Your Guide to Commercial Ice Machines

Share

Choosing the right commercial ice machine is a big deal for your business. Think of it as the quiet, hardworking hero behind every cold drink, chilled food display, and happy customer. A machine that's too small or unreliable can bring your entire service to a screeching halt, while the right one keeps things running smoothly day in and day out.

Why the Right Ice Machine Is a Game Changer

A commercial ice machine is more than just another appliance. It’s a core piece of equipment that has a direct impact on how efficient you are, how satisfied your customers are, and ultimately, your bottom line.

In places like restaurants, bars, and hotels, having a steady, plentiful supply of clean ice is something you just can’t compromise on. Running out of ice during a dinner rush? That’s a recipe for disappointed customers and a stressed-out team.

The type of ice machine you pick also matters—a lot. Today’s models are miles ahead in terms of energy and water efficiency. In fact, making the switch can even put money back in your pocket.

Some cities offer a $3,000 rebate for businesses that replace an old water-cooled ice machine with a new, ENERGY STAR® certified air-cooled one. This one change can slash water use by up to 85%.

This guide will walk you through everything you need to know, from how much space the machine takes up to the exact shape of the ice it makes. Our goal is to give you the confidence to pick a machine that not only handles your needs today but is ready to support your business as it grows.

The Foundation of Foodservice and Hospitality

The need for a dependable ice machine touches many industries, and each one has its own specific needs. A one-size-fits-all approach just doesn't work here.

- Restaurants and Bars: Ice isn't just for cooling; it's a key ingredient. It chills cocktails, keeps ingredients fresh, and is the backbone of blended drinks. The right machine means consistent drinks and faster service.

- Healthcare Facilities: In hospitals and nursing homes, ice is crucial for keeping patients hydrated, for physical therapy, and for preserving medical samples. Soft, chewable nugget ice is often the top choice for patients.

- Hotels and Lodging: Ice dispensers on every floor are an expected amenity for guests. A reliable machine prevents complaints and helps ensure a great stay.

- Convenience Stores and Grocers: These businesses need ice for soda fountains and for selling in bags. They also rely on flake ice to keep produce and seafood displays looking fresh and appealing.

At the end of the day, putting your money into the right commercial ice machine is an investment in quality, safety, and stability. It's about making sure this silent partner in your business performs perfectly, every single day.

Matching The Ice Type To Your Business Needs

Choosing a commercial ice machine is about so much more than just how much ice it can churn out. You've got to pick the right type of ice for what you're actually doing. The shape and size of the cube have a direct impact on everything from the quality of your drinks to how fresh your food displays look.

Think of ice as a key ingredient, not just something to keep things cold. Get it wrong, and you could end up with watered-down cocktails or sad-looking food displays. To get it right, you need to know the personality of each ice type and how it fits your business.

The Classic Cubes For Beverages

When you think of ice, you're probably picturing cubes. In the commercial kitchen world, they mostly come in two flavors, each designed for a specific job that can make or break a drink's taste and your bottom line.

Full-Cube Ice (Dice Ice)

Full cubes are the big, slow-melting workhorses. Their classic, solid shape makes them the go-to for high-end spirits and cocktails where you absolutely cannot have a watered-down drink.

- Best For: Upscale bars, fine dining restaurants, and catering events.

- Why It Works: That large surface area means they melt slowly, protecting the true flavor of a premium whiskey or a carefully crafted cocktail. A single, clear full cube in a glass is an instant signal of quality.

Half-Cube Ice (Half-Dice Ice)

Half-cubes are the versatile backbone of the beverage industry. They're smaller, so they take up more space in a glass, and they're a breeze to dispense. This makes them a smart, cost-effective choice for any place that's moving drinks fast.

- Best For: Fast-paced restaurants, bars, and self-service soda fountains.

- Why It Works: They pack tightly into a glass, making drinks look fuller while chilling them down in a flash. Their smaller size also plays nicely with most automatic beverage dispensers.

Specialized Ice For Unique Applications

Once you move past the standard cubes, you get into specialized ice types built for very different jobs, from creating that perfect soda experience to keeping delicate foods pristine. These are engineered for specific textures and cooling abilities.

Nugget Ice (Chewable Ice)

You might know this as "Sonic ice," and it's a huge customer favorite for a reason. Nugget ice is made from flakes of ice that have been compressed together, which creates a soft, chewable texture that soaks up the flavor of whatever it's in.

Because it’s softer and easier on the teeth, nugget ice is the preferred choice in healthcare settings for patient hydration. Its porous nature also means it's less likely to water down drinks, making it a premium option for sodas and specialty beverages.

Flake Ice

Flake ice is made of small, soft, irregular chips of ice. It packs and molds beautifully, which is why it’s perfect for creating those beds of ice you see in food displays. This kind of ice keeps everything at the right temperature and moisture level without bruising or damaging delicate products.

It’s the unsung hero of seafood counters, salad bars, and produce markets. This ice wraps perfectly around items, cooling them evenly and consistently so food looks and tastes fresh. It's also the same type of ice used in physical therapy for cold compresses.

While the right ice keeps your products cool, an organized workspace is what keeps your kitchen running smoothly. The surfaces you prepare food on are just as critical as the ice in your drinks. For more on setting up an efficient kitchen, take a look at our buying guide on prep tables to see how to pick the perfect setup.

Finding the Right Ice Machine Configuration

Once you’ve settled on the perfect type of ice for your business, the next decision is what kind of machine will make it. A commercial ice machine isn't a one-size-fits-all piece of equipment. The physical design—what we call the configuration—is just as crucial as the ice it produces. This choice will directly shape your kitchen’s workflow, how you use your space, and your total ice output.

The three main configurations you'll run into are modular, undercounter, and countertop. Each one is designed for a different environment and scale, from a huge hotel kitchen to a cozy coffee shop. Getting this right means you’ll always have the ice you need without cluttering up your valuable workspace.

Modular Ice Machines: The High-Capacity Workhorses

Modular ice machines are the titans of the industry. They're built for businesses that have a constant, heavy demand for ice. These units are essentially just the ice-making "head," which sits on top of a separate ice storage bin or a beverage dispenser. This two-part system gives you incredible flexibility.

Because the head and bin are separate, you can mix and match components to get the exact setup you need. If your business grows and you need to store more ice, you can just swap out the bin for a larger one without having to replace the whole machine.

- Best For: Large restaurants, hotels, hospitals, and busy bars that simply cannot afford to run out of ice.

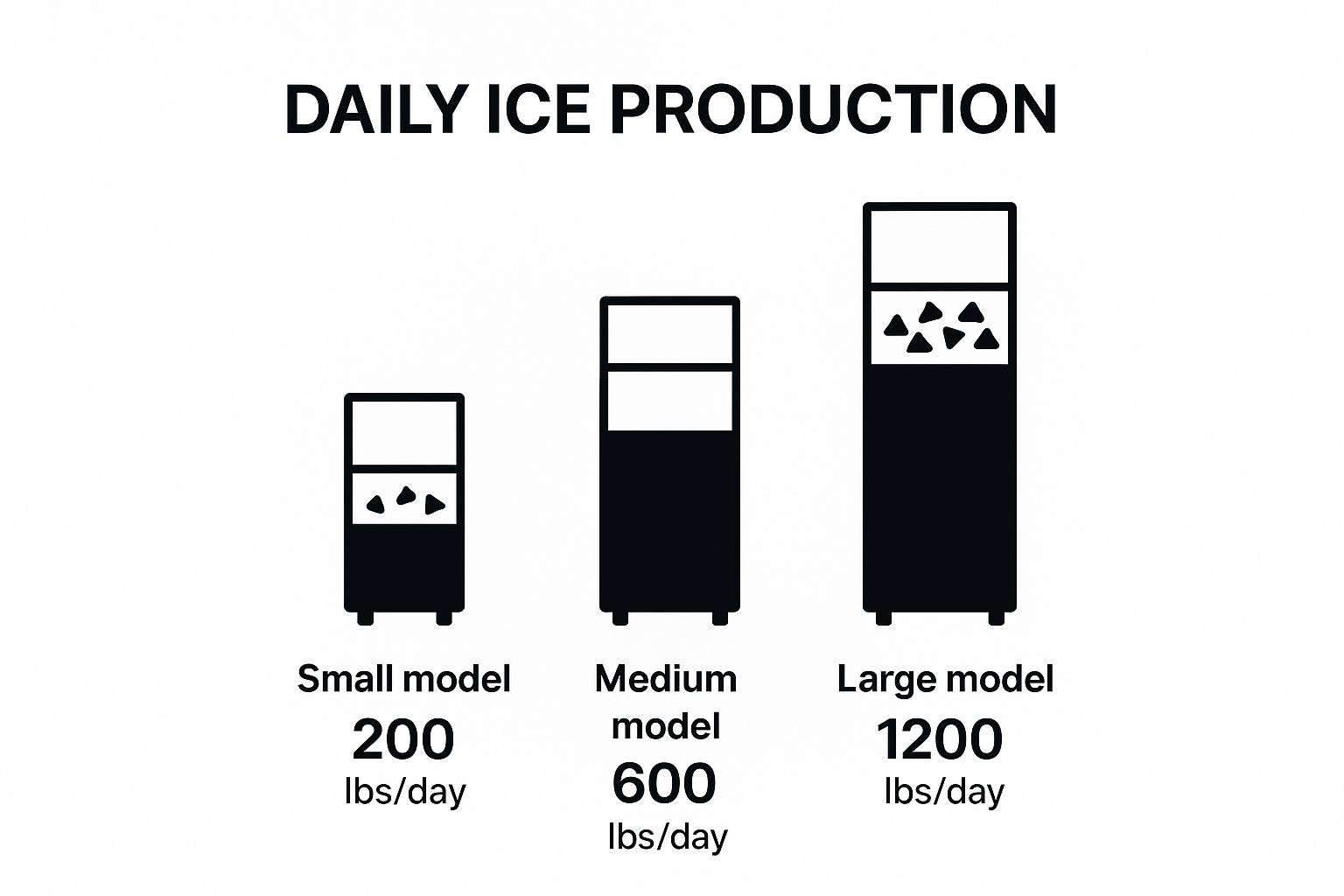

- Key Advantage: Unmatched production capacity, often ranging from 400 lbs to over 2,000 lbs of ice per day, with fully customizable storage.

As you can see, the jump in daily production from smaller models to large modular units is massive. A big modular machine can easily crank out six times more ice than a small one, which is exactly why high-volume businesses depend on this configuration.

Undercounter Ice Machines: Compact and Convenient

For any business where space is tight, an undercounter ice machine is a lifesaver. These are self-contained units that combine the ice maker and storage bin into a single, compact appliance. They’re specifically designed to fit neatly under a standard 40-inch countertop.

They put a respectable amount of ice right where your staff needs it most, like behind a bar or at a server’s station. This simple placement stops employees from having to trek across the kitchen to a central ice bin, which speeds up service and makes the whole operation run smoother.

Undercounter models are the go-to for small bars, cafes, and office breakrooms. They strike the perfect balance between a small footprint and steady ice production, typically making between 50 lbs and 350 lbs of ice each day.

Countertop Ice Machines: Self-Service Simplicity

Countertop ice machines, which you'll often see called ice dispensers, are made for direct use by customers or staff. These compact units sit right on a countertop and dispense ice straight into a cup with the push of a button or lever. They're a common sight in office breakrooms, healthcare waiting rooms, and hotel breakfast bars.

Their biggest advantage is hygiene and convenience. By offering touch-free dispensing, they cut down on the risk of contamination—a critical feature in any self-service setting. While they don't produce as much ice as other types, their real value is in providing easy, on-demand access.

To help you visualize the differences, here’s a quick comparison of the three main configurations.

Commercial Ice Machine Configuration Comparison

| Machine Type | Typical Capacity (lbs/24hr) | Best For | Key Advantage |

|---|---|---|---|

| Modular | 400 - 2,000+ | Large restaurants, hotels, hospitals | Maximum production & customizable storage |

| Undercounter | 50 - 350 | Small bars, cafes, office kitchens | Compact, all-in-one design fits under counters |

| Countertop | 50 - 400 | Self-service areas, waiting rooms | Hygienic, convenient dispensing |

Each of these configurations serves a distinct purpose. Your choice ultimately comes down to balancing your daily ice needs, your available space, and how your staff or customers will access the ice.

The Condenser: The Engine Cooling System

Every commercial ice machine generates a lot of heat during the ice-making process, and it needs a way to get rid of it. That job falls to the condenser. You can think of it like the radiator in your car—it’s essential for keeping the machine from overheating and shutting down. The right type of condenser for you will depend entirely on your kitchen’s environment.

- Air-Cooled: This is the most popular and generally most energy-efficient option. It uses a fan to pull in ambient air and blow it over the condenser coils to cool the refrigerant. It works great in most situations but needs at least six inches of clearance on all sides for proper airflow.

- Water-Cooled: This type uses a continuous stream of water to cool the system instead of air. It’s the perfect solution for really hot kitchens or cramped spaces with poor ventilation where an air-cooled model would struggle. The downside is that it uses a significant amount of water, which will impact your utility bills.

- Remote Condenser: With these systems, the condenser unit—the part that generates all the heat and noise—is installed somewhere else entirely, usually on the roof. This gets all that heat and noise out of your kitchen, creating a much cooler and quieter work environment for your staff.

Calculating Your True Ice Capacity Needs

This is where so many people go wrong. Underestimating your ice needs is one of the most common—and most costly—mistakes you can make when buying a commercial ice machine. Go too small, and you'll inevitably run out of ice during a dinner rush, leaving you with frustrated staff and disappointed customers. But if you buy a machine that's way too big, you're just throwing money away on energy, water, and ice that just melts down the drain.

Figuring out the right size isn’t a guessing game. It’s about taking an honest look at how your business actually operates. You need to move past a rough estimate and do a quick, structured calculation to make sure you invest in a machine that not only meets today’s demand but can also handle your business as it grows.

Think of it like stocking inventory for a holiday weekend. You wouldn't just take a wild guess at how much to order. You’d look at last year's sales, customer traffic, and what sells best during peak hours to make a smart call. It’s the exact same logic with ice.

Establishing Your Baseline Ice Usage

First things first, you need to figure out a baseline for your daily ice needs using some solid industry standards. These benchmarks give you a reliable starting point before you start tweaking the numbers for your own unique setup. They’re based on what businesses like yours typically go through.

Here are a few widely accepted guidelines for different types of businesses:

- Restaurants: A good rule of thumb is to plan for 1.5 lbs of ice per meal served. If you also have a bar, you’ll need to figure that out separately and add it on.

- Bars and Taverns: Plan on needing about 3 lbs of ice per seat. This covers everything from cocktails and soft drinks to glasses of water.

- Hotels: You should budget for around 5 lbs of ice per room. This accounts for guests filling up ice buckets and any on-site food and beverage services.

- Healthcare Facilities: A standard estimate is 10 lbs of ice per bed to cover patient hydration, physical therapy, and other medical applications.

These numbers are your foundation. For instance, a 100-seat restaurant would start with a baseline need of at least 150 lbs of ice per day, and that's just for the diners. This simple calculation immediately helps you narrow your focus to the right class of machines.

Adjusting for Peak Demand and Growth

That baseline gives you an average, but your business doesn’t operate on averages, does it? You have to account for your absolute busiest moments to make sure your ice machine can keep up when you need it most.

Don’t just plan for an average Tuesday; plan for your busiest Friday night. A machine that can’t handle your peak demand is fundamentally the wrong size for your operation, regardless of its daily production rating.

To really dial in your estimate, think about these critical factors:

- Peak Business Hours: Does your lunch rush drain your ice bins with fountain drinks? Is your happy hour totally packed? Pinpoint these high-volume windows.

- Seasonal Fluctuations: A booming patio in the summer or a holiday party season can send your ice consumption through the roof. You need to factor in a buffer for these predictable spikes.

- Future Growth: Are you thinking about expanding your dining room, adding a catering service, or rolling out a new cocktail menu? It's smart to add 10-20% to your final calculation as a buffer for growth.

When you layer these real-world details on top of your baseline number, you're no longer just guessing. You're creating a true operational forecast. This approach ensures the commercial ice machine you choose becomes a long-term asset, not a short-term headache you'll quickly outgrow.

Beyond Ice: Choosing the Right Prep Tables

Your commercial ice machine is the hero of chilled drinks, but every hero needs a sidekick. In the kitchen, that sidekick is the prep table. It's the unsung workhorse that dictates your kitchen's speed and organization. Just like you wouldn't use nugget ice in a highball, you don't use just any table for professional prep. Choosing the right work surface is about creating an efficient, safe, and productive workflow. This is more than just a place to chop onions; it's about building a foundation that just makes sense.

The absolute backbone of any pro kitchen is the stainless steel work table. There's a reason it's the champ. Its non-porous surface is a fortress against bacteria, it’s tough enough to handle anything you throw at it (or on it), and it cleans up beautifully. This durability and ease of sanitation make it a non-negotiable for meeting health codes. Think of these tables as the blank canvas of your kitchen. They're perfect for all sorts of general tasks, from butchering meat to plating delicate desserts. Their simple, open design gives you total flexibility.

Specialized Tables for High-Volume Tasks

But what about when you’re cranking out the same thing over and over? That’s where specialized tables come in. These units are designed to master specific, high-volume jobs by integrating refrigeration right into the workspace. It’s all about bringing ingredients and preparation together to save steps and time.

Pizza Prep Tables are engineered for one thing: making a lot of pizzas, fast. They have a wide, durable cutting board—often marble or a special plastic—that stays cool so dough doesn't stick. Right above the work surface, a refrigerated rail holds pans of cheese, pepperoni, and veggies. Everything is chilled, organized, and within arm's reach. It’s a complete pizza-making powerhouse.

Sandwich and Salad Prep Tables work on the same smart principle but are fine-tuned for delis and cafes. They also feature a refrigerated rail for cold cuts, cheeses, and greens. The main difference? The cutting boards are usually narrower because you just don't need as much space to build a sandwich as you do to stretch a pizza. Underneath, you’ll find refrigerated cabinets to store backup ingredients, keeping you stocked during the lunch rush.

By putting cold storage and a prep surface together, both pizza and sandwich tables slash food safety risks. They keep ingredients out of the temperature "danger zone" and make your whole process more efficient. This integrated design is really a cornerstone of a well-run kitchen.

A truly streamlined kitchen uses the right combination of standard and specialized tables. When you understand what each one brings to the table, you can build a cohesive workspace where every station is perfectly set up for its job. To get a deeper look at outfitting your space, you can learn more about selecting the right restaurant stainless steel tables for your menu and volume. This knowledge is key to creating a kitchen where every piece of equipment, from the ice machine down to the prep station, works in perfect harmony.

Protecting Your Investment with Proper Maintenance

A commercial ice machine is a serious investment, and just like a high-performance car, its lifespan and reliability come down to one thing: proper care. It's not a simple appliance you can just plug in and forget. Think of it as a core piece of your operation that needs regular tune-ups to keep running smoothly and avoid a catastrophic failure.

Sticking to a solid plan for installation, cleaning, and maintenance is the single best way to protect that investment. It’s how you guarantee you’re serving safe, clean ice, staying on the right side of the health department, and avoiding the nightmare of a dead machine during your busiest hours.

Setting Up Your Commercial Ice Machine for Success

The foundation for a long, trouble-free life for your ice machine is laid the moment it’s installed. Getting this right from day one is your best defense against common headaches like low ice production or parts failing way too soon. If you cut corners here, you’re just pre-paying for expensive service calls down the road.

Before the unit even shows up on a pallet, you need to get the location ready. This is about more than just clearing out a spot; you need to think about utilities and, most importantly, airflow.

Here's what absolutely must be done for a proper installation:

- Adequate Ventilation: Air-cooled machines, which are the most common, need to breathe. You have to give them at least six inches of clearance around all air vents so the condenser can push out heat. A machine suffocating in a hot, tight corner will work itself to death, producing less ice and failing much sooner.

- Correct Electrical Connections: This isn't a toaster. A commercial ice machine is a powerful piece of equipment and needs its own dedicated electrical circuit. Plugging it into an already loaded circuit is a major fire hazard and can fry the compressor. Always bring in a licensed electrician to make sure the wiring meets the manufacturer's specs and all local codes.

- Proper Plumbing and Drainage: Your machine needs a clean, dedicated water supply line, and a shut-off valve right there will make maintenance a breeze. Just as critical is the drain line. It must have a proper air gap to stop wastewater from backing up into your machine—a huge health code violation.

The Critical Importance of Routine Cleaning

Let’s be honest: an ice machine is a dark, damp box. It’s the perfect breeding ground for mold, slime, and bacteria if you don’t stay on top of it. Regular cleaning isn't just a good idea; it's a non-negotiable part of food safety. A dirty machine makes contaminated ice, which can get customers sick and destroy your reputation.

The trick is to break down your cleaning schedule into simple daily, weekly, and semi-annual tasks. Consistency is everything.

A study of ice machines in the food service industry found that 70-80% of biofilm (the technical term for that nasty slime) samples contained disease-causing microbes. This isn't just gross; it's a serious public health risk that a strict cleaning routine can prevent.

A simple but consistent routine stops buildup before it becomes a real problem. For more tips on keeping your whole kitchen sanitary, our guide on how to clean and maintain a commercial kitchen grease trap has great advice that applies to overall kitchen hygiene.

Your Essential Cleaning and Maintenance Checklist

To keep your machine humming along, you need a maintenance schedule with a few different tiers. Sticking to this routine will do more than just ensure food safety—it will dramatically cut down on surprise breakdowns and add years to the life of your unit.

Daily Tasks (5 Minutes):

- Wipe down the outside of the machine to get rid of dust and spills.

- Check the ice scoop. Make sure it's clean and stored in a sanitary holder, never in the ice bin.

- Glance into the bin. The ice should look clear, and you're just making sure no foreign objects fell in.

Weekly Tasks (15-20 Minutes):

- Shut the machine off and empty the ice bin completely.

- Give the inside of the storage bin a thorough cleaning and sanitizing, following the manufacturer’s directions with an approved solution.

- Take out, clean, and sanitize the removable parts, like the water curtain, distribution tube, and float switch.

- Clean the air filter. A dirty, clogged filter chokes the machine, making the compressor work harder and run up your energy bill.

Semi-Annual Professional Service (Every 6 Months):

- This one is crucial. Book a professional for a deep cleaning and preventative maintenance check. A certified technician will descale the entire water system to get rid of mineral buildup that clogs lines and wrecks components. They’ll also check electrical connections, refrigerant levels, and make sure all the moving parts are in good shape. This is how you catch small problems before they become big, expensive disasters.

Of course. Here is the rewritten section, following all the provided guidelines and examples to achieve a natural, human-expert tone.

Frequently Asked Questions About Commercial Ice Machines

Even after getting a handle on ice types and machine specs, you probably still have a few questions rolling around. That’s completely normal—this is a major equipment purchase, after all. Let’s tackle some of the most common questions business owners have when choosing and caring for a commercial ice machine so you can feel confident in your decision.

How Often Should I Professionally Clean My Commercial Ice Machine?

To keep your ice safe, your machine running smoothly, and the health inspector happy, you need to get it professionally deep cleaned and sanitized at least every six months. This isn't just a suggestion; it's a critical part of owning one. Daily wipe-downs and weekly air filter checks are great, but they don't replace a pro service.

A professional technician has the tools and know-how to handle the tough stuff. They'll properly descale all the internal parts you can't see and give the mechanical systems a once-over. This catches small problems before they become major, expensive breakdowns and really extends the life of your machine. When in doubt, always follow the manufacturer's specific cleaning schedule—they know their equipment best.

What Is the Difference Between an Air-Cooled and a Water-Cooled Machine?

The real difference comes down to one thing: how the machine gets rid of heat from its refrigeration system. Think of it like a car engine—it needs a way to cool down to keep running.

- Air-Cooled: These are the most popular models for a reason. They use a fan to pull ambient air over the condenser coils to cool them. They are far more energy-efficient but need breathing room—at least six inches of clearance on all sides—to get enough airflow.

- Water-Cooled: These machines use a constant flow of water to cool the condenser. They’re a lifesaver in tight, hot kitchens where an air-cooled model would just choke. The trade-off? They use a ton of water, which can send your utility bills through the roof.

Upgrading from an old water-cooled machine to a new ENERGY STAR® certified air-cooled unit can be a huge win for your bottom line. Some local utility programs even offer rebates up to $3,000 for making the switch. An air-cooled model can slash a machine's water use by as much as 85%.

For most businesses trying to keep operating costs in check, the air-cooled commercial ice machine is easily the smarter choice.

Why Is My Ice Machine Making Less Ice Than It Should?

Low ice production is a frustrating but common problem. Before you call for a service tech, it’s worth checking a few things yourself, as the fix is often surprisingly simple.

First, check the temperature of the room. If your kitchen is blazing hot, the machine has to work overtime just to get cold enough to make ice, which drastically slows it down. Make sure the unit has good ventilation.

Second, a clogged filter is a classic culprit. A dirty air or water filter is like trying to breathe through a straw—it starves the machine of what it needs. Check your filters and clean or replace them based on the manufacturer’s schedule.

Finally, dirty condenser coils are a big performance killer. When the coils get caked in dust and grease, they can't shed heat effectively. A quick, gentle cleaning can often bring your machine right back up to speed. If you’ve checked all three and the problem is still there, it’s time to call in a pro.

Can I Use a Water Filter from a Different Brand on My Ice Machine?

I know it’s tempting to grab a generic filter to save a few bucks, but it’s a bad idea. It is strongly recommended that you stick with the water filter system specified by your ice machine’s manufacturer.

Using the wrong filter can cause all sorts of headaches. It might not filter properly, leading to scale buildup that can wreck internal parts. It could also restrict water flow, which hurts both ice production and quality. But here’s the biggest reason: using an unapproved filter will almost certainly void your machine's warranty. That means a repair that would have been covered is now your problem. Manufacturer-approved filters are built for your machine’s exact needs, protecting your investment and keeping it running right.

At PrepTables.com, we provide the highest quality equipment to build an efficient and safe commercial kitchen, from the ice in your drinks to the surfaces you prep on. Explore our complete collection of commercial ice machines, refrigeration, and stainless steel work tables to find the perfect fit for your operation.

Find your ideal kitchen solution today at PrepTables.com.