Choosing the Right Hand Washing Station for Your Business

Share

At its core, a hand washing station is a self-contained unit that brings accessible hand hygiene to places where traditional plumbing just isn't an option. But calling it just a temporary sink really sells it short. Think of it as a critical tool for health, safety, and compliance in countless settings, from a buzzing food festival to a remote construction site.

Why a Hand Washing Station Is More Than Just a Sink

A hand washing station isn't just a piece of equipment; it's a visible statement about your commitment to hygiene. In any place where people gather, work, or eat, having a dedicated spot to wash hands is your first line of defense against spreading germs. It’s a fundamental part of public health.

The market reflects this growing understanding. The global hand wash station market was valued at around USD 982.1 million in 2021 and is on track to blow past USD 1,729.68 million by 2034. This boom is fueled by a global awakening to the importance of disease prevention, showing just how essential these units have become. You can dig into the numbers in this full analysis of hand wash station market trends.

A Symbol of Safety and Professionalism

Placing a hand washing station strategically does more than meet a basic need—it builds trust. For a customer at a food truck, a worker on a job site, or a guest at an outdoor wedding, seeing clean and accessible hygiene facilities sends a clear message. It shows you care about their well-being.

A hand washing station is the most basic, yet most powerful, tool for preventing illness and demonstrating a commitment to public safety. Its presence reassures everyone that their health is a top priority.

This simple act of providing soap and water can drastically cut the risk of foodborne illnesses and other contagious diseases. It takes hygiene from an afterthought and makes it a central, non-negotiable part of your operation.

Versatility Across Industries

The uses for a modern hand washing station are incredibly diverse, stretching far beyond the old stereotype of a muddy construction site or a music festival. Today’s units are designed with features tailored to the specific needs of different professional environments. This adaptability is one of their biggest strengths.

The table below gives you a quick snapshot of just a few industries where these stations are making a real impact.

Where Hand Washing Stations Make a Difference

This table highlights the critical function of hand washing stations across various sectors.

| Sector | Primary Use Case | Key Benefit |

|---|---|---|

| Food Service & Catering | Near food prep areas and for customer use at outdoor events or food trucks. | Prevents cross-contamination and ensures compliance with health codes. |

| Construction & Agriculture | Provides hygiene facilities for workers in remote or temporary job sites. | Reduces the spread of germs and improves worker welfare and morale. |

| Public Events & Festivals | Positioned near food vendors and restroom areas to serve large crowds. | Manages public health risks and enhances the guest experience. |

| Healthcare & Emergency Services | Used in field clinics, disaster relief, and temporary medical facilities. | Provides critical infection control in environments without plumbing. |

| Schools & Daycares | Placed in playgrounds or temporary classrooms to encourage frequent hand washing. | Promotes healthy habits among children and staff, reducing sick days. |

Once you see these applications, you start to understand that a hand washing station isn't just a utility—it's a strategic asset. The right station, put in the right place, improves safety, guarantees compliance, and boosts your organization's reputation.

Exploring the Different Types of Hand Washing Stations

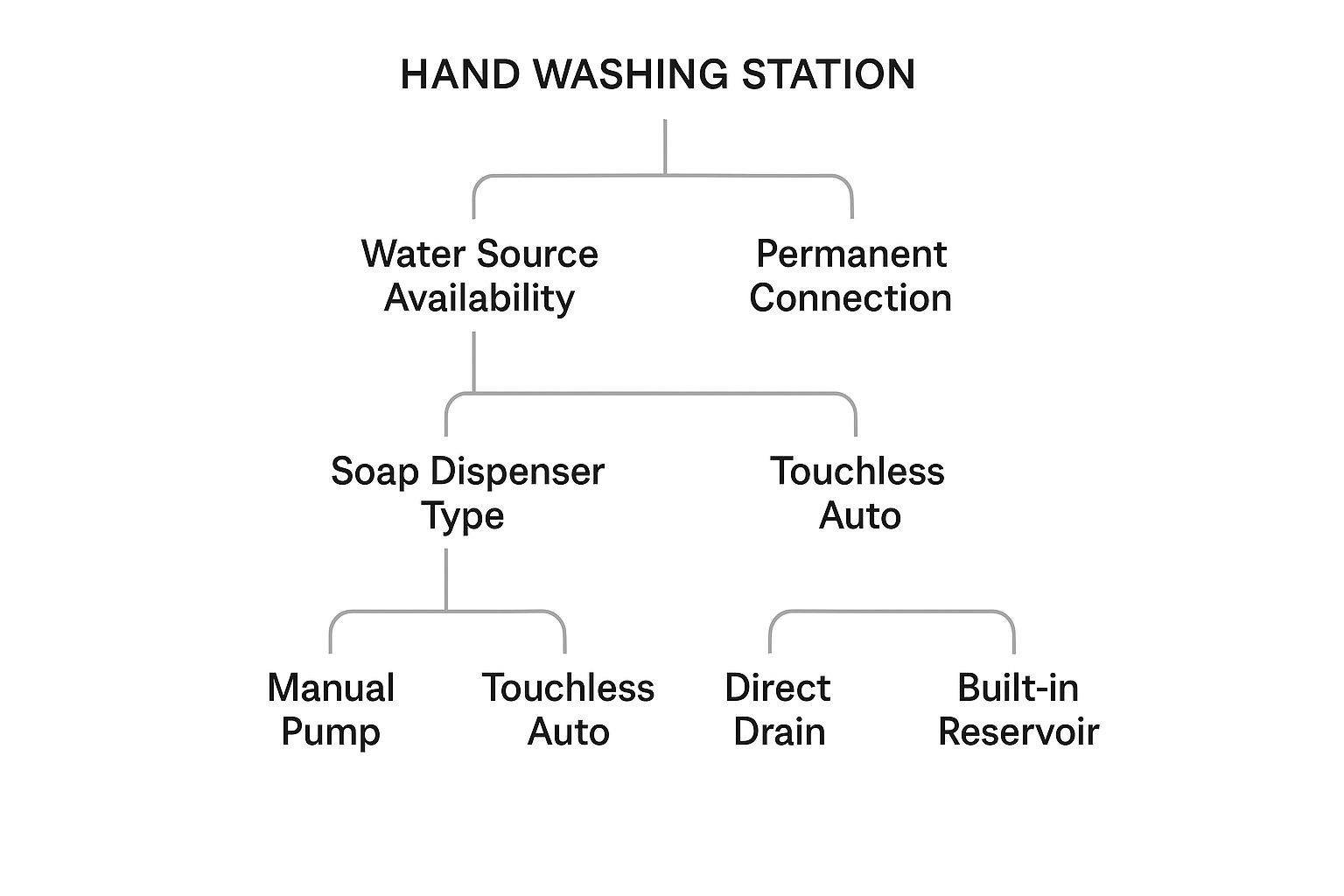

Not all hand washing stations are built the same. Picking the right one boils down to your specific situation—where you'll use it, how many people it needs to serve, and what utilities you have on hand. Your first and most important choice is between a portable unit and a permanent, plumbed-in station. This single decision sets the stage for everything else.

Think of it like this: a portable hand washing station is a lot like a heavy-duty generator. It brings essential power—or in this case, hygiene—to places where you can't just plug into a wall. They are totally self-contained, making them the perfect solution for festivals, construction sites, and remote agricultural fields.

On the other hand, a plumbed-in station is more like your building's main electrical system. It's a permanent fixture that provides a constant, reliable supply of water. You'll find these are required in settings like commercial kitchens or healthcare facilities, where nonstop water access is a must-have and integrated directly into the infrastructure.

As you can see, the decision really starts with your site's access to water and drainage. That will point you toward the right type of station from the get-go.

Portable Stations: The Flexible Hygiene Solution

When you need hand hygiene on the move, portable stations are your go-to. They are designed for complete self-sufficiency, equipped with internal tanks for both fresh and waste water. But even within this category, you’ll find some key differences in how they work.

-

Foot-Pump Operation: This is a classic and incredibly effective design. Users simply press a foot pedal to get water, which is a fantastic way to minimize hand contact with the faucet itself. It's a simple, mechanical setup that's tough as nails, making it the ideal choice for high-traffic, rugged environments like a busy job site or a weekend-long music festival.

-

Sensor-Activated Faucets: If you're aiming for a more polished or health-conscious feel—say, for a corporate event or a pop-up medical clinic—touchless models are the way to go. These battery-powered units eliminate physical contact entirely, offering the highest level of sanitation. While they do require you to keep an eye on the batteries, the extra hygiene benefit is often well worth it.

The choice between a foot pump and a sensor really comes down to a trade-off: rugged simplicity versus advanced hygiene. Neither is inherently better; they're just designed for different jobs.

Beyond how you turn the water on, the temperature is another big factor. Most basic portable units only provide cold water, which is fine for general hand washing. However, some health codes, especially for food service, demand access to hot water. For these situations, you can find advanced portable models that come with a built-in water heater, ensuring you stay compliant and get a more effective clean.

Single-User vs. Multi-User Designs

The number of people you expect is a huge driver in your decision. A single-user hand washing station is perfect for smaller-scale needs, like a lone food truck, a compact work site, or a small retail pop-up. These units are compact, light, and easy to place just about anywhere.

For larger crowds or workforces, multi-user stations are a much smarter and more efficient choice. These stations feature several basins and faucets—typically two or four—all built into one consolidated unit. This design drastically cuts down on wait times and prevents lines from forming. That’s absolutely critical for managing crowd flow at a festival or making sure a construction crew can get cleaned up fast during their break. A four-basin station, for instance, can serve four times as many people as a single unit in the same amount of time—a massive boost to your operational efficiency.

Selecting the Best Materials and Features for Durability

When you're choosing a hand washing station, you're doing more than just picking a place for people to get water. You're making an investment in a piece of equipment that needs to last. The materials and features you go with will make all the difference in how well your station stands up to daily abuse, weather, and strict sanitation rules.

Your first big decision is usually between high-density polyethylene (HDPE) and stainless steel. These two materials are workhorses, but for very different environments.

Think of HDPE as the tough, all-terrain vehicle of the hygiene world. This rugged plastic is made to handle the outdoors, take a few hits, and survive the chaos of a busy construction site or festival. It’s also surprisingly lightweight, making it a breeze to move around, and it's often the more budget-friendly choice right out of the gate.

Stainless steel, on the other hand, is the gold standard for any place where hygiene is absolutely critical. Its surface is non-porous, which makes it incredibly simple to clean and sanitize—that’s why you see it everywhere in professional kitchens and healthcare settings. While it's heavier and typically costs more upfront, its incredible durability and resistance to rust make it a smart long-term investment.

Core Materials Comparison

To really get a feel for what’s right for you, it helps to see the two materials side-by-side. Your day-to-day needs, from portability to sanitation, will point you in the right direction.

| Feature | High-Density Polyethylene (HDPE) | Stainless Steel |

|---|---|---|

| Best For | Outdoor events, construction, agriculture | Food service, healthcare, labs |

| Durability | High impact resistance, weatherproof | Scratch-resistant, corrosion-proof |

| Sanitation | Good, but can scratch over time | Excellent, non-porous and easy to sterilize |

| Weight | Lightweight and highly portable | Heavier, better for stationary or semi-permanent use |

| Cost | Generally lower initial cost | Higher initial investment, but long lifespan |

As you can see, there isn't a single "best" material. It all comes down to the right tool for the job. A food truck owner will get more value from the squeaky-clean nature of stainless steel, while an event coordinator will love how easy it is to move HDPE stations around a venue.

Essential Features That Drive Performance

Beyond the base material, a few key features really determine how useful and compliant a hand washing station will be.

First up is tank capacity. A small 10-gallon tank might be fine for a small crew, but a large public event will need stations with 50-gallon tanks or more to keep the water flowing without constant service calls.

Dispenser types also make a huge difference. Manual pumps for soap and paper towels are simple and reliable, but touchless, sensor-activated dispensers are king for hygiene. They remove a major touchpoint, which is something customers and employees increasingly expect.

The global push for better hygiene is undeniable. Access to basic handwashing facilities shot up from 67% in 2015 to 75% in 2022. This trend highlights just how important it is to have modern stations that keep people safe.

Finally, don't overlook ADA (Americans with Disabilities Act) compliance. This is non-negotiable for any station accessible to the public. ADA-compliant units feature proper basin heights, enough clearance for a wheelchair, and faucets that are easy for anyone to operate. For many businesses, providing this kind of access isn't just a courtesy—it's the law.

This same commitment to durability and cleanliness applies to all professional kitchen equipment. In fact, you can see how the benefits of quality restaurant stainless steel tables perfectly complement a hygienic workspace. By thinking through these materials and features, you can choose a hand washing station that gets the job done today and keeps performing for years to come.

Smart Placement and Installation for Maximum Use

Getting the right hand washing station is a great start, but it's only half the job. Where you actually put the thing is what determines if it becomes a go-to hygiene spot or just a piece of overlooked equipment. Thoughtful placement and proper setup aren't just about convenience—they have a direct impact on how often the station gets used, overall safety, and how smoothly your site runs.

A well-placed station practically invites people to use it. One that's poorly positioned might as well not even be there.

The real goal is to make washing hands completely effortless. You need to think like the people on your site, whether they're guests at a festival, workers on a construction crew, or staff in a busy kitchen. People follow the path of least resistance, so your station has to be right in the middle of it.

Finding the High-Impact Hotspots

Visibility and accessibility are everything. A hand washing station needs to be in a high-traffic, obvious location that people will walk past naturally. Tucking it around a corner or in some out-of-the-way spot is a surefire way to kill its effectiveness.

Think about these key placement zones:

- Near Restroom Areas: This is the classic move for a reason. Placing stations next to portable toilets just makes sense. People already expect to wash their hands after using the restroom, so putting a station right there is an easy win.

- Adjacent to Food and Drink Areas: For food vendors, festival food courts, or any catering setup, this is completely non-negotiable. It allows both your crew and your customers to clean up before and after handling food, which is huge for cutting down cross-contamination risks.

- At Site Entrances and Exits: Putting a station at the main entry and exit points encourages people to wash up as they arrive and before they head out for the day. It's a simple, effective habit to build.

The most effective hand washing station is one that requires no extra effort to find or use. Its placement should be so intuitive that hand hygiene becomes a natural part of the user's routine, not a detour.

Don’t forget about the ground itself. The surface must be level and stable to keep the unit from tipping over, which is especially important for portable stations holding a lot of water. An uneven surface is more than just a safety hazard; it can mess with how the station drains and operates.

Logistics for Portable and Permanent Stations

The type of station you choose really changes the setup game. Portable units give you incredible flexibility, but they have their own list of logistical needs. Permanent stations are more work upfront but deliver a seamless, integrated solution once they're in.

With a portable hand washing station, water management is your main job. You have to get on a clear schedule for refilling the fresh water tank and properly emptying the greywater from the wastewater tank. If you let this slide, you’ll end up with an unusable station and could even face health code violations.

For plumbed-in stations, the focus shifts to getting it hooked up correctly to your building's plumbing. This almost always requires a professional plumber to make sure the water lines and drainage are connected right, preventing leaks and guaranteeing good water pressure. It's more planning at the start, but the payoff is a low-maintenance, endless water supply.

No matter which type you have, always keep the station stocked with soap and paper towels. An empty dispenser makes even the best hand washing station completely useless. By thinking through your placement and logistics ahead of time, you create a reliable and effective resource that genuinely promotes a healthier, safer environment.

Matching the Right Station to Your Industry Needs

Choosing the right hand washing station isn’t a one-size-fits-all deal. What works for a massive outdoor festival is worlds apart from the sterile setup needed in a medical tent or the compact efficiency required by a food truck. The key is to match the station to the unique demands of your industry. Doing this right ensures you’re not just meeting hygiene standards, but actually improving your workflow and keeping everyone safe.

This means looking past the simple need for soap and water and really thinking about the day-to-day challenges of your environment. A construction site needs something tough that can serve a lot of people, while a restaurant kitchen needs something that’s NSF-certified and a breeze to sanitize. When you dial in these specific needs, your hand washing station becomes a genuine asset, not just a box to tick.

Food Service: Beyond the Sink to Prep Tables

In any business that handles food, hygiene is the foundation of a successful operation. While a hand washing station is your first line of defense, it works as part of a larger system of clean and efficient equipment. Stainless steel is the material of choice here, not just for sinks but for the prep surfaces where all the magic happens. These tables are designed for durability, ease of sanitation, and streamlined workflow.

In food service, your hand washing station and your prep tables are two sides of the same coin. Both are essential for food safety, efficiency, and compliance with health codes.

Let's explore the common types of stainless steel prep tables that form the backbone of a professional kitchen.

- Standard Work Tables: These are the versatile workhorses of the kitchen. Available with flat tops or with a backsplash to protect walls, they provide a simple, durable surface for everything from chopping vegetables to plating dishes. Undershelves are a common feature, offering valuable extra storage.

- Sandwich Prep Tables: These specialized units are a must for delis, cafes, and sub shops. They combine a refrigerated base with a series of cold wells on top for holding meats, cheeses, and toppings. A built-in cutting board runs along the front, creating an all-in-one station for building sandwiches quickly and safely.

- Pizza Prep Tables: Similar to sandwich tables, these are designed specifically for pizzerias. They feature a wide, refrigerated rail that holds multiple food pans for toppings like pepperoni, mushrooms, and peppers. The deep cutting board provides ample space for stretching dough and assembling pizzas, keeping all ingredients within arm's reach.

In any kitchen layout, these prep tables work in tandem with a dedicated hand washing station to create a complete, hygienic, and highly efficient food preparation system.

Industry Guide to Hand Washing Stations

| Industry | Recommended Station Type | Essential Features | Why It Works |

|---|---|---|---|

| Food Service | Stainless Steel (Portable or Drop-In) | NSF Certification, Hot & Cold Water, Integrated Backsplash | Easy to sanitize, meets health codes, and prevents cross-contamination in busy kitchens. |

| Construction | High-Capacity Portable (HDPE) | Multiple Basins, Foot Pump Operation, Large Water Tanks | Durable enough for rough sites, serves large crews quickly, and works without electricity. |

| Outdoor Events | Multi-Basin Portable (HDPE) | Soap & Towel Dispensers, Foot Pump | Minimizes lines in high-traffic areas, promotes hygiene, and is easy to set up and move. |

| Healthcare/Medical | Medical-Grade Portable (Stainless Steel or Polymer) | Hot & Cold Running Water, Sensor Faucets, Sealed Tanks | Ensures sterile, touch-free hand washing to meet strict infection control standards. |

| Education/Daycare | Child-Height Portable Station | Sturdy Step Stool, Easy-to-Use Faucets, Fun Colors | Accessible for small children, encourages good habits, and durable enough for daily use. |

This table is a starting point, but thinking through these specific features will get you much closer to the ideal solution for your business.

Construction Sites and Outdoor Events

The demands of a construction site or a large outdoor festival are all about scale, toughness, and high traffic. These settings require rugged, high-capacity portable stations that can handle heavy use and whatever the weather throws at them. High-density polyethylene (HDPE) is usually the go-to material here because it’s so resilient and easy to move around.

Multi-basin stations, with two or even four sinks in a single unit, are a must for managing big crowds or work crews without long waits. This design prevents bottlenecks during peak times like lunch breaks or between bands at a festival, encouraging everyone to wash their hands more often. Foot-pump faucets are another popular feature, offering a hands-free way to wash up that improves hygiene and stands up to constant use without needing batteries or power.

The need for these units is huge, particularly in the United States, where outdoor work and recreation are major parts of the economy. In 2019, the U.S. outdoor recreation economy alone accounted for $459.8 billion of the GDP, while industries like construction employ hundreds of thousands of workers who all need access to hygiene facilities. You can find more details on the market drivers for portable hygiene stations.

Field Clinics and Emergency Services

When you’re setting up a temporary healthcare site—like a field clinic, a disaster relief operation, or a pop-up testing center—the hygiene standards are as strict as they get. The number one priority is infection control. Stations in these environments have to be easy to sterilize completely and almost always need both hot and cold running water to meet medical sanitation rules.

Here, portable units with built-in water heaters, touchless sensor faucets, and sealed water tanks are absolutely critical. These features help create a controlled space that drastically reduces the risk of spreading germs. Stainless steel is often the top choice for its cleanability, but you'll also see advanced polymer stations designed specifically for medical use.

The right equipment is the foundation of a safe kitchen. For anyone outfitting a commercial space, our guide on selecting a 3-bay commercial sink is a great next step, as it's a key part of a complete hygiene system.

Common Questions About Hand Washing Stations

Even after you've picked out the perfect hand washing station, a few practical questions always seem to pop up. Getting clear, no-nonsense answers about sanitation, water, and legal stuff is what separates a smooth operation from a stressful one. Let's walk through some of the most common questions we get from operators just like you.

How Do You Keep a Portable Station Sanitary?

This is a big one. The whole point of the station is hygiene, so keeping the unit itself clean is non-negotiable. Think of it like this: a dirty sink doesn't exactly encourage people to wash their hands.

The key is a consistent cleaning routine. At the end of every single day or event, the entire unit needs a thorough wipe-down with a good disinfectant. Pay extra attention to the parts people touch the most, like faucet handles or foot pumps.

Proper water management is just as critical. The freshwater tank should be drained and refilled with fresh, potable water regularly to keep it from getting stagnant and gross. At the same time, the greywater (wastewater) tank has to be emptied according to your local health rules. You don't want to solve one hygiene problem just to create another. A clean station is a well-used station.

What Are the Water Requirements for a Portable Sink?

The water you need really depends on where and how you're using the sink. For general use at a construction site or a local park, the rule is simple: the tank must be filled with potable (drinkable) water. This guarantees the water is safe and won't introduce new germs into the equation.

Now, if you're in food service, the rules almost always get stricter. Many health departments insist on having both hot and cold running water. They'll often specify a minimum temperature for the hot water, which is usually around 100°F or 38°C. Your first call should always be to your local health authority to confirm exactly what they require. It’s the only way to be 100% sure you're compliant.

A common misconception is that any water source will do for a portable station. Using non-potable water can introduce bacteria and defeat the entire purpose of providing a hand washing facility.

Are Hand Washing Stations Required by Law?

In a lot of situations, the answer is a firm yes. The specific rules change depending on your industry and location—sometimes right down to the city level—but they are often mandated by law. For instance, the Occupational Safety and Health Administration (OSHA) frequently requires employers in fields like agriculture and construction to provide proper hand washing facilities for their crews.

For public events, food trucks, and outdoor markets, it's the local health codes you need to watch. These regulations don't just say you need a sink; they often detail how many you need based on the number of people you expect. To stay legal and avoid fines, you have to do your homework on the rules for your specific area and type of event. Nailing down these details is a fundamental part of setting up any professional workspace, a process we dive into in our comprehensive prep tables buying guide.

Ready to elevate your business's hygiene and efficiency? At PrepTables.com, we offer a premier selection of NSF-certified stainless steel work tables, commercial sinks, and refrigeration units designed for durability and performance. Explore our full collection today!