Ultimate Guide to Commercial Ice Machine Ice Maker Selection

Share

A commercial ice machine is so much more than just another appliance—it's the silent, hardworking engine that powers your business's day-to-day operations. Picking the right commercial ice machine ice maker isn't just a purchase; it's a critical strategic decision that has a direct impact on everything from customer satisfaction and safety to your bottom line.

Why Choosing the Right Ice Machine Matters

Think about the last time you got a drink with cloudy, weird-tasting ice. It instantly drags down the quality of the whole experience, doesn't it? For any business in foodservice, hospitality, or even healthcare, ice isn't just frozen water. It’s a core ingredient.

The right machine ensures you never have to face that recurring nightmare: running out of ice during a peak service rush. That kind of reliability is the bedrock of smooth operations, helping you avoid frustrating delays that cost you sales and annoy your customers.

Beyond Just Making Ice

A modern commercial ice machine does a lot more than just freeze water; it’s a guardian of your customers' health and your hard-earned reputation. Clean ice and proper handling are completely non-negotiable for safety. The perfect unit helps you meet—and even exceed—health code standards by preventing the growth of slime and bacteria that can easily contaminate your entire ice supply.

This one decision ripples through your finances in a few key ways:

- Energy Efficiency: A machine that’s the right size and is well-maintained will use less electricity and water, keeping your utility bills in check.

- Maintenance Costs: When you invest in a quality machine with good water filtration from the start, you'll have fewer breakdowns and fewer calls for expensive emergency repairs.

- Customer Loyalty: Serving up consistently clean, clear ice that’s right for your drinks or food displays is a small touch that makes a big difference to your brand's image.

The choice of a commercial ice machine ice maker is an investment in your operational backbone. It's about building a reliable system prepared for your busiest days and future growth, not just meeting today's minimum needs.

A Growing Market Driven By Need and Innovation

The importance of these machines is obvious when you look at their growing presence in the market. It’s not just restaurants and bars anymore. The global market for commercial ice makers is booming in vital sectors like healthcare, where ice is absolutely essential for patient care.

This growth is being pushed forward by some serious innovation. Today’s models are smarter than ever, often featuring digital controls, built-in water purification systems, and much better energy performance. The global market, valued at around USD 1.4 billion, is expected to climb to USD 1.86 billion by 2033. That’s a clear sign of just how crucial these machines are becoming across all sorts of industries. You can learn more about the trends driving the commercial ice machine market on Business Research Insights.

To make a smart choice, you have to get a handle on the core factors that set one machine apart from another. This guide will walk you through the essentials—like ice types, production capacity, and different machine configurations—so you can confidently pick the perfect commercial ice machine ice maker for your business.

Matching The Ice Type To Your Business

It’s easy to think of ice as just frozen water, but in a professional setting, that couldn't be further from the truth. The type of ice you choose has a direct impact on everything from your customer's drink to your operational bottom line. Think of it less like a utility and more like a key ingredient. The right choice can make a cocktail unforgettable, keep seafood looking its best, or even provide critical comfort to a patient.

Your journey to finding the perfect commercial ice machine ice maker really starts here, by understanding what each type of ice brings to the table. From the chunky, crystal-clear cubes in a high-end lounge to the soft, chewable nuggets in a fast-food soda, your ice choice says a lot about your standards and your business's day-to-day needs.

Commercial Ice Type Comparison Guide

To make this decision easier, let's break down the most common types of commercial ice. Each one has a unique personality and a specific job it's best suited for. This table gives you a quick-glance comparison to see which one fits your business model.

| Ice Type | Description & Characteristics | Melting Rate | Best For |

|---|---|---|---|

| Full Cube | Large, solid, classic square cubes. Looks great in a glass. | Slow | Bars, upscale restaurants, bagged ice sales, and any application where you want minimal drink dilution. |

| Half Cube | Smaller, rectangular cubes. Easy to dispense and pack into glasses. | Medium | High-volume establishments like fast-food restaurants, convenience stores, and beverage dispensers. |

| Nugget | Soft, small, porous, and chewable. Absorbs the flavor of the drink. | Fast | Sodas, smoothies, blended cocktails, and healthcare facilities where it's easier for patients to consume. |

| Flake | Small, soft, irregular chips of ice that mold easily around objects. | Fast | Seafood and produce displays, salad bars, and physical therapy applications. |

| Gourmet | Large, crystal-clear, and often uniquely shaped (e.g., spheres, octagons). | Very Slow | High-end cocktail bars, whiskey lounges, and luxury events where presentation is paramount. |

As you can see, the "best" ice is entirely dependent on how you plan to use it. A high-end whiskey bar would never use flake ice in a drink, just as a grocery store wouldn't use slow-melting gourmet ice to keep its fish fresh.

Deeper Dive into Ice Types

Full Cube and Half Cube Ice

Full cube ice is the undisputed workhorse of the industry. Because of its large surface area and solid form, it melts very slowly. This is exactly what you want when you're serving spirits on the rocks or any beverage where you need to avoid watering it down. It’s the go-to for bars, fine dining, and anyone selling bagged ice.

Half cube ice is all about versatility and volume. It’s smaller, which means you can pack more of it into a glass. This displaces more liquid, making drinks look fuller—a clever trick used in fast-food chains, convenience stores, and any place with self-serve beverage dispensers.

Nugget and Flake Ice

You've probably heard of nugget ice by its more popular names: "chewable ice" or "Sonic ice." It’s a huge customer favorite for a reason. It's soft, porous, and soaks up the flavor of whatever it's cooling, making it perfect for sodas, iced coffees, and blended drinks. Healthcare facilities also prefer nugget ice because it's soft and poses less of a choking hazard for patients.

Flake ice consists of small, soft, irregular pieces that are fantastic at molding to any shape. This makes it the champion for applications where complete cooling coverage is the goal.

Because of its excellent packing and cooling properties, flake ice is the standard for seafood displays in grocery stores, produce markets, and catering events. It gently cradles delicate items without bruising them, ensuring maximum freshness and visual appeal.

Gourmet and Specialty Ice

When presentation is everything, gourmet ice takes center stage. We're talking about large, perfectly clear, and uniquely shaped ice—like spheres, oversized cubes, or even octagons. They melt at a glacial pace and scream luxury. You'll find this ice in exclusive cocktail lounges, whiskey bars, and high-end events where every single detail is meant to impress.

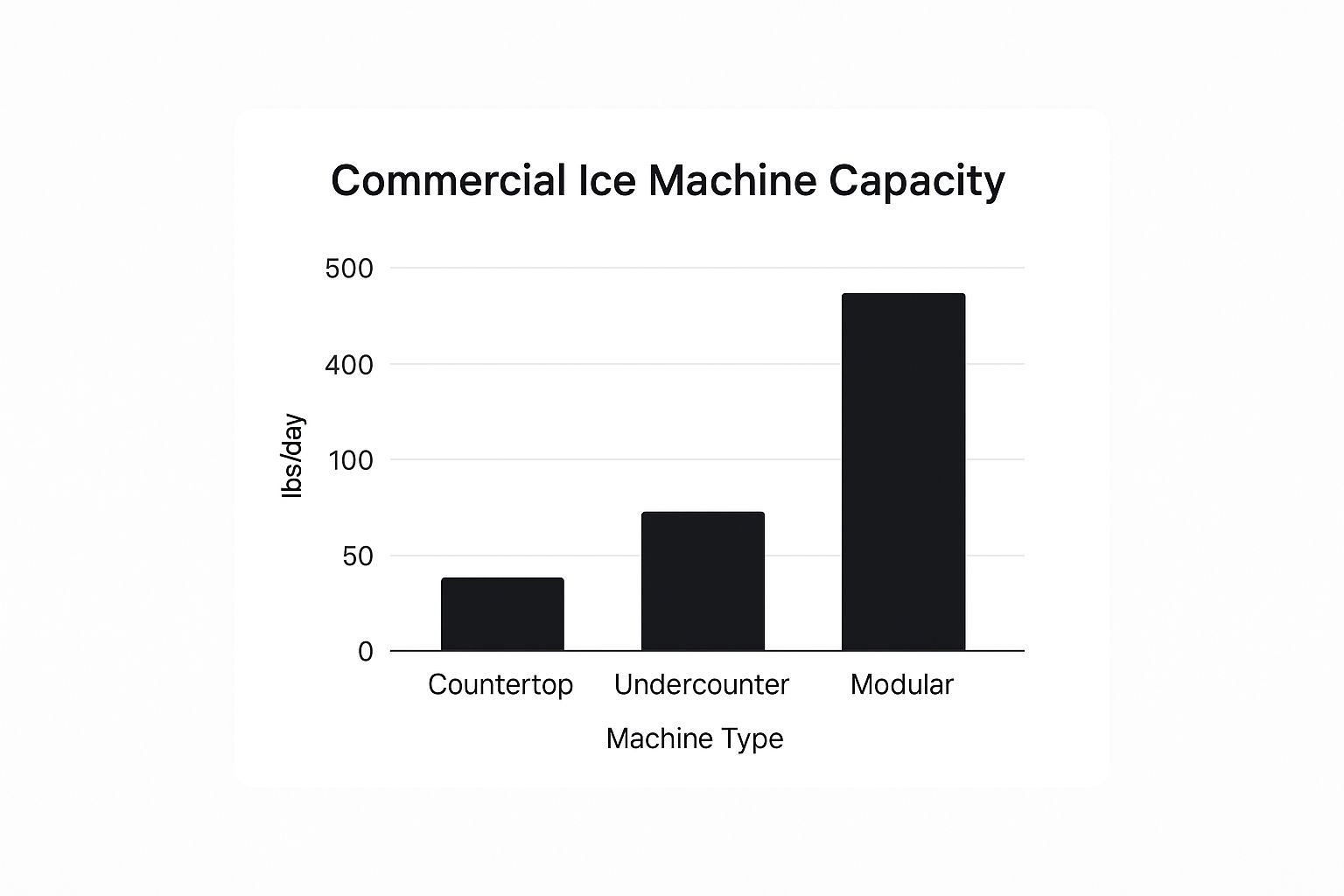

Of course, choosing the right ice type is only half the battle. You also have to match the machine's production capacity to your needs. As the chart shows, a modular unit can crank out ten times more ice than a small countertop model. It’s a powerful reminder to align the machine's capabilities with your business's real-world demand.

For a complete overview of all the factors to consider, feel free to check out our full guide on the commercial ice machine. By carefully matching the ice type and machine to your specific business, you're not just buying a piece of equipment; you're making a smart investment that will pay off for years.

Finding Your Ideal Ice Maker Configuration

Once you’ve settled on the perfect ice type for your business, the next challenge is finding a machine that actually fits your space and workflow. A commercial ice machine ice maker isn't a simple, one-size-fits-all appliance. The way it's configured—how the ice-making parts are packaged—dictates where you can put it and how your team will use it.

Think of it like buying a vehicle. You wouldn't buy a massive truck if you only have a tight city parking spot. It’s the same with ice machines. The right setup depends entirely on your kitchen layout, how much ice you go through, and your style of service. Let's break down the three main types to find your perfect match.

Undercounter Ice Machines

Undercounter ice machines are the compact heroes of the commercial kitchen. These are all-in-one units, combining the ice maker and a small storage bin into a single, tidy package. They are specifically designed to slide neatly under a standard 34-inch high counter.

This makes them the perfect solution for businesses tight on square footage or needing ice at specific points of service.

- Best for: Small cafes, office breakrooms, stadium suites, and satellite bar stations.

- Key Feature: Their compact design gives you easy, point-of-use access to ice without eating up precious floor space.

- Capacity: These units typically produce between 50 and 300 pounds of ice daily, making them ideal for lower-volume needs.

A bartender, for instance, can quickly scoop ice for drinks without trekking across a busy kitchen. This small detail keeps the workflow efficient and service moving, especially during a rush.

Modular Ice Machines

When you simply can't run out of ice, modular machines are the only way to go. These units are just the "head"—the component that actually makes the ice. They are designed to sit right on top of another piece of equipment, most commonly a large ice storage bin.

This two-piece system offers incredible flexibility. You can pair an ice-making head with a storage bin of whatever capacity you need. If your business grows, you can just swap out the bin for a bigger one without having to replace the entire machine.

Modular units are the workhorses for any place that can't afford to run dry. Their ability to connect with massive storage bins—some holding 1,000 pounds or more—makes them the backbone of high-demand operations.

These are the go-to choice for:

- Large, bustling restaurants

- Hotels and resorts

- Hospitals and healthcare facilities

- Fast-food chains

Countertop Ice Dispensers

Countertop ice dispensers are the champions of self-service. These handy units both produce and dispense ice directly into a cup with the simple push of a button or lever. They’re made to sit right on a counter, giving customers or staff sanitary, easy access to ice.

Many models also dispense water, turning them into a complete self-serve beverage station. This is a huge plus in any setting where hygiene is a top priority, as it eliminates the need for a shared, potentially contaminated ice scoop.

- Ideal for: Office breakrooms, convenience store soda fountains, healthcare lobbies, and cafeteria lines.

- Main Benefit: They boost sanitation by minimizing direct contact with the ice supply, a critical factor for any public-facing business.

The demand for these convenient machines is on the rise. The global ice maker market, valued at around USD 5.3 billion, is expected to hit USD 7.4 billion by 2033. This growth is driven by the expanding foodservice industry and a strong preference for cold drinks, especially in North America, which holds about 37.8% of the market share. You can find more insights about ice maker market trends and innovations at IMARC Group.

Choosing Your Condenser Type

Beyond the physical shape of the machine, you also have to pick its "engine"—the condenser unit. The condenser's job is to remove heat from the refrigeration system, which is how ice gets made. Your choice here directly impacts your utility bills and how well the machine performs.

There are three main types of condensers:

- Air-Cooled: This is the most common and generally most affordable option. It uses a fan to blow air over the condenser coils to cool them down. They’re simple to install but need plenty of clearance for airflow and can add extra heat and noise to your kitchen.

- Water-Cooled: This type uses a steady flow of water to cool the condenser. It’s a great choice for hot kitchens or spaces with poor ventilation because it doesn't vent heat into the room. The trade-off, however, can be much higher water bills.

- Remote-Cooled: This system splits the ice machine into two parts. The ice maker head stays in your kitchen, but the noisy, heat-producing condenser unit is installed somewhere else, like on the roof or outside. It’s the quietest and most energy-efficient option for your indoor space, but it also has the highest upfront installation cost.

By carefully thinking through your space, volume needs, and utility setup, you can select the perfect commercial ice machine ice maker configuration. For more in-depth help, our complete guide can walk you through every aspect of choosing an ice machine for commercial use.

Sizing Your Ice Machine Correctly

We've all seen it happen. The dreaded dinner rush hits, the tickets are flying, and someone yells from the bar, "We're out of ice!" It's a manager's nightmare, a complete service-stopper that leaves customers with a bad taste in their mouths.

To avoid this all-too-common scenario, you have to get beyond guesswork. It's time to learn how to accurately figure out your business's real daily ice needs. The key isn't to plan for an average day, but for your absolute busiest one.

Picking an ice machine that's too small is a recipe for constant shortages and lost sales. But go too big, and you're just throwing money away. An oversized commercial ice machine ice maker will waste electricity and water, making ice that simply melts down the drain. The sweet spot is a machine that keeps you flush with ice during peak hours without paying for wasteful overproduction.

How to Calculate Your Real Ice Needs

Figuring out your demand isn't as tricky as it sounds. It really just starts with a clear-eyed look at how and where you use ice throughout the day.

The basic idea is to tally up all the ice your operation goes through in a 24-hour period. This means ice for drinks, for keeping your salad bar or fish display fresh, and for any other back-of-house needs like filling water pitchers. And remember, you absolutely must base this on your busiest day of the week. That's what creates a reliable safety buffer.

Start with Industry Benchmarks

While every business has its own unique rhythm, there are some solid industry benchmarks that give you a fantastic starting point. Think of these as guardrails to ground your estimate in reality.

- Restaurants: A good rule of thumb is 1.5 pounds of ice for every customer meal. If you have a bar, you’ll want to add another 3 pounds per seat to that total.

- Hotels: Plan on roughly 5-7 pounds of ice per room. This should cover guest ice buckets and any food and beverage services on the property.

- Healthcare Facilities: Aim for 10 pounds of ice per patient bed to accommodate both drinking water and therapeutic uses like ice packs.

- Convenience Stores: For self-serve soda fountains, a good estimate is 6 ounces of ice for a 12-16 ounce drink and 10 ounces for a 20-32 ounce drink.

These numbers are a great baseline, but they're not the final word. If your restaurant is in a hot climate, you're known for your iced tea, or you have a bar that's always packed, you'll need to adjust upward. It’s always, always better to have a little too much ice than not enough.

To make this even clearer, the table below breaks down the typical daily ice requirements for different types of businesses. It's a handy cheat sheet to help you get a quick, accurate estimate of your production needs.

Ice Usage Estimation by Business Type (per 24 hours)

| Business Type | Estimated Ice Usage | Key Considerations |

|---|---|---|

| Quick-Service Restaurant | 1.5 lbs per customer | Factor in high-volume beverage dispensers and peak lunch/dinner rushes. |

| Full-Service Restaurant | 1.5 lbs per meal served | Add extra capacity for bar drinks, water service, and potential salad bars. |

| Bar or Nightclub | 3 lbs per seat | This accounts for cocktails, soft drinks, and blended beverages which use a lot of ice. |

| Hotel/Motel | 5 lbs per room | Covers guest ice needs, room service, and potential on-site restaurant/bar use. |

| Healthcare/Hospital | 10 lbs per bed | Includes ice for patient consumption, hydration stations, and therapeutic cold packs. |

| Cafeteria/Institutional | 1 lb per person | Consider the total number of people served throughout the day, including staff. |

This table provides a snapshot of what similar operations need, but remember to tailor these figures to your specific circumstances.

Putting It All Together

Okay, you've got your baseline number from the industry benchmarks. Now it's time to fine-tune it.

Walk through your operation and think about every single touchpoint for ice. Do your bartenders pack glasses to the brim before pouring a soda? Do you have a seafood display that needs to be iced down every morning? Each of these details adds to your total daily need.

Let’s run through a quick example. Say you have a 100-seat restaurant that serves about 200 meals on a busy Saturday. You’d start with a baseline of 300 pounds of ice (200 meals x 1.5 lbs). If that restaurant also has a 20-seat bar, you’ll tack on another 60 pounds (20 seats x 3 lbs). Just like that, you know your estimated need is at least 360 pounds of ice every 24 hours.

By taking a few minutes to do this simple math, you're setting yourself up for success. You can confidently choose a commercial ice machine ice maker that truly fits your business—avoiding the stress of shortages and the waste of overproduction.

Installation and Water Quality Essentials

You’ve just made a serious investment in a new commercial ice machine ice maker. But its day-to-day performance and how long it lasts will come down to two simple things: how it’s installed and the quality of the water you feed it.

Getting these details right from the very beginning is the single best thing you can do to avoid early breakdowns and make sure it produces the clean, crystal-clear ice your customers expect. Think of it like this: professional installation is the foundation. It's not just about finding a corner and plugging it in; it's about setting your machine up for success and, just as importantly, making sure your manufacturer's warranty is valid.

The Non-Negotiables of Installation

Proper setup isn't just about finding a spot for the unit. To get things running safely and efficiently from day one, you absolutely have to address three critical elements.

-

Proper Spacing and Ventilation: Air-cooled machines, which are the most common type you'll find, need to breathe. If you don't leave enough clearance—we're talking at least 6 inches on all sides—the machine can't push out hot air effectively. This makes it work overtime, which spikes your energy bills and will eventually burn out essential components.

-

Correct Electrical and Plumbing Hookups: This isn't a job for just anyone. A commercial ice machine pulls a lot of power and needs its own dedicated electrical circuit so it doesn't constantly trip the breaker. The water line also needs to be installed correctly with a shut-off valve, and the drain line requires a proper air gap to prevent dirty water from flowing back into the machine. This is why we always recommend professional installation.

-

Warranty Compliance: This is a big one. Many manufacturers will flat-out void your warranty if the machine isn't installed precisely to their specifications. Following the manual’s instructions on spacing, electrical, and plumbing isn’t just good practice—it's how you protect your purchase.

Why Water Quality Is Everything

Once the machine is up and running, the single most important factor for both your ice and the machine's health is the water. The unfiltered water from your tap is full of minerals, sediment, and chemicals that do more than just make your ice cloudy or taste off. Over time, those impurities build up inside your machine.

This gunk, known as scale, is like plaque in an artery. It clogs up the inner workings, forcing the machine to struggle, cutting down on ice production, and leading to catastrophic failures. In fact, poor water quality is the number one reason for ice machine service calls.

A high-quality water filtration system isn't an optional add-on; it's essential insurance for your ice machine. It directly impacts ice taste, clarity, and most importantly, the long-term reliability of your equipment.

The demand for ice machines is only growing, showing just how vital they are to businesses everywhere. Projections show the global ice maker market is set to expand to around USD 3.5 billion by 2032. This growth is driven by different needs around the world; for instance, North American consumers often look for convenience, while European businesses are more focused on efficiency and environmental impact. You can read more about the global trends shaping the ice maker market on Metastat Insight.

Don't forget about proper drainage, either. A clean setup requires a floor or wall drain, which involves plumbing know-how similar to what's needed for other kitchen essentials. Our guide on installing a 3-bay commercial sink can give you a better sense of what a proper commercial plumbing setup entails. When you match the right filtration system to your local water conditions, you're not just doing a chore—you're making a smart move to protect your investment for years to come.

A Practical Cleaning and Maintenance Routine

Your commercial ice machine ice maker is a workhorse, churning out ice all day, every day. But it can’t look after itself. The single most important thing you can do to prevent costly breakdowns, funky-tasting ice, and even serious health code violations is to stick to a consistent maintenance schedule. A neglected machine quickly becomes a breeding ground for slime, mold, and bacteria.

Setting up a simple, proactive cleaning routine isn't just a "nice to have"—it's a core responsibility of running any professional foodservice operation. This isn't just about cleaning; it's about protecting your customers, getting the most life out of your equipment, and saving yourself the headache and expense of emergency service calls. Think of it as preventative care for one of your most critical assets.

Daily and Weekly Cleaning Tasks

Little, consistent actions are what stop big problems from ever starting. These quick jobs only take a few minutes but make a huge impact on keeping your ice machine sanitary and running smoothly.

Daily Tasks (2-5 minutes):

- Wipe Down the Exterior: Grab a soft cloth and a food-safe cleaner to wipe down the outside of the machine. Pay attention to the door, handle, and scoop holder to get rid of fingerprints and prevent grime from building up.

- Check the Ice Scoop: Make sure the ice scoop is clean and stored in its proper holder. It should never be left inside the ice bin, where it can easily introduce germs.

Weekly Tasks (10-15 minutes):

- Sanitize the Storage Bin: Turn the machine off and scoop out all the ice. Use a sanitizing solution approved by the manufacturer to wipe down every interior surface, including the nooks and crannies of the door gasket and the chute. Rinse it out thoroughly, then let it completely air dry before you turn it back on. This one step is your best weapon against slime and mold.

It's a shocking statistic, but a study from the NSF revealed that 50% of ice machines in restaurants had mold growing inside. This is a clear signal that routine cleaning is too often skipped. Regular bin sanitation is your first line of defense.

Semi-Annual Deep Cleaning

Twice a year, your machine needs a much deeper clean to get rid of the internal buildup that a simple wipe-down can't touch. This process has two essential parts: descaling and sanitizing.

- Descaling: This is all about removing mineral deposits, or "scale," that build up on internal parts because of the water supply. Scale makes your machine work harder, cuts down on how much ice it can produce, and can cause parts to fail way too early. You absolutely must use a nickel-safe descaling solution made specifically for ice machines.

- Sanitizing: After you've descaled and rinsed the machine, the next step is to sanitize the entire internal water system. This kills any bacteria, mold, or slime left behind and ensures the ice you serve is perfectly safe to consume.

While some hands-on owners tackle this deep clean themselves, many find it's worth it to have a certified technician handle the semi-annual service. A pro can guarantee it's done right and will also inspect the machine for any other potential problems.

Common Issues and When to Call a Pro

Even with perfect maintenance, you might still run into the occasional hiccup. Here’s how to troubleshoot a few common problems before you panic.

- Weak or No Ice Production: First, do the simple checks. Is the machine plugged in? Is the water supply valve open? Also, make sure the air temperature around the machine isn't too hot and that it has enough space for proper ventilation.

- Strange Noises: If you hear unusual grinding or rattling sounds, that's not normal. It often points to a problem with the motor or another internal component. Your best bet is to turn the machine off right away and call for professional service.

- Cloudy or Foul-Tasting Ice: This is almost always a sign of one of two things: your water filter is clogged and needs to be replaced, or the machine is way overdue for that semi-annual deep cleaning.

Sticking to this proactive maintenance routine is the most effective way to protect your investment and ensure your commercial ice machine ice maker operates reliably for years to come.

Choosing the Right Stainless Steel Prep Tables

While your commercial ice machine ice maker handles cooling, your prep tables are where the action happens. Stainless steel prep tables are essential for any kitchen, providing a durable, hygienic, and easy-to-clean surface for every task. They come in various configurations to meet specific needs.

- Standard Work Tables: These are the most basic and versatile option, featuring a flat top with or without a backsplash. They are ideal for general prep, mixing, and plating.

- Tables with Undershelves: Adding an undershelf (or two) provides valuable storage for small appliances, containers, or ingredients, helping to keep your workspace organized and efficient.

- Mobile/Portable Tables: Equipped with casters, these tables can be moved easily around the kitchen, offering flexibility for catering operations or dynamic kitchen layouts.

Specialized Prep Tables for High-Volume Tasks

For businesses that focus on specific menu items, specialized prep tables can drastically improve workflow and efficiency.

- Sandwich Prep Tables: These units combine a refrigerated base with a work surface and a refrigerated rail on top to hold food pans of cold ingredients. This setup keeps everything from sliced meats to fresh veggies at a safe temperature and within arm's reach, speeding up assembly.

- Pizza Prep Tables: Similar to sandwich tables, these have a refrigerated rail for toppings and a refrigerated base, but they feature a much deeper work surface. This extra depth is specifically designed to accommodate large pizza doughs, making it easier for chefs to stretch, top, and prepare pizzas for the oven.

Choosing the right combination of ice machines and prep tables creates an ergonomic and highly productive kitchen environment.

Frequently Asked Questions

When it comes time to pick, install, or just maintain a commercial ice machine ice maker, it's natural for business owners to have a few questions. We’ve put together some clear, direct answers to the most common ones we hear. This should help you feel more confident about your decisions and get the most out of your investment, from power usage to knowing when to call a pro.

How Much Electricity Does A Commercial Ice Machine Use?

The power an ice machine pulls can really vary. It all depends on the machine's size, its type, and what kind of condenser it has. A small undercounter model might only use 1,000-2,000 kWh a year, but a big modular unit can easily chew through more than 5,000 kWh.

As a general rule, air-cooled machines tend to use more electricity than water-cooled or remote condenser models. To keep your energy bills in check, always look for an ENERGY STAR certified model. These are typically 10-15% more efficient than standard units.

Can I Install A Commercial Ice Machine Myself?

Trying to install a commercial ice machine yourself might look like a good way to save some cash, but it's a move we strongly advise against. It can quickly turn into a very costly mistake.

These machines aren't like your home appliances. They need specific electrical circuits, carefully installed plumbing for the water intake, and proper drain lines with air gaps. Get any of that wrong, and you're looking at poor performance, water damage, or even voiding your manufacturer's warranty.

The best practice is always to hire a certified technician. They'll make sure the machine is set up exactly to the manufacturer's specs and meets all local codes. This guarantees safety, efficiency, and keeps your warranty protected right from day one.

What Is The Pink Slime In My Ice Machine?

If you've spotted a pink or reddish slime, you're not alone. That's a very common type of airborne bacteria that just loves damp environments like the inside of an ice machine. It's a sure sign that the machine is past due for a deep cleaning and sanitizing.

This buildup doesn't just taste bad; it can be a health risk and will absolutely lead to a failed health inspection. To stop it from forming, you need a routine: regular weekly cleaning of the bin and a professional deep clean at least twice a year.

How Often Do I Really Need To Change The Water Filter?

Most manufacturers will tell you to change the water filter every six months, and that's a good baseline. However, your local water quality is the real deciding factor.

If your business is in an area with hard water or lots of sediment, you'll probably need to change it more often, maybe every three to four months. A clogged filter doesn't just slow down ice production—it also leads to cloudy, bad-tasting ice and can cause damaging scale buildup on the machine's internal parts. It's a small task that makes a huge difference.

At PrepTables.com, we know that great equipment is the backbone of any successful kitchen. From high-performance ice machines to tough stainless steel work surfaces, we have the tools you need to streamline your workflow and keep your standards high. Explore our full range of commercial kitchen solutions and build a more efficient workspace today. Find your perfect commercial equipment at PrepTables.com.