Choosing the Right work tables kitchen for Your Space

Share

Think of a kitchen work table as less of a piece of furniture and more like the central command for your entire culinary operation. Whether you're in the trenches of a busy restaurant or just deeply passionate about your home kitchen, the right table is what turns chaos into a smooth, efficient production line.

This guide is more than just a list of descriptions; it's a roadmap to help you find the absolute perfect work table for your needs.

A Tour of Stainless Steel Prep Tables

When you imagine a professional kitchen, what's the first thing you see? For most, it's the signature gleam of stainless steel. The work tables kitchen pros swear by are almost always stainless steel, and for good reason—their durability and hygiene are second to none.

But here's the thing: not all steel tables are created equal. They're built in different ways for different jobs. Getting a handle on these differences is the first real step toward building a more functional kitchen. Let's break down the main types you'll encounter.

Open Base Tables: The All-Purpose Workhorse

The most common setup you'll see is the standard open base table. This is the reliable, all-purpose champion of the kitchen. It has a simple, sturdy design with a flat top and an open undershelf, which is perfect for stashing big items like stock pots, flour bins, or other bulky equipment you need to grab quickly. The open design makes it a breeze to access everything and even easier to clean underneath. It's the go-to choice for general prep, from dicing onions to portioning out steaks.

Enclosed Base Tables: Organized & Protected Storage

If you need storage that's more organized and protected from the daily kitchen grime, an enclosed base table (or cabinet base table) is a fantastic choice. These tables come with either sliding or hinged doors, basically creating a cabinet right under your workspace.

This design is a game-changer for a few reasons:

- Storing sensitive items: It keeps things like clean linens, spare utensils, or small appliances safe from dust, spills, and whatever else is flying around the kitchen.

- Creating a cleaner look: Hiding your supplies behind doors just makes the whole kitchen look tidier and more professional. This is a huge plus in open-kitchen layouts where customers can see everything.

- Enhancing safety: It gets items off the floor and tucked away, which cuts down on tripping hazards.

Specialized Refrigerated Prep Stations

This is where we move beyond simple storage and into serious efficiency. Specialized work tables kitchen designs that have refrigeration built right in are absolute lifesavers for certain tasks.

A specialized prep table isn't a luxury; it's a strategic tool. By combining cold storage with a dedicated workspace, these units can reduce prep time by up to 30% by eliminating the need for chefs to walk back and forth to a separate refrigerator.

Take pizza prep tables, for instance. Their design is pure genius. They have refrigerated rails right on top to hold all your toppings—cheese, pepperoni, veggies—at a safe temperature. Underneath, a refrigerated cabinet keeps dough balls and backup ingredients within arm's reach.

It's the same idea with sandwich prep tables, which keep deli meats, cheeses, and condiments perfectly chilled and organized for lightning-fast assembly. These tables aren't just furniture; they're self-contained, high-octane workstations.

Why Stainless Steel Is the Industry Standard

Walk into just about any professional kitchen, from a high-end restaurant to your local corner cafe, and you'll be met with the familiar gleam of stainless steel. This isn't just a stylistic choice—it's the undisputed king of materials for the work tables kitchen professionals count on day in and day out. Why? It all boils down to a powerhouse combination of hygiene, sheer durability, and practicality that other materials just can't touch.

The biggest win for stainless steel is its non-porous surface. Picture it as a perfectly smooth, sealed shield. Unlike a wooden butcher block, which has tiny crevices that can trap bacteria and moisture, stainless steel gives germs nowhere to hide. This makes it incredibly easy to clean and sanitize, forming a hygienic barrier that is absolutely crucial for food safety.

This commitment to quality is the bedrock of the commercial kitchen furniture industry. The global market for this equipment, including these vital work tables, is a huge part of the overall furniture sector, valued at around $57 billion. That's roughly 13% of the entire worldwide furniture market, with Germany leading the way as the largest exporter, underscoring the high standards set by European manufacturing.

Understanding Stainless Steel Grades

Here’s something you need to know: not all stainless steel is the same. The "grade" of the steel tells you what it's made of—specifically, its chromium and nickel content. These elements dictate its strength and, most importantly, how well it resists corrosion. Getting this right is like picking the right knife for the job; you wouldn't use a delicate paring knife to break down a chicken.

In the kitchen world, the two grades you’ll run into most often are 304 and 430.

Key Takeaway: Think of the grade number as a performance score. A higher number like 304 generally means better corrosion resistance and a longer lifespan, making it a smarter long-term investment for busy, wet, or high-acid environments.

To really see the difference, it helps to put them side-by-side.

A Practical Comparison of Stainless Steel Grades

This table breaks down the two most common grades you'll find, helping you match the right steel to the right job in your kitchen.

| Grade | Key Composition | Corrosion Resistance | Best For | Common Price Point |

|---|---|---|---|---|

| 304 | 18% Chromium, 8% Nickel | Excellent | All-purpose use, especially wet areas like dish rooms or near sinks. Perfect for heavy-duty food prep. | Higher |

| 430 | 17% Chromium, 0% Nickel | Good | General use in dry areas like storage, equipment stands, or light-duty prep away from moisture. | Lower |

Looking at this, you can start to see where each grade really shines.

Think of 304-grade stainless steel as the premium, all-weather tire for your kitchen. That bit of nickel in its makeup gives it exceptional resistance to rust and corrosion from things like salt, acidic foods (tomatoes, citrus), and tough cleaning chemicals. This makes it the undisputed gold standard for tabletops and any surface that gets hit with constant use and moisture.

On the other hand, 430-grade stainless steel is more like a reliable summer tire. It’s perfectly fine in dry conditions and is easier on the wallet because it doesn't contain nickel. It's a fantastic choice for undershelves, table legs, or work surfaces used strictly for dry storage or assembly tasks where the risk of corrosion is low.

Making the Right Choice for Your Kitchen

So, how do you choose? It really comes down to your kitchen's specific needs and your budget. A table sitting right next to a prep sink or in a steamy dish pit absolutely needs the superior protection of 304-grade steel to keep rust at bay. But for a baker’s table used only for flouring dough, a 430-grade top is likely more than enough and will save you some money.

Ultimately, investing in the right type of stainless steel work table isn't just about buying a piece of equipment; it's about building a foundation of safety and durability that prevents costly replacements down the road. When you match the steel grade to the task, you create a smarter, tougher workspace that's built to last.

Exploring Specialty Prep Tables

Sure, a standard stainless steel table is the workhorse of any professional kitchen. But some jobs call for a specialist. It’s like a mechanic’s toolbox: a standard wrench gets you far, but sometimes you need a very specific socket to get the job done right. The same is true for the high-volume, repetitive tasks that define a busy service.

Specialty prep tables are more than just a surface to work on; they're complete, integrated workstations. They're designed to bring every single thing you need for a specific task into one tight, efficient zone. By combining prep space with refrigerated storage, they cut out wasted motion, keep ingredients safely chilled, and seriously boost your workflow.

The Anatomy of a Pizza Prep Table

If you're running a pizzeria, a dedicated pizza prep table isn't a luxury—it's essential. The entire unit is a masterclass in culinary efficiency, built from the ground up to do one thing: assemble pizzas quickly and perfectly, every single time. These are far more than just a table with a fridge slapped underneath.

The star of the show is the refrigerated rail system up top. It's a series of chilled wells designed to hold food pans packed with every topping you can think of—mozzarella, pepperoni, mushrooms, onions, you name it. This keeps everything right at the chef's fingertips, all held at a food-safe temperature below 41°F (5°C).

Right below the work surface, you'll find a refrigerated cabinet for bulk storage. This is where you stash backup ingredients, trays of pizza dough, and tubs of sauce. With this integrated setup, a cook can bang out dozens of pizzas without ever taking a step towards a separate walk-in or reach-in cooler. You’re saving precious seconds on every single order.

Mastering Speed with Sandwich Prep Tables

In the same way, sandwich and salad prep tables are the absolute engines of delis, cafes, and any quick-service spot. Just like their pizza-making cousins, these units are all about streamlining an assembly line process to lock in speed, consistency, and safety.

The layout is perfectly organized to mirror the way a sandwich is built. The refrigerated rail keeps condiments, sliced meats, cheeses, and fresh veggies in a logical order. The work surface, which often includes a built-in cutting board, gives you the ideal space to put it all together.

A well-designed sandwich prep table can reduce order completion times by 20-40%. By keeping every component chilled and organized, it minimizes cross-contamination risks and empowers staff to fulfill orders with greater speed and accuracy.

The refrigerated base offers plenty of room for backup supplies, so you never run out of anything during a chaotic lunch rush. This all-in-one station turns what could be a messy, disorganized process into a smooth, methodical operation.

Why Invest in a Specialty Table

So, when do you choose a specialized station over a standard work table? It really comes down to your menu and your volume. For a high-volume pizzeria or deli, the investment in a dedicated prep table pays for itself almost immediately through sheer output and less wasted labor.

Think about these massive advantages:

- Enhanced Workflow: Centralizing everything drastically cuts down on the time your staff spends walking back and forth to grab ingredients.

- Improved Food Safety: With integrated refrigeration, perishable items are always kept out of the temperature danger zone. This seriously reduces the risk of spoilage and foodborne illness.

- Increased Consistency: When all the ingredients are laid out in the same order every time, it becomes second nature for staff to produce a consistent product, no matter who's working the line.

- Space Optimization: These units pack three kitchen essentials—a work surface, ingredient rails, and cold storage—into one footprint. They’re a lifesaver in kitchens where every square inch counts.

For any operation that lives and dies by speed and repetition, these specialized work tables kitchen units aren't just a nice-to-have. They are a core part of a profitable, efficient business model, providing the structure needed to turn a complex task into a simple, repeatable process.

Finding the Perfect Fit for Your Kitchen

Once you’ve settled on the right type of stainless steel table, the real-world planning begins. You need to make sure the table actually fits into your kitchen's daily dance. This isn't just about finding an empty corner; it’s about picking a size that makes your workflow smoother, not one that creates a traffic jam. A table that’s too big will cause bottlenecks, but one that’s too small will kill your prep capacity.

Before you even think about table dimensions, grab a tape measure. Seriously. Map out your space and, most importantly, plan for clearance. A solid rule of thumb in commercial kitchen design is to leave at least 36 to 48 inches of open walkway around your equipment. This gives your staff room to hustle, open hot oven doors, and carry pans without bumping into each other. Thinking through how people move is everything, and you can get some great ideas on commercial kitchen layout planning to really nail down the flow.

How Much Weight Can It Handle?

Next up, think about what you're going to pile on this table. Load capacity is the maximum weight a table can safely hold, and it's a number you absolutely cannot ignore. You'll usually see two different ratings from the manufacturer: one for the top shelf and another for the undershelf, since they’re often built to handle different stresses.

For instance, if your table is just for light-duty work like plating desserts or building salads, a top shelf capacity of 400-500 pounds is probably fine. But if you’re planning to park a 150-pound commercial mixer or a heavy meat slicer on it, you’ll want a heavy-duty table rated for 800 pounds or more. Always play it safe and pick a table with a capacity that’s well above your heaviest piece of gear.

Little Features That Make a Big Difference

Beyond the basic size and strength, a few key features can completely change how a work table functions in the real world. These aren't just minor add-ons; they solve the everyday headaches of a busy kitchen.

A backsplash is one of the most useful features you can get. It’s a simple raised lip, usually 1.5 to 2 inches high, along the back of the table. Its job is simple but brilliant: it stops food, liquids, and utensils from falling down the gap between the table and the wall. That means cleaner floors, cleaner walls, and better hygiene.

Storage is the other big decision, which brings you to the choice between an open or solid undershelf.

- Open Undershelves: These are slatted or grated, so air can circulate freely. They’re perfect for storing things like potatoes, onions, or large pots. Plus, you can see everything at a glance, and it's much easier to clean the floor underneath.

- Solid Undershelves: A solid shelf gives you a stable, flat surface for smaller items that would fall right through a grated shelf—think spice containers, small appliances, or boxes of supplies.

To Move or Not to Move?

Finally, you have to decide if this table is staying put or needs to be on the move. Your choice is between stationary legs and mobile casters (wheels).

Stationary legs offer rock-solid stability. This is non-negotiable for tables holding heavy equipment or being used for tasks with a lot of force, like kneading dough. Most come with adjustable bullet feet so you can level the table, even if your floors aren't perfectly flat.

On the other hand, casters turn your table into a mobile command center. This kind of flexibility is a massive win in dynamic kitchens, letting you rearrange your setup for a different service or roll the table out of the way for a deep clean. This trend toward flexible design is why the market for mobile kitchen islands and tables is booming. It’s currently a $2.5 billion industry and is expected to grow by 7% annually through 2033. You can see the full report from Archive Market Research to get a better sense of these trends.

Decoding NSF Certification for Food Safety

In any professional kitchen, your reputation is built on safety and hygiene. When you're looking at work tables kitchen equipment, the most important seal of approval you can find is that small, round, blue NSF logo. This isn't just some sticker; it’s a guarantee. It tells you the table meets strict public health standards designed to stop foodborne illness in its tracks.

Think of NSF certification as a brutal inspection a table has to pass before it even gets a look-in from a professional kitchen. This process makes sure the equipment is designed and built to promote food safety from the ground up. It’s a huge deal for health inspectors, and having NSF-certified tables can be the difference between passing with flying colors and facing a potential shutdown.

What Does NSF Certification Actually Mean?

For a work table to earn that NSF mark, it has to meet some very specific design rules. The entire point is to get rid of any place where bacteria, mold, and other nasty stuff can hide and multiply.

Key requirements include:

- Smooth and Non-Porous Surfaces: The tabletop has to be perfectly smooth. No cracks, pits, or tiny crevices where food particles and germs can get trapped.

- Sealed Edges and Welds: Every joint and seam must be welded smooth and totally sealed. This stops moisture and bacteria from sneaking into hidden gaps.

- Coved Corners: Any corner where surfaces meet, like where a backsplash joins the tabletop, has to be curved. These "coved" corners are way easier to wipe clean than a sharp 90-degree angle.

Basically, an NSF-certified table is engineered to be ridiculously easy to clean and sanitize. If you want to really get into the weeds, you can learn more about what NSF certification is and see why it’s so critical for your gear.

"An NSF-certified table is more than a piece of equipment; it's a statement about your commitment to your customers' health. It shows you prioritize safety in every aspect of your operation, from ingredient sourcing to the surfaces where food is prepared."

While NSF is all about food safety, getting a handle on broader workplace safety standards is also smart for creating a safer kitchen environment overall.

Maintaining Your NSF Certified Work Table

Getting an NSF-certified table is step one. The real work is in the follow-through—maintaining its hygienic design. A simple but consistent cleaning routine is all it takes to keep your surfaces safe and ready for service.

Here’s a no-fuss cleaning process:

- Clear and Scrape: Get all the loose food debris and scraps off the surface. Use a plastic or rubber scraper so you don't scratch the steel.

- Wash Thoroughly: Now, wash the table down with warm water and a mild detergent. A soft cloth or sponge is best, and move in the direction of the steel's grain for a better clean.

- Rinse Completely: Rinse the surface with clean, hot water. You need to get all the soap residue off, or it can mess with the sanitizer.

- Sanitize for Safety: Last, apply a food-safe sanitizer, following the manufacturer’s directions to the letter. Let the table air-dry completely.

By knocking out these simple steps every day, you make sure your work tables kitchen surfaces remain a safe foundation for every dish you create. It’s how you live up to the high standards that NSF certification stands for.

Making Your Final Decision

Picking the right kitchen work table is a big deal. Why? Because this isn't just a piece of furniture; it's a long-term partner in your kitchen. The right table directly impacts your efficiency, safety, and the quality of your work. So, let's put what we've learned into practice and walk through a few real-world scenarios.

Scenarios to Guide Your Choice

Picture a busy bakery. They're kneading heavy dough all day and need a solid spot for a 150-pound mixer. For them, a stationary table with a hefty load capacity and a tough 304-grade stainless steel top is a must-have. Stability is everything, so adjustable bullet feet are critical to stop any wobble when that mixer is going full tilt.

Now, think about a small city cafe where every square inch counts. Their layout might need to shift from the morning coffee rush to the lunchtime scramble. The perfect fit here is a mobile work table on locking casters. It can be rolled out for morning prep and then tucked away to clear a path for customers. It's all about flexibility.

Finally, imagine a dedicated home chef who's upgrading their kitchen to a more professional setup. They want something hygienic but also stylish. A smaller, 48-inch stainless steel table with an open undershelf strikes a great balance. It gives them a dedicated prep area and easy-to-reach storage without taking over the whole room.

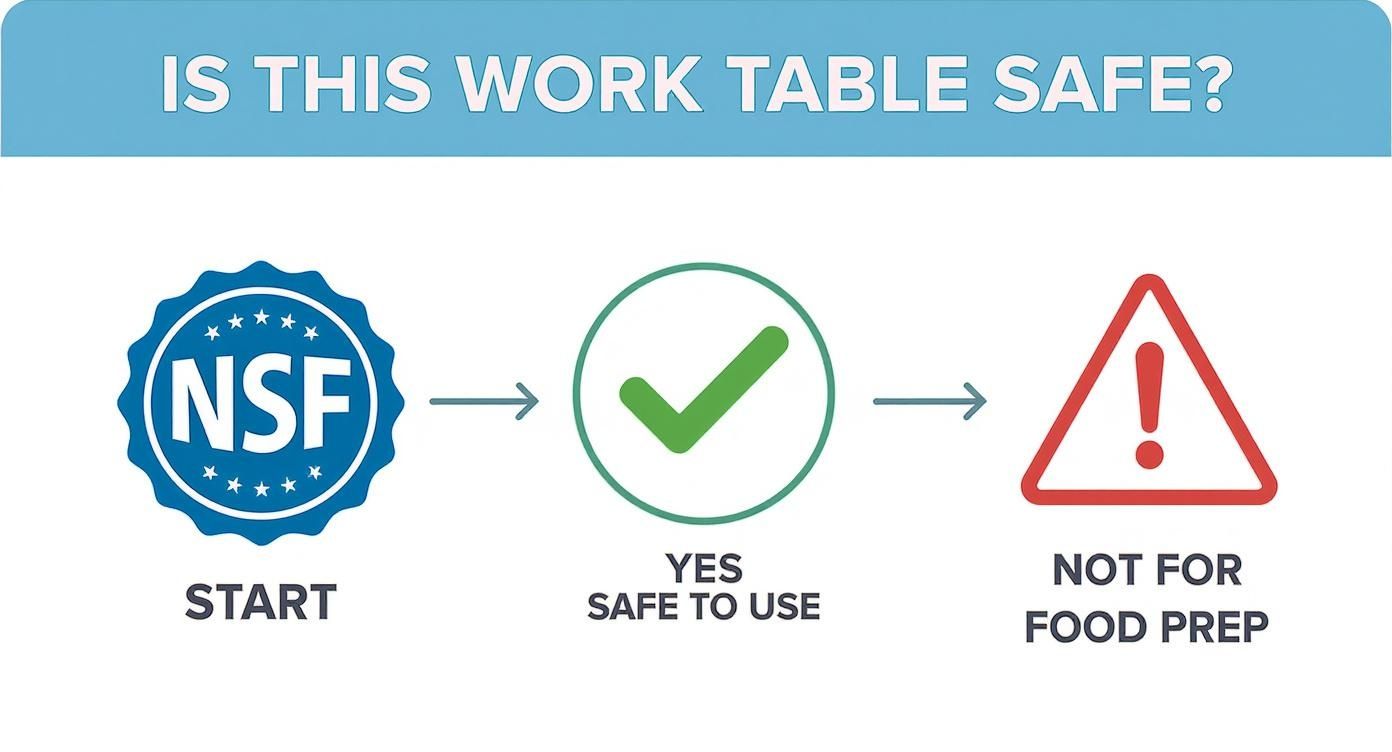

For a quick gut-check, this infographic zeroes in on the single most important factor for any surface where food is handled: safety.

As the decision tree shows, if you see that NSF seal, you know you're on the right track for food safety. It really simplifies things.

Final Questions Before You Buy

Think of this purchase as a strategic investment. The global market for kitchen and dining furniture is expected to reach $82.39 billion for a reason—people want a perfect mix of function and style. Your table needs to live up to that standard, improving both your kitchen's organization and its look. You can dig deeper into these trends over at Fortune Business Insights. And while you're protecting your investment, it's also a good idea to understand your options for commercial property insurance.

Before you click "buy," run through this final checklist:

- Primary Use: What will I be doing on this table 80% of the time?

- Space and Flow: Did I measure my space? Is there at least 36 inches of clearance all around for movement?

- Load Requirements: What's the heaviest piece of equipment or amount of product this table will ever have to hold?

- Future Growth: Is this table still going to work for me in two years?

Answering these questions honestly will make sure your new work tables kitchen surface is more than just an expense. It's a smart investment in the success of your entire operation.

Frequently Asked Questions

When you're outfitting a kitchen, a few questions about work tables always pop up. Let's clear the air so you can get the right table for the job, whether you're running a busy restaurant or just serious about your home cooking.

What Is the Best Material for a Kitchen Work Table?

For just about any professional kitchen, stainless steel is the undisputed champion. It’s non-porous, which means there's simply nowhere for bacteria to hide, making it a dream for food safety. It’s also tough as nails and can handle the daily grind of a commercial kitchen without breaking a sweat.

That said, a butcher block or wood top definitely has its place. Bakers, for instance, often swear by wood for kneading dough because of its natural feel. But wood is porous and needs regular oiling and a lot of care to keep it from cracking or harboring germs, which is why you won't see it used for prepping raw meat.

How Do I Properly Clean and Maintain My Stainless Steel Table?

Keeping your stainless steel table in top shape is pretty straightforward. For daily cleaning, a simple wipe-down with a soft cloth, warm water, and a bit of mild soap does the trick. Always give it a good rinse with clean water and dry it with a microfiber cloth—that’s the secret to avoiding those pesky water spots.

When it's time to sanitize, just use a food-safe sanitizer, following the directions on the bottle.

Important: Stay away from abrasive cleaners, steel wool, or harsh chemicals like bleach. They can scratch the surface and ruin the protective layer, which eventually leads to rust. Treat it right, and it will last a lifetime.

Can I Use a Commercial Work Table in My Home Kitchen?

You absolutely can! It’s a move we're seeing more and more from home chefs who want professional-grade gear. The upside is obvious: you get a super durable, easy-to-clean surface that can handle heavy mixers, hot pans, and anything else you throw at it.

The main things to think about are space and style. These tables are built for function, not form, so the industrial look might not vibe with every home kitchen. They also tend to be bigger and taller than your average countertop, so break out the tape measure. But if the utility-first approach works for you, it’s a fantastic addition.

Ready to find the perfect foundation for your culinary workspace? Explore a wide range of professional-grade, NSF-certified stainless steel work tables at PrepTables.com. Find the exact size and configuration you need by visiting https://preptables.com today.