What Is Cold Chain Management A Guide to Product Safety

Share

At its core, cold chain management is the art and science of keeping things cold. Specifically, it's about making sure temperature-sensitive products—like fresh produce, vaccines, or gourmet ingredients—stay within a strict, low-temperature range all the way from the farm or factory to the final customer.

Think of it as a continuous, unbroken chain of refrigerated production, storage, and distribution. This isn't just about putting something in a fridge; it's a meticulous process designed to ensure perishable goods stay safe, effective, and high-quality.

Understanding the Cold Chain Process

The best way to picture the cold chain is as a high-stakes relay race. The baton? It's "cold." This baton has to be passed flawlessly from one stage to the next without ever being dropped.

A single break in this chain—a truck’s cooling system failing on a hot day or a storage unit door accidentally left ajar—can be catastrophic. It can spoil an entire shipment of food or ruin life-saving medicines. The entire system is built to prevent these failures and maintain product integrity across huge distances and countless handoffs.

This isn't a small-time operation, either. It’s a massive pillar of public health and the global economy. The global cold chain market was valued at a whopping $365.78 billion and is projected to explode to $1.42 trillion by 2034. That growth is fueled by our increasing demand for fresh food and advanced pharmaceuticals.

The Journey of a Perishable Product

A product's journey on the cold chain begins the second it's harvested, manufactured, or prepared. The first step is always immediate cooling to a safe temperature, which is critical for stopping bacterial growth and locking in quality. From that moment on, every single step is temperature-controlled.

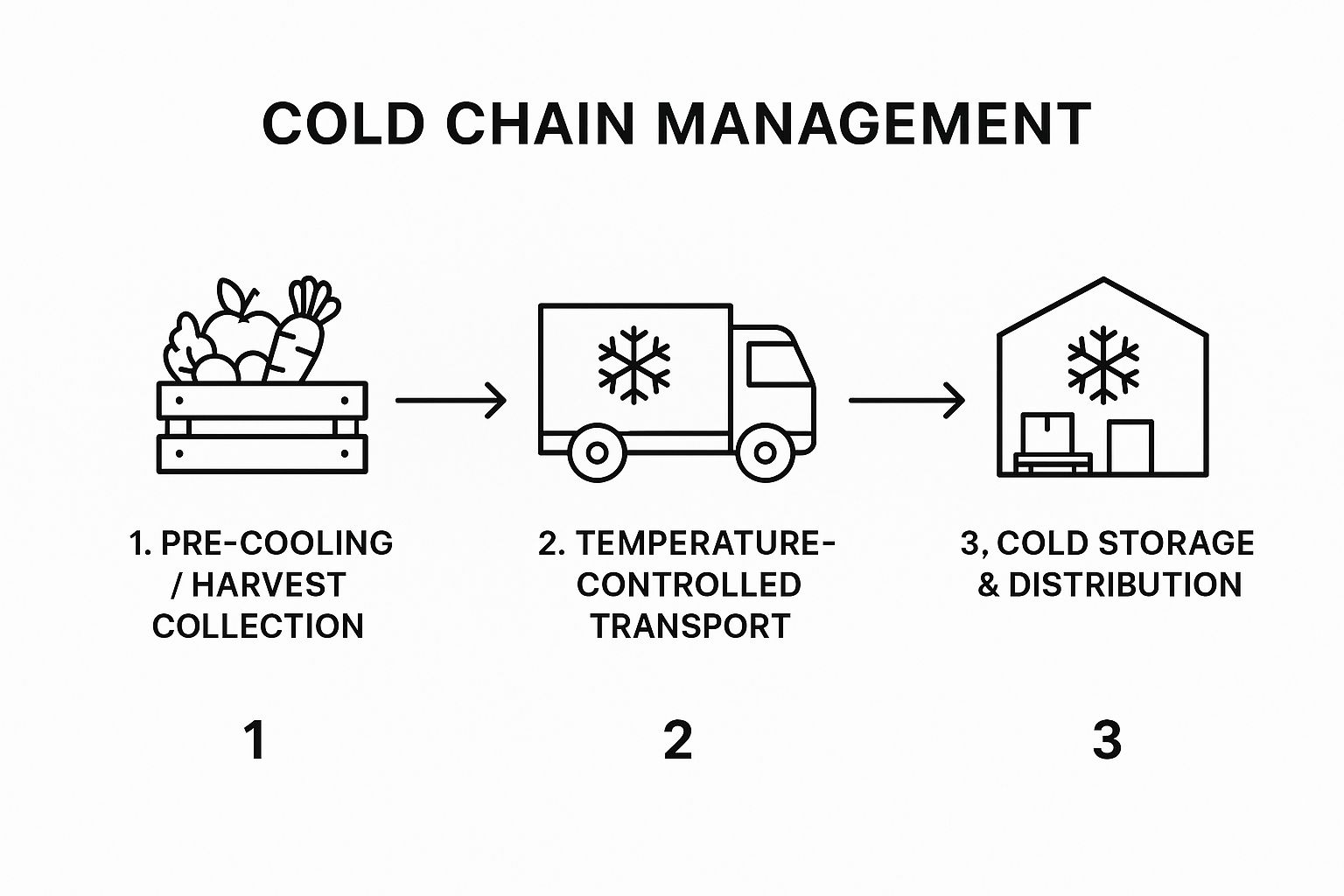

This infographic breaks down the fundamental stages of that journey, from initial collection all the way to final distribution.

As you can see, the process flows from cooling to transport to storage, and each link in that chain is equally important. Maintaining those consistent temperatures is absolutely non-negotiable.

This is where specialized equipment becomes the hero of the story. To get a better sense of how foundational pieces fit into this puzzle, it's worth checking out our guide on selecting a commercial refrigerator. Every piece of gear, from massive walk-in freezers to refrigerated trucks, acts as a vital link, making sure that "cold" baton is never, ever dropped.

The Essential Components of a Modern Cold Chain

A successful cold chain isn't about one magic piece of equipment. Think of it more like a symphony, with a whole range of components working together perfectly. Each one has a specific job to do in protecting a product from the moment it’s made to the moment it’s used. And just like the old saying goes, if one link breaks, the whole chain falls apart.

At its heart, any cold chain is built on four pillars: cooling, storage, transport, and processing. Each one depends on specialized gear designed for one simple goal: keeping products inside a very specific temperature window.

Cooling and Storage Solutions

The journey always starts with cooling. This first, critical step is all about getting products—like freshly picked vegetables or newly made vaccines—down to their ideal temperature fast. This is usually handled by powerful blast chillers or pre-cooling rooms that slam the brakes on spoilage and bacterial growth.

Once chilled, those products are moved into cold storage. This is much more than just a big fridge; it's a meticulously controlled environment. Huge, temperature-managed warehouses and distribution centers are the hubs of the cold chain, holding goods safely for hours, days, or even months. They use complex systems to keep temperatures and humidity levels rock-steady.

Transport and Processing Equipment

Next up is transport. Refrigerated trucks, often called "reefers," are the mobile links in the chain. These aren't just insulated boxes; they have their own cooling systems to maintain the right temperature whether they're driving across town or being shipped across an ocean.

Finally, we have processing. This is a crucial, and often underestimated, part of the chain where products are handled right before they get to the customer. In a restaurant kitchen, this is where ingredients are chopped, mixed, and put together. Keeping things cold during this stage is non-negotiable for preventing contamination.

The processing stage is where equipment has to bridge the gap between bulk storage and hands-on preparation. It’s all about creating small, localized cold zones right where the action is, a vital transition that requires some smart solutions.

The Role of Stainless Steel Prep Tables

When you're preparing food, you can't just leave ingredients sitting out on a counter. This is where specialized stainless steel prep tables become an indispensable part of the cold chain. They aren't just a surface to work on; they are active, temperature-controlled stations that keep everything safe and fresh. Different tables are built for different jobs, each designed to maintain the integrity of the cold chain during active food handling.

- Standard Work Tables: These are the bedrock of any kitchen, giving you a tough, hygienic surface. While they aren't refrigerated themselves, their non-porous stainless steel is a breeze to sanitize, which is huge for stopping cross-contamination between cold and room-temperature items. They often feature an undershelf for storing non-perishable equipment.

- Tables with Backsplashes: A common variation of the standard work table, these units feature a raised lip along the back. This simple addition prevents ingredients and liquids from splashing onto walls, making cleanup faster and helping maintain a more sanitary environment—a key aspect of food safety compliance.

- Sandwich Prep Tables: These units are a brilliant combination of a refrigerated base for storage and cooled ingredient wells (or pans) on top. This design lets your team build sandwiches and salads at lightning speed while keeping everything from deli meat to lettuce at a safe, consistent temperature.

- Pizza Prep Tables: Built on the same idea as sandwich tables, these have a wider, raised cutting board surface to handle large pizza doughs. They come with refrigerated rails for all your toppings and a cooled base, making sure every ingredient stays perfectly chilled until it's time for the oven.

By building refrigeration right into the workspace, these specialized prep tables act like mini cold storage units on the front lines, making sure the cold chain stays intact even during the chaos of a dinner rush.

How Technology Safeguards the Cold Chain

Modern cold chain management is a data-driven science, powered by technology that leaves nothing to chance. Gone are the days of manual temperature checks and just hoping for the best. Today, a whole network of digital tools acts as the central nervous system for the supply chain, giving operators incredible control and visibility from start to finish.

This tech-driven backbone is built on innovations that deliver real-time information and can even predict problems before they happen. Think of it like giving every single package its own personal guardian, one that reports its exact location and temperature every second of the journey. This constant stream of data allows companies to spot potential issues long before they become costly disasters.

The Power of Real-Time Monitoring

The foundation of a tech-enabled cold chain is the Internet of Things (IoT). Tiny, wireless sensors are placed inside trucks, storage units, and sometimes even individual product containers. These little devices act as digital sentinels, constantly monitoring key conditions.

These digital guardians keep an eye on several critical metrics:

- Temperature: Sending an instant alert if a container ever dips below or climbs above its safe temperature range.

- Humidity: Making sure moisture levels are just right for sensitive goods like fresh produce.

- GPS Location: Tracking the precise position of a shipment at all times, which is great for both logistics planning and security.

This constant monitoring ensures that every single link in the chain, from a massive warehouse freezer down to smaller units like commercial refrigerated prep tables, maintains the perfect environment. If a truck’s cooling unit starts to fail on the road, an alert is sent immediately, allowing someone to step in before any product is compromised.

Technology transforms the cold chain from a reactive system to a proactive one. Instead of discovering spoiled goods upon arrival, companies can anticipate and prevent temperature deviations as they happen, saving inventory and protecting consumers.

Cloud Platforms and Data Analytics

All of the data collected by those IoT sensors gets streamed to powerful cloud-based platforms. This is where the magic really happens. These platforms pull together billions of data points into a single, easy-to-read dashboard, giving managers a complete bird's-eye view of their entire operation.

This centralized data hub is becoming a massive part of the industry. In fact, the cloud-based cold chain management market was valued at around $9.12 billion and is expected to climb to $11.52 billion by 2025. The growth is fueled by the obvious benefits of having one single source of truth for all temperature and location data, as you can see in this cloud-based cold chain management market report.

Ultimately, technology is the ultimate safeguard in the modern cold chain. It connects every piece of the puzzle, from a fleet of transport trucks to the refrigerated storage in a restaurant’s kitchen. By creating a transparent, responsive, and data-rich environment, these tools help ensure that perishable goods arrive safely, every single time.

Meeting Critical Regulations and Compliance Standards

In the world of the cold chain, rules aren't just suggestions—they're the bedrock of public health. For any business that handles temperature-sensitive products, navigating this complex web of regulations is non-negotiable. These standards act as an invisible safety net, ensuring everything from food safety to drug effectiveness and, ultimately, building consumer trust.

Following these rules is about more than just avoiding hefty fines. It's about creating a bulletproof, verifiable system of safety from start to finish. Think of it as building a detailed case file for every single product, proving it was kept safe and sound at every step of its journey through meticulous record-keeping and equipment calibration.

Core Regulatory Frameworks

In the United States, two frameworks stand out: HACCP and FSMA. These systems completely shifted the industry's focus from just reacting to contamination to proactively stopping it before it can even start.

- HACCP (Hazard Analysis and Critical Control Points): This is a systematic game plan. Businesses identify potential food safety hazards—whether they’re biological, chemical, or physical—and then set up control points to stop them in their tracks. A perfect example? Making sure a refrigerated prep table always stays below 40°F.

- FSMA (Food Safety Modernization Act): Enforced by the FDA, this act gives regulators more muscle to oversee how foods are grown, harvested, and processed. It puts a heavy emphasis on science-based preventative controls across the entire food supply chain.

Compliance often comes down to the quality of your gear. Using tools and surfaces that are a breeze to sanitize is a huge part of any solid HACCP plan. This is exactly why understanding what NSF certification is becomes so critical, as it’s a guarantee that your equipment meets strict public health standards.

Choosing Compliant Prep Tables

The specific stainless steel prep table you choose can make or break your ability to meet these standards. Each design plays a distinct role in holding the line and maintaining the cold chain during the crucial food prep stage.

- Standard Stainless Steel Tables: These are the workhorses of any commercial kitchen. Their non-porous surface is incredibly easy to clean and sanitize, which is essential for preventing cross-contamination and staying on the right side of food safety rules.

- Sandwich Prep Tables: These units are brilliant because they integrate refrigerated compartments right below the workspace with cooled ingredient wells on top. This design is a textbook example of a HACCP control point in action, keeping deli meats, cheeses, and veggies at safe temperatures during assembly.

- Pizza Prep Tables: They're similar to sandwich tables but built with a larger workspace for dough and feature refrigerated rails for all your toppings. They make sure every single ingredient stays perfectly chilled until the moment it hits the oven—a key compliance factor for any pizzeria.

By selecting the right type of prep table, you’re not just buying a piece of furniture. You’re investing in a critical tool for regulatory compliance and food safety.

To get a clearer picture of who's who in the regulatory zoo, here’s a quick breakdown of the major players.

Key Cold Chain Regulations at a Glance

| Regulatory Body | Primary Focus | Key Requirement Example |

|---|---|---|

| FDA (Food and Drug Administration) | Food, pharmaceuticals, and biologics safety. | Enforces FSMA rules, requiring preventative controls and traceability. |

| USDA (U.S. Department of Agriculture) | Meat, poultry, and egg products. | Mandates specific temperature controls during processing and transport. |

| HACCP | Systematic hazard prevention in food production. | Identifying and monitoring Critical Control Points, like refrigeration temps. |

| NSF International | Public health standards for equipment and materials. | Certifying that prep tables are non-absorbent and easy to clean. |

These frameworks all work together to create a cohesive safety net that protects products and consumers alike.

Technology's role in all of this is exploding. The cold chain monitoring market, currently valued at a staggering $7.47 billion, is expected to more than double to $15.04 billion by 2030. This surge is fueled by strict rules from agencies like the FDA and USDA that demand continuous temperature logging and pinpoint data accuracy. You can learn more about the growth of the cold chain monitoring market and how it’s tied to these regulatory demands. At the end of the day, sticking to these standards isn’t just good practice—it’s absolutely essential for building a safe and reliable cold chain.

Overcoming Common Cold Chain Challenges

Aiming for a perfect cold chain is one thing, but reality always has other plans. Even the most buttoned-up system can hit a snag that puts your products at risk. Whether it's a freezer on the fritz or a simple traffic jam, knowing how to handle these bumps in the road is what separates the pros from the amateurs.

Let’s be clear: these challenges aren’t just what-if scenarios. They happen every day. A truly resilient cold chain isn't just about keeping things cold; it's about how well it holds up when things go wrong.

Equipment Failure and Human Error

Two of the biggest headaches in any cold chain are equipment breakdowns and good old-fashioned human error. A refrigeration unit on a truck can die halfway through a delivery, or a busy cook can accidentally leave a walk-in freezer door open. Both mistakes can send temperatures soaring into the "danger zone" where bacteria thrive.

It’s not just about machines, either. Someone using the wrong handling procedure or setting a thermostat incorrectly can break the chain in a heartbeat. These aren't intentional acts, just simple slip-ups with potentially massive costs.

The strongest cold chains are built on proactive prevention. The whole idea is to make failure as difficult as possible by thinking ahead and training everyone on the right way to do things, every single time.

To get ahead of these problems, businesses lean on two key strategies:

- Preventative Maintenance: You can't just cross your fingers and hope your equipment holds up. Regular, scheduled check-ups on everything—from your main warehouse coolers to the refrigerated prep tables on the line—are non-negotiable. This is how you spot trouble before it becomes a disaster.

- Constant Training: Your team needs to know this stuff inside and out. That means thorough training on handling protocols, how to monitor temperatures, and why their role is so critical to keeping food safe.

The Notorious Last Mile Problem

The "last mile" is that final, crucial step: getting a product from a local hub to the customer's door. This is, by far, the toughest part of the journey to keep temperature-controlled. Think about it—delivery vans making tons of stops, doors swinging open and shut, and products getting exposed to the outside air over and over again.

This is where the cold chain is at its weakest. A single long delay or a poorly planned route is all it takes to ruin a perfectly good product.

To tackle this, companies are getting smarter. They're using advanced software to map out the most efficient routes and investing in smaller, specialized cooling gear. Things like high-tech portable coolers and insulated packaging are becoming essential for protecting products during this final, high-stakes leg of the journey. Building a tough cold chain means you have a playbook ready for when things go sideways, ensuring your products stay safe no matter what.

Building Your Cold Chain Strategy

Putting all the pieces together into a solid cold chain plan isn’t about reacting to problems—it’s about getting ahead of them. A strong strategy is built by anticipating where things can go wrong and creating clear, repeatable steps that leave nothing to chance. You're not just handling cold products; you're actively defending their integrity from start to finish.

This framework is your blueprint for protecting products, keeping customers safe, and upholding your brand's hard-earned reputation. It all begins with taking an honest look at how your own operation works.

A Practical Checklist for Success

Creating a tough, reliable strategy involves a few key steps. Each one builds on the last, creating a system of checks and balances that works. Think of it like a series of firewalls designed to stop temperature breaches and keep everyone on your team accountable.

Here’s a practical checklist to get you started:

- Map Out Your Risks: Pinpoint every potential weak spot in your chain. Where could a temperature slip-up happen? Is it when a shipment arrives, during transport, or right at the prep station? Identify these critical control points first.

- Write Clear SOPs: Create detailed Standard Operating Procedures (SOPs) for every single task, from checking in a delivery to prepping food on a refrigerated prep table. Make them simple, clear, and easy for every staff member to find and follow.

- Get the Right Gear: Don't cut corners on your equipment. Your walk-in freezers, transport coolers, and even your stainless steel work surfaces are the backbone of your cold chain. Stick with certified, reliable tools you can trust.

- Use Smart Monitoring: Modern monitoring systems with real-time tracking and automated alerts are a game-changer. This tech is your 24/7 watch guard, sending you a notification the second a temperature starts to drift out of the safe zone.

A successful cold chain strategy is less about the equipment and more about the culture you build around it. When every team member understands their role and feels responsible for protecting the chain, the whole system gets stronger.

Getting your team invested is the final, crucial piece of the puzzle. It’s what turns your well-laid plans from a document on a shelf into a living, breathing part of your daily operation.

Cold Chain Management: Your Questions Answered

When you're dealing with temperature-sensitive products, a few questions always seem to pop up. Let's clear the air and get you the straightforward answers you need to protect your inventory.

What Is the Ideal Temperature for a Cold Chain?

There’s no magic number here—the "ideal" temperature is entirely product-specific. For example, deep-frozen foods need to stay at or below 0°F (-18°C), while fresh produce is happiest between 32°F and 40°F (0°C to 4°C). Pharmaceuticals are a whole different ballgame, with incredibly strict and narrow temperature windows.

The real goal of cold chain management isn't hitting one universal temperature, but holding the right temperature for each specific product, without fail, from start to finish.

How Does the Last Mile Affect the Cold Chain?

The "last mile" is the final sprint from the distribution hub to the customer's door, and it's easily the most treacherous part of the journey. Think about it: multiple stops, doors constantly opening and closing, and repeated exposure to outside temperatures. This is where things are most likely to go wrong.

The last mile is where the cold chain is most likely to break. Success here requires specialized equipment like insulated containers and precise route planning to minimize exposure time and protect product quality.

Food vs. Pharmaceutical Cold Chains

While both are about keeping things cold, the stakes and rules are quite different. The pharmaceutical cold chain is governed by iron-clad regulations where even a tiny temperature fluctuation can render a vaccine or medicine ineffective and unsafe. There is zero room for error.

The food cold chain, on the other hand, is focused on preventing spoilage and keeping people safe from foodborne illness. It's incredibly important, of course, but there's sometimes a bit more flexibility in the operations compared to the pharma world.

How Can Small Businesses Implement Cold Chain Practices?

You don't need a massive budget to get started. The first step for any small business is investing in reliable, certified equipment, like commercial-grade refrigerators and freezers. Using high-quality stainless steel prep tables, especially specialized models like sandwich prep tables or pizza prep tables, is non-negotiable for keeping ingredients at a safe temperature during handling.

From there, it's all about process. Create clear protocols for your team, train them on proper temperature monitoring, and keep detailed logs. These simple, low-cost steps are the bedrock of any solid cold chain strategy.

At PrepTables.com, we provide the durable, NSF-certified stainless steel prep tables and commercial refrigeration that form the backbone of a successful cold chain. Explore our full range of solutions at https://preptables.com to build a foundation of safety and reliability for your business.