Best commercial refrigeration: Your Guide to Efficient Cooling Solutions

Share

Finding the right commercial refrigeration isn't just about keeping things cold—it's about setting up your entire kitchen for success. The best commercial refrigeration is the one that fits your space, your menu, and your daily customer volume like a glove. A smart investment here boosts your food safety and makes your whole operation run smoother from day one.

How to Choose the Best Commercial Refrigeration

Picking out the right equipment can feel like a huge decision, but it gets a lot easier when you start connecting your business needs to specific features. A high-performing kitchen is built on reliable, purpose-built cooling that won’t let your team down during a dinner rush.

Think of your refrigeration as a silent partner. It's the unsung hero that protects your inventory and streamlines every single step of food prep.

The importance of getting this right is clear when you look at the market. The global commercial refrigeration sector was valued at a whopping USD 85.6 billion in 2024 and is expected to soar to USD 161 billion by 2034. This boom just underscores how critical quality cooling systems are, not just in foodservice but in all sorts of industries.

Matching Equipment to Your Business Needs

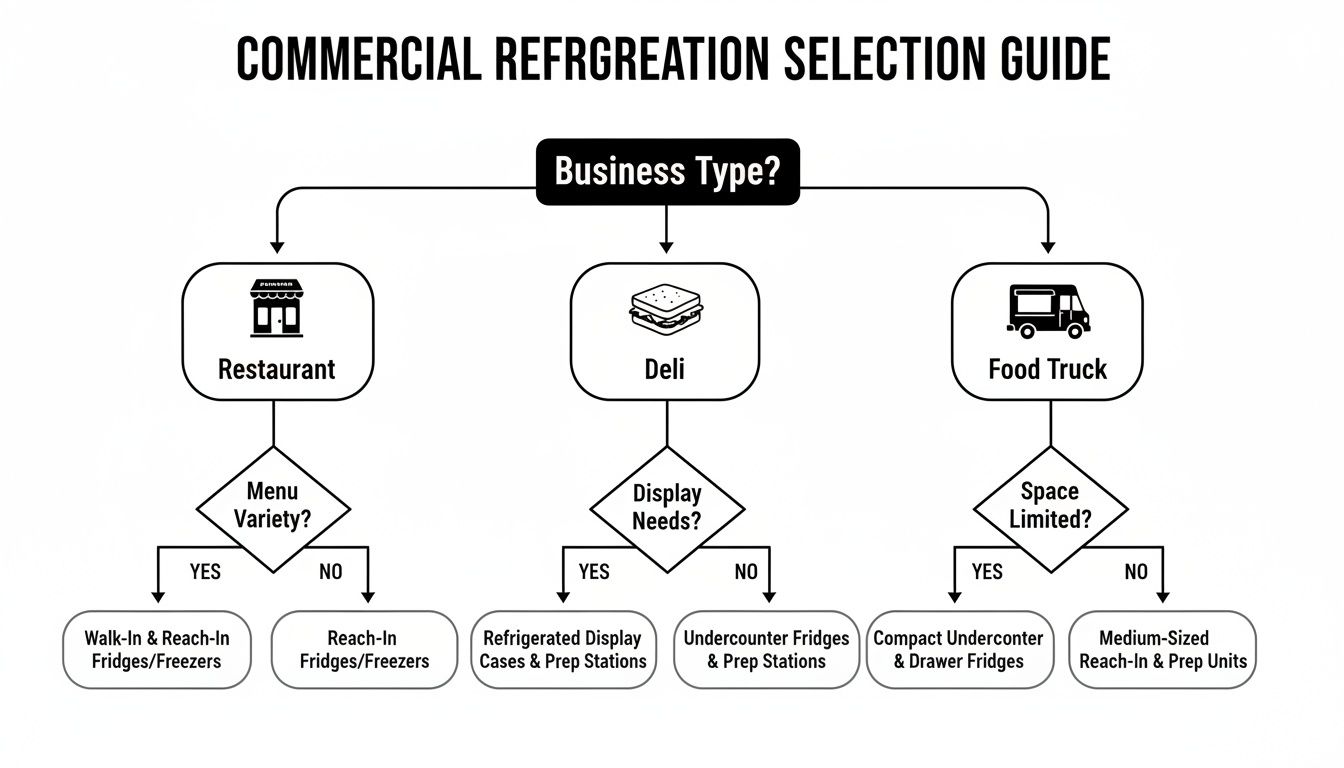

Every kitchen has its own unique rhythm, and your refrigeration needs to keep up. A bustling, high-volume restaurant is going to need a completely different setup than a compact food truck or a neighborhood deli.

To help you get started, here’s a simple way to think about your initial choices.

The biggest takeaway here? Your business type is the first and most important filter. Once you know which category you fall into—restaurant, deli, mobile kitchen, or something else—you can zero in on the options that were actually built for your kind of workflow.

To make this even clearer, this quick guide table will help you match your operation's needs to the right type of unit.

Quick Guide to Selecting Your Ideal Refrigeration Unit

| Business Type | Primary Need | Recommended Refrigeration Type | Key Feature to Look For |

|---|---|---|---|

| High-Volume Restaurant | Bulk ingredient storage and quick access | Walk-In Cooler & Reach-In Refrigerator | High capacity, durable shelving, efficient cooling system (BTU/HP) |

| Café or Deli | Ingredient prep and grab-and-go display | Prep Table & Undercounter Refrigerator | Integrated cutting boards, ingredient pans, glass doors for display |

| Food Truck or Mobile Kitchen | Compact, durable cooling for tight spaces | Undercounter or Worktop Refrigerator | Heavy-duty casters, front-breathing ventilation, robust steel gauge |

| Bar or Pub | Beverage chilling and quick service | Back Bar Cooler or Bottle Cooler | Glass doors for visibility, adjustable shelving for different bottle sizes |

This table is a great starting point, but remember that the specific demands of your menu and kitchen layout will ultimately guide your final decision. Your goal is to find the perfect mix of size, features, and power for your unique operation.

Understanding Different Commercial Refrigeration Types

Walking into the world of commercial refrigeration can feel overwhelming, but it's pretty simple once you match the right piece of equipment to its job in your kitchen. This section will break down the essential categories, from the massive Walk-In Coolers to the versatile Reach-In units and handy Undercounter refrigerators.

A great way to think about your kitchen’s cold storage is like a library. The Walk-In is the main archive where you keep everything in bulk. Reach-Ins are the easy-to-access shelves you grab from all day. And Undercounter units? They're the specialized reference desks, tucked right where you need them most. We’ll look at how each one works in a real kitchen, helping you see how they create a smooth and safe workflow.

The Powerhouse: Walk In Coolers and Freezers

For any high-volume kitchen, the walk-in cooler or freezer is the absolute command center of cold storage. These aren't just refrigerators; they're refrigerated rooms built to hold huge amounts of bulk ingredients, from boxes of produce and fresh meat deliveries to kegs and crates of dairy.

The biggest advantage here is capacity. By keeping all your bulk inventory in one spot, you make stock management a breeze and cut down on how often you need expensive supplier deliveries. This doesn't just save you money—it makes sure you have enough product ready to go for those unexpected rushes.

But their size requires serious planning. Installation is a big deal, covering everything from making sure your floor can handle the weight to ensuring the external condenser unit has proper ventilation. For a closer look at what that job involves, you can learn more about walk-in cooler installation to decide if it’s the right move for your space.

The Everyday Workhorse: Reach In Refrigerators

If the walk-in is the archive, the reach-in refrigerator is the "ready-to-go" section of your kitchen's library. These are the classic upright units that your staff will be opening and closing all day long. You’ll want them placed right near prep stations or on the main cooking line so cooks can grab ingredients without missing a beat.

Reach-in models are built for constant use. They have durable doors, adjustable shelves, and powerful compressors that can get the temperature back down fast after a door has been opened. That quick temperature recovery is non-negotiable in a busy kitchen for keeping food safe.

A key metric for these units is their ability to hold a consistent temperature despite constant door openings. A high-quality reach-in can maintain its internal climate, protecting sensitive items like dairy and proteins from temperature fluctuations that accelerate spoilage.

When you're picking one out, think about the doors. Solid doors give you better insulation and save on energy, while glass doors are great for visibility, letting staff see what’s inside without letting all the cold air out.

Compact and Convenient: Undercounter Refrigerators

Undercounter and worktop refrigerators are the masters of making the most out of a tight space. These small units slide right under your existing counters, putting cold storage exactly where it’s needed. This simple change stops chefs from having to walk across the kitchen to a reach-in, saving critical seconds during a busy service.

Worktop refrigerators take it a step further by adding a tough stainless steel top that doubles as an extra food prep surface. That dual-function design is a lifesaver in smaller kitchens like you’d find in food trucks, cafes, or bars, where every inch counts.

These units are often broken down by their specific jobs:

- Undercounter Models: Mostly for storage, fitting perfectly into a prep line to hold backup ingredients.

- Worktop Models: Combine refrigerated storage with a usable, food-safe work surface right on top.

- Chef Bases: These are low-profile refrigerated drawers designed so you can put heavy cooking equipment like griddles or charbroilers right on top of them.

Placing cold storage strategically like this is the secret to an ergonomic and efficient kitchen layout, cutting down on staff movement and speeding up the time it takes to get orders out.

A Closer Look at Refrigerated Prep Tables

In any kitchen where food is assembled to order, refrigerated prep tables are the undisputed MVPs. They perfectly marry cold storage with a dedicated workspace, creating a seamless production line that keeps ingredients fresh, safe, and literally at your fingertips. By combining these two vital functions, they cut out wasted motion and seriously speed up service.

Think about the chaos of a lunch rush. Instead of your team running back and forth between a separate reach-in cooler and a prep counter, everything they need is in one spot. This isn't just about moving faster—it's about maintaining critical food safety temperatures right up until the moment an ingredient is used.

Here, we'll dive into the world of prep tables, zeroing in on the two most common workhorses: sandwich/salad prep tables and pizza prep tables. We’ll also get into why the kind of stainless steel used to build them is a huge deal for durability and hygiene.

Sandwich and Salad Prep Tables: The Deli's Best Friend

Sandwich and salad prep tables are all about speed and flexibility, making them a must-have for delis, cafes, and any spot that builds orders on the fly. Their signature feature is a refrigerated top rail loaded with food pans, perfect for holding a whole lineup of fresh toppings, sauces, and proteins.

This setup means a cook can stand in one place and crank out complex orders with almost no wasted steps. Underneath the workspace, a refrigerated cabinet provides plenty of backup storage, cutting down on those frantic mid-shift runs to the walk-in.

The countertop itself usually comes with a cutting board, typically 8 to 12 inches deep, that runs the full length of the unit. This gives you a dedicated, food-safe area for slicing bread, chopping veggies, and putting the final touches on an order. For any business with a high-volume, customizable menu, this all-in-one design is a total game-changer.

Pizza Prep Tables: Built for a Perfect Pie

While the basic idea is the same, pizza prep tables are engineered specifically for the unique workflow of a pizzeria. The most obvious difference is the work surface—pizza tables have a much deeper cutting board, often 16 to 20 inches deep, to give you enough room to work with large pizza skins.

Another key difference is the raised refrigerated rail. Unlike the recessed wells you see on a sandwich unit, this rail lifts the ingredient pans up. This makes it ergonomically easier to grab and spread toppings across a wide pizza base, saving your cooks from having to lean uncomfortably over the unit all night.

The combination of a wide prep area and an accessible ingredient rail is perfect for an assembly-line workflow. One person can stretch the dough, another can sauce and cheese it, and a third can add toppings—all on the same continuous surface.

The refrigerated base is just as important, offering plenty of space to store dough boxes, bulk cheese, and big containers of sauce right where you need them. For a deeper dive, check out our guide on commercial refrigerated prep tables to help you pick the perfect setup.

Why Stainless Steel Quality Matters

When you're choosing the best commercial refrigeration, the metal it's made from is just as crucial as its cooling system. Prep tables are almost always built from stainless steel, but not all stainless steel is the same. The grade of the steel directly impacts its durability, how well it resists corrosion, and its overall lifespan in a tough kitchen environment.

You'll generally run into two main types of stainless steel for commercial equipment:

- Type 304 Stainless Steel: This is pretty much the industry gold standard. It has a higher content of chromium and nickel, giving it superior resistance to rust and corrosion from salts, acids, and harsh cleaning chemicals. It’s the best choice for any food contact surface, like the tabletop and interior walls.

- Type 430 Stainless Steel: This is a more budget-friendly option you'll often find on the exterior sides and back of a unit—the parts that don't touch food. It's still durable, but it just doesn't have the same anti-corrosion muscle as Type 304.

A top-quality prep table often uses a hybrid design: a Type 304 top and interior paired with a Type 430 exterior. This gives you the best of both worlds—food safety and longevity where it counts, and cost savings where it doesn't—making sure your investment can handle the daily grind for years to come.

Key Features to Evaluate Before You Buy

Once you've settled on the type of commercial refrigeration your kitchen needs, it's time to dig into the details. The spec sheet might look like a bunch of technical jargon, but it’s telling you a story about how that unit will perform under pressure, how much it will cost you to run, and how long you can expect it to last. Getting familiar with these features is the key to finding the best commercial refrigeration that truly works for you.

Think of it like buying a car. You know you need a sedan, but now you’re looking at the engine size, fuel efficiency, and safety ratings. We're doing the same thing here—moving past the general model to look under the hood. This ensures you make a smart investment that pays off every single day.

This is more important than ever. The demand for quality commercial refrigeration is massive, with the US market valued at USD 12.63 billion in 2024 and projected to climb to USD 25.02 billion by 2033. That growth means it’s critical for business owners to choose equipment that’s powerful, efficient, and up to code. You can discover more insights about this expanding market and what it means for the industry.

Compressor Power and Placement

The compressor is the heart of your refrigerator. It’s the engine that pumps refrigerant through the system to keep everything cold. Its power, usually measured in Horsepower (HP) or British Thermal Units (BTU), dictates how quickly the unit cools down after the doors have been opened. A busy kitchen with doors swinging open constantly needs a beefier compressor to keep food in the safe zone.

Where the compressor is located also makes a big difference in performance and maintenance:

- Bottom-Mounted Compressors: These are perfect for hot environments like your cook line. Since heat rises, a compressor at the bottom pulls in cooler air from the floor, putting less strain on the unit. As a bonus, the bottom shelf is raised, making it easier to grab items without bending down.

- Top-Mounted Compressors: These are a better fit for cooler prep areas or bakeries. They avoid sucking up dust, flour, and other debris from the floor that can clog the coils. Just be aware they might work a little harder in hot kitchens because they pull in warmer air from up high.

Defrost Cycles Explained

Over time, every refrigeration system builds up a layer of ice on its cooling coils. This ice acts like an unwanted blanket, forcing the compressor to work harder and use more energy. The defrost cycle is simply the unit’s way of melting this ice to stay efficient. You’ll generally run into two types.

Automatic Defrost systems run on a simple timer, kicking on at set intervals whether there’s a lot of ice or just a little. In contrast, adaptive or intelligent defrost systems use sensors to start a defrost cycle only when it’s actually needed. This smarter approach saves a ton of energy and keeps the temperature inside the cabinet much more stable, which is better for your food.

For any business looking to keep energy costs down, an adaptive defrost system is the clear winner. It eliminates pointless defrost cycles, which means lower utility bills and less wear on the compressor over the life of the unit.

Certifications That Matter: NSF and UL

When you're comparing different models of the best commercial refrigeration, keep an eye out for two critical certifications: NSF and UL. These aren't just fancy stickers; they're often required by local health departments and are your guarantee of safety and compliance.

- NSF (National Sanitation Foundation): This seal means the unit is designed to be easily cleaned and is built with food-safe materials that won’t harbor bacteria. An NSF mark gives you peace of mind that your equipment meets sanitation standards.

- UL (Underwriters Laboratories): This mark certifies that the unit's electrical components are safe and meet strict standards. It’s your protection against fire hazards and electrical problems.

Choosing a unit with both NSF and UL certifications is non-negotiable for a professional kitchen. It protects your food, your staff, and your business from health code violations and serious safety risks.

Balancing Purchase Price With Long-Term Operating Costs

That sticker price? It’s just the beginning of the story. It tells you what it costs to get the unit through the door, not what it will cost you to own it for the next five or ten years. When you're buying commercial refrigeration, the real financial picture is painted by your monthly utility bills and maintenance calls.

It’s tempting to go for the cheaper model upfront, but an energy-efficient unit often pays for itself many times over in lower electricity costs. You have to look past that initial invoice and think about the total cost of ownership. This isn't just an expense; it's a long-term asset that should be working for your bottom line, not against it.

Decoding ENERGY STAR and Efficiency Ratings

The quickest way to gauge a unit's long-term cost is to look for the ENERGY STAR label. This isn't just a fancy sticker; it’s a stamp of approval from the U.S. Environmental Protection Agency, guaranteeing the unit meets some seriously strict energy performance standards.

An ENERGY STAR certified commercial refrigerator or freezer is, on average, 20% more energy-efficient than a standard model. For a bustling restaurant kitchen, that can easily mean saving hundreds, even thousands, of dollars every single year on just one piece of equipment.

These savings come from smarter engineering—things like high-efficiency compressors that don't have to work as hard, better insulation, and more effective fan motors. Yes, these components might nudge the purchase price up a bit, but the return on your investment starts showing up on your very first utility bill.

The Role of Modern Insulation and Refrigerants

Beyond the certifications, the guts of the unit play a huge role in its daily energy appetite. Take modern insulation, for example. High-quality, foamed-in-place polyurethane insulation creates a rock-solid seal, preventing precious cold air from seeping out. This means the compressor gets to take more breaks, which directly cuts down on your electricity usage.

The type of refrigerant inside is another game-changer. The industry is making a big shift away from older synthetic refrigerants to natural, eco-friendly options like R-290 (propane). These natural refrigerants aren't just better for the planet—they're also more thermodynamically efficient. They cool things down faster while sipping less energy.

This isn't just a niche trend; it's reshaping the entire market. Energy efficiency is now a top priority, with the global market for these units projected to hit 40% by 2025. Even more telling, natural refrigerants are seeing explosive adoption, growing at 15.2% annually compared to just 4.5% for older synthetic types. You can discover more about these refrigeration market trends to see where the technology is heading.

We've laid out how a few key features can make a big difference in your wallet over time.

Energy Efficiency Feature Comparison

| Feature | Upfront Cost Impact | Long-Term Savings Potential | Key Benefit |

|---|---|---|---|

| ENERGY STAR Certification | Moderate Increase | High | Guaranteed 20% average energy reduction and lower utility bills. |

| LED Lighting | Minimal Increase | Moderate | Lasts longer and produces less heat, reducing the compressor's workload. |

| R-290 Refrigerant | Minimal to Moderate | High | More efficient cooling cycle means less energy consumed to hold temperature. |

| Polyurethane Insulation | Minimal Increase | High | Superior cold air retention, so the unit runs less often. |

| ECM Fan Motors | Moderate Increase | Moderate to High | Uses significantly less electricity than standard motors to circulate air. |

As you can see, a slightly higher initial investment in these features directly translates into lower operating costs and a healthier bottom line.

Calculating Your Return on Investment

So, how do you know if the pricier, more efficient unit is actually worth it? A quick and easy ROI calculation will give you a clear answer.

- Find the Difference: Figure out the price difference between the standard model and the energy-efficient one.

- Estimate Annual Savings: Check the unit’s spec sheet for its energy consumption data to estimate your annual savings on electricity.

- Calculate Payback Period: Just divide the initial price difference by your estimated annual savings. This tells you exactly how many years it will take for the unit to pay for itself.

Taking a few minutes to run these numbers is one of the smartest things you can do. It turns a guess into a data-driven decision that will benefit your business for years.

Simple Maintenance to Protect Your Investment

Your commercial refrigerator is one of the biggest workhorses in your kitchen. Just like any high-performance machine, it needs a bit of regular care to keep humming along efficiently for years. A simple maintenance plan is your best defense against surprise breakdowns and spoiled inventory.

By dedicating just a little time to routine upkeep, you and your team can catch small issues before they snowball into kitchen-closing emergencies. These simple tasks are the first and most important step in protecting the heart of your operation.

Creating a Simple Maintenance Checklist

Staying ahead of problems is always cheaper and less stressful than reacting to them. A simple, repeatable checklist makes sure crucial tasks don't get lost in the shuffle of a busy week. These small actions really add up, saving you big on energy bills and repair costs over the life of your unit.

Here are the non-negotiables that should be on every kitchen's refrigeration maintenance schedule:

- Clean Condenser Coils Regularly: The condenser coils are like the radiator in a car; they get rid of heat. When they get caked in dust and grease, the compressor has to work overtime, wasting energy and risking a total burnout. A quick cleaning every 90 days is all it takes to keep air flowing and the system from overheating.

- Inspect and Clean Door Gaskets: Those rubber seals around the doors are crucial for keeping the cold air in. If they're cracked, brittle, or just plain grimy, your unit will run constantly trying to make up for the cold air that's leaking out. Wipe them down daily and check for a tight seal to keep your energy bills from creeping up.

- Clear Interior and Exterior Vents: Airflow is everything for a refrigeration system. Inside, make sure boxes and containers aren't blocking the vents—this creates warm spots and forces the unit to work way harder. Outside, keep the area around the unit clear so it can properly push out heat.

Routine Cleaning and Organization

Beyond the mechanical checks, simple daily habits play a huge role in your equipment's health. A clean, organized cooler is an efficient one.

Wipe up spills the moment they happen to prevent corrosion and funky smells. Use a "first-in, first-out" (FIFO) system for your inventory so nothing gets shoved to the back to die and block airflow. A well-organized interior lets cold air move around freely, making sure every single item stays at a safe, consistent temperature.

Proactive maintenance isn't an expense; it's an investment in reliability. A well-cared-for unit doesn't just last longer—it holds more accurate temperatures, which directly protects the quality and safety of your food.

Following these steps will help you get the best possible performance out of your commercial refrigeration. For a deeper dive, especially on keeping those coils pristine, you can learn more about how to use a fridge condenser cleaner to keep your unit in top shape. By making maintenance a team priority, you’re protecting your equipment, your inventory, and your bottom line.

Frequently Asked Questions

Picking the right commercial refrigeration can feel like a puzzle, but asking the right questions makes the picture much clearer. Knowing the real-world differences between units means you'll end up with equipment that helps your crew, protects your food, and fits your layout. Here are some of the most common questions we hear from business owners.

What Are the Main Types of Stainless Steel Prep Tables?

Stainless steel prep tables are a cornerstone of any professional kitchen, but they aren't one-size-fits-all. They are specialized workstations designed to streamline workflow by combining workspace, storage, and often refrigeration. The primary types you’ll encounter are built for specific tasks:

- Sandwich and Salad Prep Tables: These units are designed for speed and customization. They feature a refrigerated rail on top to hold food pans with various ingredients, alongside an integrated cutting board. The refrigerated cabinet below stores backup supplies, making them essential for delis, cafes, and quick-service restaurants.

- Pizza Prep Tables: Engineered for pizzerias, these have a much deeper work surface to accommodate large pizza doughs. The refrigerated ingredient rail is often raised for better ergonomics, allowing cooks to easily add toppings across a wide area. The base is configured to hold dough boxes and large sauce containers.

- Standard Work Tables: These are the simplest form—a durable stainless steel surface on legs, often with an undershelf for storage. They provide a versatile, non-refrigerated space for general prep tasks like chopping vegetables or portioning ingredients. They are valued for their simplicity, durability, and ease of cleaning.

Each type uses different grades of stainless steel, typically Type 304 for food-contact surfaces due to its corrosion resistance and Type 430 for exteriors to balance cost and durability.

How Much Space Do I Need for a Walk-In Cooler?

When you’re planning for a walk-in, you need to think beyond just the box’s dimensions. Inside, you need enough room to store everything without packing it so tight that air can’t circulate—that’s how you get dangerous warm spots. A good starting point is to plan for at least 25-30 pounds of product for every square foot of shelf space.

Then there’s the outside. The condenser unit—the part that gets rid of all the heat—needs to breathe. You can’t just shove it in a closet. It needs to be placed either outdoors or in a room with great ventilation, with a few feet of clear space all around it for airflow and, just as importantly, for when a technician needs to service it.

Always check your local health and building codes before you buy anything. Many areas have strict rules about floor drains, ceiling heights, and ventilation for walk-ins that could completely change where you can install one.

Ready to find the perfect cooling solution for your kitchen? At PrepTables.com, we offer a wide selection of top-tier commercial refrigeration, from versatile prep tables to powerful reach-in coolers. Explore our collection and build a more efficient kitchen today at https://preptables.com.