Best commercial refrigerator: How to Choose the Right Unit

Share

Choosing the best commercial refrigerator isn't about picking a single "top" model off a list. It’s about finding the right piece of equipment for your kitchen's specific rhythm and demands. The workhorse unit a high-volume restaurant needs is worlds apart from what a small café requires, and the best ones blend performance, toughness, and efficiency into a single, reliable package. This guide will help you start making those crucial choices.

What Defines the Best Commercial Refrigerator

Think of your kitchen as a living, breathing system. Every single piece of equipment has a job to do, keeping the workflow smooth and the food safe. The commercial refrigerator is the heart of that system, but "best" is a totally relative term. What's perfect for one business could be a clunky, inefficient nightmare for another. Real quality is all about how well a refrigerator solves your unique operational headaches.

It all starts with understanding the three pillars of commercial refrigeration:

- Performance: Can it hold a consistent, food-safe temperature when you're slammed during a dinner rush?

- Durability: Is it built to last? Look for materials like high-grade stainless steel that can take the daily abuse of a pro kitchen.

- Efficiency: How much is this thing going to cost to run day in and day out? An energy-efficient model can save you thousands over its lifetime.

Matching the Unit to the Workflow

Before you look at a single spec sheet, you need to nail down the main job this refrigerator will be doing. Is it for bulk storage tucked away in the back, or is it going to be right in the thick of your prep line? A giant walk-in cooler is like a warehouse—perfect for stashing cases of ingredients away from the chaos. On the other hand, a specialized prep table is a chef's command center, built for speed and immediate access.

A common mistake is buying a refrigerator based on capacity alone, without considering its role in the kitchen's daily rhythm. The best unit integrates seamlessly into your workflow, saving time and reducing steps for your staff.

For example, a busy sandwich shop lives and dies by the efficiency of its sandwich prep table, which puts refrigerated ingredient pans right below a cutting board. Everything is within arm's reach. Likewise, a pizzeria needs a pizza prep table with a wide, refrigerated rail for toppings and a tough surface ready for stretching dough. These units aren't just for keeping things cold; they're designed to make production faster. Understanding these differences is the first real step to picking a refrigerator that doesn't just work, but works for you.

Choosing the Right Type of Commercial Refrigerator

Picking the right commercial refrigerator isn't about finding one "best" model. It's about matching the type of unit to your kitchen's unique workflow. Think of it like buying a car. A sports car looks great, but it’s not going to help you haul lumber. In the same way, a giant walk-in cooler is total overkill for a small coffee shop.

The key is understanding how different refrigerators actually function in a real kitchen. Once you get that, you can invest in a machine that makes your team more efficient. We'll look at the industry workhorses, from the classic reach-in units to compact undercounter models, and focus heavily on the specialized prep tables that are the command centers of any modern, fast-paced kitchen.

The Foundation Workhorses: Reach-In and Undercounter Units

Walk into almost any commercial kitchen, and you'll see a reach-in refrigerator. These upright units are the all-purpose storage workhorses, built for quick access to ingredients you use all the time. They're the reliable sedans of the refrigeration world—practical and available in tons of configurations.

Reach-in refrigerators come in two main styles:

- Solid Door Reach-Ins: These are built for one thing: efficiency. The solid doors are fantastic insulators, which helps maintain a consistent temperature, especially in a hot kitchen. That can add up to real energy savings. They're perfect for storing bulk items you don't need to see at a glance.

- Glass Door Reach-Ins: Here, it's all about visibility. Your staff can spot what they need without opening the door and letting all the cold air out. This makes them ideal for a busy prep line or even for front-of-house use where customers might see the contents.

On the other end of the spectrum, you have undercounter refrigerators. These little guys are designed to slide neatly under your countertops, making the most of every square inch. They put cold storage right where the work is happening, so your team doesn't have to walk across the kitchen for common ingredients. You can learn more about how reach-in coolers and their counterparts fit into a kitchen by exploring our detailed guide on the topic.

Specialized Workstations: Types of Stainless Steel Prep Tables

When your kitchen is all about speed and organization, a standard refrigerator just can't keep up. That's where a stainless steel prep table comes in. This isn't just a fridge; it's a complete workstation designed to assemble specific menu items as fast as possible. These units combine three critical components: refrigerated ingredient wells, a built-in cutting board, and refrigerated cabinet storage underneath. This all-in-one design means an employee can stand in one spot with everything they need at their fingertips, smoothing out the workflow and dramatically boosting output.

There are several types of prep tables, each tailored for a specific task:

Sandwich Prep Tables

A sandwich prep table is the engine of any deli, cafe, or sandwich shop. It's designed to make building sandwiches, salads, and wraps incredibly efficient. The top holds a series of refrigerated pans for all your toppings—lettuce, tomatoes, cheese, meats—kept at a safe, cool temperature right below a cutting board. This setup eliminates wasted motion, allowing staff to assemble orders quickly during a chaotic lunch rush.

Pizza Prep Tables

A pizza prep table is engineered specifically for the unique demands of a pizzeria. If a sandwich table is a nimble assembly station, the pizza prep table is a heavy-duty production line. The key differences are all about accommodating the pizza-making process: it features a raised, refrigerated rail that's deeper and wider to hold big containers of sauce and bulky toppings, and its cutting board is extra-deep to provide ample room for stretching large pizza doughs.

For a pizzeria, the prep table isn't just a piece of equipment; it's the heart of the operation. A poorly designed or underpowered unit can create a major bottleneck, slowing down the entire kitchen and costing the business money.

Deciding between these specialized tables and a standard fridge really comes down to your menu. If your business depends on assembling a high volume of a specific food item, a dedicated prep table will pay for itself in speed and efficiency. In those kitchens, it's the clear choice for the best commercial refrigerator.

Evaluating Essential Refrigerator Features and Specs

Once you've narrowed down the general type of fridge you need, it's time to dig into the details. The specs are what really separate a good refrigerator from the best commercial refrigerator for your kitchen. These features dictate how the unit holds up under pressure, how long it’ll last, and whether it’s a pain or a pleasure to use day in and day out. Looking past the price tag to understand these components is how you invest in a machine built for the real world of a busy kitchen.

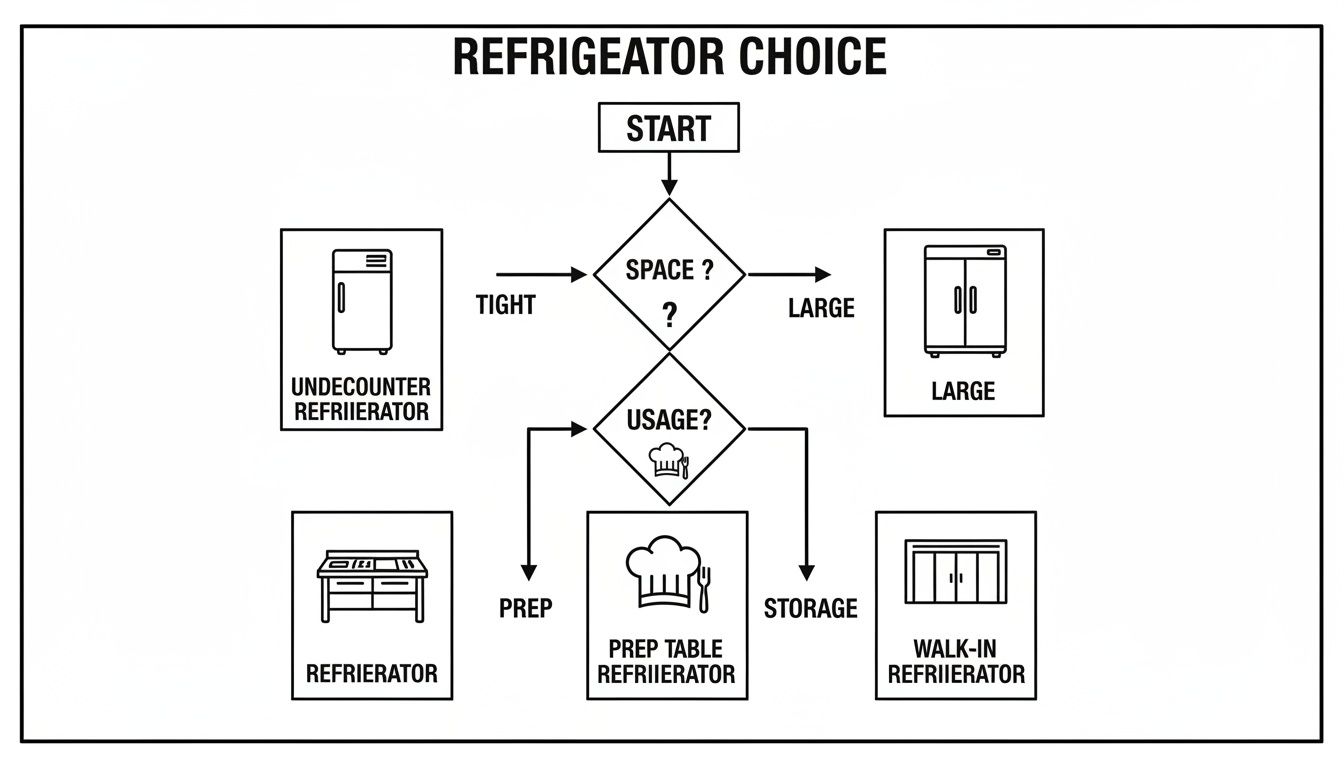

This quick decision tree can help you visualize the path from your kitchen's layout and needs to the right kind of refrigeration.

As the flowchart shows, the first question is always about physical space. This leads you to either compact undercounter units or larger models. From there, you decide based on whether you need it for bulk storage or for active, in-the-moment prep work.

The Heart of the Machine: Compressor Placement

The compressor is the engine of your refrigerator. It’s what circulates refrigerant to keep everything chilled. Where that engine is located—either on the top or the bottom of the unit—makes a huge difference in performance and maintenance.

-

Top-Mount Compressors: These are perfect for kitchens that get dusty or have a lot of flour in the air. By placing the compressor up high, it stays clear of all the gunk that gets kicked up from the floor, which can clog coils and kill efficiency. They also blow hot air upwards, which is great for keeping your prep area—and your staff—from overheating.

-

Bottom-Mount Compressors: On the flip side, these units are much more ergonomic. The lowest shelf is raised, so your staff doesn't have to bend down as far to grab what they need. Because it pulls in cooler air from near the floor, the compressor can sometimes work a bit more efficiently, but you’ll have to be diligent about cleaning the intake vents more often.

The Industry Standard: Stainless Steel Construction

In a commercial kitchen, durability isn't a bonus; it's a requirement. This is why stainless steel is the undisputed king. It stands up to corrosion, dents, and scratches way better than aluminum or plastic, ensuring your investment can handle the daily chaos of a busy service.

But not all stainless steel is created equal. The gauge, or thickness, of the steel is a tell-tale sign of its quality. Here’s the trick: a lower gauge number means thicker, tougher steel. A unit built with 18-gauge steel, for instance, is far more robust than one with 22-gauge steel and will hold up much better in high-traffic areas.

Flexible and Functional: Shelving Options

Shelving might seem like a small detail, but it has a massive impact on your kitchen’s organization and how much you can actually store. Always look for units that offer adjustable shelves. You need that flexibility to fit everything from tall stockpots to shallow sheet pans.

A common operational bottleneck is inflexible storage. The ability to quickly reconfigure shelves for a new menu item or a large delivery is a feature that pays dividends in efficiency every single day.

Most quality commercial refrigerators come with epoxy-coated or polyurethane-coated steel shelves. This coating is non-negotiable. It prevents rust and corrosion in the humid environment inside the cooler, which extends the life of your shelves and keeps things hygienic.

Precision and Convenience: Modern Controls

Gone are the days of fiddling with a simple analog dial. Digital temperature controls are standard now, and for good reason. They give you a precise, easy-to-read temperature display, which is absolutely essential for keeping food safe and passing health inspections.

Another feature you can't live without is an automatic defrost system. This handy tech stops ice from building up on the evaporator coils. Without it, the compressor would have to work overtime, burning through energy. An automatic system takes care of this maintenance for you, saving your staff time and making sure the fridge is always running at peak efficiency. Choosing a unit with these features makes your investment reliable and much easier to manage.

Sizing Your Refrigerator for Peak Kitchen Efficiency

Picking the right type of refrigerator is a big first step, but choosing the wrong size can absolutely cripple your kitchen's flow. Go too small, and you’ll never keep up with a dinner rush. Go too large, and you're just wasting precious floor space and burning cash on energy bills. Sizing isn't about what fits in the corner; it's about matching storage to the unique rhythm of your business.

Think of the internal space, measured in cubic feet, as your refrigerator's working inventory. A busy restaurant getting daily deliveries needs enough room for bulk ingredients without jamming the shelves. Overcrowding is a classic mistake—it blocks airflow and creates dangerous warm spots. A small coffee shop, on the other hand, just needs a small, efficient footprint for a few key fresh items.

Calculating Your Capacity Needs

A great place to start is with your menu and order volume. Take a hard look at your weekly ingredient purchases, mapping out the busy days versus the slow ones. This will give you a real-world baseline for how much refrigerated storage you actually need.

Here’s a practical way to break it down:

- High-Volume Restaurants: If you're serving over 200 meals a day, a big capacity is non-negotiable. These kitchens typically need 40 to 70 cubic feet of reach-in space, and that's often on top of a walk-in cooler for the real bulk storage.

- Medium-Sized Cafes or Delis: For businesses in the 75-150 meal-a-day range, 20 to 40 cubic feet is usually the sweet spot. This could be a solid two-door reach-in or a few undercounter units placed strategically.

- Small Coffee Shops or Bars: When your food menu is limited, you can easily get by with under 20 cubic feet. A single-door reach-in or a couple of undercounter models can easily handle milks, syrups, and grab-and-go items.

This need for perfectly matched equipment is fueling major industry growth. The global commercial refrigeration market was recently valued around USD 85.6 billion and is expected to nearly double, hitting USD 161 billion by 2034. This boom shows just how critical the right cooling solutions are across the entire food service world. You can learn more about this market growth and what it means for the industry on gminsights.com.

Measuring Your Physical Space and Clearance

Once you have a good idea of the internal capacity you need, it's time to pull out the tape measure. This sounds simple, but it’s where so many expensive mistakes happen. A refrigerator needs more than just enough room to slide in—it needs to breathe.

An undersized refrigerator is a daily headache, but a unit that can’t fit through your front door is a complete disaster. Always measure every doorway, hallway, and tight corner on the delivery path before you even think about ordering.

Proper ventilation is absolutely essential for the compressor to do its job without overheating. You have to account for clearance, which is just the empty space you leave around the unit. A good rule of thumb is to leave at least 2-3 inches of space on the sides and back. For a top-mounted compressor, you’ll want to leave up to 12 inches of open space above it. Skimping on this clearance forces the unit to work way harder, which means higher energy bills and a much shorter lifespan for your equipment.

Understanding Energy Costs and Food Safety Compliance

When you're buying a commercial refrigerator, the price tag is just the beginning of the story. Think of it less like a one-time purchase and more like a long-term investment. The real costs show up over years of 24/7 operation—in your energy bills and your ability to keep the health inspector happy.

A smart decision now means looking past the initial price to the day-to-day operational costs. You're choosing a partner for your kitchen, one that needs to be powerful, financially sound, and legally compliant. This is what separates a good purchase from a great one.

Demystifying Energy Efficiency and Long-Term Savings

A commercial refrigerator is one of the hardest-working pieces of equipment you'll own, and its energy consumption definitely reflects that. An inefficient model can quietly suck hundreds, or even thousands, of dollars from your profits each year through bloated utility bills.

This is where ENERGY STAR certification becomes a huge deal. An ENERGY STAR certified unit has met strict energy performance standards set by the U.S. Environmental Protection Agency. These refrigerators can be 15-30% more efficient than standard models, all thanks to better parts like high-efficiency compressors, superior insulation, and advanced motors.

Choosing an ENERGY STAR model isn't just about being eco-friendly; it's a direct investment in your bottom line. The lifetime savings on your energy bills can often completely wipe out any initial price difference, giving you a serious return on your investment.

You can also look into local programs and strategies to save energy and money to cut your operational expenses even further, making a high-efficiency unit an even smarter financial move.

The Non-Negotiable World of Food Safety Compliance

Passing a health inspection isn't a "nice-to-have"—it's fundamental to keeping your doors open. The best commercial refrigerators are designed from the ground up to meet and exceed tough public health standards. This is where certifications act as your guarantee of quality and safety.

The most important one to look for is from the NSF (National Sanitation Foundation). When you see that NSF mark, it means the equipment has been rigorously tested. It’s made from safe materials, is a breeze to clean, and is designed specifically to prevent food contamination. Things like coved corners, removable gaskets, and non-porous surfaces are all hallmarks of an NSF-approved design.

Maintaining food safety is the cornerstone of your reputation, and it all comes down to equipment that can hold precise temperatures. This is a critical piece of a much larger system, which you can read more about in our guide on what is cold chain management.

Future-Proofing with Eco-Friendly Refrigerants

The refrigeration industry is also making a big shift toward more environmentally friendly refrigerants. The old-school stuff, like hydrofluorocarbons (HFCs), are being phased out because of their high Global Warming Potential (GWP). Modern units now use natural refrigerants like R-290 (propane), which are not only better for the planet but are also more energy-efficient.

Choosing a unit with these modern refrigerants means you’re already in line with current and upcoming environmental rules. It future-proofs your investment so you won't get hit with costly mandatory upgrades down the road. This focus on compliance is especially strong here in North America, where the commercial refrigeration market is a global leader. In fact, the U.S. market alone is projected to grow from USD 23.5 billion to nearly USD 45.8 billion by 2034, driven by those strict food safety rules.

Simple Maintenance to Maximize Your Refrigerator's Lifespan

Buying the right commercial refrigerator is only half the battle. The real secret to getting years of reliable service is protecting that investment with a simple, consistent maintenance plan. Just like your car needs a regular oil change to keep running smoothly, your refrigerator needs a little routine care to avoid those expensive, middle-of-a-rush breakdowns that can stop a kitchen in its tracks.

Think of the condenser coils as your refrigerator's lungs. Usually found on the back or bottom of the unit, their job is to get rid of heat. Over time, these coils become magnets for dust, grease, and all sorts of kitchen grime, which acts like a thick blanket. This forces the compressor to work overtime just to keep things cool.

A Quick and Actionable Maintenance Checklist

Believe it or not, a dirty condenser can jack up your energy use by up to 30%. A simple cleaning every few months is one of the easiest ways to slash your utility bills and keep the compressor from burning out. If you need a detailed walkthrough on the right tools and techniques, our guide on using a refrigerator condenser cleaner has you covered.

Here’s a straightforward checklist your team can actually follow:

- Clean Condenser Coils Quarterly: First, unplug the unit. Then, grab a stiff brush or a vacuum and gently clear away all that buildup from the coils.

- Inspect Door Gaskets Monthly: Take a close look at the rubber seals around the doors. Are they cracked or torn? A bad seal lets cold air pour out, making the unit run constantly.

- Wipe Down Interior Surfaces Weekly: Spills happen. Cleaning them up right away prevents mold and keeps your food storage environment safe and hygienic.

- Ensure Proper Airflow: Never cram your shelves full. Leave some breathing room around products and make sure you're not blocking any vents. This is key for letting cold air circulate properly.

A common mistake is treating maintenance as an afterthought. Proactive care is the single most effective strategy for preventing the two biggest refrigerator problems: catastrophic equipment failure and wasted energy.

Why Small Steps Lead to Big Savings

Every one of these small tasks pays off in a big way. A clean condenser uses less electricity. A tight gasket keeps food at safe temperatures. Good airflow prevents your inventory from spoiling. It's these little, consistent actions that protect your bottom line and dramatically extend the life of your equipment.

For a broader look at keeping your kitchen equipment in top shape, you can also explore some general expert commercial HVAC system maintenance tips. When you adopt these best practices, your refrigerator remains a dependable workhorse, not a ticking time bomb of a liability.

Common Commercial Refrigerator Questions

We get it. Pulling the trigger on a major piece of equipment like a commercial refrigerator often comes down to a few final questions. To help you buy with total confidence, we've put together some straight answers to the most common things we hear from kitchen managers and restaurant owners. Think of this as your last check-in before you commit.

Why Can’t I Just Use a Residential Refrigerator?

It’s tempting to think a residential fridge is a smart, cost-effective shortcut, but that decision almost always leads to big problems down the road. Commercial units are built with heavy-duty, powerful compressors. They’re designed to bounce back quickly after the door swings open again and again in a hot, busy kitchen. A home unit just can’t keep up, which means fluctuating temperatures and a serious risk of food safety violations.

Plus, commercial refrigerators are made from durable materials like stainless steel and are NSF-certified. That means they’re designed for quick, easy sanitation that meets health code standards. Using a residential fridge in a commercial kitchen is a fast track to a failed health inspection and will almost certainly void its warranty.

How Often Should I Expect to Perform Maintenance?

Simple, consistent maintenance is the secret to a long, efficient life for your refrigerator. While you should have a professional service the unit at least twice a year, your own kitchen staff has a huge role to play in the day-to-day upkeep.

Here’s a simple schedule to follow:

- Weekly: Give all the interior surfaces a good wipe-down and check the door gaskets for any obvious cracks or tears.

- Monthly: Take a closer look at the door seals. The "dollar bill test" is perfect for this—if a bill slides out easily when the door is closed, that seal is too loose and needs attention.

- Quarterly: This is your most important task. Unplug the unit and give the condenser coils a thorough cleaning with a stiff brush or vacuum. All that built-up dust and grease has to go.

What Does the Warranty Typically Cover?

Knowing your warranty inside and out is key to protecting your investment. Most manufacturers use a tiered warranty, meaning different parts are covered for different lengths of time. A one-year parts and labor warranty is pretty standard, covering the entire machine for that first year.

The compressor is the heart of your refrigerator, so it often gets a separate, longer warranty—usually around five years. This extended coverage is a great sign that the manufacturer has real confidence in its equipment.

Just be aware that warranties typically won't cover problems that come from improper installation or a lack of basic maintenance, like forgetting to clean those condenser coils. Always take a few minutes to read the fine print so you know exactly what your responsibilities are to keep that warranty valid.

At PrepTables.com, we provide the durable, high-performance refrigeration solutions your kitchen needs to succeed. Explore our complete collection of commercial refrigerators and prep tables to find the perfect fit for your operation.

Browse our full range of commercial refrigeration equipment at PrepTables.com