Your Ultimate Guide to Choosing a Work Table Large Enough for Anything

Share

Ever tried to cook a big holiday dinner using just a tiny cutting board? It’s a nightmare. Ingredients get mixed up, stuff spills everywhere, and you're constantly worried about cross-contamination. It’s a recipe for chaos.

Now, imagine a wide-open, gleaming countertop where every ingredient, bowl, and tool has its own spot. That’s the difference a work table large enough for your kitchen makes. It takes a cramped, stressful space and turns it into a command center for productivity and safety.

Why Your Workspace Revolves Around a Large Work Table

Whether you're in a high-speed restaurant kitchen, a clean-room lab, or a busy catering operation, your main work surface is the heart of it all. It’s where everything happens—from initial prep and detailed assembly to the final touches. The size and quality of that surface directly shape your workflow, safety standards, and how much you can actually get done.

A table that’s too small is a constant bottleneck. Your team wastes time shuffling things around, and it's nearly impossible to keep things sanitary.

On the flip side, a work table large enough for the job changes the game immediately. You can set up dedicated zones: this corner for chopping, that section for plating, and another spot for assembly. This isn't just about being tidy; it’s a non-negotiable part of keeping things safe.

In any kitchen, having enough space is the first rule of preventing cross-contamination between raw meat and fresh veggies. It's a fundamental food safety practice, not just a suggestion.

The Dangers of a Cramped Workspace

Working on a surface that’s too small is more than just an annoyance—it introduces real risks and kills efficiency. These daily struggles might seem minor at first, but they add up to major headaches for your business.

A few of the challenges you'll face:

- Increased Risk of Accidents: When tools, ingredients, and hot pans are crammed together, it’s only a matter of time before someone gets cut, burned, or slips.

- Inefficient Workflow: A cluttered table forces your staff to stop and search for what they need or clear a space to work. This constant stop-and-go ruins any rhythm and wastes precious time.

- Compromised Quality: When people feel rushed and crowded, mistakes happen. An order gets plated wrong, a component is assembled incorrectly, or a critical step is missed.

Paving the Way for Success

Getting the right work table is the first real step to building a better, more effective workspace. Think of it less like a piece of furniture and more like an investment in your team's sanity, safety, and output. Things like the material, overall size, and how much weight it can hold are what separate a table that supports your operation from one that sabotages it.

A heavy-duty stainless steel table, for example, is tough as nails and incredibly easy to sanitize, making it perfect for food prep or sterile lab work. Understanding the details is key. This guide will walk you through it all, from figuring out steel grades to picking the right add-ons, so you can choose a work table large enough to be the rock-solid foundation your business needs.

Getting to Grips with Stainless Steel Gauges and Grades

When you’re picking out a work table large enough to handle your operation, the material it’s made from is everything. Think of the stainless steel as the table's DNA—it dictates its strength, how long it'll last, and whether it’s right for your specific environment. Not all stainless steel is the same, and getting a handle on gauges and grades is the key to making a smart investment.

Imagine the steel's gauge like the thickness of a shield. It's a little backward, but the lower the gauge number, the thicker and tougher the steel. This thickness is what helps the table shrug off dents, dings, and the daily grind of a busy kitchen or lab.

Decoding Steel Thickness: The Gauge System

A table's gauge tells you exactly what kind of work it was built for. If you're doing high-impact jobs like butchering or pounding out cutlets, you absolutely need a lower gauge. That thicker top can take the force without warping. For lighter prep work, a higher gauge will do the job just fine.

Here’s a quick rundown of what you’ll see:

- 14-Gauge: This is the heavyweight champion. Its substantial thickness makes it the only real choice for demanding tasks like butchery, supporting heavy equipment, or any job where the surface is going to take a serious beating.

- 16-Gauge: A fantastic, all-around option. It strikes a great balance between durability and cost, which is why it’s perfect for general food prep, assembly work, and most common commercial kitchen tasks.

- 18-Gauge: This is the most common and budget-friendly choice. It’s ideal for light-duty prep work, storage, or as a general utility surface in less punishing settings like delis or cafes.

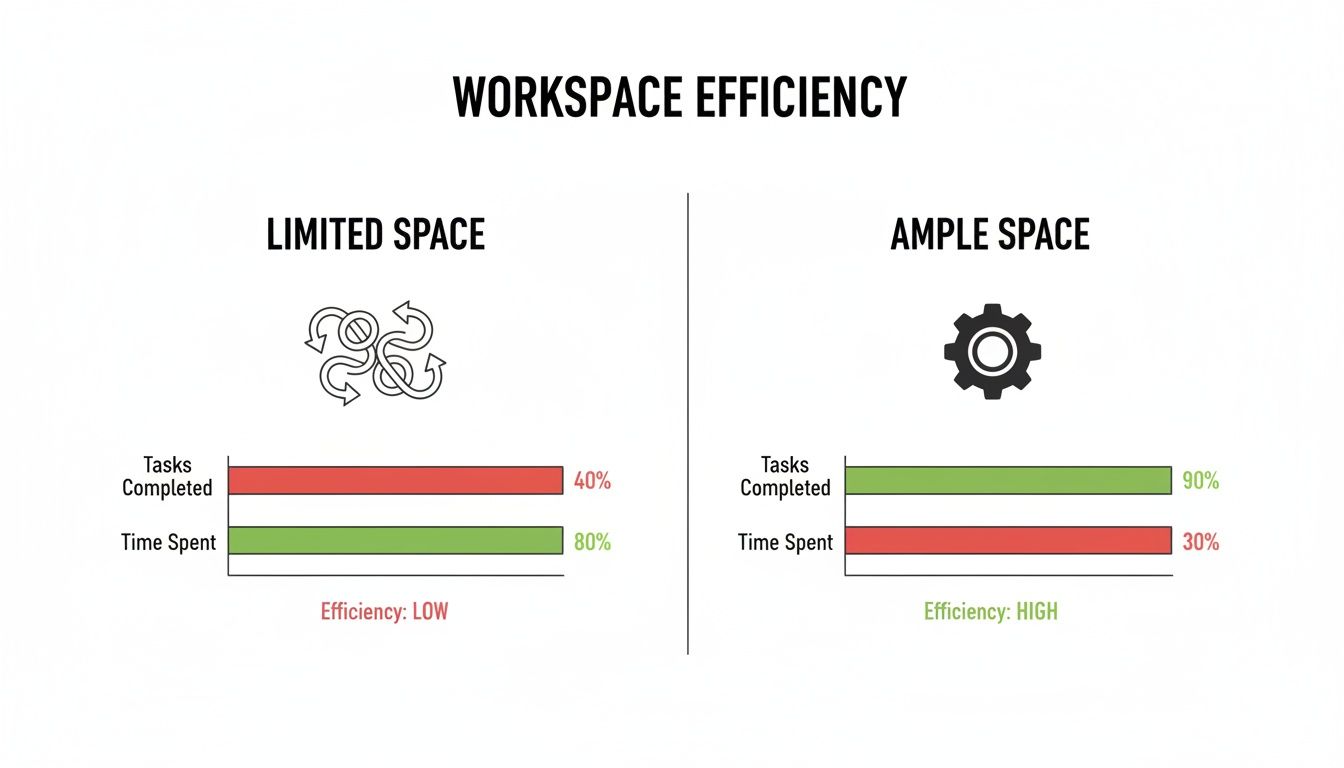

This infographic really drives home how an ample, well-organized space—exactly what a large work table provides—dramatically boosts efficiency over a cramped, chaotic setup.

It’s clear from this visual that a spacious, organized work area isn't a luxury; it's a fundamental part of running a smooth and productive operation.

Choosing the Right Steel Type: The Grade System

Beyond thickness, the steel's grade defines its chemical makeup—specifically, its ability to fight off rust and corrosion. This is absolutely critical in places where the table will be exposed to moisture, acidic foods, or harsh cleaning chemicals. The two grades you’ll run into most often are 430 and 304.

Think of 304-grade steel as the gold standard for food service. Its superior corrosion resistance means it can handle everything from lemon juice to harsh sanitizers without breaking down, ensuring a hygienic and long-lasting surface.

430-grade stainless steel is the more economical option. It's still durable, but it has less nickel, making it more likely to rust over time, especially if it's always wet. It’s a perfectly fine choice for dry storage areas or light-duty work where it won't face much moisture or corrosive stuff.

On the other hand, 304-grade stainless steel is the premium choice for any professional kitchen, lab, or food production facility. It contains more chromium and nickel, giving it fantastic protection against rust. This makes it the non-negotiable standard for food prep zones where hygiene and longevity are the top priorities.

To help you decide, here’s a quick reference chart breaking down the common gauges and grades.

Stainless Steel Gauge and Grade Selection Guide

| Steel Gauge | Common Grade | Typical Thickness | Best Use Case | Durability Level |

|---|---|---|---|---|

| 14 | 304 | 0.0781" (1.98 mm) | Heavy-duty butchering, equipment stands, intense prep | Maximum |

| 16 | 304 or 430 | 0.0625" (1.59 mm) | All-purpose food prep, general commercial kitchen use | High |

| 18 | 430 or 304 | 0.0500" (1.27 mm) | Light prep, storage, budget-conscious applications | Standard |

| 20+ | 430 | 0.0375" (0.95 mm) or less | Residential use, wall shelves, very light-duty tasks | Light |

Choosing the right combination ensures you get a table that’s not just big enough, but tough enough for the job.

The market for stainless steel tables is booming, with 304 grades leading the charge in 2023 and poised for major growth. For pizzeria owners and caterers, this means better access to large work tables that are true workhorses—often featuring 18-gauge tops that can hold 400-600 pounds, built-in undershelves, and the crucial NSF certification that health inspectors look for.

By matching the right gauge and grade to your specific tasks, you’re not just buying a piece of equipment; you're investing in a dependable asset built to last. For a deeper dive, check out our complete guide on the differences between stainless steel grades.

Finding the Perfect Size and Configuration

Choosing the right dimensions for a work table large enough for your kitchen is about more than just grabbing a tape measure. Think of it as choreographing a dance—you're designing a space that encourages smooth, efficient movement. When you get this right, your team moves faster, works safer, and feels less frustration. Suddenly, a simple table becomes the engine of your kitchen's productivity.

First things first, measure your available space. But don't just plan for the table's footprint. You have to think about the entire workflow. Your staff needs clear paths to move around without bumping into each other or dodging hot pans. A good rule of thumb is to leave at least 36 inches of clearance on all working sides. This simple step prevents traffic jams and keeps the kitchen humming.

Ergonomics and Height Considerations

The height of your work surface is just as important as its size. A table that’s too low or too high will quickly lead to back strain and fatigue, which directly drains your team's energy and efficiency. The industry standard for an ergonomic work surface is between 34-36 inches. This height is the sweet spot for most people, allowing them to work comfortably without hunching over or reaching up awkwardly.

This focus on ergonomics isn't just a fad; it's a huge shift in how professional kitchens operate. The global market for stainless steel kitchenware was valued at a massive USD 23.5 billion in 2023, a number that shows just how much pros are investing in high-quality, thoughtfully designed gear. As kitchens modernize, smart operators are choosing large work tables with ergonomic heights to make their prep areas as productive as they are durable. You can dive deeper into these trends in the commercial kitchenware market from this detailed report.

The Power of Undershelves

One of the biggest decisions you'll make is whether to get an undershelf. It's a game-changer that can practically double your storage capacity without eating up another inch of precious floor space. An undershelf brilliantly turns the empty area beneath your table into prime real estate for ingredients, tools, or small appliances.

You’ll generally find two types of undershelves to choose from:

- Solid Undershelves: These give you a stable, flat surface, which is perfect for storing things like flour bins, sealed containers, or heavy boxes. They're also a breeze to wipe down and keep drips from hitting the floor.

- Wire Undershelves: These are fantastic for promoting air circulation. That makes them ideal for cooling down hot items or storing produce like potatoes and onions that need to breathe. Plus, dust and debris tend to fall right through, making cleanup a bit easier.

The right choice really just depends on what you plan to store down there. For a closer look at all the different table setups, feel free to check out our guide on selecting a commercial kitchen work table.

Translating Load Capacity into Reality

Those load capacity numbers on a spec sheet can seem a bit abstract, but they are absolutely critical for safety and the long-term health of your table. This number tells you exactly how much weight the table can safely hold before it starts to bend or, worse, collapse. You have to match the table's capacity to your daily tasks if you want to protect your investment.

A table's load capacity isn't just a suggestion; it's a safety rating. Overloading a table can lead to equipment damage, product loss, and potential injuries. Always choose a capacity that comfortably exceeds your heaviest regular workload.

Let’s put it in perspective. A standard 18-gauge table might hold around 500-600 pounds on its top shelf and another 400-450 pounds on the undershelf. That’s plenty for general prep work like chopping vegetables or plating dishes. But what if you need to support a heavy piece of equipment, like a 100-pound commercial mixer or a large dough sheeter? For that, you’ll definitely need to upgrade to a lower-gauge (thicker) table with a much higher load capacity to guarantee stability and safety. By picturing your heaviest items, you can easily pick a work table large and strong enough for the job.

Exploring Specialized Prep Tables for Your Needs

While a standard flat-top stainless steel table is a true kitchen workhorse, certain jobs just demand a more specialized tool. This is where a work table large enough for your space transforms from a simple surface into a purpose-built station, designed to master a specific task. These tables aren't just furniture; they're workflow solutions, integrating features that turn potential bottlenecks into hubs of efficiency.

Think of it this way: a standard table is a blank canvas, versatile and ready for anything. A specialized prep table, on the other hand, is more like a blueprint, guiding your team through a specific process with precision and speed. From refrigerated units that keep ingredients perfectly chilled to tables with built-in sinks, these designs are born from the real-world headaches of busy commercial kitchens.

Refrigerated Prep Tables: The Ultimate Efficiency Boost

For high-volume sandwich shops, pizzerias, and salad bars, refrigerated prep tables are the undisputed champs. By merging a tough stainless steel work surface with built-in cold storage, they stop the constant back-and-forth trips to a separate fridge. It seems like a small change, but the impact on ticket times and order accuracy is massive.

Everything a cook needs is kept chilled and within arm's reach. This setup is absolutely critical for maintaining food safety and quality, especially when you're slammed during a lunch or dinner rush.

The Sandwich and Salad Prep Table

A sandwich prep table is meticulously engineered for one thing: assembling sandwiches, wraps, and salads at lightning speed. Its signature feature is a refrigerated rail that runs along the back of the work surface, holding multiple food pans, often called "wells."

These wells are filled with all your fresh toppings—lettuce, tomatoes, onions, cheeses, and sauces—held at a consistent, food-safe temperature. This allows one person to stand in a single spot and build complex orders without ever taking a step.

For a busy deli, a sandwich prep table isn't a luxury; it's a necessity. It directly translates to faster service, which means more customers served and higher revenue during peak hours.

Underneath the work surface, you'll find a refrigerated cabinet for bulk storage of backup ingredients. When a pan of tomatoes runs low, a replacement is just seconds away, keeping the line moving without a hitch. It’s a complete, self-contained workstation.

The Pizza Prep Table: A Wider Approach

At first glance, a pizza prep table looks similar to a sandwich table, but it's built with a few key differences tailored specifically for pizza making. The most obvious is the raised refrigerated rail, which is much wider to accommodate larger, deeper pans for ingredients like pepperoni, mushrooms, and mountains of cheese. This rail also keeps everything perfectly chilled, preventing cheese from getting oily.

The work surface itself is another critical feature. Pizza prep tables almost always have a deeper cutting board running the full length of the unit. This gives you an expansive, non-stick surface that’s perfect for stretching dough and building pies right in front of all your chilled ingredients.

Let’s break down how these two powerhouses compare:

| Feature | Sandwich/Salad Prep Table | Pizza Prep Table |

|---|---|---|

| Refrigerated Rail | Standard depth for smaller pans (e.g., 1/6-size) | Extra-deep to accommodate larger pans (e.g., 1/3-size) |

| Work Surface | Narrower cutting board for assembly | Deep, full-length cutting board for stretching dough |

| Primary Use | Delis, cafes, salad bars | Pizzerias, Italian restaurants |

| Benefit | Maximizes speed for linear assembly | Streamlines the entire pizza-building process |

Other Essential Specialized Tables

Beyond refrigeration, a few other specialized designs can really optimize your kitchen, ensuring every square foot is pulling its weight.

- Tables with Integrated Sinks: These are brilliant two-in-one units that combine a prep surface with a hand-washing or food-washing station. Dropping one in a prep zone cuts down on foot traffic and boosts hygiene by making it easy for staff to wash hands or rinse produce without leaving their area.

- Baker's Tables: While stainless steel is prized for its cleanability, bakers often need a different surface for dough work. Baker's tables usually have a thick wooden top, typically maple. Wood is less conductive than steel, which keeps delicate dough from getting too warm, and its surface is ideal for dusting with flour and preventing sticking.

- Mobile Work Tables: Taking a standard work table large or small and equipping it with casters (wheels) completely changes the game. This gives you incredible flexibility, letting you reconfigure your kitchen layout on the fly for different menus or easily roll the table out of the way for deep cleaning.

By pinpointing the most critical and repetitive tasks in your kitchen, you can choose a specialized table that acts as a true force multiplier for your team's productivity.

Customizing Your Workstation with Essential Accessories

A simple, flat work table large enough for your tasks is a great starting point. But the right accessories can transform it from just a surface into a highly efficient workstation. These add-ons are more than just conveniences; they're smart upgrades that improve organization, boost safety, and perfectly match the table to your team's workflow.

One of the most useful additions you can make is a backsplash. This simple raised edge along the back of the table acts as a critical barrier. It stops ingredients, liquids, and tools from falling behind the table, which saves a ton of cleanup time and keeps your walls and floors clean. In a kitchen setting, it's an absolute must-have for hygiene.

Mobilizing and Organizing Your Space

The ability to move your work surface can be a complete game-changer. Adding casters (heavy-duty wheels) to the table's legs gives you incredible flexibility. You can easily roll the table to another area for a specific job or move it out of the way entirely for deep cleaning—something that's nearly impossible with a fixed unit. Just make sure to look for locking casters so the table stays stable and secure once you have it in position.

Another key to an orderly workspace is having a specific place for all your tools. Drawers can be added right under the tabletop to create instant, easy-to-reach storage for knives, thermometers, spatulas, and other essential gear. This keeps your main work surface clear and uncluttered, making sure everything has its place and is always right where you need it.

Equipping your work table with the right accessories is a direct investment in your workflow. A well-organized station cuts down on wasted movement, reduces stress from clutter, and lets your team focus on their work.

Maximizing Vertical Space and Minimizing Noise

When floor space is limited, thinking vertically is key. Over-shelves, sometimes called double or triple-tier shelves, are mounted above the tabletop to create extra storage levels. This setup is perfect for keeping frequently used spices, containers, or small appliances nearby without taking up valuable prep space.

Noise is another factor that often gets overlooked in a busy commercial environment. The constant clatter of metal tools and pans on a steel surface can be really loud. Sound-deadening channels are installed on the underside of the tabletop to absorb these vibrations and significantly cut down on noise, creating a much more pleasant and less stressful workplace for your staff.

The market for stainless steel furniture, including these work tables, is a booming industry valued at USD 3.35 billion. This growth is fueled by professionals who need durable, adaptable equipment. Ergonomic accessories like adjustable-height legs are becoming standard because they directly reduce worker fatigue and injury—a crucial consideration when U.S. restaurant injury rates are around 3.7 per 100 workers. You can learn more about the global stainless steel furniture market on seelteen.com. By carefully choosing these add-ons, you can build a workstation that is safer, more organized, and perfectly customized for your needs.

Mastering Cleaning and NSF Certification

A clean work table is a safe work table. In any professional kitchen or lab, that’s not just a suggestion—it’s the law. This is where NSF certification becomes your best friend. It’s more than just a sticker; it’s your guarantee that your work table large or small is built for hygiene, helping you avoid health code violations and ensuring the table lasts.

The National Sanitation Foundation (NSF) sets the gold standard for equipment used in food service. An NSF-certified table is engineered with smooth, non-porous surfaces. You won't find any cracks, crevices, or open seams where bacteria love to hide. This smart design makes cleaning and sanitizing a breeze, which is your first line of defense against foodborne illness.

Understanding the NSF Advantage

Think of NSF certification as a blueprint for a perfectly cleanable surface. Every little detail, from the coved corners to the sealed welds, is intentionally designed to eliminate spots where germs could collect. This is especially important for a work table large enough to handle multiple prep jobs at once, as it helps prevent cross-contamination between raw meat and fresh veggies.

If you want to dive deeper into the nitty-gritty of the standards, you can learn more about what NSF certification means for your kitchen. This commitment to hygienic design doesn't just keep the health inspector happy; it also protects your investment by making sure the table can stand up to the rigors of a commercial environment.

Your Guide to Proper Maintenance and Cleaning

Keeping your stainless steel looking brand new is actually pretty simple if you get into a good routine. A consistent cleaning process prevents grime from building up, protects the finish, and keeps you compliant with health codes.

Here’s a simple, effective daily cleaning routine:

- Clear and Scrape: First things first, get everything off the surface. Use a soft plastic or rubber scraper to remove any stuck-on food bits.

- Wash Thoroughly: With a soft cloth or sponge, wash the table using warm water and a mild detergent. A pro tip: always wipe in the direction of the steel's grain to avoid creating tiny scratches.

- Rinse Completely: Next, rinse the surface with clean, warm water. This removes any soap residue that could leave streaks or attract more dirt.

- Sanitize for Safety: Apply a food-safe sanitizer, following the manufacturer’s directions to the letter. This is the most important step for killing any lingering bacteria.

- Air Dry or Towel Dry: Let the table air dry, or wipe it down with a clean, dry microfiber cloth to prevent water spots and keep it shining.

A consistent daily cleaning schedule does more than just meet health codes; it preserves the passive protective layer of the stainless steel, preventing corrosion and extending the life of your table for years to come.

For tougher stuff like hard water spots or a bit of surface rust, a simple paste of baking soda and water can work wonders. By making these easy steps a habit, you'll ensure your large work table remains a clean, reliable, and durable cornerstone of your operation.

Frequently Asked Questions

When you're diving into the world of stainless steel work tables, a few last-minute questions often pop up. Getting those answered clearly is the final step to making sure you pick the right table—one that'll be a reliable workhorse for years to come.

How Difficult Is It to Assemble a Large Stainless Steel Work Table?

Good news—most commercial tables are built for a quick setup. You can usually get one assembled in under 30 minutes, especially with a second person to help.

The process is pretty straightforward: attach the legs to the top, then slide the undershelf to the height you want and lock it in with the set screws. Just make sure everything is good and tight to avoid any wobbling. Once it's built, use the adjustable bullet feet to get it perfectly level. Of course, always give the manufacturer's instructions a quick read for any model-specific tips.

Can I Place Hot Pots Directly on a Stainless Steel Table?

Absolutely. One of the best things about stainless steel is how well it handles heat. You can take a hot pot or pan straight from the stove and set it on the table without worrying about causing any damage. It’s one of the reasons these tables are a fixture in busy kitchens.

For something screaming hot right out of a high-temperature oven, a trivet can give you a little extra peace of mind about the finish, but it’s not a must-have for everyday cooking.

What Is the Best Way to Prevent Scratches on My Table?

Stainless steel is tough, but it's not scratch-proof. The number one rule is to always use a cutting board. Never slice or chop directly on the metal surface. It’s also a good idea to avoid dragging heavy equipment with rough or sharp bottoms across the top.

When you clean, a soft cloth is your best friend. Wiping in the same direction as the steel’s grain will help keep it looking its best.

Remember, most minor scratches are purely cosmetic and will not compromise the table's structural integrity, hygienic properties, or NSF certification.

What Is the Main Difference Between a Work Table and an Equipment Stand?

This is a common point of confusion, and it’s an important one. A work table, whether it's large or small, is your all-purpose prep surface. It's designed for active tasks like mixing, chopping, and plating, with a big, open top and usually an undershelf for general storage.

An equipment stand, on the other hand, has a very specific job: to hold heavy countertop machinery like mixers, fryers, or meat slicers. They are almost always smaller and built from a heavier gauge (thicker) steel because they need to safely handle a lot of concentrated weight.

Ready to find the perfect foundation for your workspace? PrepTables.com offers a wide selection of NSF-certified stainless steel work tables, specialized prep stations, and essential accessories to build the efficient, durable, and hygienic kitchen you need. Explore our collection and elevate your productivity today at https://preptables.com.