How long does it take to make ice in commercial machines: Tips for faster output

Share

How long does it take to make ice? In a busy commercial kitchen, a single cycle usually takes anywhere from 20 to 60 minutes. But if you're managing a kitchen, the real number you care about isn't the cycle time—it's the machine's 24-hour production rate, which is a whole different ballgame.

Your Quick Guide to Commercial Ice Production Times

When your entire bar or restaurant depends on having enough ice, you need to know your machine's real-world output. Thinking about how long it takes to make one batch of ice is like asking a chef how long it takes to cook one dish. The real question is, can you handle the dinner rush? A single batch might be ready in half an hour, but that doesn't tell you if you'll run out on a packed Saturday night.

The most important metric for any professional kitchen is the 24-hour production rate. This is the number the manufacturer gives you, and it tells you how many pounds of ice the machine can crank out in a full day under perfect lab conditions. Think of the individual cycle time as a single sprint and the daily rate as the marathon.

Understanding Production Variables

Several key factors can mess with how quickly your machine produces ice. These variables can easily turn a high-performance unit into a sluggish one, drastically changing the manufacturer's official numbers if you don't keep them in check.

Here are the biggest things that slow down ice production:

- Ambient Temperature: A hot kitchen makes the machine’s condenser work overtime, which slows down the whole freezing process.

- Incoming Water Temperature: It’s simple physics. Colder water freezes faster. Using warmer tap water adds precious minutes to every single cycle.

- Air Circulation: Your ice machine needs room to breathe. If it's crammed against a wall, it can't vent heat properly, which kills its efficiency.

- Machine Cleanliness: Mineral scale from hard water builds up on the evaporator plate and acts like an insulator, making it much harder to freeze water quickly.

The reality is that a busy kitchen—with all its heat, steam, and non-stop action—is a tough environment. A machine rated for 500 pounds of ice per day in a lab will almost always produce less in your kitchen. Factoring in that difference is crucial when you're choosing the right size.

From First Batch to Full Bin

When you fire up a commercial ice machine for the first time, don't be surprised if that initial batch takes longer than the rest. The whole system needs to cool down to its ideal operating temperature. Once it gets going, the cycles will become much more consistent and faster.

You can learn more about picking the perfect machine for your needs in our detailed guide to buying a commercial ice machine.

Ultimately, knowing "how long does it take to make ice?" is less about timing a single cycle and more about smart planning. Once you understand the relationship between cycle times, daily production rates, and your kitchen's unique environment, you can make sure your ice bin is always full when you need it most.

The Science Behind Commercial Ice Machines

To really get a handle on ice production times, you have to peek behind the stainless steel curtain. A commercial ice machine isn't just a powerful freezer; it's more like a tiny, automated factory running on a continuous refrigeration cycle. It’s a precise, methodical process designed to churn out batch after perfect batch of ice.

It all starts when water flows over a super-chilled metal grid called an evaporator plate. This plate is essentially the mold for your ice. As water runs over its surface, the refrigeration system works its magic, pulling heat out of the water and causing it to freeze in thin layers.

You can almost think of it as 3D printing, but with ice. Layer by layer, the machine builds up the cube. This is the secret to getting those crystal-clear, dense cubes—impurities in the water don't have a chance to get trapped, they just get washed away with the unfrozen water.

From Liquid to Solid: The Freezing Cycle

The freezing cycle is where the heavy lifting happens. It kicks off when the machine compresses refrigerant gas, cranking up its temperature and pressure. That hot gas then heads to the condenser, where fans blow air across coils to pull the heat away, turning it into a high-pressure liquid.

This liquid refrigerant is the key. It travels to the evaporator plate and expands back into a gas, a process that absorbs a massive amount of heat from the plate and makes it intensely cold—way below freezing. This is what freezes the water flowing over it into solid cubes. The length of this cycle is the biggest factor in your total ice-making time, typically lasting 15 to 30 minutes for most commercial units.

The Harvest: Releasing the Ice

Once the ice has built up to the right thickness, the machine cleverly flips the script and begins the harvest cycle. It sends a shot of hot refrigerant gas back through the evaporator plate, warming it up just enough to break the ice's grip.

This slight warmth causes the cubes to release from the metal grid, dropping as a single sheet into the storage bin. A mechanism then breaks that sheet up into individual cubes. The harvest cycle is quick, usually lasting only a couple of minutes before the whole process starts over again.

For anyone running a business, understanding this process is crucial. It’s why you always hear that clean water and good airflow aren’t just suggestions—they're non-negotiable for keeping your machine efficient. A dirty machine or a hot, cramped space forces the refrigeration system to work overtime, stretching out each cycle and killing your daily output.

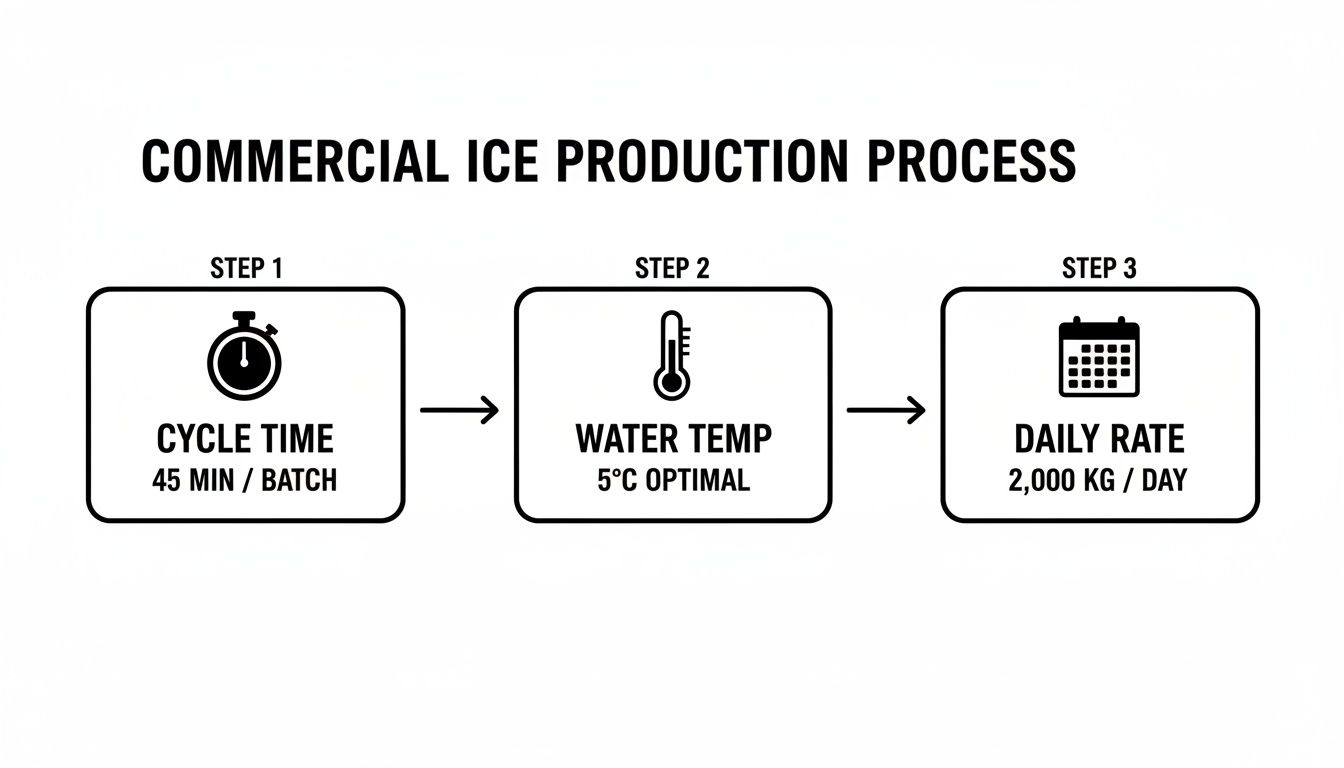

This flowchart shows how all these pieces—cycle time, water temperature, and daily rate—fit together.

As you can see, each step has a direct impact on the next. Even a small hiccup early in the cycle can snowball, leading to a big drop in how much ice you have at the end of the day.

Comparing Ice Machine Speeds for Your Business Needs

When you start digging into how long it takes to make ice for your business, you learn one thing fast: not all machines are built for the same race. The kind of output a high-volume sports bar needs is worlds away from what a small, intimate cocktail lounge requires. The key is to match the machine's production directly to your daily demand.

An ice machine is a serious investment, and its speed is probably the most critical factor in that decision. If you pick one that’s too slow, you’ll be constantly running out during peak hours, which is a nightmare for staff and customers. On the flip side, getting a machine that’s way too powerful for your needs just burns through energy and money for no good reason.

High-Volume Heroes: Modular and Undercounter Units

For businesses with a relentless, never-ending demand for ice, modular ice machines are the undisputed workhorses. These are the big-leaguers you find in bustling restaurants, hotels, and hospitals. They crank out massive amounts of ice—often 500 to over 1,000 pounds a day—and sit right on top of a separate storage bin, which lets you mix and match your production and storage capacity.

A slightly more compact but still mighty option is the undercounter ice machine. These are self-contained units that slide neatly under a standard 40-inch countertop, making them perfect for bars and cafes where every square inch of space counts. While they don't produce quite as much as the modular giants, a quality undercounter machine can still pump out a very respectable 200 to 400 pounds of ice daily.

The Need for Speed: Nugget and Flake Machines

Sometimes, it's not just about volume; it's about speed and texture. For smoothie shops, healthcare facilities, or seafood displays, nugget and flake ice machines are the clear winners. These are places where chewable, easy-to-mold ice is an absolute must.

- Nugget Ice Machines: These machines are incredibly fast. They work by scraping tiny ice crystals off a freezing cylinder and then mashing them together into small, soft nuggets.

- Flake Ice Machines: Operating on a similar principle, these units produce soft, small flakes of ice that are perfect for packing down and displaying perishable goods.

Because they operate on a continuous flow rather than a batch-by-batch cycle, they start churning out usable ice almost instantly.

Commercial ice machines are essential equipment in any professional foodservice operation, but their production cycles can vary wildly. A typical machine might take anywhere from 40 minutes to two hours to finish a full batch. However, some models are far quicker; nugget ice machines can start producing ice within 3 to 4 minutes of startup, filling a bin in about 15 minutes. In contrast, those popular crescent-shaped ice makers often need 25 to 30 minutes for each cycle. Discover more insights about these production timelines and what they mean for your business.

Specialized Ice for Unique Applications

Beyond sheer volume, the type of ice you need plays a huge role in the machine you choose and how long it takes to produce. A high-end cocktail bar has completely different priorities than a quick-service restaurant.

A cocktail lounge, for example, will prioritize quality over quantity every time. They might opt for a machine that produces large, crystal-clear gourmet cubes. These machines are intentionally slow, meticulously freezing water in layers to create dense, beautiful ice that melts slowly and won't water down a top-shelf spirit. That longer production cycle is a feature, not a bug—it’s how you get that perfect clarity and shape.

This gets to the heart of answering "how long does it take to make ice?" because the answer completely changes based on what kind of ice you’re making. A fast-food joint benefits from the rapid-fire production of standard full or half cubes to keep up with a constant stream of drink orders. The slow, methodical process of making gourmet ice would just create a massive bottleneck. Matching the machine’s speed and ice type to your specific business is the secret to a smart investment.

Identifying the Hidden Factors That Slow Production

Is your ice machine falling behind? The production rate listed on the spec sheet is almost always based on perfect lab conditions, which rarely reflect the chaos of a real commercial kitchen. A lot of things can quietly chip away at your machine's efficiency.

Often, the culprit is simply a lack of regular upkeep. Using an equipment preventive maintenance checklist is a great way to stay on top of the basics. But even a spotless machine can be held back by its surroundings. Think of your ice maker as an athlete trying to run a marathon in a sauna—the hotter and more difficult the environment, the slower it’s going to perform. Let’s look at the hidden factors in your kitchen that are probably throttling its output.

The Impact of Ambient and Water Temperature

The two biggest environmental enemies of ice production are hot air and warm water. Your machine’s whole job is to pull heat out of water until it freezes. When the air around it is hot from the cookline or the incoming water is lukewarm, the refrigeration system has to work overtime just to keep up.

This isn't a small problem; it has a massive impact on your daily ice yield. The ideal conditions for peak performance are incoming water at 50°F and surrounding air at 70°F. A more realistic standard for a working kitchen (the AHRI standard) sets the numbers at 70°F water and 90°F air. That temperature difference dramatically lengthens the freezing cycle, which means fewer harvests per day and a lot less ice in the bin when you need it.

Every single degree counts. A machine rated to produce 500 pounds of ice in those perfect lab conditions might only churn out 380 pounds in a typical hot kitchen. That’s a drop of nearly 25%, which can easily be the difference between a smooth service and telling customers you're out of ice.

Poor Ventilation and Airflow

Just like any other piece of hardworking equipment, your ice machine needs to breathe. The vast majority of commercial units are air-cooled, using fans to draw in cool air over the condenser and push out hot air. If your machine is shoved into a tight corner or jammed against a wall, it simply can’t get the airflow it needs.

This lack of ventilation traps hot air around the unit, forcing it to suck in the same warm air it just expelled. As the internal components get hotter, the entire refrigeration cycle becomes less efficient, and your ice production slows to a crawl.

- Minimum Clearance: Always check the manufacturer’s specs for clearance. Most require at least 6-12 inches of open space around any vented panels.

- Avoid Heat Sources: It’s a cardinal sin to place an ice machine next to an oven, fryer, or dishwasher. The radiant heat coming off that equipment is constantly fighting your machine’s cooling process.

The Silent Killer: Mineral Scale

The quality of your water is another huge piece of the puzzle. If you operate in an area with hard water, it’s full of dissolved minerals like calcium and magnesium. As water turns to ice, those minerals get left behind, clinging to the internal components—especially the evaporator plate where the ice forms.

This buildup, known as scale, acts like a layer of insulation. It creates a barrier between the super-chilled plate and the water, forcing the machine to run much longer to freeze each batch. Left unchecked, heavy scaling will not only kill your production speed but can also lead to expensive repairs. A good water filtration system is one of the smartest investments you can make to protect your machine and guarantee consistent output. For more on this, check out our guide on proper ice machine cleaning procedures.

Optimizing Your Kitchen for Peak Ice Machine Performance

It’s one thing to know what’s slowing your ice machine down, but it’s another to build a kitchen environment that actually boosts its efficiency. A few smart moves in your layout and daily routines can turn that struggling machine into a reliable workhorse. The goal is to always know exactly how long it takes to make ice, because proactive care is always cheaper than a frantic repair call during the dinner rush.

This really comes down to a combination of a simple maintenance schedule and smart kitchen design. When you position your ice machine alongside the right equipment, you create a system where everything works together. This synergy doesn't just get you more ice; it smooths out your entire workflow and keeps things more sanitary.

Your Essential Maintenance Checklist

Hands down, regular maintenance is the most effective way to guarantee a consistent supply of ice and add years to your machine’s life. A simple, repeatable checklist makes it easy for your team to stay on top of these crucial tasks.

- Clean Air Filters Weekly: Clogged filters are the number one cause of overheating. A quick wipe-down or wash takes just minutes but makes a huge difference in airflow.

- Wipe Down Exterior Surfaces Daily: This simple step prevents dust and grease from getting sucked into the vents, which helps with both hygiene and performance.

- Descale and Sanitize Regularly: Just follow the manufacturer’s guidelines. Most recommend descaling every three to six months to get rid of mineral buildup that dramatically slows down the freezing process.

This small investment of time prevents the most common equipment failures and keeps your machine running just like it did out of the box.

Designing a Cooler, More Efficient Workspace

The physical layout of your kitchen has a massive impact on your ice machine’s performance. If you surround your unit with equipment that throws off a lot of heat, you're making it work that much harder. This is where high-quality stainless steel prep tables become your ice machine's best friend.

Operational efficiency is a major cost factor for any foodservice business. A typical 500-pound ice machine can consume around 1000 watts of power. Field data shows older models might use 4.34 kilowatt-hours per 100 pounds of ice, while newer, more efficient units can reduce that to just 3.14 kWh—a 34% improvement that directly impacts your utility bills. Learn more about the energy performance of commercial ice machines and how to maximize savings.

The Role of Specialized Prep Tables

Choosing the right work surfaces can passively cool your kitchen and improve workflow, which indirectly helps your ice machine. Different types of stainless steel prep tables offer unique advantages for creating a more efficient, temperature-controlled environment.

Standard stainless steel work tables help you create organized prep zones away from the ice machine. This cuts down on foot traffic and clutter that can block vents. Their non-porous surface is also a breeze to sanitize, contributing to a cleaner environment with fewer airborne contaminants.

Even better are specialized units that integrate refrigeration directly into the workspace. Sandwich prep tables feature refrigerated wells for holding cold cuts and toppings, while pizza prep tables offer a chilled rail for ingredients and a cooled cabinet for dough. By localizing the refrigeration, these tables help lower the kitchen's overall ambient temperature. This gives your ice machine the cooler air it needs to run at peak efficiency and churn out ice much faster. These units streamline the assembly process, reduce food waste, and minimize the need for separate, heat-generating coolers nearby.

Choosing the Right Prep Tables for a Cooler Kitchen

Did you know your ice machine's performance is directly tied to the room it's in? Believe it or not, the right kitchen equipment can create a more stable, efficient environment for making ice. High-quality stainless steel prep tables are much more than just a place to chop vegetables; they're strategic tools that help manage workflow, boost sanitation, and—most importantly—reduce ambient heat.

When every piece of equipment works together as a cohesive system, your temperature-sensitive ice machine can operate closer to its peak potential. This means you'll get a more reliable answer to the question, "how long does it take to make ice?" because you've taken control of the variables that slow it down.

The Role of Standard Stainless Steel Tables

Even the simplest solution, a standard stainless steel work table, plays a surprisingly big part in kitchen efficiency. By creating dedicated zones for chopping, mixing, or plating, these tables help organize your workflow and keep unnecessary foot traffic away from your ice machine's air intakes.

This separation is key. When prep work is contained to its own area, there's far less clutter to obstruct airflow. Plus, stainless steel's non-porous surface is incredibly easy to clean and sanitize. This contributes to better overall kitchen hygiene by cutting down on airborne contaminants that could otherwise clog your ice machine’s filters.

When you're picking out a work table, keep an eye out for an NSF certification. This seal is your guarantee that the materials and design meet strict public health standards, ensuring the surface is non-absorbent, corrosion-resistant, and a breeze to clean—all features that support a sanitary environment for ice production.

Specialized Tables for Superior Temperature Control

While standard tables help organize your space, specialized prep tables can actively help cool your kitchen down. Units designed for specific jobs, like sandwich or pizza prep, integrate refrigeration directly into the workspace, which is a massive advantage.

These tables are absolute game-changers for keeping a lower ambient temperature. Instead of running multiple separate, heat-generating coolers, they consolidate all your cold storage into one efficient station.

- Sandwich Prep Tables feature refrigerated wells for holding cold cuts, cheeses, and veggies, keeping everything right where you need it. This cuts out the constant opening and closing of larger refrigerator doors, which lets cold air escape and makes compressors work overtime.

- Pizza Prep Tables work on the same principle, with a refrigerated rail for toppings and a cooled cabinet below for dough. The raised rail design keeps ingredients perfectly chilled and organized for lightning-fast assembly.

By localizing the refrigeration, these specialized tables significantly reduce the overall heat load in your kitchen. For a deep dive into how these units can transform your workspace, you can learn more about the benefits of commercial refrigerated prep tables.

Durability and Design Features to Consider

Beyond the type of table, the quality of construction is vital for creating a stable, long-lasting kitchen environment. The gauge, or thickness, of the stainless steel is the number one indicator of its durability. A lower gauge number means thicker, more robust steel—look for 14-gauge or 16-gauge tables for heavy-duty commercial use. They’ll resist dents and warping for years.

Other important features to look for are adjustable undershelves for flexible storage and backsplashes to protect your walls from splashes and spills. A well-built, heavy-gauge table provides a sturdy, reliable foundation for your entire kitchen operation, ensuring the workspace stays organized and efficient. This kind of stable environment is the unsung hero of consistent, fast ice production.

Frequently Asked Questions About Ice Production

Even in a perfectly run kitchen, questions about ice machines are bound to pop up. Here are some clear, straightforward answers to the most common queries we hear, helping you sort out problems and make smarter choices for your business.

Why Is My Commercial Ice Machine Making Ice So Slowly?

Slow ice production is almost always a sign of two things: a hot environment or a need for some basic maintenance. If the machine is near a hot oven or in a room with poor ventilation, the high ambient temperature is a major culprit, forcing the unit to work overtime. Warm water coming into the machine also dramatically lengthens the freezing cycle.

Another common issue is internal buildup. When condenser coils get dirty, they can't get rid of heat efficiently. At the same time, mineral scale from hard water can coat the evaporator plate, acting like an insulator and making it much harder for ice to form quickly. A consistent cleaning schedule and making sure there's enough airflow around the machine usually solves these problems.

How Do I Calculate How Much Ice My Business Needs?

A good rule of thumb for most restaurants is to plan for 1.5 to 2 pounds of ice per customer, per day. So, if you run a 100-seat restaurant, you should be looking for a machine that can produce at least 200 pounds daily.

However, some businesses need a lot more. Bars, cafes, and any place serving blended drinks or iced coffee should estimate higher, closer to 3 pounds per customer. It's always a smart move to pick a machine with a production capacity a bit higher than your calculated daily need. This gives you a buffer to handle peak hours and unexpected rushes without running out.

When you're choosing a machine, always plan for your busiest day, not your average one. This ensures you can handle peak demand, preventing shortages that could hurt service and frustrate customers.

Is Buying a New Energy Efficient Ice Machine Worth It?

Absolutely. While you might pay more upfront for an ENERGY STAR® rated machine, the savings over time are significant. These newer models are built to use far less electricity and water to produce the same amount of ice, which will show up as a lower number on your monthly utility bills.

The financial upside doesn't stop with utilities. Newer, more efficient machines often need less maintenance and are generally more reliable, which means less risk of expensive downtime. When you add up the savings on energy, water, and repairs, the machine can essentially pay for itself over its lifespan, making it a very sound investment for any operation.

At PrepTables.com, we know that an efficient kitchen is a profitable one. From high-capacity ice machines to the stainless steel prep tables that support them, our equipment is designed for durability and performance. Explore our full range of commercial kitchen solutions to build a workspace that works as hard as you do at https://preptables.com.