Your Guide to Food Safety Sanitation Guidelines

Share

Excellent food safety and sanitation guidelines are the backbone of any successful kitchen. They transform daily routines into a powerful defense against foodborne illness. This is about more than just checking off a list; it’s about creating a culture where safety is second nature, protecting your customers and cementing your reputation.

Why Food Safety and Sanitation Matter

In a professional kitchen, sanitation isn't just another task—it's the bedrock of your entire operation. Overlooking these guidelines can lead to consequences that go far beyond a failed health inspection. It puts the well-being of your customers and the future of your business on the line.

Think of sanitation less as a chore and more as a fundamental mindset. This way of thinking should inform every single action, from choosing the right prep tables to locking down your daily cleaning schedule. When you prioritize food safety, you’re actively building customer trust and creating a healthier space for both your staff and your guests.

The Real-World Impact of Sanitation Failures

The fallout from poor sanitation is severe and widespread. The numbers tell a sobering story. Globally, about 600 million people—that’s nearly 1 in 10—get sick from contaminated food every single year.

Tragically, this results in 420,000 deaths. Children under five are hit the hardest, making up almost 125,000 of those fatalities annually. You can dig deeper into this critical issue with data from the World Health Organization. These statistics are a stark reminder of our responsibility. One small oversight can have devastating effects, which is why strict food safety sanitation guidelines are completely non-negotiable.

A "sanitation mindset" means you see every surface, tool, and process through the lens of safety. It's the core belief that the cleanliness of your kitchen is just as crucial as the quality of your ingredients.

Building Your Foundation for Success

Adopting this sanitation-first approach paves the way for operational excellence. It builds a framework where safety is woven into your workflow, not just tacked on as an afterthought. This foundation gives your team the confidence to work efficiently, knowing they're part of a system designed to protect everyone.

Here’s how this mindset pays off in real, tangible benefits:

- Reduced Risk: Proactively cuts down the chances of a foodborne illness outbreak. This protects public health and shields your business from legal and financial disaster.

- Enhanced Reputation: A visibly clean and safe kitchen builds incredible trust and loyalty. Customers notice and appreciate high hygiene standards.

- Improved Efficiency: When sanitation is just part of the daily routine, it becomes second nature. This leads to a more organized, less chaotic, and more productive kitchen.

Choosing Prep Tables Built for Cleanliness

Your prep table is the absolute heart of your kitchen's workflow, making it a critical control point for sanitation. A well-chosen table isn't just a surface to work on; it’s your first line of defense against cross-contamination and the sneaky growth of bacteria. The right one simplifies cleaning, stands up to harsh chemicals, and really forms the foundation of your entire food safety plan.

Think of your prep table as the stage where every single dish begins. A cracked, porous, or poorly designed surface can undermine even the most rigorous cleaning efforts. This is why the material, grade, and specific features of your prep tables are not minor details—they are central to upholding your food safety sanitation guidelines.

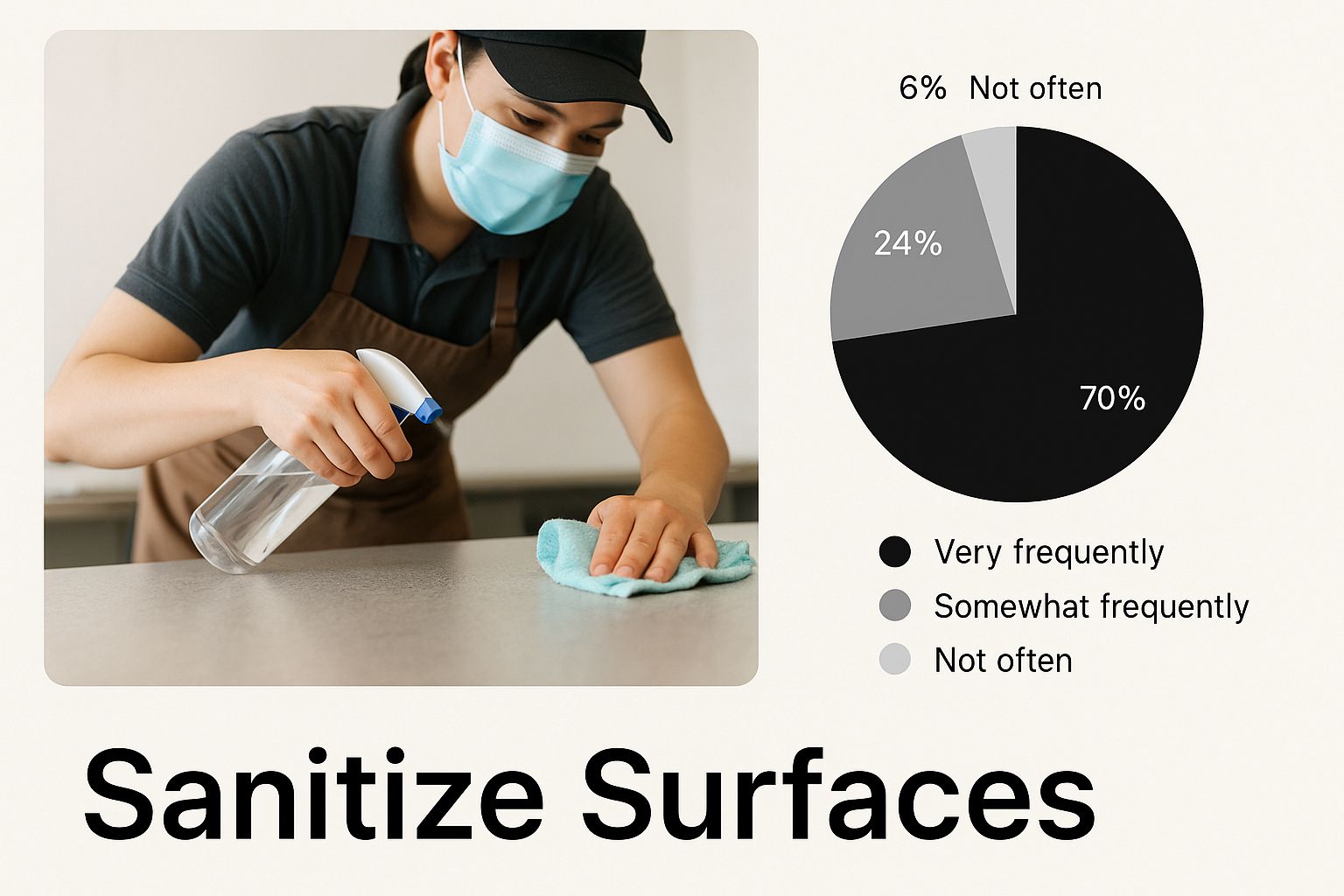

Proper surface sanitation is the cornerstone of a safe kitchen. It's a non-negotiable practice that has to be consistently applied to every prep table, every single day.

This visual really drives home the importance of diligent sanitization—a task you just can't skip if you want to prevent pathogens from spreading from surfaces to food.

Decoding Stainless Steel Grades

When it comes to sanitation, not all stainless steel is created equal. The grade of the steel directly impacts its durability, how well it resists corrosion, and how easy it is to clean. Getting the difference between the most common types is crucial for making a smart, long-term investment in your kitchen's hygiene.

In a commercial kitchen, you'll typically run into two main grades: 304 and 430.

Grade 304 stainless steel is the undisputed gold standard for any surface that touches food. It has more nickel in it, which gives it superior resistance to rust and corrosion, especially from acidic foods like tomatoes and citrus or from harsh cleaning chemicals. While it might cost a bit more upfront, its longevity and resilience make it the most cost-effective and safest choice for any primary prep surface.

On the other hand, Grade 430 stainless steel is more budget-friendly but is also more likely to rust and pit over time, particularly with constant exposure to moisture and acids. It’s a perfectly fine choice for things like equipment stands or shelving—surfaces that don't directly contact food. But for the main work surface where all the action happens, 304 grade is the hands-down champion for keeping sanitation standards high. To get a better handle on material choices, you can check out this guide on the different types of restaurant stainless steel tables out there.

Common Types of Stainless Steel Prep Tables

Beyond the grade of steel, the type of table you choose depends on your kitchen's specific workflow. Each design is built for a particular purpose and comes with its own sanitation considerations.

-

Standard Work Tables: These are the versatile, flat-top workhorses of the kitchen. Available with or without backsplashes and undershelves, their simple design makes them relatively easy to clean. The key is to choose one made from 304-grade stainless steel for the primary work surface.

-

Equipment Stands: Built to hold heavy countertop equipment like mixers or griddles, these are often lower to the ground. Since food isn't prepped directly on them, 430-grade stainless steel is often acceptable, but diligent cleaning of the surface and the area underneath is still crucial.

-

Sandwich and Salad Prep Tables: These refrigerated units combine a cutting board work surface with cooled wells (or "cold pans") on top for ingredients. The primary sanitation challenge is preventing cross-contamination between the wells and ensuring the entire unit, including door gaskets and the refrigerated base, is cleaned daily.

-

Pizza Prep Tables: Similar to sandwich units, these tables have refrigerated rails for toppings but typically feature a much larger, more durable work surface (often marble or a thick poly cutting board) for stretching dough. Flour, semolina, and cheese can easily get trapped in crevices, making meticulous daily cleaning essential to prevent mold growth and pest issues.

These specialized tables are a huge help in high-volume kitchens, but their integrated parts demand a much more rigorous cleaning schedule. The mix of multiple compartments, cooling systems, and all those different ingredients in one place can quickly create sanitation hotspots if you're not on top of it.

A critical feature for any commercial prep table is NSF certification. This seal isn't just a sticker; it's your assurance that the equipment was designed and built for easy, effective cleaning. NSF-certified tables have smooth, non-porous surfaces and are constructed to get rid of the tight corners and crevices where bacteria love to hide.

Key Design Features That Bolster Food Safety

Beyond the steel grade and the specific type of table, several design elements can make a huge difference in your daily sanitation routine. When you're picking out new equipment, look for features that are engineered to make cleaning easier, not harder.

One of the most important features to look for is coved corners. These are just rounded, seamless transitions where surfaces meet, like between a backsplash and the tabletop. This simple design choice gets rid of those sharp 90-degree angles that are notorious for trapping food debris and being a nightmare to clean properly.

Another essential feature is an integrated backsplash. A backsplash stops food bits and liquids from splashing onto walls or falling into that hard-to-reach gap between the table and the wall. These details might seem minor, but they play a massive role in creating a workspace that's easier to maintain and fundamentally safer. Choosing equipment with these smart, sanitary design elements is a proactive step toward a cleaner kitchen.

Creating Your Kitchen Sanitation Playbook

A spotless kitchen doesn’t just happen by magic. It’s the result of a solid, repeatable system. A sanitation playbook is your secret weapon, turning good intentions into reliable, everyday actions that keep your entire operation safe and up to code.

Think of it less like a simple to-do list and more like a blueprint for cleanliness. This is the guide your team can lean on, transforming abstract food safety sanitation guidelines into concrete steps that get done right, every single time.

Cleaning Versus Sanitizing: A Critical Distinction

Before you can build a schedule, your entire crew needs to be crystal clear on the difference between cleaning and sanitizing. People often use the terms interchangeably, but in a professional kitchen, they are two separate, equally vital steps. One without the other is a job half-done.

Cleaning is all about what you can see. It's the physical act of scrubbing away visible dirt, grease, and food scraps from a surface using soap or detergent and water. You can think of it as clearing the battlefield before the real fight begins.

Sanitizing is what happens next. This is the chemical step that takes down the invisible enemies—reducing dangerous microorganisms like bacteria and viruses to a safe level. A sanitizer can only do its job on a surface that’s already been properly cleaned. You have to clear the grime first to kill the germs.

Building Your Sanitation Schedule

A great sanitation plan is all about rhythm and frequency. When you break down tasks into daily, weekly, and monthly jobs, it keeps the workload manageable and ensures nothing critical gets overlooked. This structure builds a culture of cleanliness that eventually becomes second nature.

Daily Tasks (The Non-Negotiables)

These are the core habits that have to happen every single day—often multiple times a day—to shut down the immediate risk of contamination.

- Surface Sanitization: All food-contact surfaces, like prep tables, cutting boards, and slicers, must be cleaned and sanitized after every single use. This also applies when you switch from raw to ready-to-eat foods and at least every four hours during ongoing use.

- Handwashing Sinks: Every handwashing station must stay fully stocked with soap, paper towels, and hot water. No excuses.

- Trash Removal: Empty trash cans regularly to keep pests and odors at bay.

Weekly Tasks (Deeper Cleaning)

These jobs tackle the grime that builds up more slowly but is just as important for long-term hygiene and keeping your equipment in good shape.

- Deep Clean Equipment: Give your hard-working machines some love. Thoroughly delime dishwashers, clean out coffee machines, and scrub ice makers.

- Floor and Drain Maintenance: Get under the equipment to scrub floors and clean out floor drains to stop nasty buildup.

- Walk-In Coolers: Sweep and mop the floors of your walk-ins and wipe down all the shelving inside.

Monthly Tasks (Preventative Maintenance)

These bigger-picture tasks are less frequent but absolutely crucial for the safety and upkeep of your entire facility.

- Exhaust Hoods: Clean the filters on your ventilation hoods. A greasy hood is a massive fire hazard waiting to happen.

- Pest Control Checks: Do a thorough inspection for any signs of pests. Check that all seals on doors and windows are tight.

- Dry Storage Organization: Give your dry storage a once-over. Clean the shelves, check for expired products, and make sure everything is stored off the floor.

The goal of a sanitation schedule isn't just to pass an inspection; it's to create an environment where food safety is a constant. Consistency is the key to preventing foodborne illness outbreaks.

Chemical Safety and Proper Usage

Using cleaning chemicals the right way is just as important as the act of cleaning itself. Mix them wrong, and they can be useless at best—or dangerous at worst. Every person on your team needs to know the basics of chemical safety.

Dilution Ratios: Always, always, always mix chemicals according to the manufacturer’s instructions. A solution that’s too weak won’t kill anything, while a solution that’s too strong can leave toxic residue on your surfaces and even damage your equipment.

Contact Time: For a sanitizer to actually work, it needs to sit on a surface for a specific amount of time. This is called the contact time, and it can be anywhere from 30 seconds to several minutes. If you wipe it off too soon, you’ve just wasted your time.

A big part of this playbook is also understanding the basics of commercial kitchen equipment maintenance. Regular, deep cleaning doesn't just keep things sanitary; it also extends the life of your expensive appliances and keeps them running safely.

Sample Kitchen Sanitation Schedule

To help you get started, here’s a simple template. You’ll want to customize this to fit your specific kitchen, equipment, and staff roles. A clear, posted schedule keeps everyone accountable.

| Frequency | Area/Equipment | Task Description | Responsible Person |

|---|---|---|---|

| Daily | All Prep Tables | Clean and sanitize after each task and every 4 hours. | Line Cook |

| Daily | Slicers & Mixers | Disassemble, clean, and sanitize after each use. | Prep Staff |

| Weekly | Fryers | Boil out fryer, filter oil, and clean exterior. | Kitchen Manager |

| Weekly | Walk-In Refrigerator | Sweep, mop floors, and wipe down shelving. | Closing Staff |

| Monthly | Ventilation Hoods | Clean grease filters. | Head Chef |

| Monthly | Dry Storage | Organize shelves and check for expired products. | Inventory Clerk |

This table is just a starting point. A living, breathing sanitation schedule is a sign of a well-run kitchen where safety and quality are always the top priority.

Building a Culture of Food Safety

Checklists and sanitation schedules are a great start, but they don't work unless your team is bought in. Real food safety isn't just about following rules; it's about building a culture where cleanliness is a core value. This is how you turn your food safety sanitation guidelines from a boring manual into a shared responsibility that everyone on the team actually cares about.

This kind of change has to come from the top. When leadership consistently prioritizes and demonstrates safe practices themselves, it sends a clear message. It shows that sanitation isn't just for passing inspections—it’s about respecting the food, the customers, and each other.

Instilling Sanitation as a Core Value

To really build this culture, you need a steady diet of training, positive reinforcement, and clear communication. Team huddles are the perfect time to review a specific sanitation protocol, give a shout-out to someone who went the extra mile, or talk through a near-miss so everyone can learn from it.

Back up these daily talks with simple visual aids, like posters showing proper handwashing steps or charts with the right sanitizer concentrations. When everyone is speaking the same language of safety, it just becomes second nature.

Advanced Strategies for a Resilient Kitchen

Once you've got the daily grind down, a truly forward-thinking food safety program starts tackling the more complex stuff. Nailing these advanced risks is what separates a good kitchen from a great one.

-

Allergen Cross-Contact Management: This isn't something you can just wing. It demands a dedicated system. Think designated prep areas, color-coded utensils, and separate fryers for common allergens like gluten or shellfish. Every single staff member needs to understand how serious food allergies are and the strict steps required to prevent a dangerous reaction.

-

Robust Pest Control: The only way to win the war against pests is to be proactive. That means working with a licensed pro, sealing every crack and crevice pests could use to get in, and keeping a relentless cleaning schedule to remove any potential food sources. If you deny them entry and a free meal, they'll go somewhere else.

-

Staying Ahead of Global Standards: Food safety rules are always changing. Global bodies are pushing for more proactive and thorough safety measures. For example, the Global Food Safety Initiative (GFSI) now requires businesses to actively find and fix weak spots in their supply chains to stop contamination before it starts.

A proactive food safety culture is built on the principle of prevention, not just reaction. It’s about anticipating risks—from a new menu item to a supplier issue—and having a plan in place before a problem occurs.

Building a Proactive Food Safety Program

Creating a tough, resilient program also means empowering your team to think on their feet. Encourage them to ask "what if?" and to speak up immediately if they spot a potential hazard. That sense of ownership is priceless. When your team feels responsible for safety, they become your best defense.

This proactive mindset should also guide your equipment choices. Investing in gear designed for easy sanitation, like tables with rounded coved corners or a specific grade of stainless steel, directly supports your cultural goals. Understanding the nitty-gritty of these choices is a game-changer, which is why it's so helpful to know what NSF certification means for your equipment.

At the end of the day, building a culture of food safety creates a kitchen that isn't just compliant, but truly safe from the ground up.

Common Food Safety Sanitation Questions

Even with the best training and a solid playbook, questions always pop up on the fly. Getting clear, straightforward answers reinforces key lessons and helps your team make the right call when it matters most. Think of this as your quick-reference cheat sheet for the most common kitchen sanitation questions.

The goal is to apply food safety sanitation guidelines correctly and consistently. Tackling these frequent questions helps build a team that's not just compliant, but genuinely confident in their practices.

What Is The Real Difference Between Cleaning And Sanitizing

This is easily the most common point of confusion, but getting it right is non-negotiable. It’s a simple two-step process, and both parts are absolutely mandatory.

Cleaning is the first step—the physical act of removing visible dirt, food bits, and grime from a surface. It's what you do with soap and water to scrub away all the mess you can see.

Sanitizing is the chemical process that comes after cleaning. This step takes care of the invisible threat by reducing dangerous germs to a safe level. A sanitizer can't do its job on a dirty surface, which is why you must always clean first. One without the other leaves the job dangerously incomplete.

How Often Should We Be Changing Our Sanitizer Buckets

A full sanitizer bucket can create a false sense of security if the solution inside isn't actually effective anymore. The standard rule of thumb is to change your sanitizer solution every 2-4 hours.

But you should change it even sooner if it gets visibly dirty or filled with food debris. The most critical habit is to use chemical test strips regularly. It's the only way to know for sure that the sanitizer concentration is at the right level to kill pathogens.

"An ineffective sanitizer is worse than no sanitizer at all because it gives a false sense of security. Regular testing with strips is non-negotiable for ensuring your chemical solutions are actually doing their job to kill pathogens."

Why Is NSF Certification So Important For Kitchen Equipment

When you see that NSF logo on a prep table or any other piece of equipment, it’s not just a sticker. It's your guarantee of a sanitary design. NSF certification is an independent assurance that the equipment has been tested and built to be cleaned easily and effectively.

This certification means the materials are non-porous, tough, and won't corrode easily. Even more important, the equipment is constructed to avoid those little cracks, tight corners, and hidden crevices where bacteria love to hide and multiply. Choosing NSF-certified equipment is a proactive investment in your kitchen’s food safety.

What Are The Most Common Violations Health Inspectors Find

Health inspectors tend to spot the same core problems in kitchen after kitchen. The good news? That tells you exactly where to focus your training. If you can consistently nail these fundamentals, you’ll be ready for any inspection while keeping your kitchen safe every day.

The most frequently cited violations usually fall into these categories:

- Improper Food Holding Temperatures: This is all about the "danger zone" (41°F to 135°F), where bacteria multiply rapidly. Food must be kept either hotter or colder than this range.

- Poor Personal Hygiene: Simple but critical mistakes, especially inadequate handwashing, are a major red flag for any inspector.

- Cross-Contamination: Failing to keep pathogens from spreading between raw and ready-to-eat foods is a serious, and very common, violation.

- Incorrect Sanitizing Procedures: This covers everything from using the wrong chemical concentration to not letting the sanitizer sit long enough to work.

Focusing your team's energy on mastering these four key areas will dramatically improve your kitchen’s safety and keep you prepared for any inspection.

Ready to build a kitchen foundation that prioritizes safety and efficiency? At PrepTables.com, we offer a wide range of NSF-certified stainless steel prep tables and commercial equipment designed for durability and easy sanitation. Explore our selection and find the perfect fit for your operation at https://preptables.com.