Back Bar with Refrigerator: Your Quick Guide (back bar with refrigerator)

Share

A back bar with refrigerator is more than just a place to keep drinks cold. It's a purpose-built piece of commercial equipment, designed to handle the speed, display needs, and heavy use of a busy service area. For any bustling bar, it’s the command center, keeping everything chilled, organized, and right where your staff needs it.

Why a Back Bar Refrigerator Is Your Unsung Hero

Picture the peak of a Friday night rush. The place is buzzing, orders are coming in fast, and every second is precious. In that kind of environment, a standard cooler just can't keep up. This is where a dedicated back bar refrigerator proves its worth, acting less like an appliance and more like a high-performance pit crew station.

A bartender needs perfectly chilled bottles, cans, and garnishes right at their fingertips, just like a race car driver needs tires and fuel ready to go. A back bar refrigerator is engineered for exactly this. By placing it directly behind the service counter, you eliminate wasted movement. Staff can grab what they need without turning their backs on customers, keeping the whole operation flowing smoothly.

Boosting Speed and Sales

This isn't just about making life easier; it's about making more money. When you cut down the time it takes to make and serve a drink, you can handle more orders. Better service means happier customers, bigger tips, and more people coming through the door. It's a direct line to a healthier bottom line.

Models with glass doors also turn your stock into a silent salesperson. When customers see a well-lit display of premium beers, craft ciders, and chilled wines, it sparks their interest. This kind of visual merchandising can lead to impulse buys and encourage regulars to try something new, turning your cold storage into a revenue-generating machine.

A back bar refrigerator bridges the gap between storage and sales. It's a logistical powerhouse that keeps service flowing smoothly while simultaneously showcasing your products to increase revenue.

The impact these units have on the hospitality world is huge. The market for these coolers is growing, which shows just how vital they've become. In the United States, the back bar cooler market is valued at USD 2.4 billion in 2025 and is projected to hit USD 3.8 billion by 2035, growing at a steady 4.8% each year. With over 70% of U.S. bars depending on them for quick access during busy times, the numbers prove how important they are for keeping drinks—and profits—flowing. You can learn more about these market trends and their impact from Future Market Insights.

Choosing the Right Size and Type for Your Space

Picking the perfect back bar with refrigerator is a bit like choosing the right knife for a specific cut—the ideal cooler needs to fit your physical space, your storage capacity, and the way your team works.

Before you even start looking at models, grab a tape measure. You need to know the exact width, depth, and height you're working with behind the bar. Don't forget about ventilation! Most of these units need at least 2-4 inches of breathing room on the sides and back to keep from overheating, so build that clearance into your final numbers.

Sizing Up Your Options

Back bar refrigerators are made in a bunch of standard widths, so it's usually easy to find one that slides right into your existing setup. The most common sizes are tied directly to how many doors the unit has, which also gives you a good idea of its storage capacity.

- Compact Units (24" - 36"): These single-door models are the go-to for smaller cafes, food trucks, or any bar that’s tight on space. They're perfect for keeping a curated lineup of your best-selling bottles and cans right at hand.

- Mid-Size Units (48" - 60"): The classic two-door cooler is the workhorse for most small to medium-sized bars and restaurants. It hits that sweet spot between a manageable footprint and serious storage volume.

- Large Units (72" - 90"+): If you're running a high-volume pub, a busy restaurant, or a nightclub, you'll need a three or even four-door model. These beasts offer maximum capacity so you can stock a huge variety of drinks and get through a rush without constantly reloading.

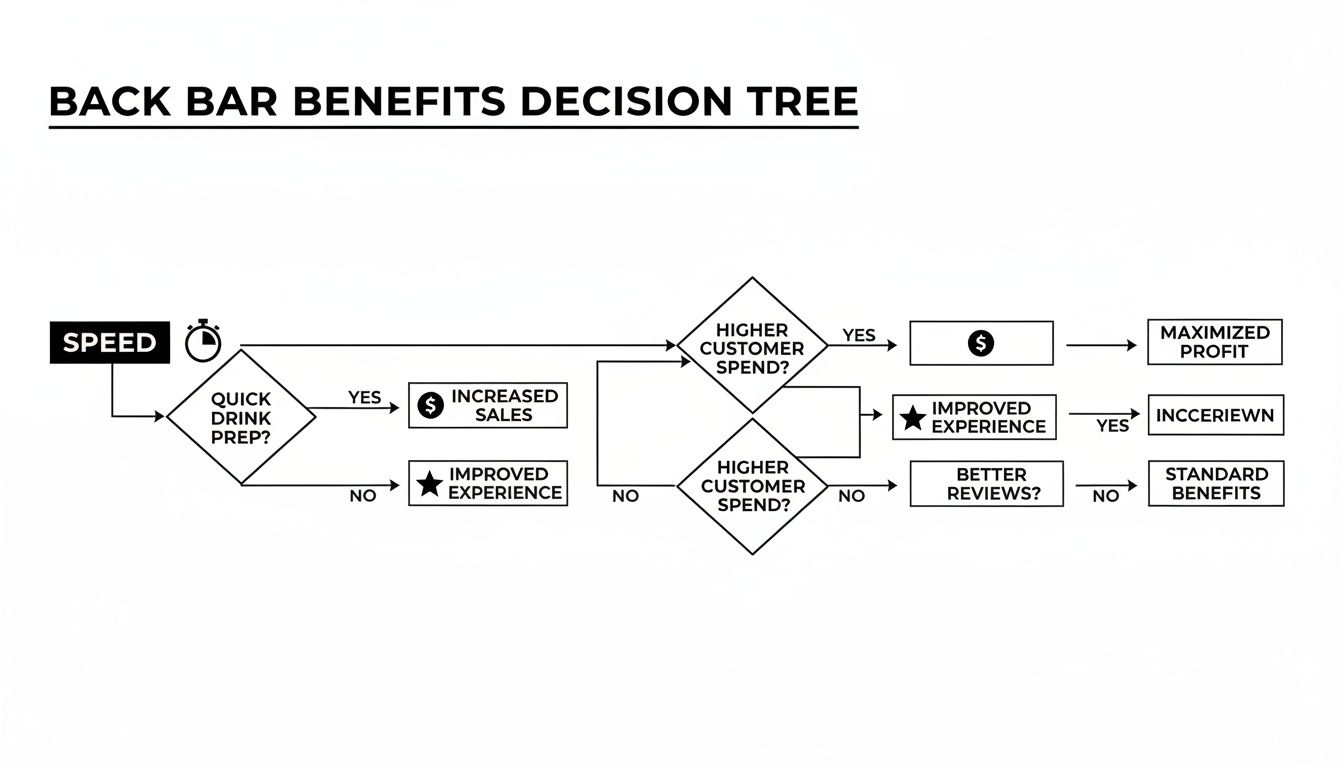

This flowchart gives you a clear picture of how the right choice can directly boost your speed, sales, and the overall customer experience.

As you can see, a smarter bar setup has a ripple effect—it makes your service faster, which in turn drives sales and makes for happier guests.

Matching the Type to Your Service Style

More than just size, the type of cooler you get should match what you serve and how you serve it. Each design is built for a specific job, helping make your workflow as smooth as possible.

Standard Bottle and Can Coolers These are what most people picture when they think of a back bar refrigerator. They come with adjustable shelves to fit everything from tall craft beer bottles to skinny energy drink cans. The glass door models are especially great for showing off your inventory and turning it into a tempting display.

Direct Draw Kegerators If you sell a lot of draft beer, a direct draw unit isn't just nice to have—it's essential. These are built specifically to hold and pour from kegs, complete with taps, CO2 lines, and couplers. They keep everything at the perfect temperature and pressure to pour a great pint, every single time.

Pass-Through Models In really busy venues, pass-through refrigerators are a total game-changer for efficiency. They have doors on both the front and the back, creating a seamless workflow. Your barbacks can restock from the back of the cooler without ever getting in the way of bartenders serving guests from the front.

A well-chosen back bar refrigerator is the heart of an efficient beverage program. It's not just about cold storage; it’s about creating a system where every bottle, can, and keg is exactly where it needs to be, when it needs to be there.

Even when you're short on space, the right equipment can make a world of difference. To get the most out of a smaller footprint, you might consider a compact but high-performing unit like the Blaze 15 Inch Outdoor Refrigerator. When you carefully weigh these options, you'll find a back bar with refrigerator that doesn't just fit your space but actually makes your whole operation better. For a deeper dive into different models, you can check out our complete guide on the back bar cooler.

Decoding the Features That Drive Performance

Once you've figured out the size and configuration you need, it's time to dig into the features that really separate a workhorse from a headache. Think of it like buying a car; the paint job is nice, but it's the engine, transmission, and build quality that get you where you need to go, day in and day out. These details are what make a back bar with refrigerator a true piece of commercial equipment that can handle the nightly rush for years.

It’s no surprise that more businesses are investing in these specialized units. The global market for back bar refrigerators hit about USD 1.49 billion in 2024 and is only getting bigger. This boom is all about the demand for precision—especially with craft beverages that need to be kept in a tight 33°F to 38°F window to protect their flavor. Features like pass-through access, which can speed up service by up to 20%, are also pushing the market forward. For a deeper dive, you can discover the full market analysis on dataintelo.com.

To help you sort through the options, we've put together a quick comparison of the most important features you'll encounter.

Back Bar Refrigerator Feature Comparison

This table breaks down the common choices you'll have to make, from door types to compressor locations, so you can match the right features to your bar's specific needs.

| Feature | Option A | Option B | Best For |

|---|---|---|---|

| Compressor | Front-Breathing | Rear-Breathing | Front: Built-in, zero-clearance installs under a counter. Rear: Freestanding units with space for airflow. |

| Door Type | Solid Doors | Glass Doors | Solid: Back-of-house storage, energy efficiency. Glass: Merchandising, customer-facing displays. |

| Door Style | Swinging Doors | Sliding Doors | Swinging: Easy access, better seal. Sliding: Tight spaces, narrow walkways behind the bar. |

| Shelving | Epoxy-Coated Wire | Stainless Steel | Epoxy: All-purpose, good airflow, corrosion-resistant. Stainless: Heavy loads, maximum durability. |

| Certification | NSF Certified | Standard (No NSF) | NSF: Required for most commercial kitchens and bars to meet health codes. |

| Energy Rating | ENERGY STAR Rated | Standard Efficiency | ENERGY STAR: Lowering long-term utility bills, eco-conscious businesses. |

Choosing the right combination of these features will directly impact your bar's efficiency, energy costs, and even your sales.

The Heart of the Cooler: The Compressor

The compressor is the engine of your fridge, and its location is a huge deal for both performance and installation. It's all about how the unit breathes and gets rid of hot air, which can be a real challenge in a cramped bar.

-

Front-Breathing Compressors: These are the go-to for built-in setups. They pull cool air in and push hot air out through a grille on the front, so you can slide them right into a custom cabinet or under a counter with no side or rear clearance needed.

-

Rear-Breathing Compressors: These units vent out the back, meaning they need a few inches of breathing room between the unit and the wall. They're often a bit less expensive but can't be enclosed, or they'll quickly overheat and burn out.

Choosing the Right Doors

Your cooler's doors aren't just for opening and closing. They play a major role in how well the unit runs, how your staff works, and what your customers buy.

Solid Doors are the champs of energy efficiency. Built from stainless steel, they're heavily insulated and do the best job of trapping cold air inside. This makes them perfect for storing backup kegs, cases of beer, and other stock that doesn't need to be on display.

Glass Doors turn your cooler into a silent salesperson. When customers can see your colorful selection of craft brews, ciders, and bottled sodas, they're far more likely to make an impulse purchase. Good models use double-pane, low-E (low-emissivity) glass, which helps with insulation and keeps condensation from fogging up the view.

Sliding Doors are lifesavers in tight quarters. If your bar has a narrow aisle where a swing-out door would constantly be in the way, sliders are the answer. They let bartenders grab what they need without blocking the walkway—a small touch that makes a huge impact during a busy service.

Materials and Certifications Matter

The guts and glory of a commercial back bar cooler come down to what it's made of and whether it's certified for professional use. This is where you separate the real equipment from the residential wannabes.

A back bar refrigerator built with cheap materials might save you a few bucks today, but it’s guaranteed to cost you more down the road in wasted energy, constant repair bills, and even potential health code fines.

Here’s what to look for on the spec sheet to know you're getting a quality piece of gear:

- Commercial-Grade Stainless Steel: The best units use a tough, corrosion-resistant stainless steel (like type 304) for both the inside and outside. It’s built to last and is a breeze to keep sanitized.

- Epoxy-Coated Shelving: Those wire shelves take a lot of abuse. A thick epoxy coating prevents them from rusting or corroding when drinks inevitably spill or condensation builds up. Adjustable shelves are also key for fitting different-sized bottles and cans while letting cold air circulate.

- NSF Certification: This is a big one. The National Sanitation Foundation (NSF) mark means the refrigerator meets strict standards for food safety and cleanability. For most health departments, this isn't optional—it's a requirement.

- ENERGY STAR Rating: A unit with the ENERGY STAR seal has been independently verified to be more energy-efficient than its peers. It uses better compressors, insulation, and gaskets to keep your electricity bill down and reduce your bar's carbon footprint.

Building Your Ultimate Commercial Prep Station

A back bar with refrigerator is a game-changer for your beverage service, but it's just one piece of the puzzle. To build a truly unstoppable commercial kitchen, you need to pair that cooler with the right stainless steel prep tables. This isn't just about adding more counter space; it's about creating a seamless workflow that takes you from cold storage to finished plate in record time.

If you're mapping out a new kitchen or a major renovation, bringing in a professional restaurant design service can be a smart move. They’re experts at making sure every piece, including specialized refrigeration and prep stations, works together perfectly to maximize your space and workflow.

Exploring the Types of Stainless Steel Prep Tables

Think of a standard stainless steel work table as your kitchen's blank canvas. These tables are built tough for a reason—they have a durable, non-porous surface that’s incredibly easy to sanitize, making them perfect for just about everything. From dicing onions to plating the final dish, they are the unsung heroes that bear the brunt of a busy service. But for ultimate efficiency, specialized prep tables are the way to go.

These units brilliantly combine chilled storage directly below a dedicated workspace, keeping your most critical ingredients perfectly cooled and literally at your fingertips. No more running back and forth to the walk-in cooler. This simple change shaves precious seconds off every single order, and during a rush, those seconds add up fast. You'll generally see two main types, each designed for a specific kind of menu.

- Sandwich Prep Tables: These are the workhorses of any deli, cafe, or sandwich spot. They have a refrigerated base for your bulk items, while the top features chilled wells perfectly sized for an army of small ingredient pans. Sliced meats, cheeses, lettuce, tomatoes, pickles—everything is organized and held at a food-safe temperature, ready to go. The integrated cutting board provides a dedicated space for assembly.

- Pizza Prep Tables: Built specifically for pizzerias, these tables take the concept a bit further. Their refrigerated rail is wider and raised to fit larger, deeper pans for things like pepperoni, mushrooms, onions, and mounds of cheese. The oversized cutting board is deep enough to handle large pizza skins, creating a perfect assembly line that helps your crew build pizzas with speed and consistency.

The big idea behind refrigerated prep tables is simple but powerful: bring the cold storage directly to the prep line. It’s a strategic move that slashes wasted motion and dramatically speeds up assembly time, which directly improves your ticket times and overall output.

Creating the Perfect Workflow

The real magic happens when you bring all these pieces together into one cohesive system. Picture this: a bartender grabs a craft beer from a sleek back bar cooler. Just a few steps away, a line cook is assembling a signature sandwich on a refrigerated prep table. You've created clear, efficient zones for drinks and food, which means no more bottlenecks and a team that moves like a well-oiled machine.

And this isn't just a strategy for huge restaurants. Food trucks, pizzerias, and delis can see massive benefits from pairing a compact back bar with refrigerator with the right prep table for their menu.

To dive deeper, check out our detailed guide to commercial refrigerated prep tables, where we break down how these units can completely transform your operation. When you start thinking of your equipment as an interconnected system, you’re not just buying appliances—you’re building a prep station that’s powerful, efficient, and ready to handle whatever the dinner rush throws at it.

Mastering Installation and Maintenance

Choosing the perfect back bar with refrigerator is a huge step, but making sure that investment lasts is where the real work begins. If you want your unit to run efficiently for years without costly breakdowns, you need to nail the installation and stick to a maintenance routine. Think of it like laying the foundation for a house—get it right from the start, and everything else will be solid.

The initial setup is your first, best chance to head off future problems. It’s not just about plugging it in. You're creating the perfect operating environment for a piece of commercial equipment that’s going to work hard for you every single day.

The Essential Installation Checklist

Getting the setup right doesn't have to be a headache. Just a few key steps will ensure your cooler is ready to perform from the moment you turn it on.

- Level the Unit Perfectly: If your cooler isn't level, you're asking for trouble. Doors won't seal right, which means cold air leaks out and your compressor has to work overtime. It can also mess with the condensate drain, leading to puddles of water. Grab a level and adjust the feet until it's perfectly stable on the floor.

- Ensure Proper Ventilation: This one is non-negotiable. As we talked about earlier, front-breathing models are great because they can be installed with zero clearance on the sides and back. But if you have a rear-breathing unit, it needs 2-4 inches of open space around the back and sides to breathe. Blocking that airflow is like forcing a runner to hold their breath—the unit will overheat, struggle to stay cold, and eventually burn out.

- Verify Electrical Hookups: A back bar refrigerator is a serious piece of machinery, and it needs its own dedicated electrical circuit. Plugging it into an overloaded circuit with other power-hungry appliances is just asking for tripped breakers and potential damage to the compressor. Always check the manufacturer’s electrical specs and follow them to the letter.

A Simple Preventative Maintenance Schedule

Once your unit is humming along, a simple maintenance plan is your best defense against surprise repair bills. These small, consistent tasks keep your cooler in top shape, saving you money on both energy costs and service calls down the road.

Preventative maintenance isn't just about cleaning. It’s about making your equipment last longer and run at peak efficiency. A few minutes each week can honestly prevent a total meltdown during a busy Friday night rush.

The commercial refrigeration market is massive, valued at $29.6 billion in 2023 and expected to grow to $56.2 billion by 2035. With so much money invested in this equipment, taking care of it is just smart business. Modern, energy-efficient back bars can cut your utility costs by 30%, but that only happens if they're properly maintained. You can see more data on the growth of the commercial refrigeration market on alliedmarketresearch.com.

Here's a simple checklist to keep you on track.

Preventative Maintenance Checklist

A little bit of regular upkeep goes a long way. This schedule breaks down the essential tasks to keep your back bar refrigerator running smoothly and hygienically.

| Frequency | Task | Why It Matters |

|---|---|---|

| Daily | Wipe down all surfaces, inside and out. | Prevents sticky messes and bacterial growth. |

| Daily | Clean up any spills immediately. | Keeps the interior sanitary and odor-free. |

| Weekly | Inspect and clean door gaskets. | Ensures a tight seal to keep cold air in and energy bills down. |

| Quarterly | Clean the condenser coils. | This is critical for cooling efficiency and preventing compressor burnout. |

Sticking to these tasks will protect your investment and ensure your cooler is always ready for service.

The most important job here is cleaning the condenser coils every quarter. Over time, these coils get caked with dust, grease, and all sorts of grime, which stops the unit from getting rid of heat. This forces the compressor to run nonstop, jacking up your energy bills and leading to a much shorter lifespan for the unit. If you're not sure how to tackle it, our guide offers easy steps on how to use a fridge condenser cleaner.

Follow this straightforward plan for installation and maintenance, and your back bar with refrigerator will be a reliable, efficient, and profitable workhorse for your business for a long time to come.

Common Questions About Back Bar Refrigerators

Even after digging into the details, you might still have a few questions floating around about picking the perfect back bar cooler for your setup. This is where we tackle the most common things we hear from bar managers, restaurant owners, and chefs. Our goal is to give you clear, straight-to-the-point answers so you can make that final decision with total confidence.

What’s the Real Difference Between a Back Bar and an Undercounter Refrigerator?

While they look alike and both tuck neatly under a counter, their design and purpose are worlds apart. A back bar refrigerator is a specialist, built from the ground up for the fast, demanding pace of a bar or busy restaurant. They are made for quick access and showing off your products.

This means you'll often find features like bright LED lighting and crystal-clear glass doors designed specifically to showcase your drinks and encourage those impulse buys. They're also built tougher to handle the constant opening and closing that happens during a hectic service.

An undercounter refrigerator, on the other hand, is more of a general-purpose player. It's usually found in a kitchen for storing prepped ingredients and doesn't have the same focus on display, heavy-duty use, or the specific shallow depth needed to fit perfectly behind a bar. Think of it as a reliable work truck versus a sleek sports car—both are useful, but one is built for performance and presentation.

How Do I Figure Out What Size Back Bar Cooler I Need?

Getting the right size is a balancing act between three things: your available space, how much you need to store, and the variety of drinks you sell.

- Measure Your Space: First things first, grab a tape measure. Get the exact width, depth, and height of the spot where the cooler is going. Don't forget to leave an extra 2-4 inches of clearance on the sides and back for proper airflow, especially for rear-breathing units.

- Estimate Your Volume: Picture your busiest night. How many bottles, cans, or kegs do you need chilled and ready to go? A small cafe might do just fine with a compact 24-inch single-door unit, but a packed nightclub could easily need a 90-inch, three-door model to keep up.

- Think About Your Menu: If you have a wide range of craft beers, wines, and mixers, you’ll need more space and adjustable shelving to handle all the different bottle and can sizes. It’s almost always better to go a little bigger than you think you need than to end up with a cooler that's too small.

Are ENERGY STAR Certified Back Bar Refrigerators Really Worth It?

In one word: absolutely. The initial price tag on an ENERGY STAR certified model might be a bit higher, but it's an investment that quickly pays for itself. These efficient coolers are designed with better compressors, thicker insulation, and tighter door seals, which can cut your energy use by 30% or more compared to standard models.

Since your refrigeration runs 24/7, that adds up to big savings on your monthly utility bills. The lower energy use also means the unit kicks out less heat, helping keep your bar area cooler and taking some of the load off your AC. Over the cooler's life, the energy savings will almost always outweigh the higher upfront cost.

What Does NSF Certification Mean, and Why Is It So Important?

NSF stands for the National Sanitation Foundation, and seeing that logo is a critical stamp of approval for public health and safety. When a back bar with refrigerator is NSF certified, it means it has been put through a battery of tests to meet strict standards for safe materials, easy-to-clean design, and reliable performance.

NSF certification is your guarantee that the equipment is built for a commercial food environment. It tells health inspectors—and your customers—that you take safety and sanitation seriously, protecting both your reputation and the public.

This includes things like:

- Hygienic Materials: Using smooth, non-porous surfaces like commercial-grade stainless steel that are simple to clean and won't harbor bacteria.

- Sanitary Design: Having coved (curved) interior corners so food particles and grime can't get trapped.

- Performance Tested: Proving that the refrigerator can hold safe temperatures consistently, even when the doors are being opened constantly.

For most restaurants and bars, having NSF-certified equipment isn't just a good idea—it's often a requirement from the local health department. It's a non-negotiable for any serious commercial kitchen.

Ready to build the ultimate prep station for your business? At PrepTables.com, we offer a wide range of NSF-certified stainless steel prep tables and commercial refrigeration to create a seamless, efficient workflow. Explore our collection and find the perfect equipment to elevate your kitchen's performance today at https://preptables.com.