Choosing Your Commercial Ice Machine Maker

Share

Picking the right commercial ice machine maker is one of those make-or-break decisions for any food or hospitality business. I’ve seen it firsthand—the right machine hums along, quietly fueling your success with a steady supply of clean ice. The wrong one? It becomes a constant source of headaches, operational snags, and unexpected bills.

This isn't just about making cold drinks; it's about investing in the heart of your daily operations.

Your Guide to Selecting the Right Ice Machine

Think about it. From keeping seafood fresh in a display case to crafting the perfect cocktail at a packed bar, high-quality ice isn't a luxury—it's essential. A dependable machine is your silent partner, ensuring you never have to tell a customer "no" and always meet health and safety codes without a second thought.

The market for these workhorses is massive for a reason. Valued at USD 5.3 billion in 2024, it's on track to hit a staggering USD 7.4 billion by 2033. North America alone makes up over 37.8% of that, which tells you just how much our restaurants, bars, and hotels rely on ice every single day. This isn't just a niche appliance; it's a cornerstone of the industry.

Key Decision Factors at a Glance

So, how do you cut through the noise and find the perfect fit? Don't get bogged down in a sea of technical jargon. Your best bet is to focus on a handful of core factors that truly matter for your day-to-day.

To make it easier, here’s a quick-glance table breaking down what you should be thinking about.

| Factor | Why It Matters | Quick Tip |

|---|---|---|

| Daily Ice Needs | Getting this wrong means either running out of ice during a rush or wasting energy on a machine that's too big. | Base your calculation on real numbers—like meals served or drinks poured—not just a gut feeling. |

| Ice Type | The shape of your ice (cube, nugget, flake) drastically changes drink presentation, dilution, and even how much you can pack into a display. | Match the ice to the job. Full cubes are perfect for classic cocktails; flake ice is a must for produce displays. |

| Available Space | The physical layout of your kitchen or bar will determine if you need an undercounter, countertop, or a larger modular unit. | Get out the tape measure! Check your footprint—and don't forget to account for ventilation clearance—before you start looking at models. |

| Utility Requirements | Water lines, electrical hookups, and proper drainage are non-negotiable. An oversight here can lead to big installation headaches. | Talk to your plumber or building manager to confirm your site's capacity. This can save you from very expensive surprises. |

A well-chosen commercial ice machine should blend seamlessly into your workflow, not disrupt it. Think of it as an investment in operational efficiency, customer satisfaction, and food safety.

By breaking the process down into these practical steps, you can turn a potentially overwhelming task into a straightforward decision. This approach helps ensure your investment pays off in both reliability and performance. For a closer look at specific models and features, you might find our in-depth article on commercial ice machines helpful as you narrow down your choices.

Calculating Your Actual Daily Ice Needs

Getting your capacity wrong is one of the costliest mistakes you can make when buying a commercial ice machine maker. If you buy a machine that’s too small, you’ll be making those dreaded emergency runs for bagged ice during your busiest hours. On the other hand, an oversized machine just burns through electricity and water, inflating your utility bills for ice you never even use.

Let’s move beyond guesswork. The real goal is to land on a precise number that’s actually driven by your business’s real-world needs, not just generic averages.

Start With Industry Benchmarks

Even though your business is unique, industry standards give you a great starting point for your calculations. These rules of thumb come from decades of experience across different types of establishments. Think of them as a baseline production target before you start fine-tuning.

Here are a few common estimates to get you in the right ballpark:

- Restaurants: A good starting point is 1.5 lbs of ice per meal served. If you have a bar, you'll need to factor in extra.

- Bars & Nightclubs: Operations heavy on beverages need a lot more ice. Plan for about 3 lbs of ice per customer.

- Hotels: The standard calculation is around 5 lbs of ice per room. This should cover guest needs for ice machines and room service.

- Healthcare: Hospitals and patient care facilities should estimate 10 lbs of ice per bed to handle consumption, ice packs, and various medical uses.

- Cafes & Coffee Shops: These businesses usually require about 1 lb of ice per customer, especially if iced lattes and blended drinks are big sellers.

A critical point to remember: these figures are for ice consumed, not just what the machine makes. You have to account for meltage inside the storage bin, which can easily eat up 10-20% of your usable ice before it ever makes it into a drink.

So, for a restaurant that serves 200 meals on a peak night, you’d need at least 300 lbs of ice (200 meals x 1.5 lbs), plus that buffer for meltage. Now, let's dial that number in.

Fine-Tune Your Calculation

With a baseline number in hand, it's time to adjust it for the specific rhythm of your business. Every place has its own peaks and valleys that a general benchmark can't account for. The key is to think critically about when and how you use ice the most.

You’ll want to consider these factors:

- Peak Demand: Don't plan for an average Tuesday. Plan for your busiest Friday night. Look at your customer counts during your peak two-to-four-hour rush to really understand what maximum demand looks like.

- Seasonal Swings: A restaurant patio in July is going to fly through ice way faster than a cozy dining room in the middle of January. If your business is seasonal, it's smart to bump up your estimate by 20-30% for those warmer months.

- Menu Specifics: What you serve really matters. A cocktail-focused bar using tall highball glasses will use a ton more ice than a pub that mostly pours beer and wine. If you're also using ice for things like seafood displays or salad bars, you have to add that volume to your daily total.

Taking the time to apply these adjustments will give you the confidence you need to choose the right size for your operation. For a deeper dive into matching machine specs with your needs, our guide on choosing an ice machine for commercial use has some more valuable tips. A little extra calculation today will save you from major headaches down the road.

Matching Ice Types to Your Business Needs

Once you've nailed down how much ice you'll go through each day, the next big decision is figuring out the right kind of ice for your business. It's a detail that's easy to overlook, but believe me, not all ice is created equal. The shape and size of the cube can make or break everything from how fast a drink waters down to how your fresh fish looks in the display case.

The right commercial ice machine maker is the one that produces the perfect ice for what you do. There's a reason the global market for these machines is seeing steady growth—around 3.5% CAGR from 2023 to 2030. From high-end bars to hospitals, everyone has unique needs. This trend is driven by innovations in machine tech and the growing variety of ice types available. If you're a data nerd like me, you can dig into the specifics in this detailed commercial ice maker market report.

Choosing Your Ideal Ice Shape

Think of the ice from your machine as a key ingredient. A craft cocktail lounge needs something completely different from a hospital cafeteria or a seafood market. Let’s look at the most common types and where they really make a difference.

-

Full Cube Ice: These are the big, classic cubes that melt incredibly slowly. Because they have a large surface area, they're the absolute best choice for premium spirits and cocktails where you want to chill the drink without diluting it. Perfect for an old-fashioned or a quality scotch on the rocks.

-

Half Cube Ice (or Diced Ice): You can think of these as the all-around workhorses of the food and beverage world. They’re smaller and more versatile, packing tightly into glasses for soft drinks, iced coffee, and even blended drinks. They dispense quickly, which is a huge plus in a fast-paced environment.

-

Nugget Ice (or Chewable Ice): Soft, porous, and famously chewable, nugget ice is a huge customer favorite. It soaks up the flavor of whatever it's in and is fantastic for sodas, smoothies, and even for therapeutic use in healthcare. Just remember, it’s less dense, so it takes up more space in the cup—something to factor into your drink costs.

-

Flake Ice: This type is made of soft, small chips that can be molded to any shape. It's the standard for displaying and preserving fresh seafood and produce in salad bars. It also cools items down fast and evenly without bruising delicate foods, making it ideal for physical therapy packs.

Think about the customer experience. A drink served with solid, crystal-clear full cubes feels premium. On the other hand, nugget ice offers that fun, crunchy texture that some people will go out of their way to find. Your ice is a small but important part of your brand.

Finding the Right Machine Style

After you've picked your ice shape, the last piece of the puzzle is choosing a machine style that works with your space and your team's workflow. How your kitchen is laid out will usually point you toward one of three main types.

1. Modular Units

These are the heavy hitters, built for places that need a ton of ice—think large restaurants, hotels, and hospitals. A modular unit is basically just the ice-making "head," which sits on a separate storage bin. This lets you mix and match, pairing a high-capacity head with whatever size bin you need.

2. Undercounter Machines

These are lifesavers in bars, cafes, and small kitchens where every inch of space counts. An undercounter machine is an all-in-one unit with the ice maker and storage bin built into a single, compact piece that slides right under a standard 40-inch countertop. They produce a moderate amount of ice and are great for point-of-use service.

3. Countertop Dispensers

You’ve seen these in office break rooms, hotel breakfast bars, and self-serve drink stations. They produce and dispense ice directly into a cup with the push of a lever or button. This setup is super convenient for guests and helps minimize contamination.

Beyond Ice: The Role of Stainless Steel Prep Tables

A commercial ice machine maker is a powerful asset, but its true value is unlocked when your entire kitchen workflow is optimized for speed and efficiency. That's where your prep surfaces come into play. In any professional kitchen, stainless steel prep tables are the undisputed champions. They are the foundation of food preparation, prized for their unmatched durability, hygienic properties, and resistance to corrosion.

The most common type you'll encounter is the standard flat-top prep table. Think of these as the versatile all-rounders in your culinary arsenal. They provide a simple, sturdy surface for everything from chopping vegetables to portioning meat. Their non-porous surface is a breeze to sanitize, which is non-negotiable for meeting health codes. Many also come with an undershelf for extra storage or a backsplash to protect walls from splashes.

Specialized Prep Stations for Peak Efficiency

While a flat-top table is essential, many businesses benefit from more specialized equipment designed to streamline specific tasks. When your menu is built around items like sandwiches, salads, or pizzas, a specialized prep table isn't just a luxury; it's a game-changer for speed, consistency, and organization. These units are engineered to pull everything you need into one ergonomic workstation.

This is where you see the genius of sandwich prep tables and pizza prep tables. They're far more than just a surface; they're complete, self-contained refrigerated workstations that keep all your essential ingredients chilled and within arm's reach.

Here's a huge takeaway for any high-volume kitchen: moving refrigeration directly to the prep line is one of the smartest things you can do. It eliminates the wasted steps of staff walking back and forth to a separate reach-in cooler. Those seconds saved on every single order add up fast, dramatically improving ticket times during a busy rush.

It might seem like a small layout change, but it makes a massive difference in your operational flow and customer satisfaction.

Pizza Prep vs. Sandwich Prep Tables: Key Differences

At a glance, pizza and sandwich prep tables look quite similar. Both feature a refrigerated base for storing bulk ingredients and a chilled rail on top to hold food pans. But the design differences are crucial, as they are engineered for very different jobs.

-

Pizza Prep Tables: These are built with a much wider and deeper cutting board, usually 19 inches or more. You need that extra real estate for stretching out large pizza doughs without making a mess or feeling cramped. The refrigerated rails are also configured to hold larger pans for high-volume toppings like cheese and sauce.

-

Sandwich Prep Tables: In contrast, these tables have a much narrower cutting board, typically around 10-12 inches deep. It's the perfect size for building sandwiches, wrapping burritos, and assembling salads. Their top rails are designed for smaller, third or sixth-size pans, which is ideal when you have a wider variety of smaller-portioned ingredients like different sliced meats, cheeses, and veggie toppings.

Choosing the right specialized table comes down to your menu. A bustling pizzeria would be seriously slowed down by a narrow sandwich table. Likewise, a deli would find a wide pizza table to be a clunky waste of valuable kitchen space. Making the right choice here is a smart investment that pays off in operational excellence every single day.

Comparing Ice Machine Cooling Systems

Let's talk about the heart of your commercial ice machine maker: the cooling system. This isn't just a minor detail—it's the core component that determines how well your machine runs, where you can even put it, and what your utility bills will look like. Picking the right one is a bit of a balancing act between the upfront cost, long-term operational expenses, and the realities of your kitchen environment.

You’ll run into three main types of cooling systems, also known as condensers: air-cooled, water-cooled, and remote-cooled. Each has its place, and understanding the pros and cons is key to making a smart purchase.

Air-Cooled Systems: The Common Choice

Air-cooled ice machines are what you'll see most often, and for good reason. They're the most affordable to buy and the easiest to get up and running. These machines work a lot like your home refrigerator, using fans to pull in the surrounding air and blow it over the condenser coils to cool everything down.

They're a solid pick for most businesses, especially if you have decent ventilation and the ambient temperature stays reasonable. The big catch? They need room to breathe. You absolutely must give them at least 6 inches of clearance on all sides for them to work properly. If you shove one into a hot, cramped corner, it’s going to struggle, producing less ice and driving up your energy costs as it works overtime just to stay cool.

Water-Cooled Systems: For Hot Kitchens

Now, if you're dealing with a tight, sweltering space where airflow is a pipe dream, a water-cooled ice machine is your hero. Think busy bakeries or a packed restaurant line. Instead of using air, these units circulate water through the condenser to pull heat away. This makes their performance rock-solid and predictable, no matter how hot the kitchen gets.

But there's a trade-off, and it's a big one: your water bill. A water-cooled machine can be a real guzzler, often using over 100 gallons of water for every 100 pounds of ice it makes. While they run quieter and won't dump extra heat into your kitchen, that ongoing water expense is something you have to budget for carefully.

Expert Tip: Before you commit to a water-cooled model, I always tell people to check with their local municipality. Some cities have strict regulations on water usage that could make these units a non-starter.

Remote-Cooled Systems: The Quiet Performer

For those who want the best of both worlds—and have the budget for it—there are remote-cooled systems. With this setup, the part that makes all the noise and heat (the condenser) is installed completely separately from the ice machine, usually outside on the roof or behind the building.

This is the perfect solution for businesses where peace and quiet are a priority, like an upscale bar or a cafe with an open-kitchen design. The installation is definitely more involved and costs more upfront, but the payoff is a cooler, more comfortable kitchen and consistently high ice production, no matter what's happening indoors.

To help you decide, it’s useful to see how these systems compare side-by-side.

Air-Cooled vs Water-Cooled vs Remote-Cooled Systems

| System Type | Best For | Pros | Cons |

|---|---|---|---|

| Air-Cooled | Most standard kitchens with good ventilation and moderate temperatures. | - Lowest initial cost - Easiest installation - No extra water usage |

- Can struggle in hot environments - Adds heat and noise to the kitchen - Requires significant clearance |

| Water-Cooled | Hot, poorly ventilated, or cramped spaces. | - Unaffected by ambient air temperature - Very quiet operation - Doesn't add heat to the workspace |

- High water consumption and cost - Higher initial cost than air-cooled - May be subject to water use regulations |

| Remote-Cooled | Customer-facing areas or businesses where noise and heat are major concerns. | - Removes all heat and noise from the kitchen - Most energy-efficient in the long run - Consistent performance |

- Highest initial cost - Most complex installation - Requires outdoor space for the condenser |

No matter which system you choose, its efficiency and lifespan are directly tied to how well you maintain it. This isn’t just about avoiding breakdowns; it’s about money.

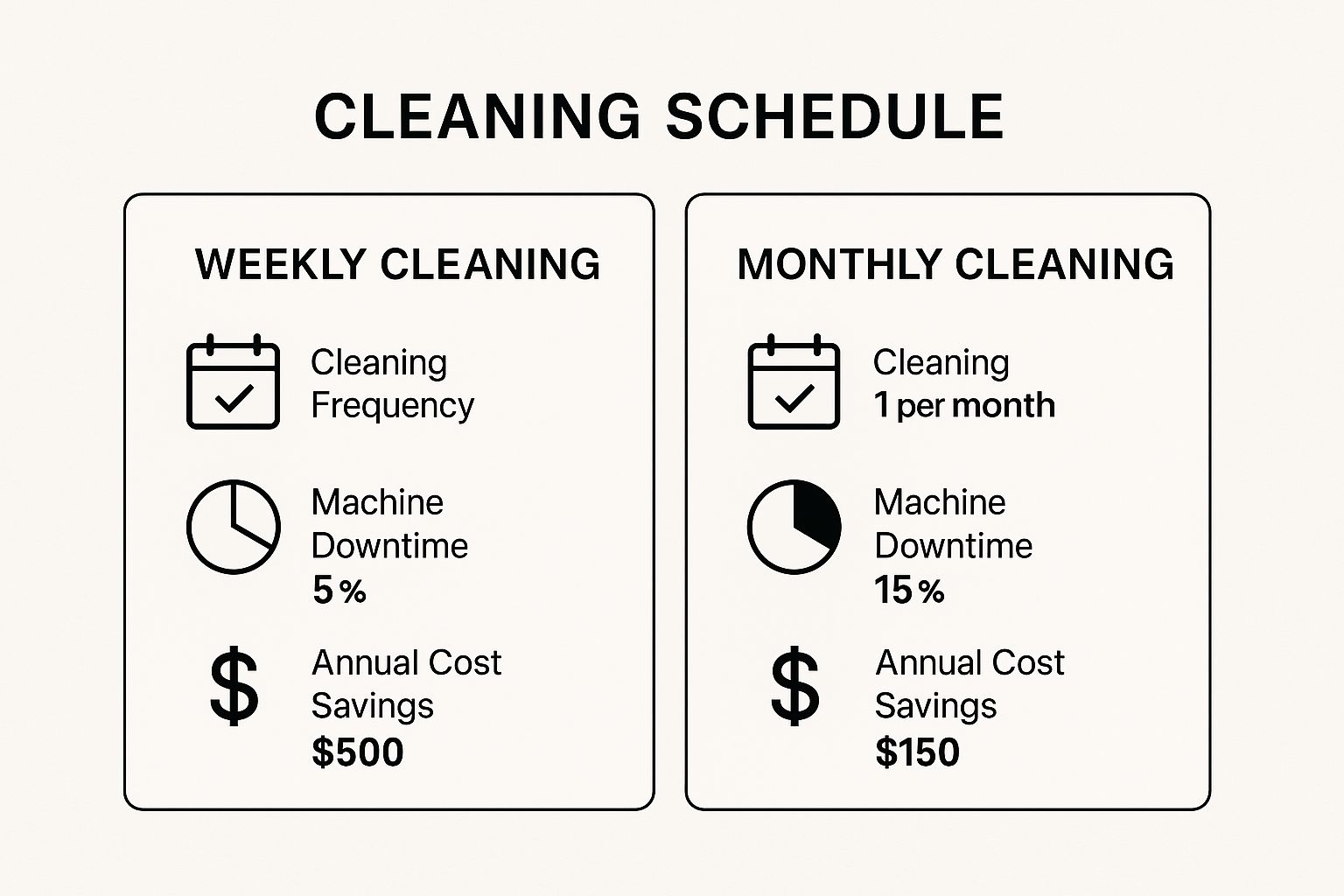

As you can see, a consistent cleaning schedule does more than just keep the machine running—it leads to real, measurable savings and less downtime, which goes straight to your bottom line.

Planning for Maintenance and Ownership Costs

The sticker price on a new commercial ice machine is just the beginning of the story. I've seen too many business owners get hit with surprise costs down the road because they only focused on the initial purchase. The real pros know that thinking about the total cost of ownership—including maintenance, sanitation, and potential repairs—is what keeps your business running smoothly and avoids nasty surprises.

An ice machine isn't a "set it and forget it" piece of equipment. It’s an ongoing commitment. If you neglect it, you’re practically inviting problems like scale buildup from hard water, or even worse, the growth of slime and mold. These issues don't just wreak havoc on the machine's internal parts; they can create serious health risks for your customers and lead to costly health code violations.

The Importance of Water Filtration

Before we even get into cleaning schedules, let’s talk about something non-negotiable: a good water filtration system. This isn't just a nice little add-on; it's essential protection for your investment. Filters are your first line of defense, removing the minerals and sediment that cause that damaging scale buildup, which can clog up water lines and destroy expensive components.

A quality filter also makes a huge difference in the taste and clarity of your ice. That directly impacts the quality of every single drink you serve. Think of it as the foundation of your maintenance strategy. It makes every other cleaning effort more effective and less frequent.

Budgeting for the Long Haul

That initial price tag is just one piece of the puzzle. A smart budget needs to account for the entire life of the machine.

You've got to factor in the potential expenses that will pop up over the years:

- Repairs: Even the most reliable machines have parts that can fail. Setting aside a small fund for service calls can turn a potential crisis into a minor inconvenience.

- Professional Servicing: Most manufacturers recommend having a pro come in for a deep clean and tune-up every six months. This service keeps your machine running at peak efficiency and can spot small issues before they become major, business-halting problems.

- Replacement Parts: Things like water pumps, sensors, and fan motors won't last forever. Being aware of the potential replacement costs for these common wear-and-tear items helps you plan ahead and avoid getting blindsided.

Your commercial ice machine is a revenue-generating asset. Investing in its upkeep directly protects your bottom line by preventing downtime and ensuring you always serve a safe, high-quality product.

The global market for these machines is on the rise, projected to hit USD 1.86 billion by 2033. This growth is driven by new tech like built-in water purification and touch-screen controls that make operation and maintenance easier than ever. You can dig into these trends by exploring the latest industry insights from Business Research Insights.

For a deeper dive into different models, check out our guide on finding the right commercial ice machine ice maker for your business. Planning for these ongoing costs from day one is the key to making sure your machine remains a reliable workhorse for years to come.

Common Questions About Commercial Ice Machines

Even with the best research, you're going to have questions when it's time to invest in something as critical as a commercial ice machine maker. It's a big purchase, and getting clear answers is the only way to feel confident you're making the right call. Let's walk through some of the most common questions I get from business owners just like you.

How Often Does A Commercial Ice Machine Need Professional Cleaning?

For most businesses, the standard recommendation from both manufacturers and health departments is a professional cleaning and service at least every six months. This isn't just a quick wipe-down; it's a deep clean that involves descaling and sanitizing all the internal parts to stop bacteria and that nasty pink slime from taking hold.

However, your specific environment plays a huge role. If your establishment has hard water or a lot of ambient yeast—think bakeries or breweries—you really need to bump that schedule up to every three months. Staying ahead of potential buildup is the single best way to protect your ice quality, keep your customers safe, and ensure your machine runs efficiently.

What Is The Average Lifespan Of A Commercial Ice Machine?

When you take good care of it, a quality commercial ice machine should serve you well for anywhere from 5 to 10 years. I've even seen some well-maintained workhorses last longer.

The two biggest factors that determine how long your machine will last are your water quality and your cleaning routine. A solid water filtration system is an absolute must-have, and you have to be disciplined about regular maintenance. If you slack off on cleaning, you could easily slash the machine's lifespan in half, forcing you into a costly replacement far sooner than you planned.

Don't forget that professional installation is vital for more than just performance—it protects your warranty. Most manufacturers will void the warranty instantly if the unit isn't installed by a certified technician. This is one DIY project that's just not worth the risk.

What Is The Difference Between A Pizza Prep Table And A Sandwich Prep Table?

At first glance, they look pretty similar, but they're engineered for completely different kitchen workflows. Both are refrigerated prep stations with rails for holding ingredients, but the real difference comes down to the depth of the cutting board and the size of the pans they're built to hold.

- Pizza Prep Tables: These tables are all about space. They have an extra-wide and deep cutting board, often 19 inches or more, giving your team plenty of room to stretch and top large pizza doughs without feeling cramped.

- Sandwich Prep Tables: These are designed for more delicate assembly work. The cutting board is much narrower, typically around 10-12 inches deep, which is perfect for building sandwiches and portioning salads. The rails are also set up for smaller pans to hold a wider variety of fresh toppings.

Matching the table to the task is a simple way to create a more natural, efficient assembly line in your kitchen.

Ready to find the perfect equipment to support your operations? From high-capacity ice makers to specialized prep tables, PrepTables.com has the durable, NSF-certified equipment you need to optimize your kitchen's workflow. Explore our full collection of commercial kitchen solutions and build a more efficient workspace today.