Your Ultimate Guide to Counter Top Refrigeration

Share

Picture this: it's the peak of your dinner rush. Tickets are flying, orders are piling up, and your line cooks are in the zone. This is where counter top refrigeration proves its worth, becoming the unsung hero of your kitchen. These compact powerhouses are the strategic workhorses that bring chilled ingredients right to the prep line, cranking up your speed and locking in food safety.

Why Counter Top Refrigeration Is a Kitchen Game Changer

In any commercial kitchen, the name of the game is efficiency. Every step a cook takes away from their station to grab something from a distant walk-in cooler is a wasted second. Those seconds add up, turning into serious delays during a hectic service. Counter top refrigeration slashes that wasted motion by creating a tight, ergonomic workflow.

When your chefs have chilled ingredients right at their fingertips, they can assemble dishes faster, keep every plate consistent, and get food out to customers quicker. It’s that simple.

But this is about more than just speed—it’s a non-negotiable part of food safety. By keeping perishable items like meats, cheeses, and prepped veggies within arm's reach and at a steady, safe temperature, you drastically reduce their time in the temperature "danger zone." That’s the 40°F to 140°F range where bacteria love to throw a party.

The Rise of Compact Cooling Solutions

It’s no surprise that the demand for these hyper-efficient units is on the rise. The commercial refrigeration market, which includes these countertop models, is set to grow from USD 12.16 million in 2025 to USD 16.19 million by 2035. This boom is all about the need for smarter, space-saving solutions in today's kitchens, especially with the rise of smaller restaurant footprints in packed urban areas. If you're interested, you can explore more market trends about commercial refrigeration solutions.

This trend points to a fundamental shift in how modern kitchens are designed. From high-volume restaurants to nimble food trucks, operators are realizing the massive benefits of decentralized cooling.

By integrating refrigeration directly into the prep line, kitchens not only improve their speed but also create a more organized and safer food handling environment. This is the core advantage that makes these units a true game changer.

Ultimately, these units bring a few key advantages to the table:

- Enhanced Workflow: It drastically cuts down on the back-and-forth, freeing up your team to focus on what they do best: cooking.

- Improved Food Safety: Ingredients stay at their ideal temperature right where you need them, minimizing the risk of spoilage and contamination.

- Space Optimization: You get essential refrigerated storage without giving up the massive floor space a traditional unit demands. This is a lifesaver for smaller kitchens.

To help you get a clearer picture of what's out there, here’s a quick rundown of the common types of counter top units and where they really shine.

Counter Top Refrigeration at a Glance

| Unit Type | Core Function | Ideal Business Type |

|---|---|---|

| Prep Rail / Topping Unit | Holding prepped ingredients (e.g., salad toppings, sandwich fillings) in pans. | Pizzerias, Salad Bars, Sandwich Shops, Delis |

| Glass Door Merchandiser | Displaying drinks, desserts, or grab-and-go items to entice customers. | Cafes, Convenience Stores, Bakeries, Food Trucks |

| Refrigerated Chef Base | A heavy-duty refrigerated drawer base designed to hold cooking equipment on top. | High-Volume Restaurants, Hotels, Institutional Kitchens |

Each of these serves a distinct purpose, but they all share the same goal: to make your kitchen run smoother.

Moving forward, we'll dive deeper into the specific types of counter top refrigeration, from versatile stainless steel prep tables to eye-catching display cases, to help you find the perfect fit for your operation.

Finding Your Perfect Prep Table

When you picture the heart of a commercial kitchen, maybe a big, roaring oven comes to mind. But honestly, the real MVP, the unsung hero of the service line, is the prep table. This isn't just a place to chop vegetables; it's a critical piece of counter top refrigeration where your menu comes to life. Getting the right one can turn a chaotic dinner rush into a smooth, well-oiled machine.

These units are much more than just a cold surface. They're specialized workstations, each built for a specific job. Because not all prep tables are created equal, you have to match the design to your kitchen's workflow and what you're serving. Let's dig into the most common types and see what makes them tick.

The Stainless Steel Advantage

Before we get into the different models, we need to talk about why stainless steel is the undisputed king of materials in any professional kitchen. It’s not just about that clean, professional shine. It’s about raw performance where it counts: hygiene and toughness.

- Exceptional Durability: Stainless steel can take a beating. It stands up to rust, corrosion, and the occasional dropped pan. In a busy kitchen where acidic things like citrus and tomato sauce are flying around, that resilience is a must-have.

- Non-Porous Surface: Wood and plastic have tiny little pores where bacteria love to hide and grow. Stainless steel doesn't. This makes it incredibly easy to clean and sanitize, which is non-negotiable for passing health inspections and keeping food safe.

- Ease of Sanitation: The smooth surface wipes clean in seconds. It won’t hang onto funky odors or get stained by food, which helps you avoid cross-contamination between things like raw meats and fresh produce.

This trifecta of features is why health inspectors and chefs are adamant about using stainless steel for any surface that touches food. It’s a smart investment in safety, efficiency, and the life of your equipment.

Types of Stainless Steel Prep Tables

Stainless steel prep tables are the workhorses of the commercial kitchen, but they aren't one-size-fits-all. Specialized designs optimize the workflow for specific menu items. The most common types you'll encounter are pizza prep tables and sandwich/salad prep tables, each engineered to make a particular task as efficient as possible.

Pizza Prep Tables: The Assembly Line Powerhouse

Picture yourself building a pizza. You need a big, wide surface to stretch the dough and instant access to tubs of sauce, cheese, and all your toppings. That is exactly what a pizza prep table is built for.

Think of it as a purpose-built assembly line for making pies. The most obvious feature is its deep, full-length cutting board, which gives you plenty of space—often 19 inches deep or more—to work with big pizza doughs without making a mess.

Right behind that cutting board sits a raised, refrigerated rail. This rail is designed to hold large, full-size food pans, so you can keep bulk ingredients like shredded cheese, pepperoni, and mushrooms right at your fingertips. The whole setup is designed to cut down on wasted movement, letting your pizza maker build and fire off pizzas at top speed.

A well-designed pizza prep table can cut assembly time by over 30%, a significant improvement during a dinner rush. Its workflow is purpose-built for high-volume, repetitive tasks.

The refrigerated base underneath gives you even more bulk storage for dough boxes, extra toppings, and more sauce. It’s an all-in-one system that keeps everything you need for pizza making chilled, organized, and ready to go.

Sandwich and Salad Prep Tables: The Versatile Organizer

If a pizza table is a specialist, then a sandwich prep table (also called a salad unit) is the jack-of-all-trades. Its design is all about a different challenge: organizing a huge variety of smaller ingredients for custom orders like sandwiches, salads, and wraps.

Instead of that extra-deep cutting board, these units usually have a narrower one, around 10-12 inches deep. That’s plenty of room to slice bread or toss a salad without eating up too much space.

The real game-changer is the refrigerated topping rail. It's set up to hold a bunch of smaller food pans (like 1/6-size or 1/9-size pans). This lets you keep dozens of different ingredients—from sliced tomatoes and onions to different cheeses and dressings—perfectly chilled and neatly organized.

This layout is perfect for any spot where customers build their own orders. A cook can just move down the line, adding a little of this and a scoop of that to create a unique meal for every person. To get a better look at these units, you can check out this guide to commercial refrigerated prep tables that breaks them down even further.

Here’s a quick chart to help you see the core differences between these two kitchen workhorses.

| Feature | Pizza Prep Table | Sandwich Prep Table |

|---|---|---|

| Primary Workflow | High-volume assembly of similar items (pizzas). | Custom assembly of varied items (sandwiches, salads). |

| Cutting Board | Deep (19"+) for large doughs. | Standard (10-12") for slicing and assembly. |

| Topping Rail | Holds fewer, larger pans for bulk toppings. | Holds many smaller pans for ingredient variety. |

| Ideal For | Pizzerias, Italian restaurants. | Delis, cafes, salad bars, sandwich shops. |

At the end of the day, picking the right prep table means looking hard at your menu. If you're slinging hundreds of pizzas a night, the specialized design of a pizza prep table is a no-brainer. But if your business is built on offering a wide variety of custom-made sandwiches and salads, the organizational power of a sandwich unit is the way to go. Once you understand these basic design differences, you can set up your prep line for maximum speed and efficiency.

Boosting Sales with Refrigerated Display Cases

Presentation can be the difference between a passing glance and a sale. While your prep tables are the hard-working heroes in the back, refrigerated display cases are your best salespeople out front. Don’t just think of this counter top refrigeration as a simple cooler; see it as a powerful marketing tool for your grab-and-go items, desserts, and drinks.

These units are built to make your products look absolutely irresistible. For cafes, delis, and markets, they’re a non-negotiable part of driving impulse buys. By putting chilled, ready-to-eat food and drinks right in the customer's line of sight, you’re creating sales that simply wouldn't have happened otherwise.

And this isn't just a hunch—it's a massively effective strategy. The market for countertop display fridges and refrigerated display cases hit USD 1.5 billion in 2024 and is expected to more than double to USD 3.2 billion by 2034. This explosion is all about consumer demand for convenience. We're seeing that well-placed units can lift impulse sales by a whopping 20-30% in busy spots.

Choosing Your Style: The Glass Matters

The style of glass on your display case directly shapes how customers see your products. Every design creates a different vibe and experience, so picking the right one comes down to your brand and what you're selling.

- Curved Glass: This style gives a sleek, elegant, and almost panoramic view of what's inside. It's a favorite for bakeries and cafes showing off cakes, pastries, and delicate desserts. The soft curve cuts down on glare and just feels more high-end.

- Straight Glass: Modern, clean, and direct. Straight glass displays give customers a clear, no-fuss view. They're perfect for delis and sandwich shops with organized rows of salads, sandwiches, and bottled drinks, creating a look that feels fresh and orderly.

- Open-Air Merchandisers: By removing the door, these grab-and-go units are all about accessibility. They practically invite customers to reach in and grab what they want. You'll want these in high-volume spots selling pre-packaged drinks, yogurts, and snacks where speed is everything.

Features That Make Products Irresistible

Beyond the glass shape, a few key features work together to make the food and drinks inside look their best. These are the details that turn a basic cooler into a machine that generates real revenue. A great countertop display fridge is an investment in your visual merchandising.

Brilliant LED lighting is a must. Old-school fluorescent bulbs can cast a yellowish, unappetizing glow, but LEDs produce a bright, clean light that makes the natural colors of your food pop. That slice of strawberry cheesecake looks richer, and a green salad looks crisper under good lighting.

A well-lit display case doesn’t just showcase products; it communicates freshness and quality. It’s a visual promise to the customer that what they see is what they’ll get.

Another game-changer is adjustable shelving. This lets you build dynamic, visually interesting displays instead of just lining things up in boring rows. You can angle shelves to feature certain items or take one out completely to fit taller things like tiered cakes or big drink bottles. This flexibility is key for adapting your display to seasonal specials or new menu items.

Finally, look for units with anti-fog glass. Nothing kills an impulse buy faster than a foggy door. Anti-fog technology, usually a heated glass or a special coating, keeps the view crystal clear, even in humid weather or when the door is opened a lot. It maintains that perfect window to your delicious offerings, keeping customer temptation right where you want it—high.

Decoding the Specs Before You Buy

When you’re investing in new equipment, it’s easy to get distracted by the sticker price or a sleek design. But to pick the right piece of counter top refrigeration, you need to put on your detective hat and dig into the technical specs. These are the details that determine whether a unit will be a workhorse or a headache in your specific kitchen. This guide will walk you through what actually matters, so you can make a smart, safe, and cost-effective choice.

First things first: break out the tape measure. Seriously. Before you even start browsing, know the exact dimensions you’re working with. This simple step can save you from the classic, costly mistake of ordering a unit that’s just a half-inch too wide for your prep line.

Capacity and Dimensions

A unit's capacity, usually measured in cubic feet, tells you how much it can hold—in theory. In reality, that number can be deceiving. A unit with a generous cubic footage might have a funky internal layout that just doesn't work with your standard pans and containers.

You have to think in practical terms. Will it hold six of your 1/3-size food pans? Can you slide two full-size sheet pans inside? Always match the unit's internal dimensions to the inventory you actually need to keep cold.

The most common mistake is buying for maximum capacity instead of optimal workflow. A slightly smaller unit that perfectly fits your standard containers will always be more efficient than a larger one that creates disorganized clutter.

This is especially true for undercounter or countertop models where every single inch is prime real estate. Look at the width, depth, and height to make sure it not only fits into its designated slot but also doesn't block your workspace.

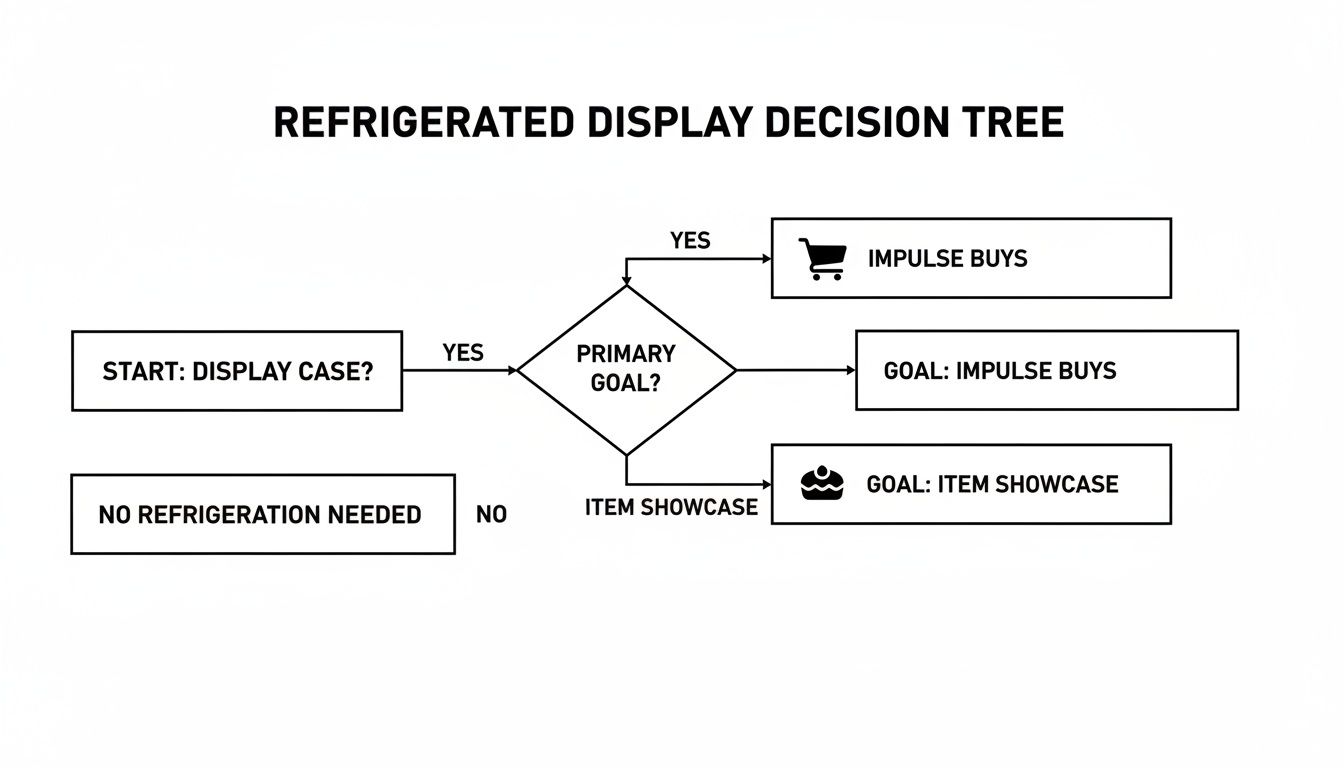

The flowchart below gives you a straightforward way to think about your goals, helping you narrow down the right type of display unit for your business.

This visual guide cuts through the confusion by starting with what you're trying to achieve, whether that's sparking impulse buys or showcasing high-end desserts.

Key Feature Comparison for Smart Buying

Understanding how technical specifications translate into real-world benefits for your business is key. This table breaks down what those spec sheet terms actually mean for your day-to-day operations.

| Specification | What It Means | Why It Matters for You |

|---|---|---|

| Capacity (Cubic Feet) | The total internal volume of the unit. | A bigger number isn't always better. Focus on a layout that fits your pans and containers efficiently to maximize usable space, not just empty air. |

| Temperature Range | The range of temperatures the unit can reliably maintain. | This is a food safety fundamental. Ensure the range (e.g., 33°F-40°F) matches health code requirements for your specific products, like dairy, produce, or meats. |

| Compressor Location | Where the compressor is located and how it ventilates. | Front-breathing units can be built-in flush with walls. Rear-breathing units need clearance, impacting where you can place them. This detail dictates your installation options. |

| NSF Certification | A guarantee that the unit meets public health standards. | This is non-negotiable for commercial use. Health inspectors will look for this seal, as it ensures food-safe materials and easy-to-clean design. |

| ENERGY STAR Rating | A federal certification for energy efficiency. | While it might cost more upfront, this certification translates directly into lower monthly utility bills, saving you significant money over the unit's lifespan. |

Thinking through these points before you purchase ensures the equipment you choose is a true asset, not a future problem waiting to happen.

Temperature Range

Not all chilled food is created equal. The perfect temperature for keeping milk fresh isn't the same as what you need for raw fish or delicate produce. A unit's temperature range is a critical spec that has a direct impact on both food safety and quality.

Most standard commercial refrigerators hold steady between 33°F and 40°F, which covers a huge variety of ingredients. However, if you're dealing with very specific items, like certain desserts or sushi-grade fish, you may need a unit that can hold a colder, more precise temperature. Always confirm the manufacturer's stated range meets the health code standards for everything you plan to store.

Compressor Location and Ventilation

The compressor is the heart of any refrigeration unit, and its location is a crucial detail that many people overlook. This spec determines where you can—and can't—safely install the equipment.

You’ll typically see two main types of ventilation systems:

- Front-Breathing Units: These models pull in cool air and push out hot air through a grille on the front, usually at the bottom. This design is perfect for building units directly into a counter or placing them flush against a wall without any risk of overheating. They are your best bet for any built-in application.

- Rear-Breathing Units: These require open space around the back and sides to get proper airflow. They are often a bit more budget-friendly, but you have to give them several inches of "breathing room." Blocking that airflow is one of the fastest ways to overwork the compressor and kill your investment.

Certifications That Matter

Finally, when you're comparing models, keep an eye out for two very important logos: NSF and ENERGY STAR.

- NSF (National Sanitation Foundation): For any commercial kitchen, this certification is a must-have. It's your guarantee that the unit is built with food-safe materials and is designed to be easily cleaned and sanitized. Your health inspector will be looking for it.

- ENERGY STAR: A unit with this label has been certified to be more energy-efficient than its standard counterparts. It may have a slightly higher purchase price, but an ENERGY STAR-rated refrigerator can save you hundreds of dollars on your electricity bills over its lifetime.

The Next Generation of Smart Refrigeration

What if your prep table could text you before a tiny temperature shift becomes a massive health code violation? It’s not science fiction anymore—it's the new reality of smart counter top refrigeration. This isn't just about keeping things cold; it's about integrating IoT (Internet of Things) tech to give you total control over your kitchen's most critical equipment.

This technology connects your refrigeration units directly to the internet, turning them into smart, data-driven tools. Instead of just crossing your fingers and hoping everything is working, you get real-time data and alerts sent straight to your phone or computer. It's like having a dedicated equipment manager on duty 24/7.

Practical Benefits of a Connected Kitchen

Smart refrigeration isn't some flashy gimmick. It’s about solving the real, expensive problems that every food service business faces. The benefits are tangible, hitting your bottom line and giving you some much-needed peace of mind.

Imagine getting an instant alert if a cooler door is left open after closing, or if a display case's temperature starts creeping up overnight. That early warning can save you thousands of dollars in spoiled product.

Smart refrigeration changes the game from reactive crisis management to proactive quality control. It empowers you to fix a problem before it costs you money, inventory, or your hard-earned reputation.

There's a good reason the smart technology market is booming. While the entire smart fridge market is projected to hit USD 4.1 billion in 2025, these connected countertop and undercounter units are becoming non-negotiable in commercial kitchens. These IoT models allow for remote monitoring and automated temperature control, which can slash energy use by up to 30% and dramatically cut down on food waste. You can learn more about the growth of the smart refrigerator market and why it's becoming so important.

Key Smart Features to Look For

When you're shopping for smart counter top refrigeration, a few key features deliver the biggest bang for your buck in a busy kitchen. These tools work together to make your operation safer, more efficient, and ultimately more profitable.

- Remote Temperature Monitoring: This is a big one. It lets you check on your equipment from anywhere, anytime. You get a perfect digital log for health inspections and absolute certainty that your inventory is always being held at a safe temperature.

- Automated Alerts: Get texts or emails for critical events—think temperature swings, power outages, or a door left open too long. This immediate heads-up is crucial for preventing spoilage before it starts.

- Predictive Maintenance Diagnostics: The smartest units monitor their own health, tracking compressor cycles and other vital signs. They can warn you about a potential problem before a catastrophic failure happens, letting you schedule maintenance on your terms instead of dealing with a costly emergency repair during the dinner rush.

Simple Maintenance to Maximize Your Investment

Your countertop refrigeration unit is a daily workhorse. Just like any other critical piece of equipment in your kitchen, a little bit of preventive care will go a long, long way. The two most important things you can do to protect your investment are proper installation and routine maintenance—these will extend its lifespan and save you from the stress of a costly emergency repair down the line.

Getting the setup right from day one is absolutely essential. The single biggest mistake we see operators make is failing to provide adequate ventilation. Every single unit needs space to breathe, which allows the compressor to push out heat efficiently. If you block that airflow, you're forcing the compressor to work overtime, leading to premature burnout and total system failure.

Always follow the manufacturer’s specs for clearance, which is usually a few inches at the back and sides. While you're at it, make sure the unit is perfectly level. An unbalanced unit can keep the doors from sealing properly, causing cold air to leak out. That's a huge waste of energy and a major risk to your food's safety.

Creating a Simple Maintenance Checklist

Once your unit is installed correctly, a simple, consistent maintenance routine is your best defense against breakdowns. You don’t need to be a technician; these are straightforward tasks that any staff member can handle. Following a regular schedule ensures your counter top refrigeration operates at peak efficiency.

Here is a basic checklist to get you started:

- Clean Condenser Coils Monthly: The condenser coils are what release heat from the unit. Over time, they get caked with dust, grease, and all sorts of kitchen debris, forcing the compressor to work much harder than it should. A quick cleaning with a stiff brush can dramatically improve energy efficiency and prevent overheating.

- Inspect Door Gaskets Weekly: Those rubber seals around the doors, known as gaskets, are critical for holding the temperature steady. Check them for any cracks, tears, or brittleness. A simple test is to close the door on a dollar bill; if you can pull it out easily, the seal is weak and probably needs to be replaced.

- Sanitize Interior Surfaces Daily: This is a basic but critical food safety step. At the end of each day, wipe down all interior surfaces with a food-safe sanitizer to stop bacterial growth and prevent any cross-contamination.

Think of maintenance not as a chore, but as a small, regular investment in your equipment's health. Five minutes of cleaning a condenser coil today can save you from a $500 emergency repair bill next month.

Following this simple plan will not only prolong the life of your equipment but also keep it running safely and efficiently. For more detailed instructions, a guide on using a specialized refrigerator condenser cleaner can provide step-by-step visuals. If you want to delve deeper into more advanced upkeep for your entire refrigeration lineup, it can be useful to compare different approaches like predictive vs. preventive maintenance strategies. These habits will make sure your investment pays off for years to come.

Frequently Asked Questions

When you're outfitting a kitchen, a lot of practical questions pop up. For counter top refrigeration, getting the small details right can really impact your kitchen's workflow and how efficiently you operate. Let's tackle some of the most common questions business owners have when they're picking out, installing, and using these vital units.

Getting clear answers on everything from the specific design of a prep table to why certifications matter helps you make a smarter investment.

What Is the Main Difference Between a Pizza Prep and Sandwich Prep Table

The big difference is how they're designed for a specific workflow. A pizza prep table is all about high-volume pie making. It has a very deep cutting board, often 19 inches or more, so you have plenty of room for large doughs. The refrigerated rails are set up to hold full-size pans for heaping on bulk toppings like cheese and sauce.

A sandwich or salad prep table, on the other hand, is built for variety. The cutting board is usually not as deep, and the refrigerated rail is designed to hold lots of smaller pans. This setup is perfect for keeping a wide array of ingredients organized and portioned out, making it fast to build custom sandwiches, salads, or wraps.

Should I Choose a Front Breathing or Rear Breathing Unit

This decision is all about your kitchen space and where you plan to put the unit. Front-breathing units are made to vent from the front, typically through a grille near the bottom. This design lets you install them right up against a wall or even build them into a counter without worrying about the compressor overheating. They're the go-to choice for tight spaces.

Rear-breathing units need a few inches of clear space behind and on the sides to ventilate properly. They are often a bit friendlier on the budget, but you can't box them in. If you can't guarantee enough room for air to flow, you should always go with a front-breathing model to avoid it breaking down prematurely.

Why Is NSF Certification So Important for Commercial Equipment

NSF (National Sanitation Foundation) certification is a stamp of approval that shows a piece of equipment meets strict standards for public health and safety. It’s an independent guarantee covering several critical points.

NSF certification isn't just a sticker; it's confirmation that the equipment's materials are safe for food contact, its design is easy to clean and prevents bacterial growth, and it can reliably maintain safe temperatures.

Health departments all over the country require food service equipment to be NSF-certified. This makes it a non-negotiable for passing inspections, staying compliant, and ensuring food safety.

Ready to optimize your kitchen with the perfect prep station? The experts at PrepTables.com can help you find the ideal counter top refrigeration solution to boost your efficiency and food safety. Explore our extensive collection of commercial prep tables and refrigeration units today!