Choosing Your Ice Machine for Commercial Use

Share

Choosing the right commercial ice machine is a huge decision for any business in food service, hospitality, or even healthcare. This isn't just about buying another piece of equipment; it's about investing in the heart of your operation. The right machine impacts everything from the quality of your drinks and food safety to how smoothly your day runs. It's a balancing act between finding the right capacity, minding your energy bills, and getting the specific type of ice your customers love.

Your Guide to Selecting a Commercial Ice Machine

This guide is designed to cut through the noise and give you a clear path to selecting the perfect machine. Don't think of this as just buying an appliance. See it for what it is: a strategic business move. The right unit will elevate what you offer, make your team's workflow easier, and keep utility costs in check for years.

Making an informed choice is more important than ever. The global commercial ice machine market is already valued at roughly $1.47 billion in 2025 and is set to grow at a steady 5.4% each year through 2033. This boom is fueled by the ever-expanding food service world, especially quick-service restaurants and caterers who need a reliable, high-quality supply of ice day in and day out.

Why Your Ice Machine Matters So Much

In a professional kitchen or bar, an ice machine is a true workhorse. It quietly supports three of the most important parts of your business:

- Product Quality: The shape, clarity, and purity of your ice directly change how a drink tastes and looks.

- Operational Efficiency: A dependable machine means no last-minute ice runs or service hiccups, letting your staff stay focused on customers.

- Financial Health: Choosing an energy-efficient model means lower monthly utility bills, which adds straight to your bottom line.

A well-chosen commercial ice machine becomes one of the unsung heroes of your daily grind. It makes sure every cocktail is perfectly chilled, every food display is kept at a safe temperature, and every customer gets the quality they came for.

Your ice machine does more than make frozen water; it protects your inventory, delights your customers, and supports your profitability. Viewing it as a long-term asset rather than a simple expense is the first step toward making a smart investment.

To help you get started, this table breaks down the main things you'll need to think about.

Quick Guide to Commercial Ice Machine Selection

| Key Consideration | What to Look For | Impact on Your Business |

|---|---|---|

| Ice Type | Full-cube, half-cube, nugget, flake? Match the ice to your primary use (drinks, displays, etc.). | Directly affects drink quality, presentation, and food preservation. Nugget ice is a customer favorite. |

| Daily Capacity | How many pounds of ice do you need in 24 hours? Calculate based on peak demand. | Too little, and you run out during a rush. Too much, and you waste energy and money. |

| Energy & Water Use | Look for ENERGY STAR® certified models. Compare water consumption per 100 lbs of ice. | A more efficient machine significantly lowers your monthly utility bills and is better for the environment. |

| Installation Space | Consider the machine's footprint, plus clearance needed for air circulation and maintenance. | A poor fit can lead to overheating, reduced efficiency, and difficult repairs. |

This table is just a starting point. The best choice comes from understanding how the type of ice you need, the daily production capacity your business demands, and the long-term energy efficiency of the machine all work together. For a complete overview, check out our comprehensive guide to commercial ice machines. Let’s dive in and find the perfect machine that will become a reliable partner for your business.

Matching Ice Shape and Machine Type to Your Needs

It’s easy to think of ice as just frozen water, but in a commercial setting, it’s a core part of the customer experience and your daily operations. Just like a chef picks a specific knife for a specific job, choosing the right ice shape can make or break a drink, a food display, or even a patient's comfort.

Thinking about the ice itself is always the first step. Before you can choose the right ice machine for commercial use, you need to know what you’re trying to make. Each ice shape has unique traits that make it perfect for some situations and a total miss for others.

A Guide to Common Ice Shapes

Let's break down the most common types of ice. Each one brings something different to the table, and your choice here will narrow down your machine options significantly.

- Full-Cube Ice (or Dice Ice): This is your classic, slow-melting cube. Its large size and minimal surface area mean it chills drinks without watering them down too quickly. It’s the go-to for high-end cocktails, spirits on the rocks, and bagging for retail sale.

- Half-Cube Ice (or Half-Dice Ice): As the workhorse of the industry, half-cubes are incredibly versatile. They pack tightly into glasses for great displacement and are perfect for high-volume beverage service in fast-food spots, busy bars, and self-serve soda fountains.

- Nugget Ice (or Chewblet® Ice): This is the soft, chewable ice that customers love. It’s porous, so it soaks up the flavor of the drink, and it’s much gentler on blender blades. That makes it the top choice for smoothies, frozen cocktails, and fountain drinks where the experience matters.

- Flake Ice: Made of small, flat, soft pieces, flake ice is perfect for creating beautiful food displays. It molds around seafood, produce, and salad bar items without bruising them, which also makes it valuable in healthcare for therapeutic packs.

The connection between your ice and your business model is direct. A craft cocktail bar would look silly serving flake ice, and a seafood market has almost no use for big, slow-melting full cubes.

Connecting Ice Type to Machine Style

Once you’ve landed on the right ice shape, you can match it to a machine style that fits your kitchen's layout and production volume. Think of it like putting the right engine in a vehicle—you wouldn't put a four-cylinder in a semi-truck, and you shouldn't put a tiny machine in a massive hotel.

The main categories of commercial ice machines are all about their construction and where they live in your space.

Choosing a machine isn’t just about how much ice it makes, but how it delivers that ice and fits into your workflow. The right combination of ice shape and machine type will support your staff, delight your customers, and protect your bottom line.

There are three primary styles to consider for your business.

- Modular Ice Machines: These are the heavy lifters. A modular unit is just the ice-making "head," and it requires a separate storage bin or dispenser to sit on. This component-based approach offers the highest production capacity, making it perfect for large restaurants, hotels, and institutions that need hundreds or even thousands of pounds of ice every day.

- Undercounter Ice Machines: These are the all-in-one problem-solvers. They combine the ice maker and storage bin into a single, compact unit designed to fit perfectly under a standard 40-inch countertop. They are the ideal solution for small bars, cafés, office break rooms, or any spot where space is tight.

- Countertop Ice Dispensers: Just as the name suggests, these machines sit right on a counter and dispense ice, and often water, directly into a cup. You'll see them most often in self-serve environments like office kitchens, hospital waiting areas, and cafeterias, where easy access is key.

Beyond restaurants and bars, healthcare is a major user of commercial ice. There's a growing trend of ice machines in hospitals and clinics, where ice is critical for everything from patient care and hydration to preserving medical supplies.

Figuring Out Your Daily Ice Needs

There are few things worse than running out of ice during a dinner rush. It’s a nightmare scenario for any restaurant, bar, or hotel. On the flip side, buying a massive machine that churns out way more ice than you ever use is just a drain on your cash and your energy bill. This is why getting a solid handle on your daily ice production needs is probably the most important step you'll take when picking an ice machine for commercial use.

Think of it like ordering food for a big holiday weekend. You wouldn't just guess; you'd look at past sales and make an educated forecast. The same logic applies here. A little bit of smart calculation upfront means you'll get a machine that keeps up with demand without becoming an expensive, underused piece of equipment.

Start With Industry Benchmarks

A great place to start is with some tried-and-true industry benchmarks. These numbers give you a solid baseline based on what businesses like yours typically use. Of course, you’ll need to tweak them for your specific operation, but they point you in the right direction.

Here are some general rules of thumb for daily ice consumption:

- Restaurants: 1.5 pounds of ice per seat. So, for a 100-seat spot, you’re looking at a baseline of 150 pounds a day.

- Bars & Cocktail Lounges: 3 pounds of ice per customer. If you’re planning for 100 guests on a busy night, you'll need at least 300 pounds.

- Hotels & Motels: 5 pounds of ice per room. A 100-room hotel would need a machine that can produce 500 pounds daily.

- Healthcare Facilities: 10 pounds of ice per patient bed. This covers everything from patient drinks to ice packs.

- Cafeterias & Self-Serve Stations: 1 pound of ice per person.

Keep in mind, these numbers are for a 24-hour period. It's also critical to know that an ice machine's production rating is based on perfect lab conditions—usually 70°F air and 50°F water. If your kitchen gets hotter than that (and whose doesn't?), your machine's output will drop.

A classic rookie mistake is buying a machine that exactly matches your daily estimate. Always tack on a 20% buffer to whatever number you land on. This covers you for surprise rushes, heat waves, and the simple fact that machines don't always perform at 100% in the real world.

Adjust for Your Specific Operation

Those benchmarks are just the starting line. The next, and most crucial, step is to adjust that number based on how your business actually runs. No two restaurants or bars are the same, and a few key factors can send your ice usage through the roof.

Think about these high-consumption variables:

- Menu Items: Are you known for your blended drinks, smoothies, or frozen margaritas? Those drinks can gobble up three times more ice than a simple soda.

- Food Displays: If you have big salad bars or seafood displays on ice, that's a whole separate calculation. You need to account for all that flake or nugget ice on top of what you use for drinks.

- Peak Hours & Seasonality: Does your business get slammed during lunch? Is your patio the place to be in the summer? Your ice machine has to be able to handle those peaks, not just the 24-hour average.

- Water Stations: A self-serve water station for customers will burn through ice much, much faster than just serving water from the bar.

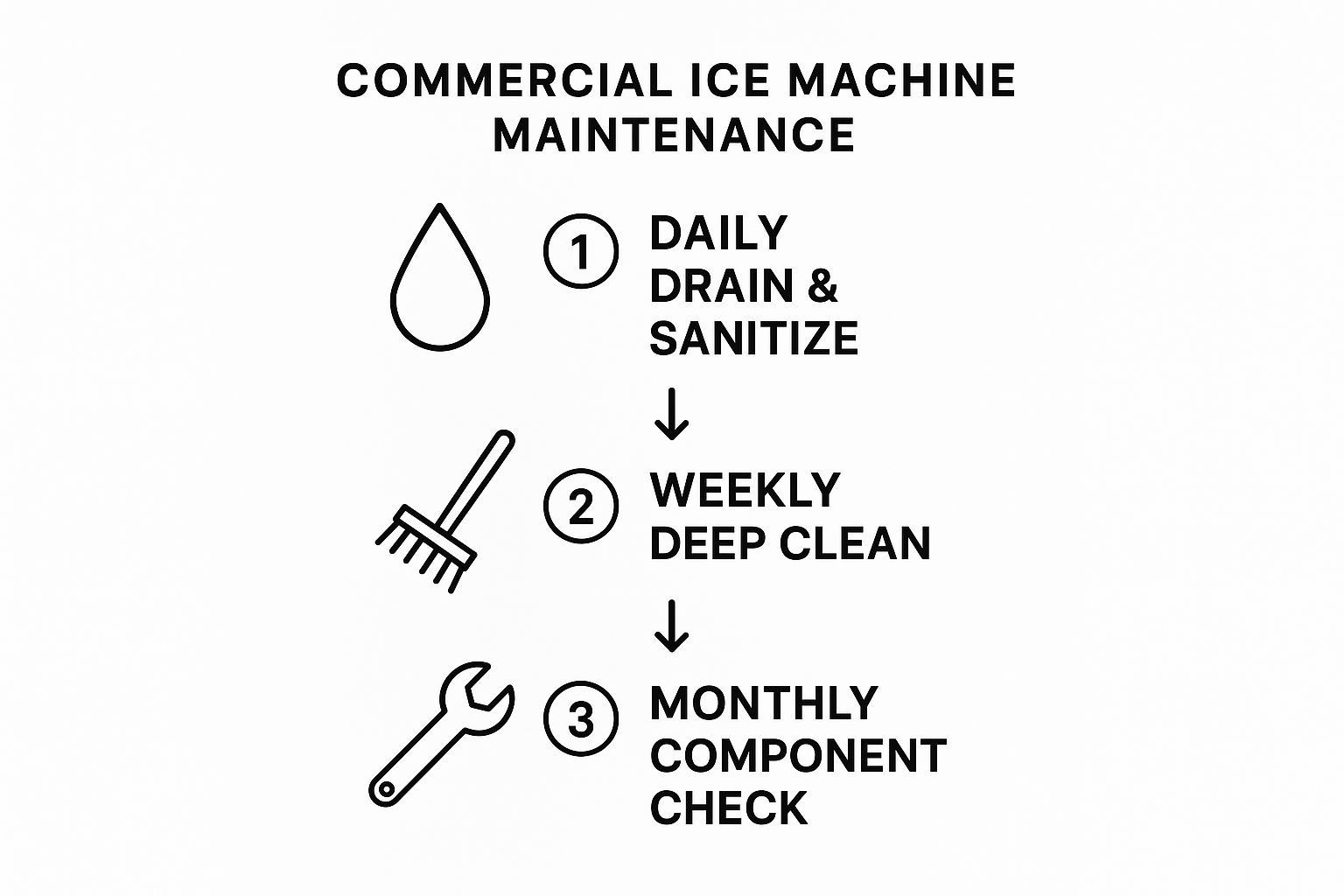

Taking a hard look at these factors will give you a much more realistic picture of your true ice needs. It ensures the ice machine for commercial use you choose can survive your busiest Saturday night, not just a quiet Tuesday afternoon. This infographic also drives home how simple maintenance keeps your machine running at its best.

As you can see, staying on top of maintenance—from daily cleaning to monthly check-ups—is absolutely essential. It's what guarantees your machine actually produces what it's supposed to. If you let it slide, you'll see that output drop right when you need it most.

Choosing Between Air-Cooled and Water-Cooled Systems

The condenser is the heart of your ice machine for commercial use. It’s the part that does all the heavy lifting, pulling heat out of the water so that ice can actually form. How it gets rid of that heat—using either air or water—is one of the biggest decisions you'll make. It’s a choice that ripples out to affect your utility bills, your kitchen's temperature, and even the comfort of your staff.

Let's break it down with an analogy. An air-cooled condenser is a lot like the radiator in your car; it uses a fan to blow air across coils to cool things down. A water-cooled condenser, on the other hand, operates more like a boat engine, using a steady stream of water to whisk heat away. Both get the same job done, but their ideal environments and running costs couldn't be more different.

The Case for Air-Cooled Ice Machines

Most commercial kitchens go with air-cooled systems, and for a few very good reasons. They generally cost less upfront and are a breeze to install—most just need to be plugged in, with a simple connection to a water line and a drain. That straightforward setup makes them the go-to choice for a huge number of businesses.

But here’s the catch: their greatest strength is also their main drawback. Because they rely on the surrounding air for cooling, they need space to breathe. We’re talking at least six inches of clearance on all sides and the top. More importantly, they pump hot air right back into your kitchen. In an already bustling, hot kitchen, that extra heat puts a bigger load on your HVAC system and can make for a pretty uncomfortable workspace.

- Pros: Lower initial cost, simpler installation, and they're easy to find.

- Cons: Heats up the kitchen, needs a lot of ventilation, and becomes less efficient in hot spaces (over 80°F).

When Water-Cooled Systems Make Sense

A water-cooled ice machine for commercial use is a more niche, but incredibly effective, piece of equipment. These units don't vent any hot air into the room, which makes them a lifesaver in cramped, hot kitchens or any spot with poor airflow. They’re also much quieter than air-cooled models since you don't have a big fan kicking on and off all day.

The trade-off, as you might guess, is water usage. These machines need a constant flow of water just for the cooling process, which can definitely show up on your water bill. A typical water-cooled unit uses around 100 gallons of water for every 100 pounds of ice it makes just for cooling—that’s on top of the water that becomes the ice itself. Installation is also more involved, as it needs its own dedicated water line for cooling.

While the initial price and water use of a water-cooled machine can be higher, its performance in hot settings is second to none. In a sweltering kitchen, a water-cooled unit will hum along, producing ice at its full rated capacity. An air-cooled machine in the same spot? Its production could easily drop by 20% or more.

This really shows that it's not about which type is "better," but which one is the right fit for your unique setup.

Making the Right Choice for Your Business

To figure this out, you need to take a hard look at your kitchen's layout, your local climate, and what you pay for utilities.

Choose an air-cooled machine if:

- You’ve got plenty of space and good ventilation.

- Your kitchen temperature usually stays below 80°F.

- A lower upfront cost and easy installation are your top priorities.

Choose a water-cooled machine if:

- Your kitchen is tight on space, crowded, or always hot.

- You're in a climate where high ambient temperatures are the norm.

- A quieter machine is important for your environment.

- Your water costs are fairly low, especially compared to your electricity costs.

At the end of the day, picking a condenser for your ice machine is a strategic business decision. You're balancing the upfront investment against the long-term running costs—a choice that directly impacts your kitchen's workflow and your bottom line.

Boosting Your Bottom Line with Energy Efficiency

When you're shopping for a commercial ice machine, it's easy to get fixated on production capacity and the initial price tag. But that sticker price? It’s only the beginning of the story. The true cost of owning an ice machine shows up month after month on your utility bills, and that’s where an efficient model can save you thousands over its lifetime.

Think of an efficient ice machine as your most reliable employee—one that works tirelessly without padding the expense report. It uses less electricity and less water to produce the same amount of ice, directly chipping away at your monthly overhead. This isn't just about being "green"; it's about making a smart financial decision that strengthens your bottom line.

Decoding ENERGY STAR and Other Certifications

When you see that little blue ENERGY STAR logo on an ice machine, don't just glance past it. That’s not just a sticker; it's a seal of approval from the U.S. Environmental Protection Agency (EPA), guaranteeing the machine meets some seriously strict performance standards.

An ENERGY STAR certified commercial ice machine is, on average, 15% more energy-efficient and 23% more water-efficient than a standard model. Those numbers translate into real, tangible savings that add up fast.

These certified models are built smarter from the ground up, often featuring high-efficiency compressors and better heat exchangers. They simply work more intelligently to freeze water. This engineering doesn't just cut your electricity bill; it also slashes your water consumption, tackling two of your biggest utility expenses at once.

While electricity gets a lot of the attention, don't forget about water. A machine that wastes water is like having a leaky faucet you never fix—a constant, needless drain on your profits. Proper water management, including routine cleaning, is essential for both efficiency and hygiene. You can get a better sense of why clean water systems are so critical by reading our guide on the essentials of a 3-bay commercial sink.

The Shift to Eco-Friendly Refrigerants

Another huge piece of the efficiency puzzle is the type of refrigerant running through the machine's veins. The industry is finally moving away from old-school hydrofluorocarbons (HFCs) like R-404A, which have a major negative impact on the environment. New regulations and a push for sustainability have manufacturers embracing much better, eco-friendly alternatives.

Refrigerants like R-290 (propane) are quickly becoming the new gold standard. Not only do they have an incredibly low global warming potential (GWP), but they are also more efficient, meaning they cool things down faster while using less power. Choosing a machine with a modern, green refrigerant gives you a few key advantages:

- Future-Proofs Your Investment: You won't be stuck scrambling for costly retrofits when environmental regulations get even tighter down the road.

- Reduces Your Carbon Footprint: It shows your customers you care about sustainability, which is a powerful message for any brand.

- Lowers Energy Bills: These refrigerants just perform better, which means lower operating costs for you.

This global shift is also shaped by what different markets demand. For example, here in North America, the focus is often on user-friendly, high-efficiency machines for places like fast-food spots and bars. Over in Europe, there's an intense focus on sustainability, with tough regulations pushing for innovation in green refrigerants and materials. You can read more about these global market trends to see how manufacturers are adapting.

At the end of the day, picking an efficient commercial ice machine is a strategic move that will pay you back for years to come.

Installation, Maintenance, and Maximizing Lifespan

Your ice machine for commercial use is a serious investment and, frankly, the unsung hero of your daily operations. Protecting that asset starts the second it arrives. Getting the installation right isn't just a good idea—it's the single most important thing you can do to make sure your machine runs smoothly and reliably from day one.

Think of it like laying the foundation for a house. If you cut corners there, you're going to be dealing with cracks and leaks for years to come. A proper setup right out of the gate heads off immediate performance headaches and paves the way for a long, productive life.

The Installation Checklist

Before that delivery truck even thinks about backing up to your door, you need a solid plan. A rushed installation is just asking for expensive service calls down the road. A little prep work here will save you a world of hurt.

Here are the absolute non-negotiables for a professional setup:

- Dedicated Water Line: Your ice machine needs its own clean water supply. Period. Tapping into a line that also feeds a sink or dishwasher is a recipe for introducing grime and messing with water pressure, which kills your ice quality.

- Proper Drainage: Every commercial ice machine needs a floor drain. Make sure it's close by and has the correct air gap to prevent dirty water from backing up into your machine—that's a major health code violation you don't want.

- Specific Electrical Requirements: You have to check the spec sheet for this. Most commercial units need their own dedicated circuit. This prevents tripped breakers that will inevitably shut down ice production during your busiest hours.

- Sufficient Clearance: We’ve touched on this, but it’s critical. Air-cooled models need room to breathe, which usually means six inches of clear space on all sides. If you block that airflow, the machine will work harder, suck down more energy, and eventually burn itself out.

Neglecting proper installation is like trying to run a marathon with your shoes untied. You might make it a few steps, but you’re setting yourself up for a spectacular failure. A flawless setup is the cheapest insurance you can buy for your new equipment.

A Proactive Maintenance Schedule

Once your machine is up and running, the game shifts to proactive care. Regular maintenance isn't just about a quick wipe-down; it's about guaranteeing food safety, staying on the right side of the health inspector, and preventing those catastrophic breakdowns that always seem to happen on a Saturday night.

A consistent schedule is everything. The industry standard is to deep clean your ice machine at least once every six months. If you're a high-volume spot or you're in an area with hard water, you should probably be doing it quarterly.

A full maintenance routine needs to include:

- Cleaning and Sanitizing: This gets rid of the slime, mold, and bacteria that love to grow on all the parts that touch water and ice. That gross "pink slime"—a common airborne bacteria—can build up fast and contaminate your entire ice supply if you don't stay on top of it.

- Descaling: This is the process of removing mineral buildup (scale) from the water lines and internal components. Scale makes the machine work way harder than it should, slashes your ice production, and leads to expensive parts failing way too soon.

- Filter Changes: If you have an external water filter (and you absolutely should), it needs to be replaced on schedule, usually every six months. A clogged filter is a useless filter, letting all that scale and other gunk flow right into your machine.

Organizing your maintenance is just as critical as organizing your kitchen. While your ice machine handles the chilling, having the right surfaces for food prep is equally important for hygiene and workflow. In our guide on restaurant stainless steel tables, we discuss various types, including specialized models like pizza prep tables and sandwich prep tables. These units often combine refrigerated storage with a durable work surface, streamlining your assembly line. Understanding how these pieces of equipment work together is key to creating a truly efficient and safe kitchen.

Frequently Asked Questions

Running a business means you've got questions, and when it comes to commercial ice machines, we've got answers. Let's walk through some of the most common things people ask, so you can feel confident about your equipment.

How Often Should I Clean My Commercial Ice Machine?

This is easily one of the most critical questions. The general rule of thumb is a full, deep clean and sanitization at least once every six months.

But that's just a starting point. Your kitchen's environment really dictates the schedule. If you do a lot of baking with airborne yeast, or if you're in an area with hard water, you'll want to be more aggressive. In those cases, bump up the cleaning to once every three months. This stops slime, mold, and scale from building up, keeping your ice safe and your machine running smoothly.

What Is That Pink Slime in My Ice Machine?

Seeing a pink or reddish film in your machine is alarming, and for good reason. That gunk is typically an airborne bacteria called Serratia marcescens. It loves damp places and can spread through your ice supply fast if you don't tackle it.

While it's not the most dangerous bacteria out there, it’s a huge red flag that your machine has a sanitation problem. It's also a guaranteed way to fail a health inspection. The only real defense is a consistent cleaning and sanitizing schedule.

A clean machine is a safe machine. That pink slime isn't just ugly; it's a visual warning that your ice may not be safe for customers. Staying ahead of it with proactive cleaning is your best bet.

Does an Ice Machine Need a Water Filter?

Yes. Just, yes. While a machine might technically run without one, a water filter is one of the smartest investments you can make for its health and longevity.

A good filter accomplishes two key things:

- It pulls out sediment, chlorine, and other impurities that make your ice taste and smell funky.

- It dramatically cuts down on mineral scale, which is the number one enemy of internal components and a huge cause of production slowdowns.

Think of it like cheap insurance for your ice machine for commercial use. You're protecting all those sensitive parts, which means fewer emergency service calls and better-tasting ice for your customers.

Can I Install an Ice Machine Myself?

It's tempting to try and save a few bucks with a DIY install, but for a commercial unit, it's almost always a mistake. These aren't like countertop appliances; they have very specific needs. Getting it wrong can easily void your warranty and lead to some serious damage.

A professional installation guarantees everything is done right—the dedicated water line, the proper drainage with a sufficient air gap, and the correct electrical hookup. Starting off on the right foot saves you from endless headaches down the road and makes sure your machine works as hard as you do from day one.

Ready to find the perfect ice machine and other essential kitchen equipment for your business? Explore the wide selection of durable, high-performance options at PrepTables.com and build a more efficient, reliable kitchen today. Visit us at https://preptables.com.