What Is NSF Certification and Why It Matters

Share

Ever spot that little blue NSF logo on a prep table and wonder what it’s all about? Think of it as a stamp of approval from an independent, third-party group. It’s their way of saying a product meets some pretty tough standards for public health and safety. It’s not just a sticker—it’s a promise that the equipment is safe to use where food is handled.

Understanding the NSF Certification Mark

You can think of NSF certification as a super-detailed health inspection, but for products before they even make it to your kitchen. The organization behind it, NSF International, is a globally recognized authority on public health. They don't just take a company's word that a product is safe; they put it through a battery of tough tests to make sure it holds up.

This isn't a quick once-over. The process is intense and looks at a few critical areas:

- Material Safety: Every single component is analyzed to ensure no nasty chemicals can leach out and contaminate food.

- Design and Construction: They check the product's design to make sure it can be cleaned easily and completely. No cracks or crevices where bacteria can throw a party.

- Performance: The equipment has to do its job as promised without creating any new food safety risks.

When you see that NSF mark, it means the product has passed with flying colors.

This independent verification is a cornerstone of modern food safety management. It provides assurance to health inspectors, business owners, and consumers that the equipment is designed specifically to help prevent foodborne illness.

This dedication to safety is exactly why NSF certification is basically a must-have in most commercial kitchens. It ensures every piece of certified gear is helping you run a safe and hygienic operation.

The Story Behind the NSF International Seal

To really get why that little blue NSF seal is such a big deal, you have to go back in time. We're not talking about some modern corporate boardroom—this story starts in the 1940s, right in the middle of the post-war boom. Soda fountains and lunch counters were the place to be.

But behind the scenes, there was a serious problem. There were no consistent, nationwide sanitation standards for the equipment being used. One city had one set of rules, the next state over had a totally different one. It was a mess for restaurant owners and a real headache for public health officials who had no single, reliable benchmark for safety.

From University Project to Global Authority

This chaos led to a brilliant idea. In 1944, the National Sanitation Foundation was born at the University of Michigan’s School of Public Health. A forward-thinking group of professors and health officials got together with one goal: to create a single, science-based set of standards for food safety that everyone could follow.

They did something pretty novel for the time—they brought everyone to the table. Industry experts, regulators, and scientists all collaborated to hammer out standards that were both practical and effective. This built a foundation of trust that’s still the organization's calling card today. And their very first standards? They were for the soda fountain and lunch counter gear that started it all.

This wasn't just about writing a rulebook. It was about creating a common language for safety that the entire industry could understand and trust, moving from just reacting to problems to actively preventing them.

The idea caught on like wildfire. By 1975, a national survey revealed that a staggering 90% of public health departments in the U.S. required NSF certification for food-service equipment. It had officially become the gold standard. You can discover more about NSF International's foundational history and its incredible journey.

That journey—from a university project to the independent, global authority now known as NSF International—is what gives the seal its power. It stands for decades of collaboration and a rock-solid commitment to keeping people safe, one piece of certified equipment at a time.

How a Product Earns Its NSF Certification

Getting that little blue NSF seal on a product isn't as simple as filling out a form. It's a tough, multi-stage journey—think of it as a never-ending "health check-up" for a piece of equipment, making sure it’s safe not just on day one, but for its entire life in your kitchen. The process is demanding for a good reason.

It all starts with a detailed application, but that’s just the opening act. From there, the product goes through an intense evaluation. This isn't just a quick once-over. NSF International, as an independent global organization, brings in teams of engineers, toxicologists, and microbiologists to pick apart every single detail. Their ISO/IEC 17025 accredited labs run a whole battery of tests to confirm that a product, like a stainless steel prep table, lives up to every public health standard. You can learn more about how NSF International maintains these high standards of quality.

The Certification and Audit Cycle

Even after a product passes all the initial tests, the work isn't done. One of the most critical steps is an unannounced inspection of the factory where it’s made. Auditors show up to make sure the facility follows strict rules for cleanliness, material traceability, and quality control, ensuring that every single unit off the line is identical to the one that got tested.

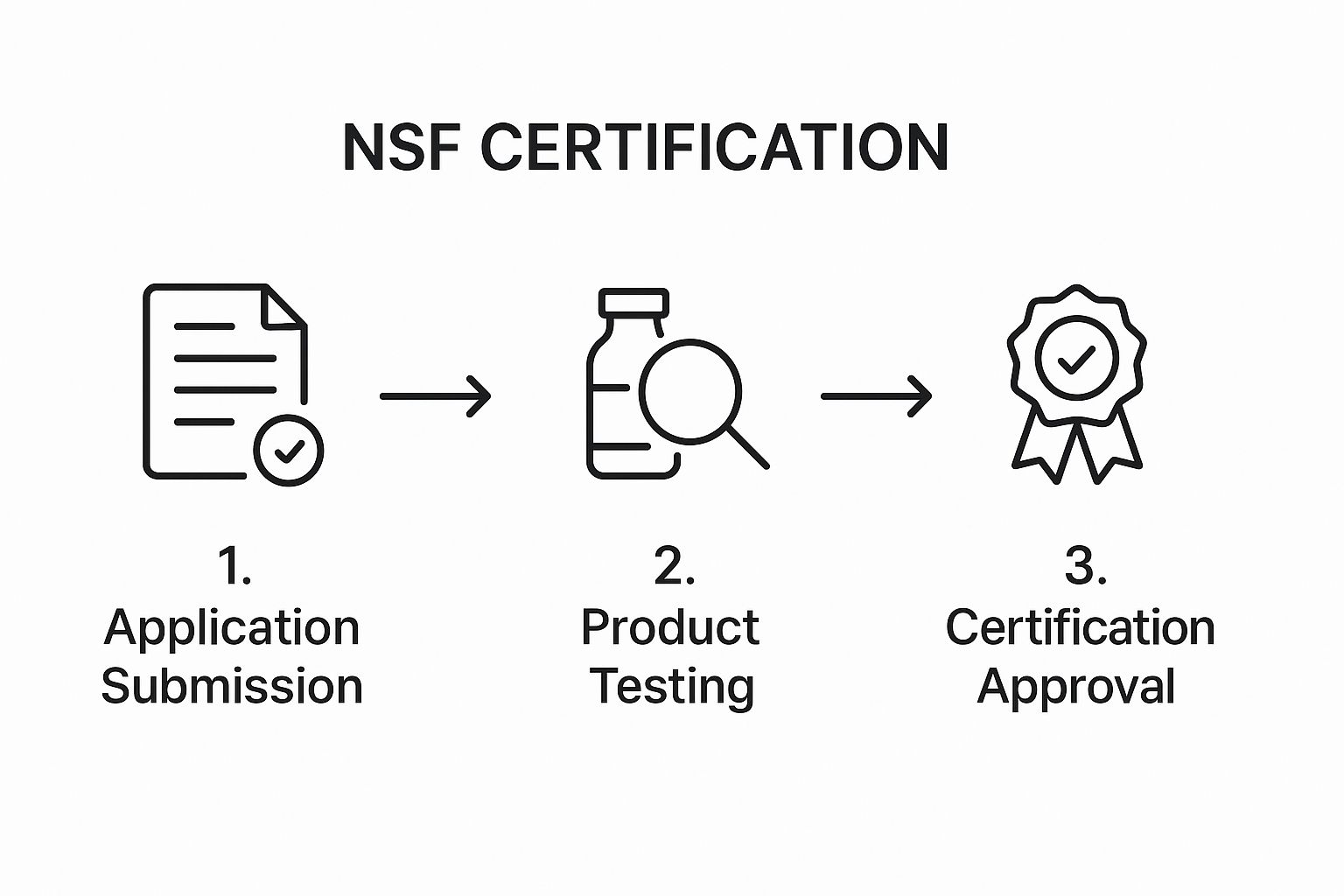

This infographic breaks down the initial journey into three main phases.

As you can see, certification is a structured, step-by-step process. It kicks off with the application and only gets the final stamp of approval after passing some seriously tough testing.

But earning the seal is just the beginning. To keep it, companies must agree to ongoing, unannounced annual audits and periodic re-testing. This commitment ensures that safety standards never slip.

This cycle of continuous testing and surprise inspections is what guarantees the NSF mark remains a symbol of safety you can trust. It’s this long-term dedication that truly separates certified products from everything else, giving business owners and customers total peace of mind. You can explore our guide on selecting a quality stainless steel prep table that meets these demanding standards.

Why NSF Is Crucial for Commercial Prep Tables

So, how does all this apply to the heart of your kitchen—the commercial prep table? A prep table is more than just a surface; it's where the magic happens. It’s also a critical point for controlling foodborne illness, which is why NSF certification is an absolute must-have for this piece of equipment.

The specific rulebook for these tables is NSF/ANSI 2: Food Equipment. This isn't just a friendly suggestion; it's a detailed blueprint for safety. It means every single part of the table has been designed to stop bacteria cold.

Designing for Food Safety

Think about an old wooden cutting board scored with deep knife grooves. Those little crevices are perfect hiding spots for germs. NSF/ANSI 2 is designed to prevent exactly that, but on a much larger scale, by requiring prep tables to have smooth, non-porous surfaces that are a breeze to sanitize.

This standard gets very specific about design features that make a world of difference:

- Seamless Construction: Certified tables have rounded, coved corners instead of sharp 90-degree angles. This simple change eliminates those hard-to-clean spots where food bits and bacteria love to hide.

- Non-Porous Materials: They have to be built from materials like stainless steel that won’t soak up moisture, grease, or food particles. No absorption means no place for bacteria to take root and multiply.

- Corrosion Resistance: The materials must be tough enough to stand up to cleaning chemicals and acidic foods without rusting or breaking down, ensuring they never leach harmful substances into your food.

A table without the NSF seal might look the part, but it's often the tiny, invisible flaws—microscopic cracks, hidden seams, or porous materials—that pose the biggest risk. An NSF-certified table is engineered from the ground up to leave no place for pathogens to hide.

Using a non-certified table is a gamble with your customers, your staff, and your reputation. A tiny crack or a seam that’s tough to clean can quickly become a breeding ground for contamination. That NSF seal on a prep table is your guarantee that it was built to protect against these dangers, making it a cornerstone of a safe kitchen.

Choosing the Right NSF Certified Prep Table

Seeing that NSF seal on a prep table is a great start, but it doesn't automatically mean it's the right one for your kitchen. The real trick is looking beyond the certification to find a table that actually helps your workflow, instead of getting in the way. Let's dig into the different types of NSF certified prep tables you'll come across.

The absolute workhorse of any commercial kitchen is the classic stainless steel prep table. These tables are superstars for a reason—they're incredibly durable and a breeze to keep sanitized. But here's something you need to know: not all stainless steel is created equal. The specific type of steel, or its grade, plays a huge role in how it performs and what it costs.

If you want to go deeper on materials, take a look at our guide on how to pick the perfect commercial stainless steel prep table.

Comparing Stainless Steel Grades

When you're shopping for a stainless steel table, you'll mainly see two grades, and each has its own strengths:

- 304 Stainless Steel: Think of this as the premium option. It's packed with more chromium and nickel, making it highly resistant to rust and corrosion. This is especially important when dealing with salt or acidic foods like tomatoes and citrus. It's the go-to for any surface that's in constant, direct contact with food.

- 430 Stainless Steel: This is the more budget-friendly choice. It’s still tough and perfectly fine for many NSF-approved uses, but it has less nickel. That just means it's a bit more likely to show corrosion over a long time. It’s a great, cost-effective pick for table legs, undershelves, or for tables used in dry storage areas where it won't be exposed to corrosive stuff.

Beyond the steel grade, keep an eye out for features your kitchen really needs. A backsplash is fantastic for keeping your walls clean from splashes, and an undershelf adds super convenient storage space for equipment and supplies right where you need it.

Specialized Prep Tables for Specific Tasks

If your kitchen is cranking out high volumes of specific dishes, a simple flat-top table might not cut it. That’s when you start looking at specialized refrigerated prep tables. These units have to meet strict NSF standards too, specifically NSF/ANSI 7, which covers all commercial refrigerators and freezers.

Specialized tables like these build refrigerated storage right into your prep line. For these, NSF certification is a double-win. It guarantees the materials are safe and easy to clean, and it ensures the cooling system can hold food at safe temperatures, even when the kitchen is hot and hectic.

Here's a quick comparison of some popular NSF-certified table types.

Comparison of NSF Certified Prep Tables

| Table Type | Key Features | Primary Use | NSF Design Focus |

|---|---|---|---|

| Standard Stainless Steel | Flat, durable work surface; optional backsplash and undershelf. | General food prep, mixing, chopping, and plating. | Material safety (e.g., 304/430 grade), cleanability, and structural integrity. |

| Sandwich Prep Table | Refrigerated wells for ingredients, cutting board, and cold cabinet storage below. | Assembling sandwiches, salads, and subs quickly and efficiently. | NSF/ANSI 7 compliance for temperature control; easy-to-clean ingredient wells. |

| Pizza Prep Table | Raised, refrigerated rail for pans; wide cutting surface for dough. | Building pizzas with toppings kept cool and within easy reach. | NSF/ANSI 7 compliance for the rail; durable surface for dough work. |

This table shows how different designs are tailored to specific kitchen jobs, with NSF standards ensuring safety and performance across the board.

Two of the most common specialized tables you'll see are:

- Sandwich Prep Tables: These units are designed for speed. They have refrigerated wells up top to keep all your cold cuts, cheeses, and veggies chilled and within arm's reach. They almost always come with a cutting board that runs the full length of the unit and a refrigerated cabinet below for backup ingredients.

- Pizza Prep Tables: Built on a similar idea, these tables have a raised, refrigerated rail that perfectly fits standard-sized food pans full of toppings. The key difference is the extra-wide cutting board surface, giving you plenty of room to stretch out large pizza doughs.

Ultimately, the choice between a standard stainless steel table and a specialized unit really boils down to your menu and how your team works. By understanding what’s out there, you can pick an NSF certified table that’s a perfect fit for your operation.

The Real-World Benefits of NSF Equipment

Think of NSF certification as more than just a sticker you need to pass a health inspection. Investing in NSF-approved equipment pays you back in ways that strengthen the very foundation of your business. It all comes down to three things: protecting the public, staying on the right side of the law, and guarding your hard-earned reputation.

When you choose certified gear, you're making a statement about your commitment to quality. It's something customers notice, building instant trust. It also tells your staff you're serious about giving them a professional-grade, reliable tools to do their job right.

A Smarter Long-Term Investment

Beyond that initial peace of mind, NSF-compliant equipment is almost always a better value in the long run. Why? Because these products are built to a higher standard. They typically use superior materials and more thoughtful designs, making them tougher and a whole lot easier to maintain. Better construction means fewer breakdowns and replacements down the road.

And that little blue seal carries real legal weight. Back in 1980, the NSF even had to defend its right to certify equipment in a Supreme Court case. They won, cementing the seal's authority and legal standing across the U.S. You can read more about NSF's historical milestones to see how deep their roots go.

At the end of the day, the NSF seal isn't just a compliance checkbox. It's a real investment in safety, reliability, and the peace of mind that comes from knowing you've done things the right way.

So, when you're asking yourself what is NSF certification, don't see it as another business expense. Look at it as a strategic move that protects your customers and strengthens your operation from the inside out.

Got Questions About NSF Certification? We’ve Got Answers.

When you're outfitting a commercial kitchen, navigating food safety standards can feel like a maze. Let's clear up some of the most common questions about NSF certification and what it really means for your equipment.

How Can I Be Sure a Product Is Actually NSF Certified?

The best way to know for sure is to go straight to the source. Don't just take the seal on the product at face value.

You can visit the NSF International Online Certified Product Listings. This is a public database where you can look up any product by its company name, type, or the specific standard it’s certified for. It’s a quick, easy step that gives you instant peace of mind that the certification is legitimate and current.

Is NSF Certification Required by Law?

This is a common point of confusion. While NSF certification isn't a federal law on its own, it's often mandated by state and local health departments.

Most health codes require that your food service equipment is certified by an ANSI-accredited program, and NSF is the gold standard everyone recognizes. It’s always smart to double-check your local health department’s specific rules to stay compliant.

So what's the difference between an NSF seal and a UL (Underwriters Laboratories) one? Think of it this way: NSF is all about public health and sanitation, while UL is focused on electrical safety and fire risk. Many pieces of kitchen equipment will have both, since they cover different safety bases.

This is why it’s so important to get it right when you're buying everything from your main prep tables to your commercial kitchen shelves. Meeting the right standards isn't just about passing inspections—it's about running a safe, professional kitchen.

At PrepTables.com, we take the guesswork out of it. We offer a huge selection of NSF certified equipment built for the demands of a busy kitchen. Check out our professional-grade stainless steel tables and other commercial essentials at https://preptables.com.