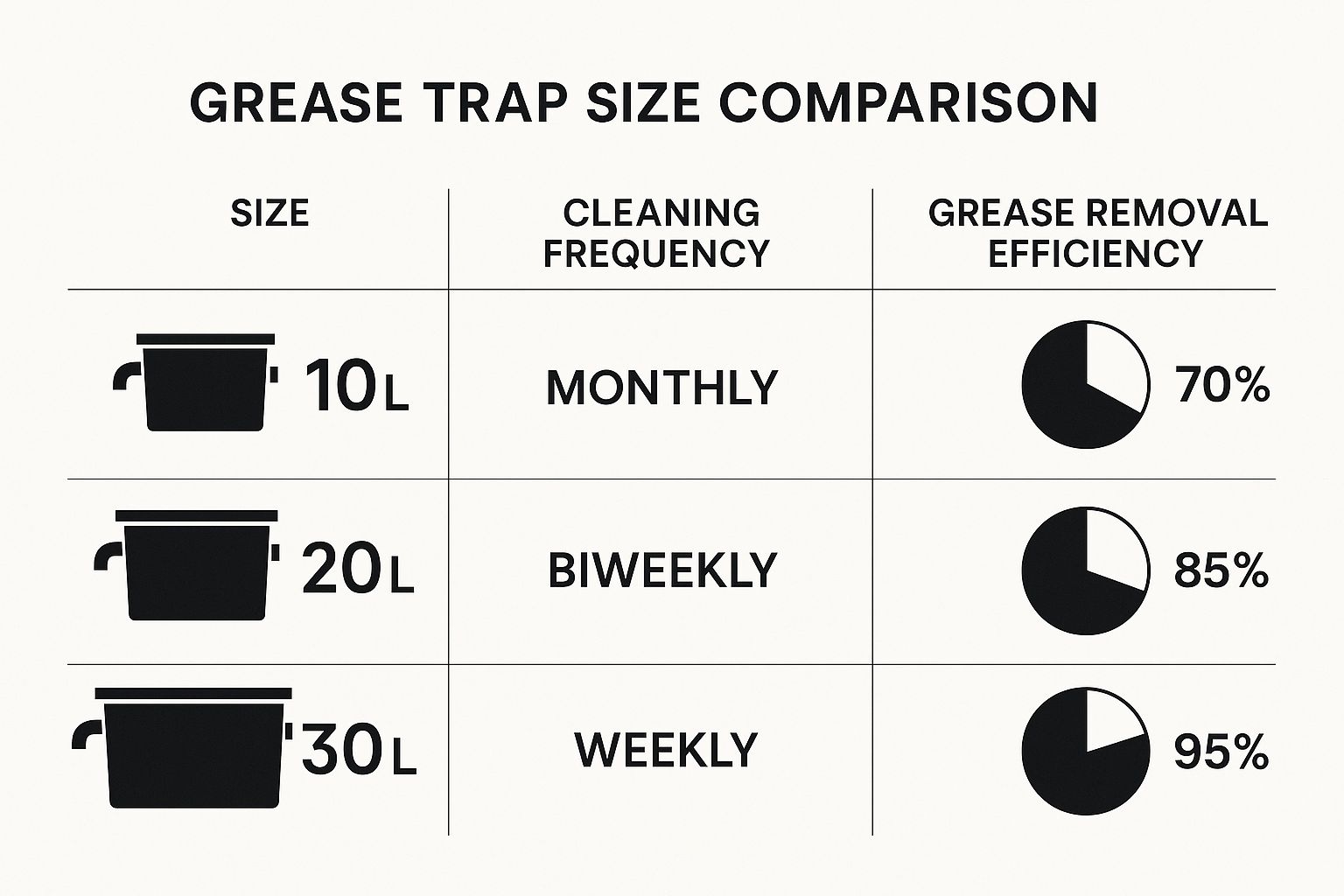

This visual gives a great breakdown of how a trap's size connects to its cleaning needs and overall efficiency.

As you can see, a bigger trap doesn't just hold more grease; it's also much better at capturing it. Of course, even the big ones need consistent maintenance to keep working properly.

Gravity Grease Interceptors (Large Volume)

When you get into high-volume operations—think large restaurants, hospitals, or food processing plants—the gravity grease interceptor is the industry standard. These are enormous, high-capacity tanks, often holding 1,000 gallons or more, that are usually buried underground just outside the building.

Their sheer size is their biggest advantage. It allows them to hold a massive amount of wastewater for a longer time, letting gravity do its work to separate the FOG much more effectively. Because they're so large, they only need to be pumped out by a professional rendering service every few months. The main downsides are the hefty initial price tag and the serious amount of space you need for installation.

Expert Insight: It’s easy to think of gravity interceptors as "set it and forget it" systems, but they're not. Skipping a scheduled pumping can lead to disastrous backups and environmental fines that are way more expensive than routine maintenance ever would be.

The entire grease trap market is growing, reflecting the expansion of the food service industry worldwide. The market for all trap types was valued at around $2.5 billion in 2025 and is expected to climb to $3.5 billion by 2033. This growth is fueled by more people moving to cities and stricter rules about wastewater. Under-sink and floor-mounted models are huge contributors here because they fit so well into most commercial kitchens. If you want to dive deeper into the numbers, you can explore the full research on grease trap market growth.

Automatic Grease Recovery Units (GRUs)

Automatic Grease Recovery Units, or GRUs, are the modern, high-tech solution to grease management. Just like the smaller hydromechanical traps, they're installed right at the point of use. The key difference is that they have an automated system for getting rid of the grease they collect.

GRUs use a small heating element to keep the collected FOG in a liquid state. Then, at scheduled times, the unit automatically skims this liquid grease off into a separate, sealed container. This makes removal and recycling incredibly easy. It also drastically cuts down on how often you have to do manual cleanings and practically eliminates nasty odors. While they have the highest upfront cost of the three, the savings on labor and maintenance over time can make them a very smart investment for busy kitchens that can't afford downtime.

Comparing Kitchen Grease Trap Technologies

To make the decision a bit clearer, it helps to see the three main types of grease traps compared side-by-side. This table breaks down their key differences, from initial cost to daily operation, helping you see which one truly fits your kitchen's needs.

| Feature | Hydromechanical (Manual) | Gravity Interceptor (Large) | Automatic Recovery Unit (GRU) |

|---|---|---|---|

| Best For | Small kitchens (cafes, delis) | High-volume kitchens (restaurants, hospitals) | Busy kitchens prioritizing efficiency |

| Installation | Indoor, under-sink, low cost | Outdoor, underground, high cost | Indoor, point-of-use, moderate cost |

| Capacity | Small (20-50 gallons) | Very Large (1,000+ gallons) | Small to Medium |

| Maintenance | Frequent manual cleaning (daily/weekly) | Professional pumping (quarterly) | Automated removal, minimal cleaning |

| Upfront Cost | Low | Very High | High |

| Long-Term Cost | High labor/maintenance costs | Moderate pumping fees | Low labor/maintenance costs |

| Odor Control | Poor | Good (if sealed properly) | Excellent |

Ultimately, the "best" trap is the one that aligns with your operational reality. A small cafe doesn't need a 1,000-gallon tank, and a massive hotel kitchen would be overwhelmed by a manual trap. Weighing these factors will point you toward the most practical and cost-effective solution for your business.

Calculating the Right Size for Your Grease Trap

Choosing the right size for your kitchen grease trap isn't just a quick guess—it's a crucial calculation that can make or break your kitchen's daily operations and budget. Think of it like buying an air conditioner. Too small, and it'll run nonstop without actually cooling the room. Too big, and you've just overpaid for a unit that's constantly kicking on and off, wasting energy.

It’s the same story with a grease trap. If it’s too small for the wastewater your kitchen pumps out, it’ll get overwhelmed in no time. That means constant clogs, nasty backups, and a complete failure to do its one job. But going too big isn't a solution either. An oversized trap lets wastewater sit for too long, leading to anaerobic decomposition that churns out nasty hydrogen sulfide gas—leaving your kitchen smelling like rotten eggs.

Sizing Based on Your Kitchen Sinks

The most common way to size a smaller, point-of-use grease trap is by looking at the sinks it’s connected to. This is the method most plumbing codes stand by, and it gives you a solid estimate of the maximum flow rate your trap will need to handle. Don’t worry, you don’t need to be a math whiz to figure this out.

First, you’ll calculate the total volume of your sink basins in cubic inches. Just measure the length, width, and depth of each sink compartment and multiply those three numbers together (L x W x D).

If you’ve got a standard three-compartment sink, you’ll do this for each basin and then add the totals together. That gives you the sink's total capacity in cubic inches.

Converting Sink Volume to Gallons Per Minute

Once you have the total cubic inches, you need to convert that figure into gallons, since grease traps are rated in gallons. It's a simple conversion: there are 231 cubic inches in one U.S. gallon.

The formula looks like this:

(Total Sink Volume in Cubic Inches) / 231 = Total Sink Capacity in Gallons

This number tells you how many gallons of water your sinks can hold. But since a sink doesn't drain in a split second, the industry standard assumes it takes about one minute to drain completely. That's why this gallon capacity becomes your gallons per minute (GPM) flow rate.

Key Concept: The calculated Gallons Per Minute (GPM) is the magic number. Grease traps are rated by the GPM they can handle. For example, a 20 GPM trap is built to properly separate grease from water that's flowing at a rate of 20 gallons every single minute.

A Practical Sizing Example

Let's walk through a real-world example with a typical commercial three-compartment sink. Imagine each basin measures 24 inches long, 24 inches wide, and 14 inches deep.

-

Calculate the volume of one basin: 24" (L) x 24" (W) x 14" (D) = 8,064 cubic inches

-

Calculate the total volume for all three basins: 8,064 cubic inches x 3 basins = 24,192 cubic inches

-

Convert the total volume to gallons: 24,192 / 231 = 104.7 gallons

-

Determine the required GPM rating: With a one-minute drain time, the required flow rate is 104.7 GPM.

In this case, you'd need a grease trap rated for at least 105 GPM. Don't forget to account for any other fixtures draining into the same trap, like prep sinks or a commercial hand washing station, as their flow adds to the total. Our guide on those can give you some great insights. Getting the size right from the get-go saves you from a world of headaches and ensures you invest in a unit that’s a perfect match for your kitchen.

Navigating the Installation Process

Picking the right size and type of grease trap is just the start. If you don't get the installation right, you’ve wasted your time and money. A perfect unit installed poorly is a useless unit. This is the part where you set your kitchen up for long-term success and dodge the common mistakes that lead to clogs, nasty smells, and expensive plumbing calls.

Your first big decision is where to put it. It’s tempting to shove it in a forgotten corner, but that’s a huge mistake that will come back to haunt you during cleaning time. Your grease trap needs to be easy to get to for routine maintenance. For a smaller under-sink model, that means leaving enough room to pop the lid off and scoop it out without playing Tetris with your cleaning supplies. For big outdoor interceptors, make sure the manhole covers aren't buried under landscaping or used as a parking spot.

Choosing the Right Material for Your Environment

The material your trap is made of is a big deal. It affects how long it will last and how well it stands up to the daily grind of a commercial kitchen. Each option has its own trade-offs between cost, durability, and corrosion resistance.

- Stainless Steel: This is the top-of-the-line choice, the kind you’ll see in pro kitchens that can’t afford downtime. Stainless steel is a champ at resisting rust and corrosion, plus it’s non-porous and a breeze to clean. It's a true long-term investment.

- Plastic (Polypropylene): This is a very common and budget-friendly option. Plastic grease traps are lightweight, which makes installation much easier. They won’t rust and handle chemicals well, but they can get brittle or warp if exposed to extreme temperatures.

- Concrete: You’ll only see concrete used for massive outdoor gravity interceptors. These things are built like tanks and can last for decades. The downside? Concrete is porous and can be eaten away by gases over time unless it has a protective inner lining.

A well-equipped kitchen relies on durable materials, not just for plumbing but for prep surfaces too. Stainless steel prep tables are a prime example. They come in various types to suit different needs, from simple work tables with flat tops to specialized units like sandwich prep tables with refrigerated compartments and pizza prep tables with raised rails for toppings. Their non-porous surface and durability make them, like a stainless steel trap, essential for a high-functioning, hygienic kitchen and a natural complement to a powerful three-bay commercial sink.

Venting and Professional Installation

Venting might sound technical, but it’s an absolutely critical part of the installation. A proper vent lets air into the trap to stop a vacuum from forming, which could otherwise suck grease right out of the trap and into the city sewer—the very thing you're trying to prevent. It also gives the smelly gases that build up inside a safe way to escape.

Crucial Reminder: Installing a grease trap is not a weekend DIY job. You're dealing with complex plumbing codes, specific venting rules, and the need for a perfect, leak-proof seal. This is a job for a professional.

Hiring a licensed plumber who knows your local FOG ordinances is the single most important thing you can do. They'll make sure the trap is installed to code and works correctly from day one. This initial investment protects your business from the massive headaches that fats, oils, and grease can cause. In fact, the global market for these devices was valued at around $1.34 billion in 2024 for a reason. You can learn more about grease trap market trends to see just how essential they are for keeping commercial kitchens sanitary and avoiding plumbing disasters.

Mastering Grease Trap Maintenance and Cleaning

A kitchen grease trap is only as good as its last cleaning. If you neglect it, you’re basically installing a security guard who’s always asleep—it provides a false sense of security while completely failing at its one job. This guide will walk you through the practical steps to keep your trap clean, compliant, and working perfectly.

Forgetting about your grease trap until there’s a problem is a recipe for disaster. Once it’s full, it can’t capture any more FOG (fats, oils, and grease). That leads to slow drains, nasty odors, and plumbing emergencies that can shut your entire kitchen down. The only way to prevent this chaos is with consistent, scheduled maintenance.

The 25% Rule and Your Cleaning Schedule

The most widely accepted industry standard for knowing when to clean your grease trap is the 25% Rule. It’s a simple guideline: once the combined layers of floating grease (the scum on top) and settled food solids (the sludge at the bottom) take up 25% or more of the trap's total liquid depth, it’s time for a cleanout.

If you let it go past this point, the trap's efficiency plummets. There simply isn't enough clean water left inside for the FOG and solids to separate properly.

So, how often do you need to check it? There's no one-size-fits-all answer. Your cleaning schedule depends entirely on what your kitchen is pushing out.

- High-Volume Kitchens: Restaurants with a lot of fried foods, charbroilers, or woks might need to clean their traps weekly, or sometimes even more often.

- Low-Volume Kitchens: A small café or deli with a less grease-heavy menu might find that a monthly service is plenty.

The best approach is to start by checking your trap weekly. See how fast it hits that 25% mark. This observation will help you create a reliable maintenance schedule that’s perfectly tailored to your kitchen's output.

DIY Cleaning vs Professional Rendering Services

When it’s time to get the job done, you have two basic choices: tackle it yourself or call in the pros. For those smaller, under-sink units, a DIY cleaning can be a manageable, cost-effective option if you do it right.

A Step-by-Step Guide to Manual Cleaning:

- Gear Up: Before you even think about opening that lid, put on heavy-duty rubber gloves and safety goggles. The contents are not just unpleasant; they're full of bacteria.

- Break Up the Scum: Grab a small scraper and gently break apart the solid layer of grease floating on the top.

- Scoop Out the Grease: Use a small bucket or scoop to remove all the floating FOG. Put it into a watertight container for proper disposal later.

- Remove the Water: Bail out the remaining water so you can get to the sludge at the bottom.

- Scrape the Sludge: Scrape the sides and bottom of the trap clean, removing all the gunk and accumulated food solids.

- Reassemble and Test: Put the baffles and lid back in place, then run hot water from the sink to make sure everything is flowing smoothly again.

While DIY saves some cash upfront, hiring a professional rendering service offers huge benefits, especially for larger traps. Pros use powerful vacuum equipment to pump out the FOG and solids quickly and completely. More importantly, they give you a manifest or report documenting that the waste was disposed of legally. This paperwork is your golden ticket—it's the proof of compliance you'll need during a health inspection. A well-organized kitchen, from its restaurant stainless steel tables to its waste systems, simply runs better.

Warning: Avoid Dangerous Cleaning Myths Never pour chemicals, drain cleaners, or enzyme treatments down your drain thinking it's a shortcut. These products don't magically eliminate grease; they just break it down into smaller droplets that can re-solidify further down your pipes, creating blockages that are even worse. Many of these chemicals can also damage your pipes and the trap itself, leading to much more expensive repairs. Physical removal is the only truly effective and compliant method.

Understanding FOG Regulations and Staying Compliant

Let's get straight to the point: ignoring grease trap regulations is one of the quickest ways to see your foodservice business get shut down. That kitchen grease trap isn't just a clever piece of equipment—it's a legal requirement in nearly every town and city. These rules, often called FOG ordinances, exist for a very good reason: to protect public sewer systems from the absolute nightmare of grease buildup.

Think of it this way: these devices aren't just "recommended." They are a non-negotiable part of your operating permit. If you don't comply, your entire operation can be stopped in its tracks. The responsibility for knowing and following these laws lands squarely on you, the business owner.

Locating and Interpreting Your Local Ordinances

Every single municipality has its own unique rulebook for managing fats, oils, and grease (FOG). These local ordinances will tell you everything from the required size and type of grease trap you need to how often it must be cleaned and what records you have to keep. Your first job is to hunt down these regulations.

You can usually find this information on your local government's website, probably under the public works, water, or health department pages. Try searching for terms like "FOG ordinance," "grease management program," or "wastewater discharge permit." If you strike out online, just pick up the phone and call your local health inspector or public works office. It’s the most direct way to get answers.

Key Insight: Don't just give the regulations a quick scan. You need to print them out and really read them. Pay very close attention to the details, like cleaning frequency (e.g., "must be cleaned every 90 days or when 25% full") and record-keeping rules. These are the exact things inspectors will be checking.

The Health Inspection and Your Best Defense

When that health inspector walks through your door, you can bet your grease trap and its maintenance log are on their checklist. They aren't just looking to see if you have a trap; they're looking for solid proof that you're actually maintaining it properly. This is where keeping meticulous records becomes your strongest defense.

Your maintenance log needs to clearly show:

- The date of every single cleaning or pumping service.

- The name of the company that did the work.

- How much grease was actually removed.

- Where the collected waste was taken for disposal.

This log is your proof that you’re actively managing your FOG and meeting your legal duties. Without it, an inspector is likely to assume the worst.

The penalties for not complying are steep for a reason—they're meant to be a powerful deterrent. A single violation can easily lead to fines in the thousands of dollars. Worse yet, repeated problems can get your business license suspended on the spot, forcing you to close your doors until you fix the issue. This push for stricter rules is a huge factor in the growth of the global automatic grease trap market, which hit around $2 billion in 2025 and is set to keep climbing. You can discover more about the trends in automatic grease traps to see how compliance is pushing the industry forward.

Ultimately, investing in a compliant FOG system isn't just an expense—it's an essential insurance policy for your business.

Grease Trap FAQs: Your Questions Answered

Even after you get the hang of what a kitchen grease trap does, a few questions always pop up about the day-to-day. Getting some straight answers is the best way to take the mystery out of managing your trap, keeping your kitchen humming, and staying on the right side of local regulations. Let's tackle the most common ones.

How Often Do I Really Need to Clean My Grease Trap?

There’s no magic number here. The right cleaning schedule is all about your kitchen's output. The most important rule to follow is the "25% Rule": you must have your trap cleaned out once the combination of fats, oils, grease (FOG), and solids takes up 25% of the trap's total liquid space.

To figure out your specific timing:

- High-FOG Kitchens: If you're frying a lot of food, grilling meats, or whipping up rich sauces, start by checking the trap weekly.

- Low-FOG Kitchens: For a place like a coffee shop that mainly deals with drinks and pastries, a monthly check might be all you need.

The best approach is to keep a close eye on your trap for the first month. See how fast it hits that 25% mark. That simple observation will give you a reliable cleaning schedule that’s perfectly matched to your kitchen.

Can I Just Pour Chemicals Down the Drain Instead?

No, absolutely not. This is probably one of the most damaging myths floating around in grease management. Pouring hot water, so-called "degreasers," or enzyme products down the drain is not a substitute for having your trap physically pumped.

These chemicals don't actually eliminate grease. All they do is break it down into smaller bits, which lets it sneak past the trap and then harden up again deeper in your plumbing or, even worse, in the city's sewer lines. This mistake often leads to much bigger clogs that are a nightmare to fix and cost a fortune.

Critical Reminder: The only proper and legal way to clean a grease trap is through physical removal. Chemicals can wreck your plumbing, harm the environment, and land you in hot water with local FOG enforcement.

What Are the Warning Signs of a Failing Grease Trap?

Your grease trap will almost always tell you when it’s full or having problems. Paying attention to these signals can save you from a messy, expensive shutdown.

Keep an eye out for these tell-tale signs:

- Slow Draining Sinks: If your three-compartment sink or floor drains are backing up, it's a classic sign your trap is full and can't take on any more water.

- Foul Odors: A nasty, rotten-egg smell wafting up from your drains is a dead giveaway that old grease and food scraps are decomposing in the trap.

- Grease in Unexpected Places: Seeing a greasy film in your sinks or noticing grease seeping out from the manhole cover of an outdoor unit means you need to call for service immediately.

For kitchen equipment that matches the durability and reliability of a well-maintained grease trap system, explore the professional-grade options at PrepTables.com. Find everything from NSF-certified work tables to commercial refrigeration to build a more efficient and hygienic kitchen. https://preptables.com