A Guide to Profitable Food Truck Design

Share

A killer food truck design is about so much more than a cool paint job. It's the strategic blueprint for whether your business sinks or swims. A thoughtfully planned layout has a direct line to your service speed, how efficiently your staff works, and—most importantly—your bank account. You're essentially engineering a high-performance kitchen on wheels.

Your Blueprint for a Profitable Mobile Kitchen

Think of your food truck's interior like a machine. Every single gear has to turn in perfect sync. The real difference between a chaotic, money-losing operation and a smooth, profitable one almost always comes down to the choices you make before you ever serve a single customer. This isn't just about cramming equipment into a tight space; it's about crafting an ergonomic workflow that’s built specifically for your menu.

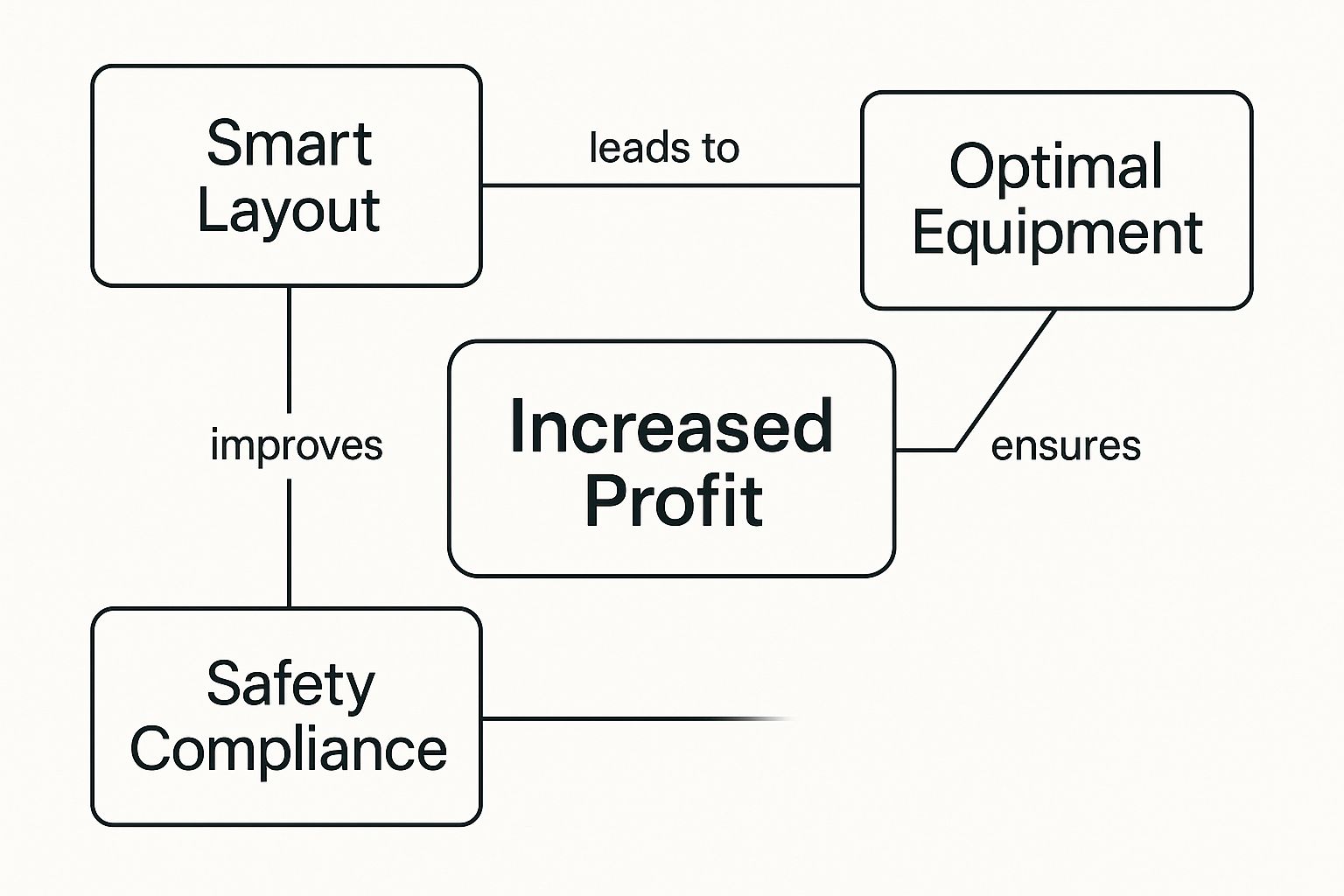

The whole game boils down to three things: a smart layout, the right equipment, and rock-solid safety compliance.

This guide will walk you through a proven process, starting with the basics and building up to a fully optimized mobile kitchen. You'll see real-world examples of how squeezing every last inch of value out of your space is the key to building a business that can thrive anywhere. As you're laying the groundwork, checking out some profitable food truck ideas can really help you nail down your concept from the start.

The Pillars of Successful Food Truck Design

The global food truck market is exploding for a reason—people love unique, convenient food on the go. The market is on track to hit around USD 5.8 billion in 2025 and is projected to jump to USD 10.9 billion by 2035. That incredible growth has forced food truck design to get a lot smarter, with a huge focus on layouts that are both efficient and squeaky clean.

This infographic breaks down how these core design elements all work together to make you money.

As you can see, a great layout, the right gear, and meeting safety codes aren't separate tasks. They're totally interconnected pieces that fuel your financial success. If you let one area slide, the others will suffer for it.

The most successful food truck operators I've met all get one thing: their truck isn't just a kitchen. It's a carefully engineered profit center. Every single design decision has to be weighed against how it will impact your speed, safety, and customer happiness.

Key Focus Areas for a Winning Design

To build a mobile kitchen that actually works in the real world, you have to obsess over a few key areas right from the beginning. Each one plays a critical role in whether your venture gets off the ground.

- Workflow and Layout: The physical journey an order takes—from the ticket printing to the moment you hand food to a customer—needs to be as short and direct as humanly possible. No wasted steps.

- Equipment Selection: Choosing the right size and type of equipment is everything. Your gear has to pump out your menu items efficiently without hogging precious real estate.

- Safety and Compliance: Following every local health and fire code is completely non-negotiable. A design that can't pass inspection is a design that has failed, period.

- Customer Experience: Don't forget the service window! The way customers order and pick up is part of your truck's design. An easy, welcoming setup is what brings people back again and again.

Designing Your Food Truck Layout for Speed

The moment you start sketching out your food truck’s interior, you’re basically writing its operational DNA. In the cramped world of a mobile kitchen, every single step matters. A smart layout isn't just nice to have; it directly translates into faster service and, you guessed it, more money in your pocket.

Think of it as choreographing a dance. You want your staff, equipment, and ingredients to move in perfect harmony. The difference between a chaotic mess during a lunch rush and a smooth, high-speed operation almost always comes down to the layout you choose. There’s no single “best” option—the right choice is always dictated by your menu and workflow.

Core Food Truck Layout Configurations

Every successful food truck design is built on one of three battle-tested configurations. Each one has its own strengths, depending on what you’re cooking up.

-

Assembly Line Layout: This is the undisputed champ for step-by-step food production. Picture a taco or burrito truck where an order moves logically from one end (the tortilla station) to the other (salsas and service). It’s incredibly efficient for any menu with a consistent build process.

-

Galley Layout: Think of a ship's kitchen—two parallel counters with a narrow aisle down the middle. This setup is perfect for the long, thin footprint of most food trucks because it maximizes counter and equipment space along both walls. Everything stays within a quick turn or a single step.

-

Zone-Based Layout: This setup is a lot like a traditional restaurant kitchen, with dedicated stations or "zones" for different jobs. You might have a prep zone, a cooking zone with your grills and fryers, and a finishing zone right by the service window. It works great for more complex menus where different items need different kinds of prep.

The Kitchen Work Triangle Reimagined

In a normal kitchen, designers live by the kitchen work triangle. It's a simple concept that connects the three main work areas: the sink, the fridge, and the stove. The idea is to keep them close to cut down on traffic and wasted motion. But in a long, narrow food truck, you have to adapt.

Instead of a triangle, you're creating a tight, efficient work line. Your main storage (refrigeration), your primary prep area (prep tables), and your main cooking equipment should be placed in a logical sequence. The goal is the same: reduce wasted steps. Fewer steps mean less fatigue for your crew and precious seconds shaved off every single order.

Every unnecessary step taken during a lunch rush is lost revenue. A smart layout isn't a luxury; it's a fundamental business tool that pays you back with every order you serve.

Matching Your Layout to Your Menu

Your menu is the ultimate blueprint for your food truck’s design. An assembly line is a dream for burgers, sandwiches, or custom bowls. But for a menu that requires multiple separate cooking processes at once, it would just create a massive bottleneck.

In the United States, the food truck market is set to grow from USD 1.09 billion in 2025 to USD 1.51 billion by 2030, and smart, innovative design is a huge part of that success. This growth comes from operators who figure out how to squeeze every ounce of efficiency from their limited space.

For a closer look at how your menu should drive your design choices, you can explore our detailed guide on common food truck layouts. It will help you see exactly how different menus thrive in specific setups. Ultimately, the best layout lets you execute your most popular dishes flawlessly during your busiest hours.

Choosing Your Essential Kitchen Equipment

If your food truck’s layout is the skeleton, the kitchen equipment is its heart and muscles. These are the tools that bring your menu to life. And right at the core of any functional mobile kitchen, you’ll find stainless steel. Think of stainless steel prep tables as the unsung heroes of your entire operation—they're the durable, reliable backbone for every single dish you create.

You really can't overstate their importance in a high-speed food truck. Unlike wood or plastic, stainless steel is non-porous. That means it resists bacteria and germs, making it incredibly easy to sanitize and keep the health inspector happy. It's also tough enough to handle the constant heat, dings, and spills of a crazy-busy kitchen.

Understanding Stainless Steel Prep Tables

Here's the thing: not all prep tables are created equal. The right choice comes down to your specific menu, your workflow, and the precious inches you have to work with. Picking the right table is a foundational step that directly impacts how fast you can get food out the window.

The most common option you'll see is the standard flat-top work table. These are the versatile workhorses, perfect for chopping, mixing, and general assembly. Most come with an adjustable undershelf, which is an absolute lifesaver for storing small appliances, ingredient bins, or extra cookware. That kind of double-duty function is non-negotiable in a tight space.

For trucks with next-to-no floor space, a wall-mounted prep table is a brilliant solution. By fixing the surface directly to the truck’s interior wall, you free up the floor underneath for trash cans, mobile coolers, or just some much-needed legroom. It’s a smart design choice that helps keep walkways open and less cluttered.

Specialized Prep Tables for High-Speed Menus

Now we're getting to the real game-changers. For certain high-volume menus, specialized prep tables aren't a luxury—they are an absolute necessity for speed and consistency. They essentially create self-contained, high-efficiency workstations that can totally transform your process. Two of the most impactful types are sandwich prep tables and pizza prep tables.

-

Sandwich Prep Tables: Picture a standard prep table but with a refrigerated rail on top. This unit holds pans of cold ingredients like lettuce, tomatoes, and sauces, all within arm's reach. Below the cutting board, you have undercounter refrigeration for backup supplies. This setup means your staff isn't constantly walking back and forth to a separate fridge, which shaves critical seconds off every single order.

-

Pizza Prep Tables: These work on a similar principle but are purpose-built for slinging pies. They feature a wider, deeper refrigerated rail to hold big containers of cheese, pepperoni, and other toppings. The workspace is usually deeper to handle large pizza crusts, and the undercounter fridge is designed to hold dough trays at the perfect temp.

These specialized tables are the definition of smart food truck design. They combine three essential functions—storage, refrigeration, and a work surface—into a single, compact footprint. This consolidation is how you build an ergonomic and profitable mobile kitchen.

Investing in one of these units turns a multi-step process into a fluid, one-station operation. For a burger joint, a sandwich shop, or a pizzeria on wheels, that efficiency boost is massive. It allows one person to assemble complex orders quickly without creating a logjam. For more ideas on outfitting your mobile kitchen, check out this guide on essential food truck kitchen equipment.

Beyond the Prep Table: Core Equipment

While prep tables are the foundation, they don’t work in a vacuum. Your cooking gear, refrigeration, and sanitation stations have to be chosen with the same ruthless focus on space and efficiency.

- Compact Cooking Gear: Always prioritize countertop or undercounter models when you can. Griddles, fryers, and charbroilers designed for smaller kitchens give you the power you need without eating up precious real estate.

- Undercounter Refrigeration: On top of your specialized prep tables, undercounter fridges and freezers are vital. Tucking them under your main work surfaces maximizes your workspace and keeps bulk ingredients close.

- Mandatory Sinks: This one isn't a choice. Every health department requires a very specific sink setup, which usually means a three-compartment sink for washing, rinsing, and sanitizing, plus a totally separate handwashing sink. These are non-negotiable parts of a compliant food truck.

Every single piece of equipment has to earn its spot on your truck. By carefully selecting compact, multi-functional, and specialized units, you build a cohesive system where everything works together for a faster, smoother, and more profitable operation.

Optimizing Your Workflow for Peak Efficiency

If your layout and equipment are the stage, then your workflow is the main performance. In the tight confines of a food truck, every single second you can save adds directly to your bottom line. Optimizing your workflow is all about engineering an environment where every movement is deliberate, turning your truck from a simple kitchen into a high-speed, ergonomic production line.

The real goal here is to create a seamless process that kills bottlenecks and cuts down on the physical strain for you and your team. This isn't about just trying to work faster; it's about designing a smarter truck that makes efficiency feel effortless. It’s the difference between a chaotic, stressful scramble during a rush and a smooth, profitable service.

The Journey of an Order

To really see this in action, let's walk through a single order in a well-designed burger truck. When done right, the whole process should feel like a perfectly choreographed dance, with each step flowing logically into the next.

- Order In: The ticket prints out right next to the griddle station. The cook can see it instantly without taking a single step.

- Cooking: The cook reaches to their left, grabs patties from the undercounter fridge, and gets them on the griddle. Buns are waiting in a warmer directly above. Easy.

- Assembly: Once cooked, the burger slides over to the adjacent prep station. The assembler adds toppings—lettuce, tomato, onions—from a refrigerated prep rail, all within arm's reach.

- Finishing & Handoff: The finished burger gets wrapped and placed on a pass-through shelf that leads straight to the service window.

In this setup, nobody had to cross paths, and no one took more than a single step to do their job. That's the heart of an efficient workflow: minimize movement to maximize output.

Mastering Storage and Accessibility

You can't have a smooth workflow without smart storage, especially when space is at a premium. The "first-in, first-out" (FIFO) method is absolutely critical here. It’s a simple system that ensures you’re using older stock before the new stuff comes out, which is a huge help in reducing waste and spoilage.

To make FIFO work, use clear, labeled containers and organize your shelves so that new inventory is always placed behind what's already there. This naturally forces staff to grab the oldest items first. On top of that, you need to position your most-used tools and ingredients where they’re easiest to grab. Spatulas, tongs, and squeeze bottles should be on magnetic strips or in holders right at their stations.

A disorganized truck creates friction. Every moment your staff spends searching for an ingredient or a tool is a moment they aren't serving a customer. Smart food truck design removes that friction entirely.

Creating a Safe and Productive Environment

An efficient workflow is only truly possible in a space that is safe and comfortable for your crew. Several key design elements have a direct impact on both productivity and well-being.

- Non-Slip Flooring: A greasy floor is just an accident waiting to happen. Investing in high-quality, non-slip flooring is a non-negotiable safety measure that lets your team move quickly and with confidence.

- Powerful Ventilation: A food truck kitchen pumps out a massive amount of heat, smoke, and grease. A commercial-grade vent hood isn't just a code requirement; it's essential for air quality and keeping the temperature bearable. This directly impacts your staff's stamina and focus.

- Strategic Lighting: A dimly lit kitchen is both dangerous and inefficient. You need bright, focused lighting over each workstation—the prep area, the cookline, and the service window. It’s critical for food safety, quality control, and reducing eye strain during those long shifts.

These aren't just afterthoughts; they are the foundation of a food truck designed around human ergonomics. By building a safe, well-lit, and reasonably cool workspace, you're empowering your team to perform at their best, turning your well-designed layout into a truly efficient and profitable mobile kitchen.

Navigating Health Codes and Safety Regulations

A killer food truck design is completely worthless if it fails its first health inspection. Don't think of local regulations as annoying hurdles to jump over; they're a fundamental part of your design specs from day one. Ignoring them is the fastest way to end up with expensive, soul-crushing rebuilds right when you should be opening your service window.

While the nitty-gritty rules can vary by city and state, a core set of requirements forms the foundation for any compliant food truck. Getting these right at the blueprint stage isn't just a good idea—it’s the only way you’ll operate legally and safely. The goal is to build a compliant truck from the ground up, not try to shoehorn in fixes later.

Universal Water and Sanitation Requirements

Every health department in the country obsesses over one thing above all else: sanitation. For a food truck, that conversation begins and ends with your water and sink setup. This system is non-negotiable and is usually the first thing an inspector scrutinizes.

You're required to have two distinct sink systems:

- A Three-Compartment Sink: This is your warewashing workhorse. Each basin has a specific job—one for washing with soap, one for rinsing with clean water, and one for sanitizing with an approved solution.

- A Separate Handwashing Sink: This sink must be totally independent and used only for washing hands. It needs to be easily accessible from your prep and cooking areas and must have both hot and cold running water, soap, and paper towels.

A failed inspection often boils down to the simple, foundational stuff. Inspectors don't care about your slick branding if your handwashing sink is out of reach or your water tanks are too small. Master the basics first.

Critical Fire Safety Regulations

Beyond sanitation, fire safety is the other major pillar of a compliant food truck. You’re running a high-heat kitchen inside a metal box, often with flammable propane tanks just a few feet away. Cutting corners here isn't an option; it puts your entire business and your personal safety on the line.

Your fire safety system has several key parts that need to be baked into your design:

- Commercial-Grade Vent Hood: This system sits over your cooking line to pull grease, heat, and smoke out of the truck. It's your first line of defense against grease fires.

- Fire Suppression System: Built right into the vent hood, this system has nozzles pointed at your cooking gear. If a flare-up happens, it automatically douses the area with fire-suppressing chemicals.

- Fire Extinguishers: You'll need specific types. A Class K extinguisher is mandatory for grease fires in the kitchen, and you’ll also need a Class ABC extinguisher for other types of fires (electrical, paper, etc.). Make sure they’re mounted somewhere obvious and easy to grab.

- Propane Tank Security: Propane tanks have to be stored outside the main cabin, usually in a securely mounted cage on the tongue or back of the vehicle. All the lines and connections must meet strict safety codes.

Design Clearances and Global Standards

Giving your equipment enough breathing room is a huge part of both fire safety and general sanitation. Health codes dictate specific distances between hot equipment and any combustible surfaces to prevent fires. These rules also make sure there’s enough space for your team to work safely and for you to properly clean between and behind units. You can learn more about applying these principles in our guide on food safety and sanitation guidelines.

These design principles aren't just a local concern, either. In major markets across Europe and Asia, hygiene regulations and vehicle emission standards are pushing designers to innovate within even tighter constraints. This has created a dynamic where food truck design isn't just about function; it's a marketing tool that reflects brand identity. As you can read in the full global market report for food trucks, adapting your design to be compliant is a universal key to success, giving you a competitive edge by enhancing mobility and consumer appeal no matter where you operate.

Got Questions About Your Food Truck Design? Let's Answer Them.

Getting your food truck design right often comes down to the details. While the big-picture layout is a huge piece of the puzzle, it's the specific choices—like what kind of prep surfaces you install—that really dictate how smoothly your kitchen runs. And when it comes to prep surfaces, understanding your stainless steel options is step one.

Stainless steel is the undisputed king of the commercial kitchen, and in a food truck, its benefits are even more critical. The material is non-porous, which makes it a dream to sanitize and keep hygienic—a must for passing health inspections. It's also tough as nails, standing up to the heat from your cookline and the daily grind of a busy mobile kitchen.

What are the different types of stainless steel prep tables?

Not all stainless steel tables are created equal. Different types are built for different jobs, menus, and layouts. The most common is the standard flat-top work table. Think of these as the all-purpose workhorses of your kitchen. They give you a simple, open surface for everything from dicing onions to plating up your final dishes. Most also have an undershelf, which is a lifesaver for stashing supplies and keeping that precious floor space clear.

But what if your menu is all about high-speed assembly? That's where specialized units like sandwich prep tables and pizza prep tables come in. These tables are built to be complete, self-contained workstations.

-

Sandwich Prep Tables: These units are brilliant for any truck serving sandwiches, salads, or bowls. They have a refrigerated rail built right into the work surface, keeping your meats, cheeses, and toppings perfectly chilled and right at your fingertips. This design cuts out the need to constantly walk back and forth to a separate fridge, which shaves valuable seconds off every single order.

-

Pizza Prep Tables: Built on the same idea, these tables just supersize it for pizzeria-style menus. They feature a much wider and deeper refrigerated rail to hold big pans of sauce, cheese, and all your toppings. The work surface is also massive, giving you plenty of room to stretch dough and build your pies without feeling cramped.

The choice between a basic flat-top and a specialized prep unit is one of the most important decisions in your food truck design. For a high-volume, assembly-line-style menu, a refrigerated prep table isn't just a nice-to-have—it's the engine that drives your profit, packing storage, cooling, and prep into one efficient footprint.

At the end of the day, the right prep tables are more than just a place to work. They are a core part of your system, supporting your menu, speeding up your workflow, and helping you serve more customers, faster. Making a smart choice here is one of the final, crucial steps to building a mobile kitchen that's truly set up for success.

Ready to build the backbone of your mobile kitchen? At PrepTables.com, we offer a huge selection of NSF-certified stainless steel work tables, specialized sandwich and pizza prep units, and all the essential commercial equipment your food truck needs. Explore our collection and design a more efficient kitchen today at https://preptables.com.