Choosing Your Back Bar Cooler

Share

Think of a back bar cooler as the unsung hero behind any great bar. It’s far more than just a fridge; it's a specialized piece of equipment designed from the ground up to keep service smooth, drinks perfectly chilled, and sales flowing. Its design is all about handling the intense demands of a busy bar, which sets it leagues apart from your standard home refrigerator.

The Essential Role of a Back Bar Cooler

From a packed local pub to a high-end cocktail lounge, the back bar cooler is the operational heart of the operation. Its main job is to hold beverages at the absolute perfect serving temperature, making sure every beer is frosty and every mixer is crisp. This instant access means bartenders can grab what they need and serve drinks faster, which is a lifesaver during a weekend rush.

Your home fridge might get opened a handful of times a day. A bar cooler? It's opened constantly. It’s built to take that abuse, with a powerful compressor and forced-air cooling that snaps the temperature right back down after the door closes. This kind of reliability is what good service and speed are built on.

More Than Just Refrigeration

Beyond just keeping things cold, a back bar cooler plays a few other critical roles that directly impact a bar's bottom line. It's part merchandiser, part organizational tool, and a huge boost to your team's efficiency.

Here’s how it breaks down:

- Product Display: Glass door models are a game-changer. They turn your inventory into a visually appealing display, tempting customers with your selection of craft beers, wines, and top-shelf spirits. It's amazing what a little visibility can do for impulse buys.

- Workflow Optimization: With everything within arm's reach, bartenders can mix and pour without missing a beat. Less running around means more drinks served and happier customers.

- Inventory Management: A well-organized cooler gives you an instant visual on your stock levels. Staff can see what’s running low at a glance, making reordering a breeze and preventing you from running out of a bestseller mid-shift.

A back bar cooler is a direct investment in efficiency. Its whole purpose is to shrink the time between a customer's order and that first satisfying sip, which has a massive impact on both satisfaction and sales.

Market Growth and Importance

The rising importance of this equipment is easy to see in the market trends. The global back bar cooler market is growing steadily, pushed along by a thriving hospitality industry. In 2025, the market is expected to be worth around USD 1.5 billion, with projections showing a Compound Annual Growth Rate (CAGR) of about 5% through 2033. This isn't just a niche product; it's becoming a standard for any serious establishment.

Protecting the flavor and integrity of your spirits is a top priority, and understanding optimal whiskey storage practices really drives home the value of your cooler's stable temperature control. This isn't just a nice-to-have feature; it's essential for safeguarding your inventory. You can dive deeper into why this matters so much in our guide on food safety and temperature control.

Finding the Right Type for Your Bar

Picking out the right back bar cooler isn’t a one-size-fits-all situation. It's really about matching the unit to your bar's specific flow, the space you have to work with, and what you're serving. The choices you land on, especially when it comes to doors and overall capacity, will have a real impact on your daily workflow and even your bottom line.

Think of it like this: the cooler a high-volume sports bar needs is going to be completely different from the sleek setup in an intimate cocktail lounge.

Glass Doors Versus Solid Doors

The first big decision you'll face is the door type. This one choice changes everything from how your staff grabs a drink to how customers see what you've got on offer.

Glass door coolers are basically a silent salesperson. They put your chilled inventory on display, turning your craft beer selection or colorful canned cocktails into a visual menu. This is a great way to encourage impulse buys and helps bartenders find what they need in a split second, which is a lifesaver during a crazy rush.

On the flip side, solid-door coolers are the workhorses of efficiency. Their insulation is top-notch, meaning they hold their temperature like a fortress, especially in a hot, crowded bar. That translates directly to lower energy bills and less wear and tear on the cooling system. A classic speasy that prides itself on perfectly chilled spirits would probably go for a solid-door unit to prioritize temperature stability over flashy displays.

Now, let's talk about how those doors open.

To help you decide, here’s a quick comparison of the most common door types for back bar coolers.

Comparing Back Bar Cooler Door Types

| Door Type | Key Advantage | Main Disadvantage | Best For |

|---|---|---|---|

| Hinged (Swing) | Full, unobstructed access | Requires clearance to swing open | Restocking quickly; wider aisles |

| Sliding | Saves space; no "swing out" | Can only access one side at a time | Tight spaces behind the bar |

| Glass | Merchandising; quick identification | Less energy efficient | Showcasing craft beers & cocktails |

| Solid | Superior insulation; energy efficient | Hides inventory; staff must open to see | Temperature-sensitive items; efficiency |

Choosing between hinged, sliding, glass, or solid doors really comes down to balancing your need for display, space, and energy efficiency.

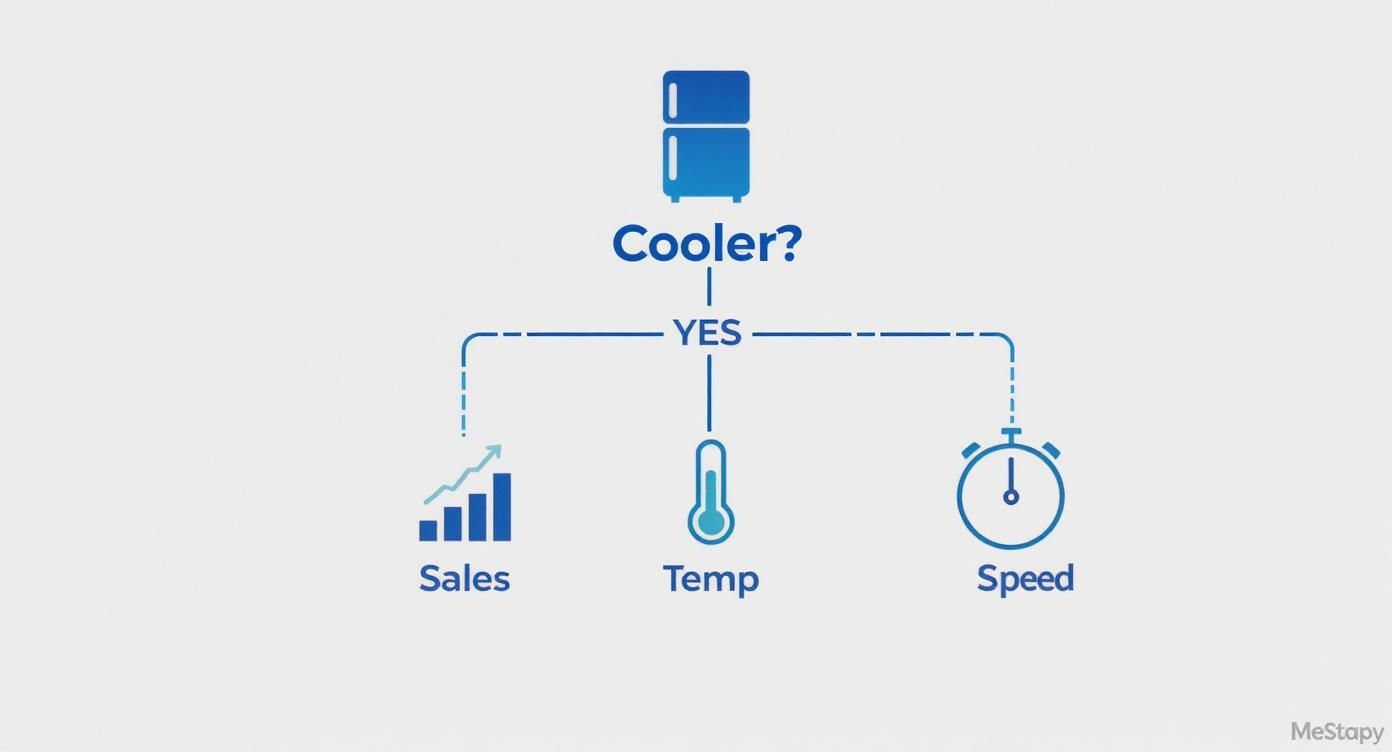

This infographic breaks down the key decision factors when selecting a back bar cooler for your establishment.

As you can see, a back bar cooler does more than just chill drinks—it directly influences your sales, temperature control, and how fast your service is.

Finding the Right Size and Capacity

The size of your cooler needs to make sense for your sales. A little single-door unit might be all a small café or a boutique hotel bar needs. But for a sprawling nightclub that goes through hundreds of bottles and cans a night, a massive three-door model is the only way to go.

Looking at the market, it's clear that capacity is a huge factor. Smaller coolers—under 100 liters—are often the choice for smaller spots or mobile bars where every inch of space counts. The most popular units, however, fall in the mid-range between 100 and 300 liters, hitting that sweet spot of holding plenty of stock without taking over the whole bar. For a deeper dive into these market trends, you can check out this detailed report on back bar coolers.

Ultimately, the best back bar cooler is one that fits seamlessly into your operational flow. Consider not just your current menu but also your future growth when making a selection.

While a back bar cooler is a specialized piece of equipment, it helps to understand the whole cooling landscape. To learn more about different types of cooling units, take a look at our complete guide to choosing a commercial refrigerator.

What Really Makes a Great Back Bar Cooler?

So you've figured out the size and door style you need. That's a great start, but the real magic of a high-performing back bar cooler lies in the details—the stuff under the hood. These core features are what separate a professional-grade workhorse from a glorified dorm fridge. Getting these right is how you make a smart investment that keeps your drinks perfectly chilled and your bar running smoothly.

The single most important part of any back bar cooler is its refrigeration system. You'll want to look for units with forced-air cooling. This technology uses internal fans to push cold air into every nook and cranny of the cabinet. It’s what prevents those dreaded warm spots, ensuring a bottle pulled from the back corner is just as icy as one right in front. During a busy service, that kind of consistency is everything.

Precision Control and Built-to-Last Construction

A powerful cooling system doesn’t mean much without a way to control it. That's why a precise digital thermostat is an absolute must-have for any serious bar. It gives you the power to dial in the exact temperature and keep an eye on it, making sure every beer, wine, or soda is served exactly as it should be for the best customer experience.

The materials and build quality also have a huge impact on how long your cooler will last. Here's what to keep an eye on:

- Durable Exteriors: There's a reason stainless steel is the gold standard in commercial kitchens. It's tough enough to handle the inevitable bumps and scrapes of a busy bar, it won't rust, and it’s a breeze to wipe down and sanitize.

- Adjustable Shelving: Your inventory changes. Your cooler should be able to change with it. Adjustable shelves let you reconfigure the space on the fly to fit tall wine bottles, short cans, or bulky mixers, so you never waste precious cold space.

- Bright Interior Lighting: Good lighting sells drinks. Modern coolers use energy-sipping LED lighting that makes your products pop without adding extra heat. It’s a small touch that makes a big difference in presentation while keeping your energy bills down.

A well-built back bar cooler is designed for the realities of a commercial environment. From its robust cooling system to its thoughtful interior layout, every feature is geared toward enhancing workflow and protecting your valuable inventory.

Smart Features for Security and Easy Upkeep

Finally, don't overlook the practical features that make daily life easier and protect your bottom line. Many professional coolers come with security locks on the doors. It’s a simple feature, but it's invaluable for preventing inventory shrinkage and securing your expensive stock overnight.

Another critical, but often forgotten, feature is a good condensation management system. This could be anything from heated glass doors that prevent fogging to an automatic defrost cycle that stops ice from building up. These systems keep your products clearly visible and ensure the cooler runs efficiently without you having to constantly mess with it. When you focus on these essential features, you’re not just buying a piece of equipment—you’re investing in a reliable asset for your business.

How to Maximize Energy Efficiency and Sustainability

Let’s be honest, your back bar cooler is one of the hardest-working pieces of gear you own. It’s humming along 24/7, keeping everything perfectly chilled. But that constant work comes at a cost—both to your utility bill and the environment. Choosing an energy-efficient model isn't just about being green; it's a savvy business move that pays for itself over time.

The entire industry is leaning into sustainability. Market research shows the back bar cooler market was valued at around USD 6.3 billion in 2025 and is expected to climb to USD 10.2 billion by 2035. A massive driver for that growth is the demand for efficient models running on sustainable refrigerants. You can dig deeper into these market trends to see how it’s shaping the hospitality world.

Decoding Efficiency Certifications

When you're trying to figure out which cooler is truly efficient, look for one little sticker: ENERGY STAR. That certification is your best friend. It means the Environmental Protection Agency (EPA) has verified that the cooler is, on average, 20% more energy-efficient than a standard model. That’s a direct saving on your monthly bills, plain and simple.

An ENERGY STAR cooler is engineered from the ground up to do more with less. They’re built with better components, like high-efficiency compressors and fan motors that keep things just as cold while sipping, not gulping, electricity.

The Big Switch to Greener Refrigerants

One of the most important changes in cooler technology has been the move to eco-friendly refrigerants. For years, everything ran on hydrofluorocarbons (HFCs), which were pretty rough on the atmosphere. The new gold standard is R290, which is essentially propane—a natural, non-toxic hydrocarbon.

R290 has a Global Warming Potential (GWP) of just 3. To put that in perspective, older refrigerants had GWPs in the thousands. It’s not just better for the planet; it’s also more efficient at cooling, meaning your unit recovers temperature faster and uses less energy to do it.

By picking a cooler that uses R290, you're getting ahead of the curve, staying compliant with new regulations, and making an investment that will last.

Key Design Features That Boost Sustainability

Beyond the technical specs, the physical design of a cooler plays a huge role in its efficiency. These features all work together to keep the cold air in and the warm air out, giving the cooling system a much-needed break.

- Top-Notch Insulation: A good cooler should have thick, high-density polyurethane foam insulation. This is what stops the cold from seeping out, which is absolutely critical in a busy, often hot bar environment.

- Self-Closing Doors: Think about how many times a cooler door gets opened during a rush. If it’s left ajar, even for a second, cold air pours out and the compressor has to kick on. Self-closing or positive-seal doors snap shut every time, keeping the internal temperature stable.

- Low-Energy LED Lighting: Old-school incandescent bulbs actually produced a surprising amount of heat, forcing the cooler to work harder. Modern LED lights are bright, make your products look great, and generate almost no heat. It's a small detail that makes a big difference.

Installation and Maintenance That Protects Your Investment

You've just made a smart investment in your bar's efficiency and appeal. But getting the most out of your new back bar cooler doesn’t stop at the purchase. Proper installation and a simple, consistent maintenance routine are absolutely essential. Think of it like a performance car—you wouldn't skip an oil change, and you shouldn't skip basic cooler care either.

Getting the setup right from day one is your first step toward a long, trouble-free service life. Rushing this part is a recipe for headaches down the road.

The Foundation of Proper Installation

Before you even think about plugging it in, a few quick checks will set your cooler up for success. The whole idea is to give the unit a perfect environment to work in, free from any unnecessary strain.

First, make sure the back bar cooler is on a completely level surface. If it's tilted, even slightly, the doors might not seal correctly. That lets cold air seep out and forces the compressor to work overtime, which is a real energy hog. An uneven base can also create vibrations that wear out the motor and other parts way too soon.

Next, you have to think about airflow. A cooler’s compressor is like its engine—it generates heat, and it needs room to breathe.

- Ventilation is critical: Always, always leave at least 2-4 inches of empty space around the back and sides of the unit. Blocking those vents is the fastest way to make it overheat, which kills its cooling power and can lead to a total compressor failure.

- Avoid heat sources: This one's a biggie. Never stick your cooler right next to a hot griddle, a fryer, or in a sunny spot. All that external heat forces the unit to battle just to stay cold, sending your energy bills through the roof.

- Dedicated electrical circuit: A commercial cooler is a workhorse and needs its own dedicated electrical outlet. If you plug it into an overloaded circuit, you're risking poor performance and creating a serious safety hazard.

A Simple Maintenance Routine for Longevity

Once your cooler is up and running, a repeatable maintenance schedule is your best friend. It’s the single best way to avoid costly repairs and unexpected downtime. These tasks barely take any time but pay you back tenfold in efficiency and lifespan.

Proactive maintenance isn't a cost; it's an insurance policy. A few minutes of cleaning each month can prevent an emergency repair bill that costs hundreds, if not thousands, of dollars.

A well-maintained cooler doesn't just last longer—it keeps your drinks at that perfectly consistent, crisp temperature your customers love. For a wider look at keeping your whole kitchen in top shape, our guide on commercial kitchen equipment maintenance has some great tips that apply to everything you own.

To get you started, here is a simple checklist for keeping your back bar cooler in prime condition.

Your Back Bar Cooler Preventative Maintenance Checklist

| Frequency | Task | Why It's Important |

|---|---|---|

| Daily | Wipe down spills and interior surfaces | Prevents sticky residue buildup and keeps the environment for your beverages clean and hygienic. |

| Weekly | Inspect door gaskets (seals) | Checks for any cracks or gaps that are letting cold air escape, ensuring an airtight seal for top efficiency. |

| Monthly | Clean the condenser coils | Removes the dust and gunk that act like an insulator, helping the unit release heat and cool effectively. |

| Quarterly | Check and calibrate the thermostat | Guarantees the temperature display is accurate, which protects your product and ensures perfect serving quality. |

Following this simple schedule will go a long way in protecting your cooler and ensuring it serves your bar well for years to come.

Common Questions About Back Bar Coolers

Figuring out the world of commercial refrigeration can definitely bring up a lot of questions. Whether you're picking out your first back bar cooler or thinking about an upgrade, getting clear, direct answers is the key to investing with confidence. Here, we'll tackle some of the most common and practical questions we hear from operators.

Getting these queries answered helps take the mystery out of the selection process, making sure you land a unit that perfectly fits your bar’s specific needs and day-to-day flow.

How Do I Choose the Right Size Back Bar Cooler?

The right size really boils down to three key things: your sales volume, how many different products you stock, and the actual physical space you have to work with. A great starting point is to estimate the maximum number of bottles or cans you need ice-cold during your absolute busiest shift. That gives you a solid baseline for the capacity you're aiming for.

Next, get out the tape measure and check your under-bar area. It's so important to leave at least 2-3 inches of clearance on the sides and back for the unit to breathe and ventilate properly. A small coffee shop might be perfectly happy with a single-door unit, but a high-volume sports bar with a huge craft beer menu will almost certainly need a three-door model—or even a few separate units—just to keep up.

What Is the Difference Between a Back Bar Cooler and a Commercial Refrigerator?

While they both keep things cold, think of it this way: a back bar cooler is a specialist, and a commercial refrigerator is more of a generalist. Back bar coolers are designed from the ground up for the fast-paced, high-demand environment behind a bar. They have powerful cooling systems built for lightning-fast temperature recovery after the doors are opened again and again, ensuring every single drink you serve is perfectly chilled.

They're also built to a standard height (usually 34” to 36”) so they slide neatly under most bar counters. On top of that, they often come with features like glass doors and bright LED lighting to really merchandise your products effectively. A standard commercial refrigerator is just engineered for general food storage and simply doesn't have these specialized features needed for beverage display and quick pull-down chilling.

Can I Use a Back Bar Cooler in a Home Bar?

Absolutely. Plenty of home bar enthusiasts go for a back bar cooler because they love the professional look and superior performance. That said, there are a couple of things to keep in mind before you pull the trigger.

Commercial-grade compressors are often noticeably louder than their residential cousins, which could be a real consideration in a home setting. You'll also need to make sure you have a dedicated electrical circuit and enough ventilation to handle the unit's power draw and cooling needs.

How Often Should I Clean the Condenser Coils?

For any busy commercial spot, cleaning the condenser coils every three months is a solid best practice. If your bar is in an environment with a lot of dust, grease, or even flour from a nearby kitchen, you should bump that up to a monthly cleaning.

Neglecting the condenser coils is one of the most common and costly maintenance mistakes you can make. Dirty coils force the compressor to work way harder, leading to higher energy bills, poor cooling, and a much shorter lifespan for your equipment. A quick brushing or vacuuming is all it takes to head off major problems down a road.

At PrepTables.com, we provide the durable, efficient, and reliable commercial refrigeration solutions you need to keep your operations running smoothly. Explore our full range of back bar coolers and other essential equipment by visiting us at https://preptables.com.