Choosing Your Commercial Kitchen Work Table

Share

Every great dish has to start somewhere. In a professional kitchen, that somewhere is almost always the commercial kitchen work table. This isn't just a slab of steel; it's the command center for everything that happens during service. The right table dictates your kitchen's workflow, ensures you're up to code, and stands up to the nightly chaos.

The Unsung Hero of Every Professional Kitchen

Think of the work table as a chef's canvas. It’s the foundational surface where raw ingredients become something special. In the high-stakes world of food service, every single piece of equipment has to pull its weight. A wobbly or poorly placed table can throw a wrench in the whole operation, causing delays and even creating safety risks.

On the flip side, a thoughtfully chosen work table feels like an extension of the chef. It provides a rock-solid, sanitary, and organized space that makes everyone more productive. From the first chop of the night to the final plate, this surface is in the thick of it, which is why its design and durability are so vital. Investing in a good table is really an investment in your kitchen’s future.

Standard Stainless Steel Prep Tables

The most familiar sight in any commercial kitchen is the standard stainless steel prep table. There's a good reason for that. Its non-porous surface doesn't harbor bacteria and is incredibly easy to sanitize—a non-negotiable for passing health inspections. These tables are the ultimate workhorses, handling just about any task you throw at them.

- General Preparation: This is where you'll see chefs chopping vegetables, butchering proteins, or mixing up a sauce.

- Assembly: It's the go-to spot for building complex dishes before they hit the heat.

- Landing Space: A safe, heat-resistant place to set down hot pans straight from the stove or oven.

They come in all sorts of sizes and often include an undershelf for extra storage, making them a flexible fit for any kitchen layout.

Specialized Workstations for Peak Efficiency

While the standard prep table is a jack-of-all-trades, some kitchens need a specialist. That’s where specialized workstations come in. These units are built from the ground up to streamline one specific task, which can dramatically boost your speed and consistency. The most common examples you'll see are for making pizzas and sandwiches.

A dedicated prep station isn't a luxury; it's a strategic tool for high-volume kitchens. By consolidating ingredients, tools, and workspace, these tables reduce staff movement and minimize preparation time for every order.

Pizza prep tables are engineered to pump out pies. They usually have a wide, flat work surface (marble is a popular choice for dough) and a refrigerated rail at the back. This rail holds all your toppings in cooled pans, keeping everything fresh and right at the chef's fingertips. Underneath, a refrigerated cabinet stores extra dough, cheese, and sauces.

In the same vein, sandwich and salad prep tables are all about organization and speed. They have refrigerated wells to hold deli meats, cheeses, veggies, and dressings. A cutting board is often built right into the front edge, creating a perfect assembly line. It’s an all-in-one design that keeps every ingredient fresh, organized, and ready to go.

Understanding Stainless Steel: The Industry Standard

Walk into any professional kitchen, and you’ll be surrounded by stainless steel. It’s the undisputed champion for a commercial kitchen work table, and for very good reasons. Its surface is non-porous, giving bacteria nowhere to hide. It stands up to rust and corrosion, and it can take the daily beating of a fast-paced culinary environment without flinching.

But here’s something seasoned pros know: just saying "stainless steel" isn't enough. The real story is in the details—specifically, the grade and the gauge (thickness). Getting this right is like choosing the perfect knife for a specific task. You wouldn't use a paring knife to break down a side of beef, right? The same logic applies here. Picking the right steel ensures your table is a long-term asset, not a short-term headache.

Decoding Stainless Steel Grades

The "grade" of stainless steel tells you what it's made of. This blend of metals determines how tough it is and how well it fights off rust and corrosion. For kitchen gear, you'll almost always run into two main players: 304 and 430.

Think of 304 stainless steel as the top-tier, food-safe workhorse. It has more chromium and nickel in the mix, which gives it fantastic protection against corrosion from salt, acidic ingredients like tomatoes or citrus, and strong cleaning chemicals. This is exactly what you want for any surface that food will actually touch—so, the tabletop itself.

Then there’s 430 stainless steel. This one is more of a structural support player. It has less nickel, which makes it more budget-friendly but also a bit more susceptible to corrosion over time. While you wouldn't want it for your main prep surface, it's perfectly strong and durable for the parts that don't touch food, like the legs, frame, and undershelves.

A smart manufacturer often uses a mix of both grades. They'll put the premium 304 stainless steel on the top where it matters most and use the more economical 430 stainless steel for the base. This gives you a high-quality, long-lasting table without an unnecessarily high price tag.

Understanding Steel Gauge: The Secret to Strength

Next up is the "gauge." This is simply a measurement of the steel's thickness, but it works in a way that can feel a bit backward at first: the lower the gauge number, the thicker and stronger the steel. A 14-gauge table is a beast compared to an 18-gauge one.

Here’s a quick breakdown of what you’ll typically find:

- 14-Gauge: This is the heavyweight champion of work tables. It's incredibly thick and built to handle serious abuse, making it the go-to for butcher shops, heavy-duty prep involving mallets, or supporting hefty equipment.

- 16-Gauge: The most common and versatile choice for a reason. 16-gauge steel hits the sweet spot between brute strength and affordability. It's more than tough enough for the vast majority of kitchen tasks, from vigorous chopping to mixing heavy doughs.

- 18-Gauge: This is the lightest-duty option. Being the thinnest, 18-gauge steel is best for tasks that don't involve a lot of impact or weight, like assembling sandwiches, plating dishes, or light prep work.

Choosing the right gauge is all about matching the table's muscle to the job you need it to do. Putting a flimsy table in a high-impact spot is a recipe for disaster, but overpaying for a 14-gauge tank just for plating might be overkill.

This level of detail is exactly why stainless steel dominates professional kitchens. In fact, the global market for stainless steel tables was valued at around $1.2 billion and is expected to climb to $1.8 billion, driven by the industry's strict demands for hygiene and durability. To learn more, you can explore the market trends that highlight why this material is so essential.

When you understand the difference between grades and gauges, you can look past the price tag and choose a commercial kitchen work table with the precise strength and quality your operation truly needs.

A Guide to Commercial Kitchen Work Table Types

Finding the right work table for your commercial kitchen isn’t a one-size-fits-all deal. It's really about matching the tool to the task. Sure, a standard stainless steel table is a must-have for just about any kitchen, but for certain menu items, specialized units can be a total game-changer for your workflow. It's like a mechanic's toolbox—you've got your standard wrench that handles a lot of jobs, but sometimes, you absolutely need a specific socket to get things done right.

The demand for these specialized tables speaks volumes. The global market for food prep tables was valued at USD 1.18 billion and is expected to climb to USD 1.62 billion. This isn't just a trend; it shows how essential these workstations—from pizza and sandwich tables to refrigerated worktops—have become for running a modern, efficient kitchen.

Let's break down the different types of tables out there, from the all-purpose workhorses to the highly specialized stations, to help you build a kitchen designed for speed and quality.

The All-Purpose Workhorse: Standard Prep Tables

The standard stainless steel prep table is the true backbone of almost every professional kitchen. It gives you a clean, tough, and versatile surface that can handle a massive range of tasks. These tables are the definition of simple, functional design, offering a reliable spot for chopping, mixing, plating, and everything in between.

They also come in a few key configurations to fit your space and needs:

- Flat Top Tables: This is your basic, no-frills design. It’s a simple, open surface perfect for general prep work.

- Tables with Undershelves: These are a huge help for organization. The shelf underneath is perfect for storing bulk ingredients, small appliances, or extra cookware, keeping your main workspace clear.

- Tables with Backsplashes: A backsplash is a small but mighty feature. That raised edge along the back stops food and liquids from splashing onto the wall, which makes cleanup way easier and keeps things more sanitary.

These tables are fundamental, but their real strength is how adaptable they are. They can be the main prep area in a small cafe or a key supporting player in a huge restaurant kitchen.

Heavy-Duty Equipment Stands

Not every surface in a kitchen is meant for chopping onions. Some are built specifically to hold up heavy, expensive, and often vibrating equipment. That's where an equipment stand comes in. It’s a specialized table with one job: to provide an incredibly stable and sturdy base for heavy-duty appliances.

Think about a 60-quart commercial mixer or a hefty meat slicer. Putting something like that on a standard prep table is asking for trouble—it could wobble, become unstable, or even damage the equipment or the table itself. Equipment stands are built differently, usually from lower-gauge (thicker) steel with reinforced legs and frames to handle all that weight and vibration safely.

Using a dedicated equipment stand isn't just about stability; it's a critical safety measure. It ensures that heavy machinery operates on a solid foundation, reducing the risk of accidents and protecting your valuable equipment investment.

These stands typically have a smaller footprint than a full-sized work table, so you can place equipment exactly where you need it without hogging precious floor space. They are the unsung heroes that keep the heaviest parts of your kitchen running smoothly and safely.

Refrigerated Prep Tables: The Ultimate Workflow Boosters

When you're cranking out high volumes of specific dishes like pizzas, salads, or sandwiches, a refrigerated prep table is an absolute game-changer. These units combine cold storage and a workspace into one self-contained assembly line, keeping all your ingredients fresh and right at your fingertips.

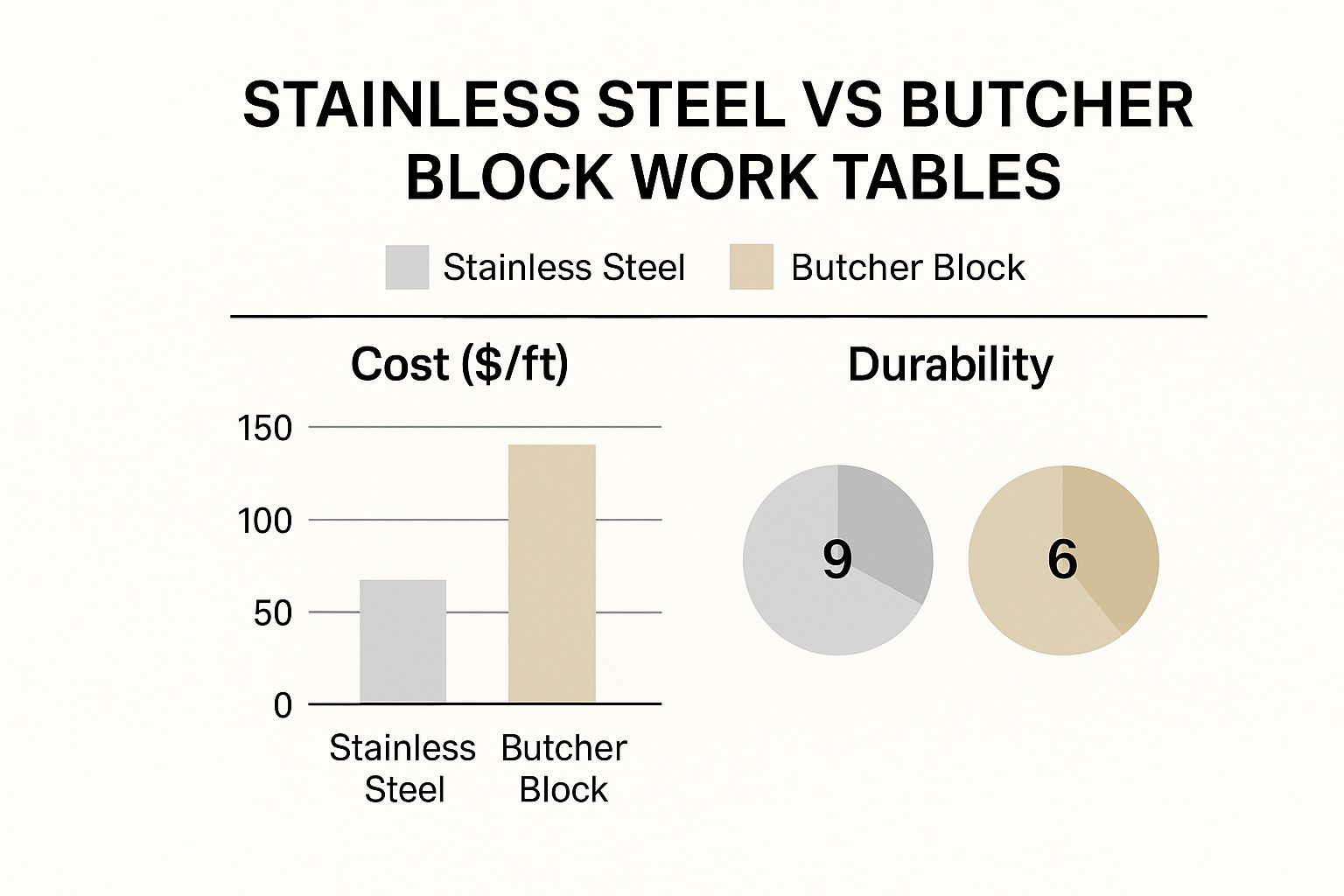

This image perfectly illustrates the cost-versus-durability trade-off for tabletop materials. While stainless steel might have a higher upfront cost per foot, its incredible resilience makes it a smarter long-term investment for the wear and tear of a busy commercial kitchen.

Pizza Prep Tables

A pizza prep table is engineered for one thing: making pies quickly and consistently. It usually has a deep cutting board or even a marble surface for stretching dough, right next to a refrigerated rail on top that holds pans of toppings—cheese, pepperoni, veggies, you name it. Underneath, a refrigerated cabinet gives you bulk storage for dough, sauce, and extra ingredients, all kept at a food-safe temperature.

Sandwich and Salad Prep Tables

In the same way, a sandwich and salad prep table is all about rapid assembly. It has refrigerated wells on top for pans of deli meats, cheeses, chopped veggies, and dressings. A full-length cutting board runs along the front, creating an ergonomic space to build orders. This all-in-one setup means your staff isn't constantly walking back and forth to a separate fridge, which slashes ticket times and improves order accuracy. You can learn more about why material choice matters by reading about the benefits of a stainless steel work table for these kinds of setups.

To help you visualize the differences, let's compare these two popular refrigerated table types side-by-side. Each is built for a specific menu, and knowing the key distinctions can help you make the right choice for your operation.

Comparison of Specialized Prep Tables

| Feature | Pizza Prep Table | Sandwich/Salad Prep Table |

|---|---|---|

| Work Surface | Deep cutting board or marble slab for dough. | Narrow, full-length cutting board for assembly. |

| Top Rail | Deep refrigerated rail holds full-size pans. | Shallow refrigerated wells for smaller ingredient pans. |

| Refrigeration | Larger cabinet below for dough boxes and bulk items. | Standard refrigerated cabinet for backup ingredients. |

| Ideal Use | High-volume pizza production. | Quick assembly of sandwiches, salads, and wraps. |

Ultimately, whether you choose a pizza prep table with its deep rails or a sandwich table with its long cutting board, you're investing in efficiency. Both are designed to put everything an employee needs within arm's reach, turning a multi-step process into a streamlined, single-station task.

Choosing the Right Features for Your Workflow

The little details are what turn a simple commercial kitchen work table from just a stainless steel surface into the command center of your kitchen. Getting the features right makes every task smoother, safer, and more organized. When you tailor these add-ons to how your kitchen actually operates, you build an efficient and ergonomic space that genuinely helps your team.

Think of a basic work table as a blank canvas. The features you choose are the brushstrokes that transform it into a functional masterpiece. Let's dig into the most important customizations that can make a standard table a true workhorse.

Keeping Your Walls Clean and Spills Contained

Two of the most practical features you can get are backsplashes and specialized edges. These simple additions are lifesavers for maintaining a clean, professional kitchen and can save you a ton of time on cleanup.

A backsplash is just a raised lip along the back of the table, but its job is critical. It acts as a barrier, stopping food, grease, and liquids from splattering all over your walls. Not only does this keep things looking sharp, but it also prevents moisture and grime from building up in hard-to-reach places.

The edge type of the work surface also plays a surprisingly big role in day-to-day operations.

- Square Edges: This is your standard, no-frills flat edge. They're perfect for lining up multiple tables to create one long, seamless workspace.

- Marine Edges: You might also hear these called "anti-drip" edges. They have a slightly raised lip around the entire perimeter, creating a small dam that contains spills. If you’re working with liquids, sauces, or anything that can roll away, this feature is an absolute must-have to keep messes on the table and off your floors.

Seriously consider a marine edge for any station dedicated to saucing, brining, or carving.

Making the Most of Your Kitchen's Footprint

In a professional kitchen, every square inch counts. Your work table shouldn't just be a prep surface; it should be a key part of your storage solution. The right shelving keeps everything your staff needs within arm's reach, cutting down on wasted steps and streamlining your entire process.

An organized station is a productive station. Using shelves to create a dedicated 'zone' for specific tasks cuts down on clutter, minimizes wasted movement, and makes the whole kitchen safer for your team.

An undershelf is the most common storage add-on for a reason. Located right below the main surface, it’s the perfect spot for stashing bulk ingredients, mixing bowls, or small appliances. It gets things off the floor but keeps them right where you need them.

For even more organizational punch, look at adding an overshelf. Sometimes called a double-tier shelf, this gives you a second or even third level of storage above the workspace. It’s ideal for spices, finishing oils, plating tools, or anything a chef needs to grab in a hurry without breaking their rhythm.

Deciding Between Mobility and Stability

Finally, you need to think about how your table will meet the floor. The choice between stationary legs and mobile casters really boils down to your kitchen's layout and how you work.

Stationary legs offer unmatched stability. If you'll be doing any heavy-duty tasks like butchering, running a large mixer, or kneading dense dough, you need fixed legs. They ensure the table stays put and won't wobble or shift during intense work.

On the other hand, casters (wheels) give you incredible flexibility. Putting your work table on casters means you can easily roll it out of the way for deep cleaning or quickly reconfigure your kitchen for a special event. This is a game-changer in smaller or multi-purpose kitchens. Just make sure to get casters with reliable locks to keep the table stable when it's in use.

How to Make the Right Purchase Decision

Choosing the right commercial kitchen work table is a big deal. It's a decision that directly affects your kitchen's daily grind, its efficiency, and even its safety. With a sea of options out there, it’s easy to get lost. The key is to look past the price tag and think about how a table will actually perform in your kitchen, day in and day out. A methodical approach ensures you end up with a long-term asset, not just a temporary fix.

Let's walk through the essential steps, from getting your measurements right to understanding which features are truly non-negotiable for your menu and workflow.

Start with Space and Budget

Before you even start browsing, grab a tape measure. You need to know the exact footprint you’re working with, but don’t forget to account for things like door swings, nearby appliances, and most importantly, clear walkways. A cramped kitchen is a clumsy, dangerous kitchen, so make sure your team has plenty of room to move without creating a traffic jam.

Next, set a realistic budget. But here’s the thing: think of it as an investment, not just a purchase. That cheaper, flimsy table might look like a bargain now, but it's going to dent, warp, or fail under pressure, costing you more down the road. The sweet spot is finding the right balance between what you can spend today and what you need to last for years.

Prioritize NSF Certification for Compliance

This one is critical. If you see an NSF certification, know that it's more than just a sticker. It’s your guarantee that the table is up to snuff with public health and safety standards. An NSF-certified table is built to be a breeze to clean and sanitize, with smooth surfaces and no little nooks or crannies for bacteria to thrive.

For any surface that touches food, NSF certification is pretty much a must-have to pass your health inspections. Trying to cut corners here can lead to failed inspections, fines, or even getting shut down. It's simply not worth the risk.

Investing in NSF-certified gear is foundational to running a safe and compliant kitchen. To get a deeper understanding of what it all means, check out our guide on what is NSF certification and why it matters so much.

Match the Table to Its Intended Task

Finally, you need to match the table's specs to the job it will be doing every single day. This is where knowing your materials and gauges really pays off. Think about the most punishing task this table will ever face, and choose one that can handle it.

- For Heavy-Duty Work: If you’re going to be butchering, running a heavy-duty mixer, or sliding massive stockpots around, you absolutely need a low-gauge (thicker) steel like 14-gauge. It has the backbone to prevent sagging and keep things stable.

- For General Prep: For all the daily chopping, mixing, and assembling, a 16-gauge table is the workhorse of most kitchens. It strikes the perfect balance between durability and cost.

- For Light-Duty Applications: An 18-gauge table is perfectly fine for lighter tasks. Think plating dishes, assembling sandwiches, or holding small countertop appliances.

Getting this right is what separates efficient kitchens from chaotic ones. It's no surprise that the global market for commercial tabletop products, including work tables, was valued at USD 11.27 billion and is expected to climb to USD 19.26 billion. This growth shows just how vital these tools are. Modern kitchens—from island and zone layouts to open concepts—all rely on smartly chosen equipment to make their workflow, well, work. You can explore more about this growing market on Verified Market Research.

By asking the right questions about your space, your compliance needs, and the table’s true function, you can be confident that you’re not just buying a piece of steel, but making a smart investment that will improve your kitchen from day one.

Keeping Your Stainless Steel Table in Top Shape

A good commercial work table is a serious investment, built tough to handle the daily grind of a busy kitchen. But "built tough" doesn't mean "indestructible." A little bit of regular care goes a long way in keeping it in prime condition for years to come.

Think of it like this: a quick wipe-down with warm water and a bit of mild dish soap is all it takes to clear away food scraps. This simple habit does more than just keep things clean; it protects the invisible protective chromium oxide layer that gives stainless steel its legendary rust resistance.

It's also crucial to know what not to use. Stay away from harsh, abrasive scouring pads, any cleaners with chloride, and especially bleach. These can eat away at the steel's finish, leading to tiny pits and a dull, worn-out look.

Simple Routines for a Lasting Shine

Creating a routine is the easiest way to stay on top of maintenance.

-

Daily Wipe-Down: At the end of every shift, a quick wash with a soft cloth, warm water, and a mild detergent is perfect. Just be sure to rinse off any soap residue.

-

Weekly Deep Clean: For tougher spots or stains, a sprinkle of baking soda and a gentle scrub with a damp cloth usually does the trick. Always rinse it clean and dry it right away.

-

Avoid Harsh Chemicals: This is a big one. Never use steel wool, chlorine bleach, or cleaners containing ammonia. They are the sworn enemies of a stainless steel finish.

"Consistent, simple care is the secret to making your tables last and keeping your kitchen hygienic," kitchen consultant Marco Ruiz often advises.

A few minutes of prevention can save you from big headaches down the line.

Preventing Scratches and Rust

Scratches are often unavoidable, but you can dramatically reduce them. The number one rule? Always use cutting boards. Plastic or nylon boards provide a safe buffer, protecting the metal from direct contact with your knives.

Rust spots, while rare, can pop up if salty or acidic foods sit on the surface for too long. If you see a small spot forming, don't panic—just act fast.

- Dab a little white vinegar directly onto the spot.

- Gently rub the area with a soft cloth.

- Rinse it completely with water and dry it thoroughly.

This quick treatment will stop rust from spreading and keep your table looking pristine.

Checking for Stability and Safety

Every month or so, take a moment to check that the leg bolts and adjustable feet are still tight. A wobbly table is a hazard during busy prep times. If you have a mobile table, give the casters and their locks a quick inspection to make sure they're rolling smoothly and locking securely.

By folding these simple habits into your kitchen's routine, you're not just protecting your equipment—you're upholding the highest standards of food safety. For a deeper dive, check out our complete guide on how to clean stainless steel. A little effort now saves a lot of time, money, and stress later.

Frequently Asked Questions

It's completely normal to have a few questions when you're about to invest in a new commercial kitchen work table. Getting the right answers means you’ll end up with a piece of equipment that truly fits your kitchen's workflow, your budget, and your specific needs. Let's tackle some of the most common questions we hear from chefs and restaurant owners.

What's the Real Difference Between 304 and 430 Stainless Steel?

Think of it like choosing between a heavy-duty rain jacket and a light windbreaker. Both have their place, but you wouldn't use them for the same thing.

304 stainless steel is your top-of-the-line, all-weather option. It's packed with chromium and nickel, giving it fantastic resistance to rust and corrosion. This makes it perfect for the actual tabletop—the surface that gets hit with everything from acidic lemon juice to harsh sanitizers.

On the other hand, 430 stainless steel is a more budget-conscious choice. It's still tough and durable, but it's a bit more susceptible to corrosion over the long haul. That's why you'll often find it used for parts that don't directly touch food, like the legs or the undershelf.

A smart and very common setup is a table with a 304 grade top for food safety and durability, supported by a 430 grade base to keep costs down. It’s the best of both worlds.

How Do I Know What Gauge My Work Table Should Be?

The "gauge" of the steel is just a fancy way of talking about its thickness—and the lower the number, the thicker and stronger the steel. Your decision here really comes down to what you plan on doing with the table.

-

Heavy-Duty Work (14-Gauge): If this table will be a home for a massive 60-quart mixer, a heavy meat slicer, or serve as your main butchering station, you need the strength of 14-gauge. It's built like a tank and won't buckle under pressure.

-

General Prep (16-Gauge or 18-Gauge): For everyday chopping, mixing, and assembling plates, a 16-gauge or 18-gauge table is more than enough. These gauges offer a great mix of sturdiness and value for most common kitchen tasks.

Is NSF Certification Actually a Big Deal?

In a word: yes. If you're using a table for any kind of food prep, NSF certification isn't just a nice-to-have, it's a must.

This stamp of approval means the table has been designed and built to be easily cleaned and sanitized, with no cracks or crevices where bacteria can hide. It's a non-negotiable for passing health inspections and, more importantly, for keeping your food and your customers safe.

Can I Put Hot Pans Right on the Stainless Steel?

Go for it. One of the best things about stainless steel is its incredible heat resistance. You can slide a hot pot or sizzling pan directly onto the surface without worrying about scorching or melting.

Just a small heads-up: repeatedly placing extremely hot items on the exact same spot, especially on a thinner gauge table, could cause minor warping over a long period. For massive stockpots coming straight off a high-BTU burner, using a trivet is good practice, but for most day-to-day cooking, it's not necessary.

At PrepTables.com, we live and breathe commercial kitchens. We offer a huge selection of NSF-certified work tables built to handle the heat and hustle of any professional environment. Find the exact size, gauge, and style you need to make your kitchen run smoother and safer.

Check out our full collection at https://preptables.com and find your perfect fit today.