How to Improve Workplace Efficiency in Your Kitchen

Share

If you want to make a real, immediate impact on your kitchen's efficiency, don't overthink it. The secret isn't some complex new workflow system. It’s right in front of you: the prep table. This single piece of equipment is the command center of your entire operation, setting the pace for everything that follows. Choosing the right one lays the groundwork for a faster, safer, and more productive kitchen.

The Real Foundation of Kitchen Efficiency

Think of your prep table as more than just a piece of furniture—it’s the heart of your kitchen. A well-designed stainless steel table can be the difference between a smooth service and a chaotic one, directly affecting everything from how quickly your team can prep to their comfort and safety. The right setup can eliminate bottlenecks and smooth out the entire journey from raw ingredients to plated dishes.

This isn't just a hunch; it's about making smart, targeted improvements. Globally, workplace productivity saw a tiny 0.4% bump in 2024, according to the OECD. But in the United States, where businesses often focus on these kinds of practical upgrades, productivity jumped by at least 1.5% in the same year. It shows that focusing on the core of your workspace pays off. You can dig into more employee productivity statistics to see just how much small, strategic changes can add up.

Understanding the Types of Stainless Steel Prep Tables

The classic stainless steel prep table is the undisputed workhorse of most commercial kitchens for a reason. It’s incredibly versatile. Available in a huge range of sizes and setups, these tables give you a flat, durable, and easy-to-sanitize surface that’s perfect for just about any task, from dicing onions to butchering proteins.

However, the world of prep tables goes far beyond a simple flat top. Several distinct types are designed to maximize efficiency for specific kitchen tasks:

- Standard Work Tables: These are the all-purpose champions. They often feature an undershelf for storage, a backsplash to keep walls clean, and adjustable feet for stability. Their simplicity is their strength, making them adaptable to any general prep need.

- Open Base Tables: Similar to standard tables but without an undershelf, these are designed to accommodate large, bulky equipment. You can easily slide a floor mixer or a large ingredient bin underneath, creating an integrated and space-saving workstation.

- Wall-Mounted Tables: For kitchens tight on floor space, these tables mount directly to the wall. They are excellent for light-duty tasks and make floor cleaning incredibly easy since there are no legs to work around.

- Mobile Tables (with Casters): Equipped with wheels, these tables offer maximum flexibility. They can be moved for easy cleaning or to reconfigure the kitchen layout on the fly, making them ideal for dynamic kitchen environments.

Specialized Workstations: Sandwich and Pizza Prep Tables

When you’re pumping out a high volume of specific items, a specialized table isn't a luxury—it's a necessity. These units are designed as all-in-one stations that cut wasted motion down to almost zero, which is a massive boost for workplace efficiency.

Take a sandwich prep table. It’s a brilliant combination of a cutting board work surface and refrigerated wells sitting right in front of the chef. Every filling—meats, cheeses, veggies—is chilled and right at their fingertips. No more walking back and forth to the walk-in.

A pizza prep table works on the same principle. It typically has a wide surface, often made of marble or kept refrigerated, that’s perfect for stretching dough. It also has refrigerated rails and compartments for all the toppings, so a cook can build an entire pizza without taking a single step. This kind of integrated design turns a complicated process into a smooth, assembly-line flow, which will slash your ticket times and let you serve more customers.

A good prep table isn't just a surface; it's a tool designed to solve specific problems in a busy kitchen. Choosing the right features can make a world of difference.

Here’s a quick breakdown of some essential features and how they directly contribute to a better workflow.

Key Prep Table Features for Maximum Efficiency

| Feature | Efficiency Benefit | Best For |

|---|---|---|

| Undershelf | Maximizes vertical storage, freeing up the main work surface. | General storage, small appliances, and ingredient bins in any kitchen. |

| Backsplash | Prevents spills and messes, protecting walls and simplifying cleanup. | Wet prep areas or stations placed against a wall. |

| Adjustable Feet | Ensures a stable, level work surface on uneven floors, improving safety. | Any kitchen environment, especially older buildings with uneven flooring. |

| Casters (Wheels) | Provides mobility, allowing for easy cleaning and kitchen reconfiguration. | Kitchens that require flexible layouts or frequent deep cleaning. |

| Refrigerated Rails | Keeps cold ingredients chilled and within arm's reach. | High-volume sandwich, salad, or pizza stations. |

Ultimately, matching the table’s features to your menu and workflow is the key to unlocking its full potential and making your entire operation run more smoothly.

Selecting the Right Stainless Steel Prep Table

It might seem like a simple decision, but picking a prep table has a huge ripple effect on your kitchen's entire flow. The small details between different tables can mean the difference between a smooth service and constant frustration. The right choice is a cornerstone of a well-run, productive kitchen.

Not all stainless steel is created equal. Your first big decision is the grade of the steel itself. You'll mostly run into two kinds: 430-grade and 304-grade.

Think of 430-grade as the workhorse for lighter-duty tasks. It's a solid, budget-conscious choice for dry storage areas or prep work that doesn't involve a lot of moisture. But when things get wet, you need to think a little differently.

For most food prep stations, especially near sinks, 304-grade steel is the smart investment. It has more nickel and chromium, which makes it far more resistant to rust and corrosion. Yes, it costs a bit more upfront, but its ability to stand up to the daily abuse of a busy, wet kitchen means you won't be replacing it prematurely. That's real long-term savings.

Matching Table Design to Kitchen Tasks

Beyond the steel, the table's physical form needs to match its function. The design you pick should directly support the job being done in that specific part of your kitchen.

Take a table with a backsplash, for instance. That simple raised edge is a game-changer for any table pushed against a wall. It stops food, liquids, and utensils from disappearing into that impossible-to-clean gap, which is a big win for sanitation and easy cleanup.

On the other hand, you have open-base tables. These don't have an undershelf, leaving the space underneath completely clear. This is the perfect setup for sliding large equipment underneath, like a 60-quart floor mixer or a big rolling ingredient bin. It lets you build an integrated workstation where everything is exactly where it needs to be.

The goal is to make every square inch of your kitchen work for you. Integrated features like undershelves turn unused vertical space into valuable storage, keeping your primary work surface clear and ready for action.

Specialized Tables for High-Volume Prep

When your menu is built on assembly-line dishes, a standard flat-top table can quickly become a bottleneck. This is where specialized workstations like sandwich prep tables and pizza prep tables can completely change your operation. These aren't just tables; they're self-contained productivity machines.

A sandwich prep table gives you a cutting board right next to refrigerated rails holding all your ingredients. Everything from meats and cheeses to veggies is chilled and right at the cook's fingertips. No more running back and forth to the walk-in. This slashes wasted movement and time.

To see all the possibilities, check out our guide on the different types of stainless prep tables.

Pizza prep tables work the same way. They have large, often refrigerated, surfaces perfect for stretching dough, with built-in cold wells for sauces and toppings. By putting all the components into one ergonomic station, your team can build pizzas faster and more consistently. An investment like this pays off directly in shorter ticket times, a higher capacity for orders, and a much calmer kitchen.

Specialized Tables for High-Volume Kitchens

When your kitchen’s success is built on churning out orders with speed and consistency, a simple flat-top table just won't cut it. It quickly becomes the biggest bottleneck in your operation.

If your menu is all about high-volume assembly—think sandwiches, salads, or pizzas—the secret to unlocking real efficiency is in specialized equipment. These units aren't just tables; they’re complete, self-contained workstations engineered to eliminate wasted movement and seriously boost your output.

Investing in one of these specialized tables essentially turns a chaotic, multi-step process into a streamlined assembly line. Instead of your staff running back and forth between a standard table and multiple coolers, every single component they need is integrated right into one ergonomic station. It’s a simple change that makes a massive difference in productivity.

This idea of focused, smarter work is popping up everywhere. A 2025 report mentioned that even though the average workday has gotten shorter by 36 minutes, overall productivity has actually climbed by 2%. It just goes to show that smarter, more concentrated work beats just putting in more hours. You can read more about how work patterns are evolving at eptura.com.

The Sandwich Prep Table Advantage

For any deli, café, or bustling lunch spot, the sandwich prep table is an absolute game-changer. Just picture a line cook trying to throw together a club sandwich during the lunch rush. With a standard setup, they're grabbing lettuce from one cooler, sliced turkey from another, and tomatoes from a third, all while dodging other staff in a packed kitchen. Every trip is wasted time.

A sandwich prep table kills that problem on the spot. It has refrigerated wells, often called "rails," built right into the top, holding all your cold ingredients in neat little pans. The cutting board is integrated directly into the workspace, and the refrigerated base below keeps all your backups chilled and ready.

This setup means a cook can plant themselves in one spot and pump out order after order with everything within arm's reach. The payoff is immediate:

- Drastically Reduced Ticket Times: When you cut out all those extra steps, you shave precious seconds off every single order. During a busy service, that adds up fast.

- Improved Food Safety: Ingredients stay at their optimal, food-safe temperature until the very moment they’re used, cutting down on spoilage and risk.

- Enhanced Consistency: A perfectly organized station means every sandwich gets made the exact same way, every single time.

Mastering High-Volume Pizza Production

The same exact logic applies to pizza prep tables. These are specifically engineered to create a perfect, seamless flow from a ball of dough to a finished pie ready for the oven. A typical pizza station can be a messy, chaotic affair. A specialized table brings some much-needed order.

These units almost always have a wider, deeper work surface—often made from marble or refrigerated steel—that’s perfect for stretching dough without it sticking. Raised, refrigerated rails hold all your essential toppings, from sauce and cheese to pepperoni and peppers. Below, a large refrigerated cabinet is ideal for storing dough boxes and backup ingredients.

By creating a dedicated, all-in-one pizza assembly line, you empower your team to handle massive order volumes without sacrificing quality or speed. This is how pizzerias maintain efficiency during the dinner rush.

At the end of the day, picking the right equipment is one of the most fundamental parts of running a successful kitchen. For a closer look at all your options, check out our complete guide to restaurant stainless steel tables and find the perfect fit for your menu.

Designing a Smarter Kitchen Workflow

Even the best prep table on the market can’t fix a chaotic kitchen. Real efficiency isn't about the gear you buy; it's about how you arrange your space to create a seamless, natural path for every task, from the moment ingredients come through the door to the final plate-up.

Think of it as adapting the classic "kitchen work triangle" for the high-stakes world of commercial kitchens. The goal is simple: create a direct, logical line from your walk-ins and dry storage to your prep tables, and then straight to the cooking line. Every single step you cut out is time saved and a potential collision avoided during the dinner rush.

Establishing Dedicated Work Zones

The secret to a smooth service is creating dedicated work zones built around your prep tables. If you have a station for chopping vegetables, it needs everything for that job right at arm's reach—knives, cutting boards, waste bins, the works. This simple setup stops chefs from having to crisscross the kitchen just to grab a tool, a common interruption that throws off everyone's rhythm.

When you create these self-sufficient zones, you drastically cut down on wasted movement and keep your staff laser-focused on their specific roles. That kind of clarity is a lifesaver when the kitchen floor feels more like a crowded highway during a busy service.

This isn't just kitchen theory; it's a proven business strategy. A recent study found that 44% of business leaders pointed to process and workflow optimization as a top priority for boosting efficiency. That's nearly on par with employee wellness (45%) and upskilling (51%). You can dive deeper into the latest productivity strategies over at myhours.com.

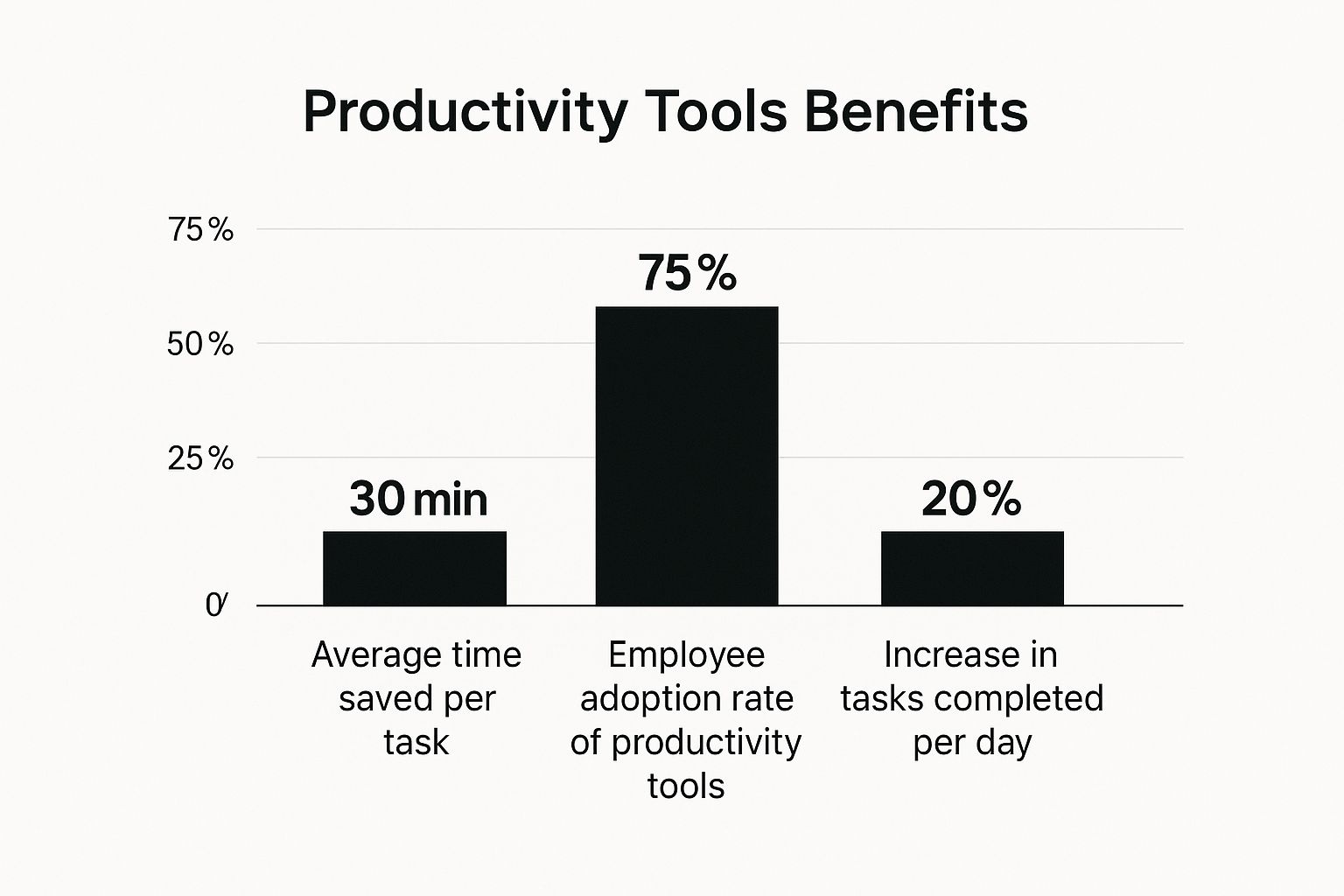

The benefits of smarter tools and workflows aren't just theoretical. They're tangible.

As the data shows, fine-tuning how work gets done delivers major wins in time saved and output increased. It’s a direct line to a more productive kitchen.

A well-organized prep station is the heart of this system. But how do you choose the right table to anchor each zone? It all comes down to what you're making.

Stainless Steel vs Pizza vs Sandwich Prep Tables

| Table Type | Primary Use Case | Key Features | Efficiency Impact |

|---|---|---|---|

| Standard Stainless Steel | General prep, chopping, mixing, plating | Flat, durable surface; undershelves for storage | Versatile foundation for any station; maximizes vertical space. |

| Pizza Prep Table | Assembling pizzas, calzones, flatbreads | Refrigerated rail for toppings, marble or granite top | Keeps ingredients chilled and within reach, speeding up assembly. |

| Sandwich/Salad Prep Table | Building sandwiches, salads, bowls | Refrigerated wells for cold ingredients, cutting board | Eliminates trips to the walk-in, drastically cutting prep time. |

Choosing the right table for the job is the first step in creating a truly efficient work zone. A standard table is a great all-rounder, but for specialized, high-volume items like pizzas or sandwiches, a dedicated prep table is a game-changer.

Ergonomics and Employee Well-being

Finally, don’t overlook the human element in your layout. The ergonomics of your workspace matter. A lot.

Setting your prep tables at the correct height, ensuring there’s proper lighting, and providing anti-fatigue mats can dramatically reduce the physical toll on your team. It's a simple fact: a comfortable chef is a faster, more focused, and happier chef.

Remember, a well-designed kitchen reduces both physical and mental stress. When your team isn't fighting their environment, they can pour all their energy and focus into what they do best: creating incredible food, quickly and safely. This thoughtful approach to workflow is the ultimate strategy for improving efficiency where it truly counts.

Maintaining Equipment for Lasting Performance

An efficient kitchen is a reliable one, and that starts with your equipment. Let's be honest, a dirty, wobbly, or neglected prep table isn't just a hygiene risk; it’s a productivity killer that can bring your entire operation to a crawl.

Building simple, consistent maintenance routines into your day protects your investment. More importantly, it ensures your workstations are always safe, clean, and ready for whatever the dinner rush throws at you. When equipment just works, your team can focus on the food, not frustrating interruptions.

Daily Cleaning Protocols

For stainless steel, daily cleaning is non-negotiable. It has to happen.

At the end of every single shift, all tables should be cleared off completely. Wipe them down with a soft cloth and a mild, food-safe detergent, then rinse and dry them thoroughly. This simple step stops food residue from hardening into a nightmare and prevents bacteria from taking hold.

Stay away from harsh, abrasive cleaners like steel wool or anything with chlorine. These can easily scratch the surface or, even worse, strip away its protective layer, making it way more likely to rust and corrode over time.

A clean workspace is a fast workspace. When staff don't have to stop and scrub a dirty surface before starting a task, service flows uninterrupted, directly boosting kitchen output.

Tackling Stains and Rust

Even with perfect daily cleaning, stubborn spots can pop up. For tough stains or a bit of minor rust, a paste made from baking soda and water works wonders as a gentle abrasive.

Just apply the paste, let it sit for a few minutes, and then scrub gently with the grain of the steel. Use a soft cloth or a nylon brush for this.

If you’re dealing with more stubborn rust, you might need a specialized stainless steel cleaner. Always follow the manufacturer's instructions to the letter and rinse the surface completely afterward to get rid of any chemical residue. A little regular care prevents these small issues from turning into big, expensive problems.

Routine Structural Checks

Beyond a clean surface, the physical stability of your table is critical for both safety and efficiency. A wobbly table is a dangerous one—it can cause spills, or worse, serious injuries.

Make it a weekly habit to run through some quick structural checks. It only takes a few minutes.

- Tighten Fittings: Check all the nuts, bolts, and screws on the legs and undershelves. The vibrations from a busy kitchen can loosen them over time.

- Level the Feet: Make sure the adjustable bullet feet are set firmly. This stops any rocking or instability, especially on uneven kitchen floors.

- Inspect Casters: If your table is on wheels, check that the locks work properly. Also, make sure the wheels are clear of any gunk or debris that could stop them from moving smoothly.

These quick checks are vital for keeping your work environment secure and productive. For more in-depth advice on keeping all your gear in top shape, check out our guide on caring for commercial kitchen equipment.

Your Questions About Kitchen Efficiency Answered

Even the best-laid plans run into questions, especially when you're trying to fine-tune the workflow in a busy commercial kitchen. Getting straight answers fast is key to making the right calls without missing a beat. Let’s tackle some of the most common questions we get about choosing and using prep tables to build a smarter workspace.

What Is the Best Grade of Stainless Steel for a Prep Table?

For almost any commercial kitchen, 304-grade stainless steel is the gold standard. There's a reason you see it everywhere. Its high chromium and nickel content gives it fantastic resistance to rust and corrosion, which is exactly what you need for direct food contact and wet areas near sinks. It's the most durable, long-lasting choice for the daily grind.

Now, if you're on a tight budget and the table is just for dry storage or light-duty tasks away from any moisture, 430-grade is a practical alternative. But for your main food prep areas, investing in 304-grade is a no-brainer. It pays for itself in longevity and hygiene down the road.

How Do I Determine the Right Size Prep Table?

Getting the size right is a crucial balancing act between the space you have and what you need to get done on it.

- Measure Your Space First: Before you do anything else, grab a tape measure. Critically, you have to leave at least 36 to 48 inches of clear walkway around the table. This is non-negotiable for staff to move safely and quickly, especially during a hectic dinner service.

- Analyze the Workflow: Next, think about what's actually going to happen on that surface. A compact 48-inch table might be perfect for a small sandwich station. But if you're a high-volume bakery, you'll need something like a 96-inch table to have enough real estate for rolling out massive batches of dough.

- Consider Equipment: Finally, don't forget about the equipment. Will a mixer sit on top? Does a proofing cabinet need to slide underneath? I always recommend sketching out your layout on a floor plan before you buy anything. It helps you see the flow and can save you from a very expensive sizing mistake.

Are Refrigerated Prep Tables Worth the Extra Cost?

In a high-volume kitchen? Absolutely, yes. The upfront investment for a refrigerated pizza or sandwich prep table is higher, but the payoff is huge and comes in a few different ways.

These tables completely slash the time your team spends walking back and forth to separate coolers. That simple change directly speeds up order fulfillment, which means better ticket times and a more consistent product for your customers.

They also give you a massive boost in food safety by keeping perishable ingredients perfectly chilled right up until they're used. This efficiency doesn't just cut down on potential food waste—it helps keep your entire operation running safely and smoothly.

Should I Choose a Prep Table with Wheels?

Wheels, or casters as they're known in the industry, bring a ton of flexibility to your kitchen layout. They make it incredibly easy to roll a table out of the way for a deep clean underneath. Need to reconfigure the line for a special event or a new menu? No problem. For hygiene and adaptability, they're a huge win.

But there is a trade-off to consider. For stations where you’re doing heavy-duty work like butchering or intense dough kneading, a stationary table with fixed legs is going to give you much better stability. The good news is that many high-quality casters come with locking mechanisms, giving you the best of both worlds—mobility when you need it and a solid foundation when you don’t.

Ready to build a more efficient kitchen? The right equipment is the foundation of a smarter workflow. At PrepTables.com, we offer a huge selection of NSF-certified stainless steel tables, specialized refrigerated workstations, and all the commercial kitchen equipment you need to optimize your space. Explore our collection at https://preptables.com and start building a more productive operation today.