Mastering Food Truck Layouts for Peak Performance

Share

The layout of your food truck is the very heartbeat of your business. It's what dictates your service speed and, ultimately, how much money you make. A well-thought-out food truck layout creates a logical flow that keeps your staff moving efficiently, gets rid of bottlenecks, and makes smart use of every last square inch of your mobile kitchen.

This isn't just about where you stick the fryer. It’s about creating an ergonomic system that lets your team hustle at their absolute best.

The Blueprint for a High-Profit Food Truck Layout

Before a single piece of equipment gets bolted down, the best food truck layouts start with a crystal-clear vision of the menu and how you'll serve customers. The real goal here is to build a space where your crew can prep, cook, and hand off food with maximum efficiency and zero wasted motion. Every single step, from grabbing ingredients to passing an order out the window, should feel natural and sequential.

This isn't just a matter of convenience; it’s a core part of being profitable in a ridiculously competitive market. The food truck world is booming because the best operators have mastered this kind of efficiency.

In fact, the industry in the United States has been growing at a rate of 13.2% year-over-year from 2015 to 2025, and it's projected to hit $2.8 billion in revenue by the end of 2025. A big part of that growth comes from smart, innovative layouts that allow for fast, high-quality service. You can dig into more stats over on ibisworld.com.

Assembly Line vs. Zone-Based Designs

Your first big layout decision comes down to two main philosophies: the assembly line or the zone-based model. Each has its pros and cons, and the right choice really depends on how complex your menu is.

-

Assembly-Line Layout: This is your go-to for simple, repeatable menus—think tacos, burgers, or gourmet sandwiches. Equipment is set up in the order you use it, creating a straight path from raw ingredients to the finished product right at the service window. It’s all about forward motion.

-

Zone-Based Layout: If you've got a more diverse menu, like one with fried items and fresh salads, a zone-based design is the way to go. You'll dedicate specific areas (or "zones") for different jobs—a frying zone, a cold prep station, a griddle area, and so on. This setup is fantastic for preventing cross-contamination and lets your team work on multiple orders at once without tripping over each other.

The Importance of Ergonomics and Flow

Beyond the big-picture design, the real secret to a killer food truck layout is ergonomics—making the workspace fit the worker, not the other way around. A cramped, illogical space just leads to slower service, frustrated staff, and a ton of potential safety issues.

The best layouts minimize how many steps your team has to take and how much they have to bend and reach.

A classic mistake is putting the equipment first and the people second. A layout that forces your crew to constantly sidestep each other or walk from one end of the truck to the other will absolutely kill your service speed during a rush, no matter how fancy your gear is.

Think of your truck as a tiny factory where the product is delicious food. Every movement should have a purpose. For instance, putting your main fridge right next to your main prep table can save dozens of steps every hour.

While these ideas are crucial for a mobile kitchen, they're built on the same foundation as larger restaurant operations. You might find some useful tips in our guide on commercial kitchen layout planning for more on those core concepts. Nailing down your workflow from the start is the most important step toward building a high-profit food truck that can crush any lunch rush that comes its way.

Mapping Your Workflow from Ticket to Customer

The best food truck layouts are built for one thing: speed. From the moment a customer places their order, the clock is ticking. Every wasted step, every clumsy reach for an ingredient—it all costs you time, and ultimately, money. The goal is to map out a logical path for every single order, from the ticket printer to the customer's hand.

Think of it like a dance. Your kitchen needs to be choreographed so your team can move fluidly without bumping into each other or creating logjams. This all starts by breaking down your tight quarters into four distinct, functional zones.

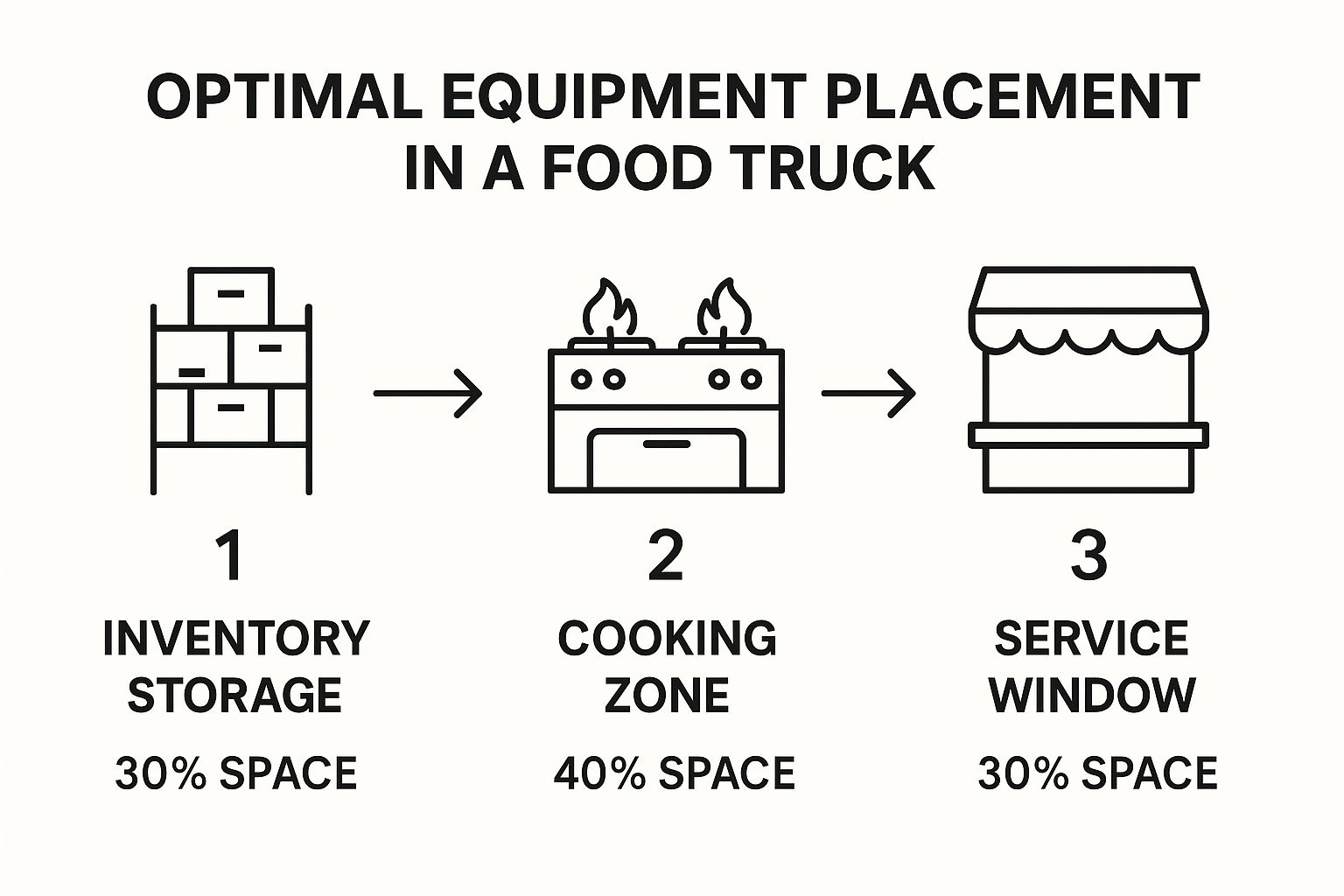

This visual gives you a solid idea of how space is typically allocated for these critical areas.

As you can see, the cooking zone usually eats up the most real estate. It's followed closely by storage and service, which really drives home how important it is to balance your layout for both fast production and smooth customer interactions.

The Four Essential Food Truck Zones

A smart layout brings order to the chaos of a busy service, turning complex tasks into a predictable rhythm. When you give every square foot a clear purpose, efficiency just becomes second nature.

Here’s a breakdown of the four primary zones you need to plan:

- Cold and Dry Storage: This is where every dish begins. Your refrigerators, freezers, and dry goods shelving must be easy to get to from the prep area. A classic pro-tip is to stick your main fridge right next to your prep station—it’s a simple move that can save hundreds of steps every single shift.

- Food Preparation Area: This is where the magic happens—chopping, mixing, and assembling raw ingredients. This station needs to be spotless, well-lit, and sandwiched right between your storage and cooking line to keep things moving.

- The Cooking Line: The heart and soul of your operation. This is home to your griddles, fryers, and ovens. The trick is to arrange your equipment in the exact order it’s used for your most popular dishes. If you’re slinging burgers, your griddle should flow directly to the station where you build and wrap them.

- Service and POS Window: The final handoff. This zone is for plating, garnishing, and passing orders out the window. It also needs to house your point-of-sale system and have room for condiments, napkins, and bags. Keeping this area separate from the cooking line is key to preventing your order-taker and cooks from tripping over each other.

Creating a Linear Food Path

What you're really trying to build is a linear workflow. Food should move in one direction through the truck. Ingredients come out of storage, go to the prep station, hit the cooking line, and finally get passed out the service window. This one-way street approach is the bedrock of any high-volume food truck.

A well-designed workflow doesn't just make you faster; it makes the job less stressful for your team. When everyone knows their station and the flow is intuitive, you reduce mental fatigue and minimize errors, even during the craziest lunch rush.

Let's take a taco truck, for instance. The refrigerated salsa and toppings should live next to the prep counter. That counter should be right next to the griddle for heating tortillas and cooking meat. Finally, the assembly area needs to be right by the service window for a speedy hand-off. It’s that simple.

Optimizing Movement and Efficiency

Once your zones are mapped out, it's time to fine-tune the small movements within them. Think about how your team will actually use the space. You need enough room for two people to pass without doing that awkward sideways shuffle—a minimum of 36 inches for main pathways is a good standard.

Place your most-used smallwares—tongs, spatulas, squeeze bottles—within arm's reach of their stations to cut down on time spent searching. Every second you shave off adds up big time over a lunch rush. Honing this skill is what separates the good trucks from the great ones. For more practical advice, check out our guide on how to improve workplace efficiency to squeeze even more performance out of your layout.

By meticulously planning this journey from ticket to customer, you’re building the foundation for a smooth, fast, and seriously profitable operation.

Choosing The Right Equipment and Making It Fit

The equipment you choose is the real heart of your food truck layout. It directly controls your workflow, how fast you can serve, and what you can even put on your menu. Picking the right gear isn't just about finding something that fits in the space—it's about arming your crew with the tools they need to pump out amazing food, even when you're slammed.

Think of it as a constant balancing act between an appliance's power, its footprint, and its overall usefulness. A high-volume burger joint needs a beast of a griddle, while a wing truck lives and dies by its high-capacity fryers. Every single piece of equipment has to earn its spot on the truck.

The sheer variety of successful food truck concepts out there proves just how adaptable—and profitable—this business can be. In 2025, the average food truck in the U.S. brought in a reported $346,000 in revenue, a testament to how these mobile kitchens can be tailored to almost any cuisine.

Maximizing Your Vertical and Floor Space

On a food truck, every inch is prime real estate. Wasting space is like throwing money out the window. The best layouts are masters of using both horizontal and vertical space.

The easiest win? Think up. Wall-mounted shelving is non-negotiable. It gets your dry goods, small containers, and other supplies off your valuable prep surfaces, giving your team room to actually work without swimming in clutter.

For your floor plan, under-counter refrigeration is an absolute game-changer. These units pull double duty, giving you cold storage and a functional worktop in one footprint. This opens up floor space a normal fridge would hog, giving you a wider, safer walkway or even room for another piece of cooking equipment.

The goal is to build up, not out. By using shelving and under-counter units, you create clear, open work zones. This makes the truck feel larger and helps your staff move more freely and safely during a chaotic rush.

Understanding Prep Table Essentials

Your stainless steel prep tables are the unsung heroes of your entire operation. They're where every single dish gets chopped, mixed, and plated. Picking the right ones is fundamental to an efficient layout.

Types of Stainless Steel Prep Tables:

- Standard Work Tables: These are your basic workhorses, offering a simple, tough surface. Look for models with an open undershelf for invaluable extra storage, or enclosed base tables for a cleaner look.

- Tables with Backsplashes: A built-in backsplash is a small feature with a huge impact. It prevents food and liquids from splashing onto the wall, which simplifies cleanup and helps maintain a hygienic workspace.

- Mobile or Wheeled Tables: For layouts requiring flexibility, a table on casters is a major asset. You can easily roll it aside for deep cleaning or reposition it to adapt your workflow for special events or menu changes.

- Sandwich Prep Tables: These units are efficiency powerhouses. They combine refrigerated storage in the base with chilled wells on top for holding ingredients, all topped with a cutting board work surface. This allows staff to assemble sandwiches, salads, or burritos in one spot without moving.

- Pizza Prep Tables: A must for any mobile pizzeria, these tables feature a wide, flat surface for stretching dough and a refrigerated rail along the back to hold sauces, cheeses, and toppings. This creates a perfect, streamlined pizza-building station.

Investing in the right type of prep table is one of the most significant things you can do to boost your output. For more ideas on outfitting your truck, check out our comprehensive list of essential food truck kitchen equipment.

Here’s a quick look at how your equipment needs can change based on what you’re serving.

Cooking Equipment Comparison for Common Food Truck Concepts

This table breaks down the core cooking gear for a few popular food truck ideas. Use it to start thinking about what appliances you need to prioritize and where they'll fit into your workflow.

| Food Truck Concept | Essential Cooking Equipment | Key Placement Consideration |

|---|---|---|

| Taco Truck | Flat-top Griddle, Charbroiler, Fryer, Steam Table | Griddle and charbroiler should be side-by-side for a seamless cook-to-assemble workflow. Steam table near the service window. |

| Burger Joint | Large Flat-top Griddle, Deep Fryer, Charbroiler | The griddle is the centerpiece. Place it centrally with fryers nearby to coordinate burger and fry orders simultaneously. |

| Pizza Truck | Pizza Oven (deck or conveyor), Pizza Prep Table | The oven is the focal point and heat source; ensure proper ventilation. The prep table should be directly adjacent to the oven. |

| BBQ Rig | Smoker, Holding Cabinet, Charbroiler, Fryer | The smoker is often external or at one end. The holding cabinet needs to be near the cutting/assembly station for efficiency. |

Choosing the right combination of equipment isn't just a logistical puzzle; it's a strategic decision that will define your truck's success day in and day out.

The Critical Role of Your Prep Table Station

If your cooking line is the heart of your food truck, then the prep station is its brain. This is command central. It's where raw ingredients get transformed into the dishes your customers line up for, and the foundation of this entire zone is your stainless steel prep table.

Picking the right table is a decision that ripples through your entire operation, affecting workflow, speed, and ultimately, your sanity during a rush. A solid prep table gives you an organized, tough, and hygienic workspace that can handle the relentless pace of a busy service. It's more than just a surface; it's the hub of your production line.

Navigating Standard Stainless Steel Prep Tables

When you start shopping, you’ll quickly see a few standard designs pop up. Each one is built for different kitchen needs, so think hard about how you’ll actually use it day in and day out.

-

Tables with Undershelves: This is the workhorse of most food trucks for a reason. That open undershelf is gold for storing bulk items like bags of flour, big containers of oil, or small appliances like a stand mixer or food processor. It keeps your floor clear and your most-used items just a reach away.

-

Tables with Backsplashes: A built-in backsplash might seem like a small detail, but it has a huge impact on cleanliness. That little raised edge stops food, liquids, and all kinds of gunk from splashing onto the wall. Not only does this make cleanup way faster, but it’s also a feature that health inspectors absolutely love to see.

The global food truck market is booming, projected to hit $7.87 billion by 2030. That growth is all thanks to people craving unique, high-quality street food. To get a piece of that pie, you have to be fast and efficient. Your layout, built around a smart prep station, is your ticket in. You can dig into the numbers in the full food truck market report.

Why Steel Gauge Is a Big Deal

You'll see terms like "16-gauge" or "18-gauge" thrown around. This number tells you how thick the steel is, and it’s a direct indicator of how much abuse it can take. Here's the trick: the lower the gauge number, the thicker and stronger the steel.

For the chaos of a food truck kitchen, 16-gauge is what you want for your main work surfaces. It's beefier, resists dents and dings, and won't bow when you load it up with heavy equipment. While 18-gauge is a little thinner, it's still a perfectly solid, budget-friendly choice for lighter-duty tasks or secondary prep areas.

Revolutionize Your Workflow with Specialized Prep Tables

For a lot of food truck menus, upgrading to a specialized refrigerated prep table is the single biggest leap in speed you can make. These units are brilliantly designed to mash cold storage, a cutting board, and a work surface into one compact, super-efficient station.

They create a true assembly line. When all your ingredients are chilled and right in front of you, your team can build orders in a fraction of the time it takes to run back and forth to a separate fridge.

Investing in a refrigerated prep table isn't just buying equipment; it's buying time. The seconds you save on every single order translate directly into more customers served per hour and, ultimately, higher profits.

Sandwich and Salad Prep Tables

If your menu is all about sandwiches, salads, burritos, or bowls, a sandwich prep table is pretty much non-negotiable. These units have a refrigerated base with a worktop that’s lined with chilled wells or pans.

You load those pans with all your cold ingredients—meats, cheeses, lettuce, tomatoes, sauces—and they stay safely chilled right where you need them. Most also have an integrated cutting board running the full length, creating the perfect linear station to build an order from start to finish.

Pizza Prep Tables

For any mobile pizzeria, a pizza prep table is the undisputed champion. These are designed with an extra-deep work surface, giving you plenty of room to stretch dough. But the real magic is the raised, refrigerated rail along the back.

This rail holds all your pizza toppings—sauce, cheese, pepperoni, veggies—in chilled pans. Your pizza maker can stand in one spot, stretch the dough, top it, and slide it into the oven without taking more than a step. It’s that kind of focused workflow that lets a tiny team pump out dozens of pizzas an hour.

To help you sort through the options, here’s a quick comparison of the different prep table styles you'll encounter.

Types of Stainless Steel Prep Tables for Food Trucks

Choosing the right prep table isn't just about filling a space; it's about matching the equipment to your menu and workflow. A taco truck has very different needs than a mobile bakery. This table breaks down the most common types to help you find the perfect fit.

| Table Type | Primary Use Case | Key Feature | Best For |

|---|---|---|---|

| Standard with Undershelf | General chopping, mixing, and assembly. | Open lower storage for bulk goods. | All food truck concepts needing basic, versatile workspace. |

| Table with Backsplash | Prep against a wall where splatter is likely. | Raised edge to protect walls and ease cleaning. | High-volume prep, especially with liquids or messy ingredients. |

| Sandwich/Salad Prep Table | Assembling sandwiches, salads, burritos, bowls. | Refrigerated wells for cold ingredients on top. | Delis, taco trucks, salad concepts, and sandwich shops. |

| Pizza Prep Table | Building pizzas from scratch. | Wide surface with a raised refrigerated topping rail. | Any truck serving fresh-made pizzas. |

Ultimately, the best prep table is the one that makes your job easier, faster, and cleaner. By thinking through your daily tasks first, you can invest in a piece of equipment that will pay for itself in saved time and smooth service.

Designing for Safety and Health Code Compliance

Let’s be honest: a killer food truck layout means nothing if it can't pass a health inspection. Getting this right isn't just about ticking boxes on a form. It's about building a professional kitchen on wheels that keeps your customers, your crew, and your entire business safe from the get-go.

Health inspectors are laser-focused on one thing: preventing foodborne illness. This means every inch of your layout has to support clean, safe food handling. Thinking about compliance from day one isn't a chore—it's the bedrock of a mobile food business that's built to last.

Mastering Sinks and Surfaces

The very first thing an inspector will check is your sink setup. You absolutely need separate, dedicated sinks for different jobs, and where you put them is a huge deal for both workflow and compliance.

- Hand-Washing Sink: This one is non-negotiable. It’s only for washing hands, period. It needs to be super accessible to anyone prepping or cooking, and always stocked with soap and paper towels. A great spot is right near the start of your prep line to encourage constant use.

- Three-Compartment Sink: This is your warewashing workhorse for washing, rinsing, and sanitizing every tool, pan, and piece of equipment. The order is set in stone, and the sink itself must be big enough to completely submerge your largest stockpot.

- Food Prep Sink: Planning to wash fresh produce? You'll likely need a fourth sink just for that. Keeping it separate is key to stopping cross-contamination in its tracks.

Beyond the sinks, every surface in your truck has to be non-porous, smooth, and easy to clean. This is why stainless steel is king. It’s the industry standard for a reason—it’s tough, won’t react with food, and you can sanitize it effectively. It’s the only real choice for your walls, counters, and shelving.

Critical Ventilation and Hood Systems

Cooking in a tight space creates a ton of heat, smoke, and greasy air. A properly sized and installed ventilation hood isn't a luxury; it's a massive fire safety and air quality requirement everywhere.

Your hood needs to hang over all your heat-producing gear—fryers, griddles, you name it. It has to be powerful enough to suck all those vapors out, which means pairing it with the right exhaust fan. You’ll also need to clean the hood and its filters religiously to prevent grease buildup, which is a primary cause of food truck fires.

One of the most common and expensive mistakes I see is an undersized or poorly placed hood system. It's not just a code violation; it's a serious fire hazard that puts your whole dream at risk.

Fire Safety and Egress Essentials

Fire safety is no joke in the close quarters of a mobile kitchen. Your layout must include a few critical features to meet fire codes and make sure everyone can bail out fast in an emergency.

You'll need at least one Class K fire extinguisher right on the cooking line, specifically for grease fires. You'll also need one or more Class ABC extinguishers for other types of fires, placed near the exits. Make sure they’re all professionally inspected and tagged every year.

Finally, keep your egress paths clear. This means no clutter in the walkways and ensuring all your doors can be opened easily from the inside without a key. Most codes require at least 36 inches of clear width in main pathways. Building these safety features into your layout from the start will save you from major headaches and get you on the road safely and legally.

Choosing the Right Stainless Steel Prep Tables

Think of your prep tables as the heart of your food truck kitchen. This is where every single order gets its start, so picking the right stainless steel surfaces is a massive deal for your speed, cleanliness, and overall workflow.

You'll see everything from simple work tables to fancy refrigerated units out there. The choice you make isn't just about filling a space; it's about investing in gear that directly helps you sling food faster. And yes, the material is a no-brainer—it has to be stainless steel. Its non-porous surface is the industry gold standard for a reason.

Breaking Down the Different Prep Table Styles

Not all stainless steel is created equal, and the same goes for the tables themselves. In the tight quarters of a food truck, you need every piece of equipment to pull double duty.

A standard work table with an undershelf is your foundational piece. It's more than just a surface; that bottom shelf is invaluable for stashing bulk ingredients, containers, or small appliances, keeping precious floor space from getting cluttered.

If you're placing a table against a wall, opting for one with an integrated backsplash is one of the smartest small upgrades you can make. That little lip keeps food and liquids from splashing onto the wall, making cleanup a breeze and keeping the health inspector happy. Pay attention to the steel's thickness, too. For heavy-duty chopping or high-traffic areas, 16-gauge steel is tougher and more resistant to dings than the more common 18-gauge.

Getting Specialized for Maximum Speed

This is where you can really start to optimize your food truck layout. Specialized tables that combine prep space with refrigeration are absolute game-changers, cutting down on wasted steps and streamlining your entire process.

A refrigerated prep table isn't just a piece of equipment; it's an investment in speed. When all your cold ingredients are right there, you shave precious seconds off every single order. During a busy lunch rush, those seconds add up to more sales.

Take a look at these two workhorses:

-

Pizza Prep Tables: These are a must for any mobile pizzeria. They're built with an extra-deep workspace for stretching dough and a raised, refrigerated rail that keeps all your toppings perfectly chilled and within arm's reach. One person can build and fire off pizzas in a single, fluid motion.

-

Sandwich Prep Tables: If you're building sandwiches, salads, or burritos, this is your assembly line. They have refrigerated wells built right into the countertop for meats, cheeses, and veggies, often paired with an integrated cutting board. It creates a self-contained station that massively increases how many orders you can push out.

At PrepTables.com, we stock the durable, NSF-certified stainless steel and refrigerated prep tables you need to build a fast, efficient, and compliant food truck kitchen. Explore our full collection of commercial-grade equipment today.