Food Truck Kitchen Equipment Your Essential Guide

Share

Kitting out a food truck is a huge undertaking, and your success often comes down to the gear you choose. Think of it less like shopping and more like building a high-performance engine in a tiny space. The right equipment is the foundation for everything—from nailing your menu during a hectic lunch rush to sailing through your next health inspection.

Building Your Food Truck Kitchen From The Ground Up

Let's be real: your mobile kitchen is a complex machine. To get it right, we need to break it down into its core components—cooking, cooling, prepping, and safety. Each piece has a job to do, and they all need to work together seamlessly so you can serve customers without a single hiccup.

This isn't just about convenience; it's smart business. The global food truck market is exploding and expected to hit USD 7.5 billion by 2032. This boom is fueled by diners craving unique eats and entrepreneurs drawn to the lower startup costs. You’re looking at an investment between USD 50,000 to USD 200,000, a fraction of the multi-million dollar price tag for a traditional restaurant. You can dig deeper into these numbers and market growth trends on PersistanceMarketResearch.com. This growth just proves how critical it is to invest in compact, tough, and efficient equipment from day one.

The Three Core Kitchen Zones

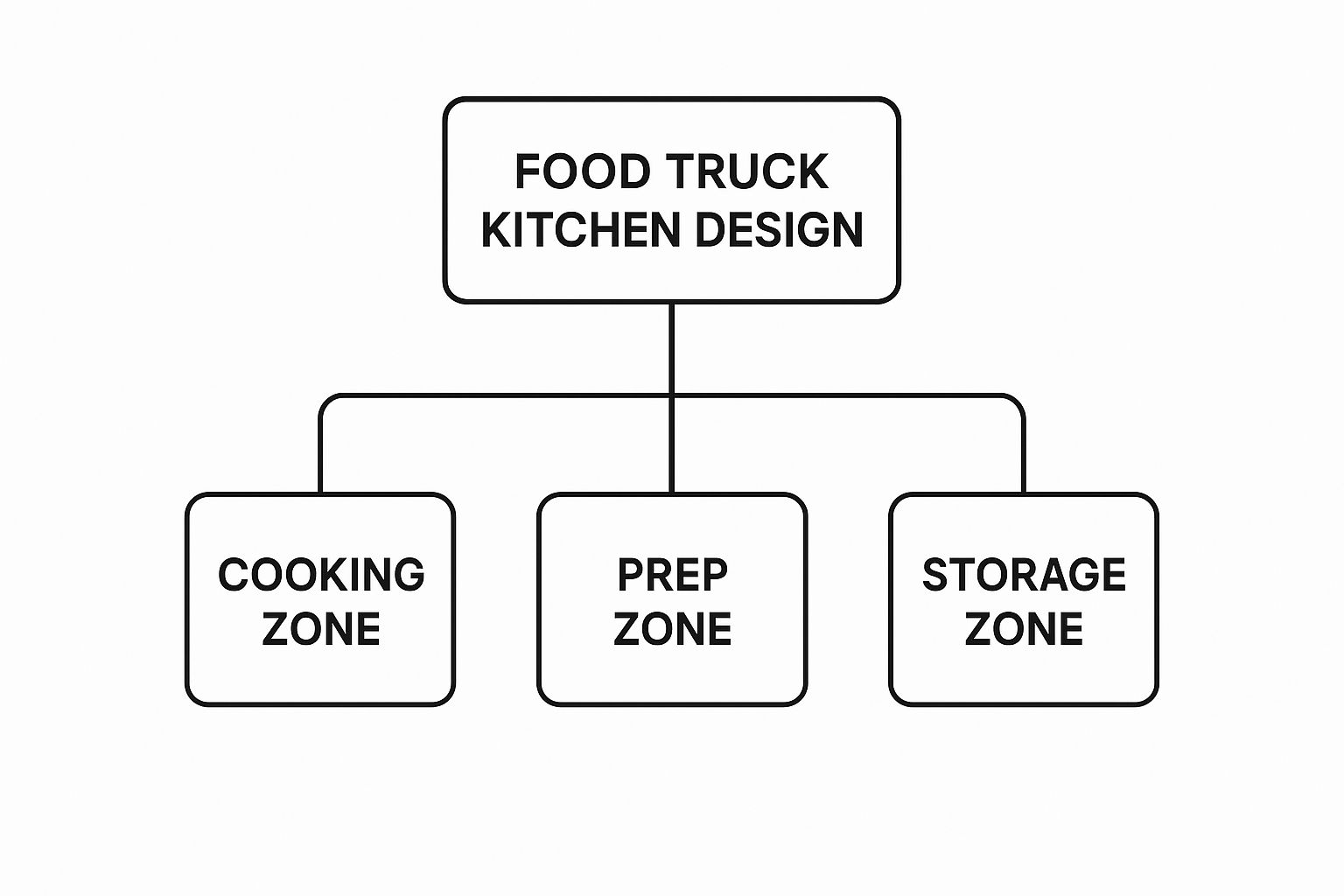

A well-oiled food truck kitchen isn't just a random collection of appliances. It's carefully organized into distinct zones to make your workflow smooth and safe. Once you visualize the space this way, you'll see exactly how every piece of equipment fits into the puzzle.

This image breaks down the three fundamental zones of a food truck kitchen.

As you can see, every tool has a home, whether it’s for searing burgers, chopping veggies, or keeping ingredients ice-cold.

An organized layout isn't just about looking tidy—it's about speed. When you split your kitchen into Cooking, Prep, and Storage zones, you create a natural flow. This simple strategy cuts down on crossover, eliminates clutter, and helps your team pump out orders faster than ever.

To get started, it helps to think in terms of broad categories. The table below gives you a quick snapshot of the essential equipment groups, what they do, and a few examples you'll find in almost any successful food truck.

Core Equipment Categories For Your Food Truck Kitchen

| Equipment Category | Primary Function | Example Appliances |

|---|---|---|

| Cooking Equipment | Applying heat to prepare menu items. | Griddles, Charbroilers, Deep Fryers, Ranges |

| Refrigeration | Keeping ingredients at safe, cool temperatures. | Undercounter Refrigerators, Prep Tables, Freezers |

| Prep & Storage | Providing space for food assembly and organization. | Stainless Steel Tables, Sinks, Shelving |

| Safety & Sanitation | Ensuring compliance and a safe work environment. | Ventilation Hoods, Fire Suppression, Hand Sinks |

Think of this table as your initial checklist. It’s the framework you’ll use to make smart, informed decisions on every piece of equipment you buy for your new mobile kitchen.

Choosing Your Cooking And Refrigeration Powerhouses

Think of your menu as a promise you make to your customers. Your cooking and refrigeration gear? That’s how you keep it. Picking the right appliances goes way beyond just looking at features; it's about finding reliable partners that can take the heat of a crazy lunch rush and survive the bumps in the road. These machines are the beating heart of your entire mobile kitchen.

Honestly, the equipment you need is almost completely dictated by what you're serving. A truck slinging smash burgers has a totally different shopping list than one dishing out fresh, hot donuts. Getting this right is a huge factor in your success, because the right gear means you can pump out consistently awesome food, fast.

Deciding on Your Cooking Core

Your first big fork in the road is choosing between propane and electric cooking equipment. This one decision ripples out to affect everything from your daily running costs to where you can physically park and serve.

-

Propane: This is the old-school, go-to choice for most food trucks, and for good reason. It delivers powerful, instant heat that’s perfect for griddles and fryers. Best of all, propane is self-contained. You aren’t tethered to an outlet, which gives you incredible freedom. The trade-off? You have to budget for refilling tanks and follow strict safety rules for hauling flammable gas.

-

Electric: On the other hand, electric appliances like induction cooktops are gaining a lot of ground. They're praised for their clean energy and incredibly precise temperature control. Plus, with no open flames, they can be a safer option. The big catch is their massive power hunger. You’ll need a seriously powerful generator or guaranteed access to shore power, which can really limit your location options.

For many operators, the answer is a hybrid setup. You might run a high-heat beast like a griddle on propane but use electric for smaller gear like food warmers. It’s all about finding your personal balance of mobility, power, and cost.

Specialized Cooking Equipment for Your Menu

Once you've landed on a power source, it's time for the fun part: picking the actual appliances. These are the workhorses that will bring your menu to life.

-

Griddles & Flat Tops: If you're doing anything from pancakes and eggs to burgers and cheesesteaks, these are non-negotiable. Their huge, even cooking surface lets you juggle multiple orders at once, making them a true cornerstone for a ton of different concepts.

-

Charbroilers: Want that authentic, smoky flavor and those perfect grill marks on your steaks or burgers? A charbroiler is the only way to get it. It delivers a real-deal barbecue taste that a flat-top just can't touch.

-

Deep Fryers: For any truck built around french fries, donuts, or fried chicken, a commercial-grade deep fryer is an absolute must. Look for models with a fast recovery time—that means the oil gets back up to temperature quickly after you drop in cold food. This is the secret to getting a crispy, golden-brown finish, not a soggy, greasy mess.

Key Insight: Don't just buy the biggest, most powerful appliance you can find. I can't stress this enough: measure your truck's interior meticulously. A high-performance fryer that won’t fit through the door is just an expensive, stainless steel paperweight. Always balance what it can do with how much space it takes up.

Refrigeration That Can Handle the Road

Keeping your ingredients properly chilled is every bit as important as cooking them correctly. But you can't just throw any old fridge in a food truck. These units have to be tough enough to handle constant vibration and fluctuating outside temperatures.

Undercounter refrigerators are the undisputed champs of space efficiency. They slide right under your prep counters, putting cold ingredients exactly where your hands need to be. This kind of ergonomic setup is what separates a smooth, fast workflow from a chaotic one. If you have bigger storage needs, a tall, skinny reach-in refrigerator could be the better call.

When you're shopping, hunt for units specifically rated for mobile use. These "mobile-rated" fridges often have tougher compressors, reinforced door latches, and a sturdier build designed for life on the move. They might cost a bit more upfront, but they'll save you a fortune in spoiled food and service calls down the line, protecting both your bottom line and your reputation.

Of course, your stainless steel work surfaces are just as vital, giving you a clean, tough space for all your prep. To get a better feel for what makes a quality surface, you can learn more about restaurant stainless steel tables and what they bring to the table.

Selecting Prep Tables That Maximize Your Workflow

In a food truck, your prep table isn’t just a piece of metal. It's the command center. It’s where your ingredients are transformed, and where your entire service rhythm is either made or broken. Picking the right one isn't about just finding something that fits the space—it's about choosing a partner that actively makes you faster and more efficient.

Think of it as the stage for your culinary show. A bad one creates traffic jams and slows you down. The right one can feel like having an extra pair of hands on deck. The goal here is to build a powerful, ergonomic assembly line inside the four walls of your truck.

Understanding Stainless Steel Prep Tables

When you think of any professional kitchen, you're picturing stainless steel. There's a good reason it's the industry gold standard: it's tough as nails, non-porous (so bacteria has nowhere to hide), and a breeze to sanitize. That last point is a big one for keeping the health inspector happy.

- Standard Work Tables: These are your basic, no-frills workhorses. Just a simple, flat top for all your chopping, mixing, and plating. Most come with an undershelf for storage, which is a lifesaver in tight quarters.

- Tables with Backsplashes: That small raised edge along the back of the table is a game-changer. It stops ingredients and liquids from falling into the gap behind your equipment, keeping your truck cleaner and preventing lost utensils.

- Enclosed Base Tables: These tables swap the open undershelf for a cabinet with sliding or hinged doors. This is a great way to store extra equipment or dry goods, keeping everything protected from dust and spills.

Think of your prep table like the deck of a ship—it has to withstand a constant assault from sharp knives, heavy pans, and endless wipe-downs. Investing in a thicker gauge and higher-grade steel is like building that deck to weather any storm, protecting you from dents, rust, and the headache of a premature replacement.

Specialized Prep Units for Ultimate Efficiency

While every truck needs a standard work table, specialized prep tables can be total game-changers for your workflow, especially if your menu leans a certain way. These units have refrigeration built right in, putting all your cold ingredients at your fingertips.

-

Sandwich Prep Tables: If you're slinging sandwiches, wraps, or salads, a sandwich prep table isn't a "nice to have," it's a must-have. They have a refrigerated base with a rail of cold wells on top, perfectly sized for standard food pans. Right in front of those wells is a deep cutting board that runs the length of the table, giving you a dedicated space for assembly. This all-in-one setup creates a self-contained station where one person can build an entire order without taking more than a step.

-

Pizza Prep Tables: A pizza prep table is an absolute necessity for any mobile pizzeria. They are engineered specifically for the pizza-making process, with a deeper refrigerated rail for larger topping pans and a much wider cutting board. That extra depth is non-negotiable for stretching dough and building large pizzas without making a mess. A good pizza prep table makes the whole process cleaner, faster, and lets you pump out more pies during the dinner rush.

Choosing the right type of table is a critical decision. You can explore more options in our prep tables buying guide to find the perfect fit for your menu.

Installing Ventilation And Safety Systems You Can Trust

Let's talk about the unsung heroes of your food truck: the safety systems. While your shiny new griddle gets all the attention, it’s the equipment humming quietly in the background that truly protects your business, your people, and your investment. These systems aren't just a good idea—they're legally required and your first line of defense against the very real risks of cooking in a small, mobile space.

Getting this right is crucial, especially in a booming market. The U.S. food truck scene is projected to climb from USD 1.09 billion in 2025 to USD 1.51 billion by 2030. Trailers, which carry all this essential kitchen gear, represent over 43.3% of the market, thanks to their lower startup costs and flexibility. This growth puts a spotlight on the need for top-notch, reliable equipment. You can dig into more stats on this explosive growth with these U.S. food truck market insights from Mordor Intelligence.

Understanding Commercial Kitchen Hoods

Your commercial kitchen hood is arguably the single most important piece of safety gear in your entire truck. Think of it as the lungs of your kitchen. Its whole job is to suck up dangerous, grease-laden vapor, smoke, and blistering heat from your cooktop and vent it safely outside.

Without a working hood, grease coats every surface, creating a massive fire hazard. The heat and smoke would quickly make the tight space of a truck kitchen unbearable and flat-out dangerous for your crew. That’s why every health department in the country makes a proper commercial hood system a non-negotiable requirement.

For a food truck, you'll almost certainly need a Type 1 hood. These are built specifically to handle grease and are installed right over your fryers, griddles, and charbroilers. A low-profile or "concession" hood is usually the perfect fit, designed to work powerfully in the low-ceiling, compact environment of a mobile kitchen.

Automatic Fire Suppression: The Ultimate Guardian

Think of an automatic fire suppression system as your silent, on-duty firefighter. It's a network of nozzles built right into your ventilation hood, all pointed directly at your cooking appliances. If a grease fire ever flares up, the system instantly detects the spike in heat and smothers the flames with a specialized fire-retardant chemical.

This isn't an optional upgrade; it's required by law in pretty much every jurisdiction. It works hand-in-hand with your hood to neutralize the biggest threat to your business.

A fire can gut a food truck in minutes. An automatic suppression system reacts in seconds, often killing a fire before it can even spread. It's the most critical safety investment you'll make, protecting your livelihood when you need it most.

Completing Your Safety Framework

While the hood and suppression system do the heavy lifting, a truly safe setup includes a few other key players. These pieces work together to make sure you're ready for anything and fully compliant with regulations.

- Fire Extinguishers: You absolutely need at least one Class K fire extinguisher, which is made for grease fires. You’ll also need a standard ABC extinguisher for other types of fires (paper, electrical, etc.).

- Gas Line Integrity: If you're running on propane, your gas lines must be installed by a certified professional and checked for leaks regularly. A faulty gas line is a catastrophic risk waiting to happen.

- First-Aid Kit: It's a kitchen. Cuts and burns will happen. A well-stocked first-aid kit is essential for handling minor injuries on the spot.

These safety systems are the foundation of any professional food truck. By investing in reliable, compliant equipment from the start, you’re building a secure workplace where your team can focus on what they do best: cooking incredible food.

Designing A Compliant Water And Sanitation System

Think of your water and sanitation system as the unsung hero of your food truck. It’s the behind-the-scenes workhorse that’s absolutely critical for food safety, but it's also one of the most common reasons trucks fail health inspections. Getting this right isn't just about ticking a box for the health department; it's about making sure your business can actually stay open and run without a hitch.

When an inspector steps on your truck, one of the first things they'll look at are your sinks. The universal, non-negotiable rule is a three-compartment sink for washing dishes and a totally separate hand-washing sink. This isn't just some bureaucratic red tape—it's a core food safety rule designed to keep germs from dirty dishes far away from clean hands.

Sizing Your Water Tanks Correctly

One of the biggest decisions you'll face is choosing the right size for your freshwater and greywater tanks. Go too small with your freshwater tank, and you’ll be shutting down in the middle of a busy lunch rush. If your greywater tank is too small, it'll overflow, creating a disgusting, unsanitary mess nobody wants to deal with.

A few key things will dictate your tank size:

- Your Menu: A coffee truck churning out lattes is going to burn through a lot more water than a truck selling pre-packaged ice cream bars.

- Service Volume: The more customers you serve, the more you'll be washing hands, rinsing produce, and cleaning utensils.

- Local Health Codes: This is the big one. Many health departments have minimum tank sizes. They almost always require your greywater tank to be at least 15% larger than your freshwater tank to create a safety buffer and prevent overflows.

As a general rule of thumb, a 30-gallon freshwater tank and a 42-gallon greywater tank is a decent starting point. But always, always check your local health department's specific requirements first. They have the final say, and building to their specs from the start will save you from expensive and frustrating fixes down the road.

Essential System Components

Beyond the big tanks and sinks, a few other parts are absolutely necessary to get your system working like a real kitchen. These components all work together to give you hot and cold running water on demand.

You'll need a solid water pump to pressurize the lines and give you good, strong water flow at the faucet. A water heater is also a must-have. It needs to be powerful enough to deliver water at the temperatures your health department requires, which is often around 100°F for hand-washing sinks.

That three-compartment sink is the heart of your cleaning station. Each basin has a specific job: one for washing, one for rinsing, and a third for sanitizing. Getting this setup right is make-or-break for passing inspections. To dig deeper, check out our guide covering the essentials of a three-bay commercial sink. This is the system that allows you to operate cleanly, avoid shutdowns, and serve your customers with confidence.

Alright, let's ditch the robotic tone and get real about setting up your food truck kitchen. This isn't just about cramming gear into a box; it's about creating a space that works as hard as you do.

Creating A Food Truck Layout For Peak Efficiency

So, you've got all the right kitchen equipment. That's a great start, but it's only half the story. The real secret sauce is how you arrange it all. A smart layout is what transforms your tiny metal box into a lean, mean, money-making machine.

The goal is simple: create a kitchen where every step, every turn, and every reach has a purpose. When you get it right, your team moves faster, works smarter, and can absolutely crush the lunch rush without breaking a sweat.

Think of it this way: the food truck world is booming. With 68% of the world's population expected to live in cities by 2050, the hunger for quick, quality street food isn't going anywhere. The market is projected to grow like crazy—between 7% and 11% annually from 2025 to 2030. To grab your piece of that pie, you need more than a great menu. You need an intelligent layout. If you're curious, you can discover more about how global trends are shaping the food truck industry and pushing kitchen design forward.

Proven Layouts For Mobile Kitchens

While your truck has its own quirks, most winning layouts borrow from a few battle-tested concepts. These designs are all about creating a logical flow for the food, from raw ingredients to the final dish handed out the window. It’s all about cutting down on wasted movement and confusion.

-

Assembly Line Layout: The undisputed classic. You arrange your equipment in the same order you build your food. For a burger truck, it’s a straight shot: fridge (patties/buns) → griddle (cooking) → prep station (toppings/sauce) → service window. It’s incredibly intuitive and perfect for menus where every item follows a similar path.

-

Zone-Based Layout: This is for trucks with a more varied menu. You create specific "zones" for different tasks—a prep zone, a cooking zone, a finishing zone, and a cleaning zone. This way, one person can be frying fries while another is building a sandwich, and neither is bumping into the other. It keeps everyone in their own lane.

Ergonomics And Minimizing Wasted Motion

Ever heard of ergonomics? It’s just a fancy word for designing a workspace that fits the worker, not the other way around. In a food truck, it means putting the things you use most often right where you can grab them without thinking. It’s like the "golden triangle" in a home kitchen (sink, stove, fridge), but adapted for life on four wheels.

Your real enemy is the unnecessary step. If your cook has to walk two feet to grab a spatula or turn completely around to get toppings from another fridge, you're bleeding precious seconds on every single order. Those seconds add up fast, and during a rush, they represent real money walking away.

The trick is to arrange your kitchen so everything vital is just an arm's pivot away. This isn't just about speed; it's about stamina. A well-designed space reduces physical strain, which means less burnout and a team that can stay sharp and fast through a long, busy shift.

Maximizing Every Inch With Smart Storage

Finally, an efficient layout squeezes every last drop of usefulness out of your space—especially the vertical space. You know your floor space is limited, but what about your walls? Or under the counters? That's prime real estate.

Get creative with these storage ideas:

- Wall-Mounted Shelving: Get your spices, dry goods, and go-to utensils up and out of the way, right above your prep counters.

- Magnetic Knife Strips: They keep your knives safe, sharp, and instantly accessible without cluttering up a drawer or countertop.

- Custom Cabinetry: It's a bigger investment upfront, but cabinets built specifically for your containers and small appliances mean zero wasted space. Everything has its perfect home.

- Undercounter Storage: The area below your prep tables and sinks is a goldmine. It's the perfect spot for bulk ingredients, cleaning supplies, and anything else you don't need in your immediate line of sight.

By blending a logical workflow with smart ergonomics and clever storage, you're not just organizing equipment. You're building a high-performance engine designed for pure profit.

Your Food Truck Equipment Questions Answered

Let's be honest, figuring out your food truck kitchen can feel like a puzzle, especially when you get to the prep tables. These aren't just surfaces; they're the heart of your operation. It’s where every single order gets its start. Making the right call here means setting yourself up with a workspace that's tough, efficient, and easy to keep clean, no matter what the dinner rush throws at you.

Think of your prep table as another crew member. A bad one just gets in the way and slows everything down. The right one? It makes the whole workflow smoother and faster.

The Different Kinds Of Stainless Steel Prep Tables

In any professional kitchen, stainless steel is the only real choice, and for good reason. The stuff is built to last, a breeze to sanitize, and won't rust on you. But not all stainless steel is created equal. The type you pick will absolutely affect how well it holds up over time.

You've got a few options, and each one is built for different kinds of work and budgets.

-

Standard Work Tables: These are your basic, no-frills workhorses. Just a simple, flat top for all your chopping, mixing, and plating. Most will come with an undershelf for storage, which is a lifesaver when you're working in the tight quarters of a food truck.

-

Tables with Backsplashes: It might seem like a small detail, but that little raised edge along the back of the table is a game-changer. It stops ingredients, liquids, and utensils from falling into that black hole behind your equipment. This keeps your truck cleaner and saves you the headache of fishing out a lost knife.

-

Enclosed Base Work Tables: These tables swap the open undershelf for a cabinet with sliding or hinged doors. It's a fantastic way to store extra equipment or dry goods, keeping everything protected from dust and spills while giving your kitchen a much tidier look.

When you're looking at a standard table, pay attention to the steel gauge. It's simple: a lower number means the steel is thicker and stronger. A heavy-duty 14 or 16-gauge table can take a beating and resist dents way better than a flimsy 18-gauge model. For a busy food truck, it's a smart investment that pays off in the long run.

Specialized Refrigerated Prep Tables

While every truck needs a standard work table, a specialized prep table with built-in refrigeration can seriously level up your efficiency. These units combine your cold storage and prep space into one powerhouse station.

Sandwich and Pizza Prep Tables

Sandwich prep tables are engineered for speed. They have refrigerated wells right on top to hold all your toppings, keeping everything chilled and right at your fingertips. A cutting board runs the length of the unit, creating the perfect assembly line for cranking out sandwiches, salads, or burritos without missing a beat.

In the same vein, pizza prep tables are custom-built for slinging pies. They come with a wider and deeper refrigerated rail to handle bigger pans of toppings and a much bigger cutting board. That extra real estate is crucial when you're stretching dough and building pizzas, making the whole process quicker and less messy.

At PrepTables.com, we get it—the right gear is everything for a successful mobile kitchen. We’ve got a massive selection of tough stainless steel work tables, specialized sandwich and pizza units, and commercial refrigeration to help you build a food truck that’s ready for anything. Find the perfect equipment for your workflow at https://preptables.com.

Tackling food truck equipment for the first time brings up a lot of questions. To help you sort through it all, we've put together some quick answers to the things we hear most often from new owners.

Frequently Asked Questions About Food Truck Equipment

| Question | Answer |

|---|---|

| What's the most important piece of equipment for a food truck? | Beyond your cooking line, a high-quality stainless steel prep table is crucial. It's your primary workspace for everything, so its size, durability, and features (like an undershelf or backsplash) directly impact your daily efficiency. |

| Why is stainless steel gauge so important? | The gauge indicates the thickness of the steel. A lower number (14-gauge) is thicker and more durable than a higher one (18-gauge). For the constant abuse of a food truck environment, a lower gauge means fewer dents and a longer lifespan. |

| Do I really need a refrigerated prep table? | If your menu involves assembling cold items like sandwiches, salads, or tacos, then yes. A refrigerated prep table keeps all your ingredients safely chilled and within arm's reach, dramatically speeding up your service times. |

| How do I choose between a backsplash and a flat top table? | A backsplash prevents food and liquids from falling behind your equipment, making cleanup easier and more hygienic. If the table is against a wall, a backsplash is highly recommended. If it's an island, a flat top is fine. |

| Can I use a regular table instead of a commercial one? | It's not recommended. Commercial-grade tables are built to withstand heavy use, constant cleaning with harsh chemicals, and meet health code standards for sanitation. A residential table simply won't hold up. |

Hopefully, these answers clear up some of the basics. Choosing the right equipment from the start is one of the best investments you can make in your food truck's future.