Your Essential Guide to the Perfect Work Table Kitchen

Share

Walk into any professional kitchen that truly hums, and you'll find it: the stainless steel work table. It's so much more than just a surface. It's the stage where a chef's ideas take shape, the central hub for prep, plating, and everything in between. Think of it as the master craftsman's workbench—absolutely essential for efficiency, safety, and creativity.

The Unsung Hero of Every Professional Kitchen

For any serious culinary operation, from a packed restaurant to a slick food truck, the right work table kitchen setup is non-negotiable. This one piece of gear anchors your entire workflow, ensures hygiene standards are met without a second thought, and stands up to the brutal demands of daily service. It’s not just another purchase; it's a core investment in your business's success.

The market knows this, too. The commercial kitchen equipment market, which leans heavily on these durable tables, is projected to grow by a staggering USD 41.81 billion, expanding at a healthy CAGR of 7.4%. This boom is fueled by the explosion of quick-service restaurants and cloud kitchens, where every square inch of efficient workspace counts.

The Different Types of Stainless Steel Prep Tables

While a simple flat-top table is the foundation, the world of stainless steel prep tables is surprisingly diverse. Each type is engineered to solve a specific problem in the kitchen, from basic prep to high-volume assembly lines.

- Standard Prep Tables: This is the quintessential kitchen workhorse. Prized for its durability and how easy it is to sanitize, it’s the all-purpose surface for chopping, mixing, and general plating. They often come with options like undershelves for storage or backsplashes to protect walls.

- Mobile/Portable Tables: By adding a set of caster wheels, a standard table becomes a mobile workstation. This offers incredible flexibility for cleaning, rearranging floor plans, or creating temporary prep stations during a rush.

- Equipment Stands: These aren't your typical tables. Built with heavier gauge steel and reinforced legs, they are designed specifically to hold heavy equipment like mixers, slicers, or griddles, providing a stable and secure base.

- Pizza Prep Tables: These specialized units feature a wide work surface (often marble to keep dough cool) and a refrigerated rail along the top. This rail holds pans of toppings—cheese, pepperoni, veggies—keeping them fresh and within arm's reach for rapid pizza assembly.

- Sandwich Prep Tables: Similar to pizza tables, these are designed for the rapid assembly of sandwiches and salads. They combine a cutting board work surface with refrigerated wells for meats, cheeses, and condiments, creating a perfect, efficient assembly line for a busy lunch rush.

Of course, while you're getting your kitchen's physical setup just right, don't forget about your customers. For businesses like cafes, smart tools like loyalty applications for cafes can be just as crucial to your overall operation.

When you’re in the market for a new stainless steel work table kitchen, it's easy to get bogged down by the jargon. Terms like "gauge" and "grade" get thrown around, but what do they actually mean for your day-to-day operations?

Getting these two things right is the key to a smart investment. Think of it like this: you wouldn't send a soldier into a major battle with flimsy armor. The same principle applies right here in your kitchen.

The "gauge" of the steel is simply its thickness. But here's the tricky part: the lower the number, the thicker and tougher the steel. It's your table's first line of defense against the daily chaos of a busy kitchen—heavy mixers, sharp cleavers, and constant, relentless use.

Decoding Steel Gauge for Kitchen Duty

Picking the right gauge is all about matching the table's muscle to the job you need it to do. Get it wrong, and you'll end up with a dented, wobbly surface that’s not just inefficient, but downright unsafe.

Here’s a quick rundown of the common gauges you'll see:

- 14-Gauge: This is the undisputed heavyweight champion. It’s incredibly thick and built for the most demanding jobs. Think butchering, pounding out cutlets, or holding up a massive commercial mixer without breaking a sweat.

- 16-Gauge: This is your versatile all-rounder. A 16-gauge table hits that sweet spot between serious durability and a reasonable price point. It can handle just about any general prep work, from heavy chopping to supporting mid-weight appliances, which is why it's a favorite in so many kitchens.

- 18-Gauge: Lighter on its feet and easier on the wallet, 18-gauge steel is perfect for less strenuous tasks. It’s ideal for assembling salads, plating desserts, or as a general utility surface where you don't expect heavy impacts or a lot of weight.

Choosing the right gauge isn't a new problem. Back in the 1980s, the industry's shift to robust 16-20 gauge steel was a game-changer, slashing maintenance costs by an impressive 40% because the tables could finally withstand dings from mixers and slicers. More recently, post-2020 European hygiene rules triggered a 12% jump in demand, with German kitchens leading the way on ergonomic table heights that cut chef back strain by 22%. You can learn more about the commercial cooking equipment market's evolution.

Understanding Stainless Steel Grades

Now, beyond thickness, we have the "grade." This tells you about the steel's actual makeup—and most importantly, how well it fights off rust and corrosion. This is where you decide if your table needs to be a warrior ready for anything or if it can live a quieter life in a dry corner of the kitchen. The two grades you'll encounter most are 304 and 430.

Think of 304 grade stainless steel as the marine-grade, all-weather option. It has more chromium and nickel in the mix, giving it top-tier protection against rust from water, acidic foods like citrus and tomatoes, and strong cleaning chemicals. This makes it the only real choice for almost any food prep area, especially where things get wet.

Key Takeaway: If a surface is going to have direct and frequent contact with food—especially anything wet or acidic—304 grade steel is the non-negotiable industry standard for safety and a long lifespan.

On the flip side, 430 grade stainless steel is a more budget-friendly pick. It's still strong and perfectly food-safe, but with less nickel, it's more likely to rust over time if it's constantly exposed to moisture or salt. It's a great, economical choice for dry applications, like equipment stands, shelving for dry goods, or a work surface in a bakery where it won't be dealing with corrosive ingredients all day.

Choosing the right grade and gauge is what ensures your work table kitchen will be a reliable partner for years to come. Want to get even deeper into the science? Check out our complete guide to stainless steel grades explained on PrepTables.com.

To make it even simpler, here's a quick reference table to help you match the right steel to your kitchen's needs.

Stainless Steel Gauge and Grade Selector

A comparison of common stainless steel gauges and grades to help you choose the right work table for your kitchen's specific needs.

| Specification | Description | Best For | Common Use Case |

|---|---|---|---|

| 14-Gauge / 304 Grade | The thickest, most corrosion-resistant option available. The absolute toughest combination for demanding environments. | Heavy-duty butchering, high-moisture prep areas (fish, produce), or supporting extremely heavy equipment like industrial mixers. | Butcher shops, fish markets, high-volume restaurant kitchens. |

| 16-Gauge / 304 Grade | The industry workhorse. Offers excellent durability and superior corrosion resistance for all-purpose use. | General food prep, chopping, mixing, and supporting most standard kitchen appliances in any environment. | Most restaurants, cafes, and commercial kitchens. |

| 18-Gauge / 304 Grade | A lighter-duty top with excellent rust protection. Best for tasks that don't involve heavy impact. | Assembling sandwiches and salads, plating, light prep work where moisture is present. | Salad bars, sandwich shops, dessert stations. |

| 16-Gauge / 430 Grade | A durable top with standard corrosion resistance. A great budget-conscious choice for dry areas. | Equipment stands, dry goods storage, work surfaces in bakeries where moisture and acids are not a major concern. | Bakeries, pizzerias (for dough work), dry storage areas. |

| 18-Gauge / 430 Grade | The most economical option. A light-duty top best suited for dry tasks with minimal wear and tear. | Storing boxed dry goods, holding light equipment, general utility tasks away from the main prep line. | Storage rooms, non-food labs, utility closets. |

Ultimately, taking a moment to assess the specific demands of your workspace—from the weight of your equipment to the acidity of your ingredients—will guide you to the perfect table that serves you well for years.

Finding the Right Work Table for Your Kitchen

When you hear "work table," it's easy to picture a simple flat-top surface. But that's like saying all vehicles are the same. A sports car and a dump truck both have wheels, but you're not hauling gravel in a Ferrari. The same logic applies to your kitchen—there's a whole world of specialized stainless steel work tables, each built to solve a specific problem.

Your choice really boils down to one question: what do you spend most of your day doing? If you're chopping vegetables from dawn till dusk, your needs are vastly different from a kitchen running a high-volume sandwich line. The right table isn't just a surface; it's a dedicated tool that makes you faster, more organized, and ultimately, better at what you do.

Standard Stainless Steel Prep Tables

This is the quintessential kitchen workhorse. It’s the strong, silent type—durable, simple, and incredibly easy to sanitize. The standard prep table is the foundation of most commercial kitchens, giving you a clean, reliable surface for chopping, mixing, seasoning, and all sorts of general prep.

But "standard" doesn't mean basic. These tables often come with a couple of game-changing options: backsplashes and undershelves.

- Backsplashes: Think of this as a raised lip along the back of the table. It’s a simple feature, but it’s brilliant. It stops food, liquids, and utensils from falling into that awful, hard-to-clean gap between the table and the wall.

- Undershelves: This is a no-brainer. Adding a lower shelf nearly doubles your storage without eating up more precious floor space. It’s the perfect place to stash bulk ingredients, small appliances, or prep containers, which keeps your main work surface free and clear.

Specialized Refrigerated Prep Tables

Now we're getting into the specialized gear. For any kitchen where ingredients need to stay cold and be within arm's reach, a refrigerated prep table is non-negotiable. These units brilliantly combine a work surface with built-in cold storage, creating an efficient, self-contained workstation. They're designed to streamline any assembly-line process where speed and temperature are everything.

You'll mainly see two types in this category: pizza prep tables and sandwich prep tables. Each one is finely tuned for its job, turning a clunky, multi-step process into a smooth, ergonomic flow.

Foodservice efficiency studies have shown a specialized prep table can slash assembly time for items like pizzas or sandwiches by up to 30%. The magic is in minimizing movement—a chef has every single component right there, without taking a single step.

Pizza Prep Tables

A pizza prep table is a pizzaiolo's best friend. It’s got a wide, flat work surface—often marble or stainless steel—that’s perfect for stretching dough. Right above it, you have a refrigerated rail with slots for food pans, keeping your cheese, pepperoni, and veggies perfectly chilled and ready to go.

This setup means a cook can build a pizza from start to finish without ever leaving their station. They stretch, sauce, and top in one continuous motion. In the heat of a dinner rush, that kind of efficiency is priceless.

Sandwich Prep Tables

In the same vein, sandwich and salad prep tables are engineered for pure speed. They feature a cutting board that runs the length of the unit, sitting directly in front of refrigerated wells holding all your meats, cheeses, veggies, and condiments. The layout creates a natural left-to-right (or right-to-left) workflow.

An employee can grab the bread, load it up with ingredients from the cold wells, and pass the finished sandwich down the line in just a few seconds. This is the engine that powers delis, cafes, and quick-service spots through the chaos of a lunch rush.

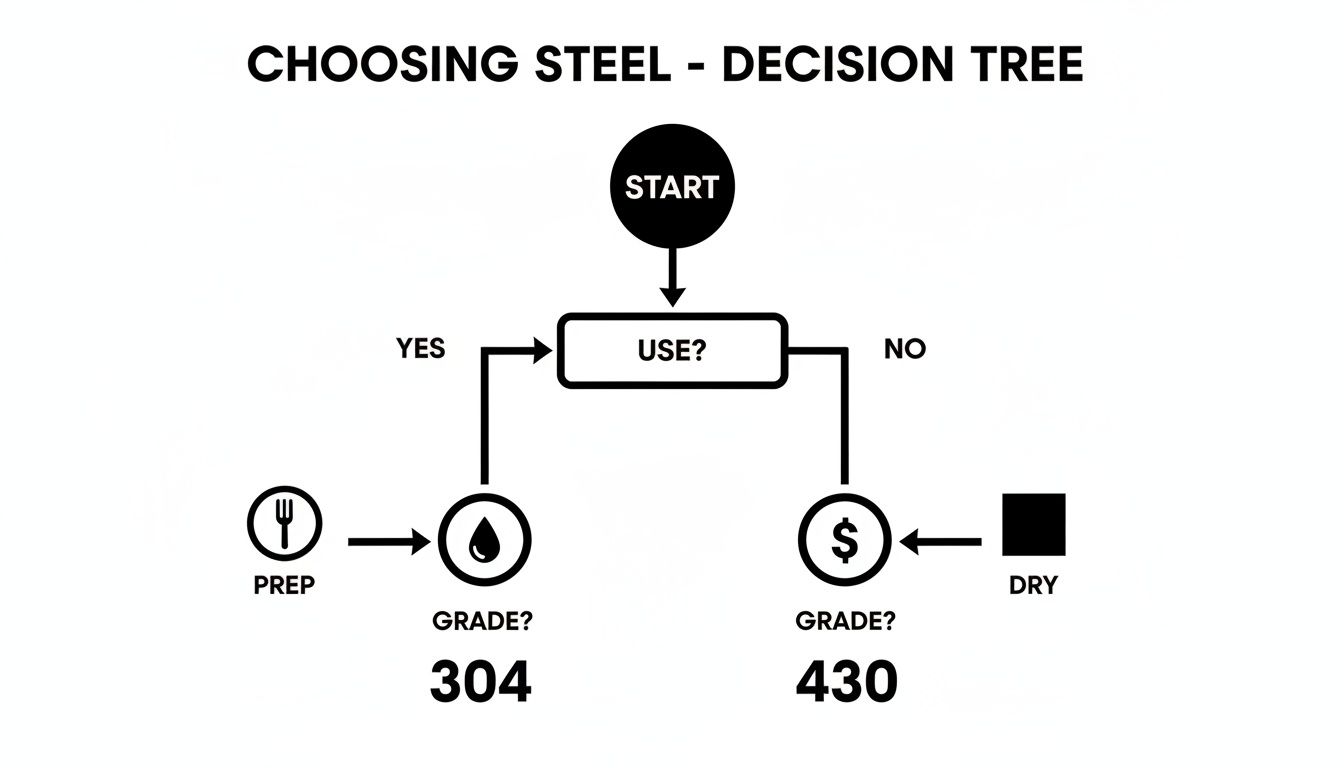

Choosing the right type of stainless steel is a foundational step in this process. This simple decision tree visualizes the core choice between 304 and 430 grade steel based on your kitchen's environment.

As the infographic shows, it’s pretty straightforward: if your prep work involves any moisture (the prep icon), the corrosion-resistant 304 grade is a must. For strictly dry applications, 430 grade is a perfectly fine, cost-effective choice. If you want to dive deeper into planning and materials, this guide to lab workstations and tables offers some great insights. The principles of optimal setup are just as true in a high-demand kitchen as they are in a lab.

Sizing Your Table for a Perfect Workflow

Picking the right size for a work table kitchen setup isn't just about filling an empty spot on the floor. It's a strategic move that dictates the entire rhythm of your operation. Go too big, and you create bottlenecks that choke high-traffic areas. Go too small, and you'll end up with a cluttered, inefficient mess. The real goal is to strike that perfect balance, maximizing your workspace without killing movement.

Before you even glance at a tape measure, map out your kitchen and identify the essential clearance zones. Your staff needs a bare minimum of 36 inches of walkway space to move safely, especially when they're hustling with hot pans or heavy stock pots. Shoving a table too close to a doorway or another piece of equipment is a recipe for disaster and can bring your workflow to a dead stop.

Ergonomics: The Secret to Productivity

Once you know your spatial limits, it's time to think about height. Most standard work tables stand between 34 to 36 inches tall, which is the sweet spot for keeping most people in a comfortable, neutral posture. This isn't just about feeling good—it's about preventing injuries and burnout over long, grueling shifts.

A table that’s too low or too high forces your team to hunch over or strain their shoulders, leading to chronic back and neck pain down the road. Good ergonomics can seriously boost morale and cut down on costly injuries. In fact, some industry data shows that adjustable-height tables can reduce injury claims by as much as 28% in certain catering operations. It's a small detail with a huge impact on your team's well-being and output.

Key Configurations to Consider

Beyond the basic length, width, and height, a few key features can completely transform a table's usefulness. These options let you customize your workstation for the specific jobs happening there.

Here are three of the most important configurations to look for:

- Undershelves: This might just be the most valuable add-on you can get. An undershelf gives you crucial storage space for bulk ingredients, containers, or small appliances, keeping your main work surface clear and ready for action. Adjustable ones are even better, giving you the flexibility to store items of all shapes and sizes.

- Backsplashes: A simple raised edge at the back of the table, a backsplash is your best friend for keeping messes contained. It stops liquids from splashing onto walls and prevents ingredients or tools from falling into that impossible-to-clean gap. It's a small feature that makes cleanup way faster and helps maintain sanitation.

- Marine Edges: Think of these as a raised perimeter around the entire table, designed to contain spills and stop liquids from dripping onto the floor. If you're doing any prep that involves liquids—from washing produce to marinating meats—a marine edge is a non-negotiable feature for safety and cleanliness.

The right setup turns a simple surface into a high-performance workstation. The pros agree: 90% of culinary professionals say a load capacity over 800 lbs is critical, which is often supported by a sturdy undershelf. And for those in tight quarters, like the 65% of food trucks that doubled their prep speed after an upgrade, every well-planned inch counts. You can dig deeper into these trends by reviewing market insights on FutureMarketInsights.com.

If you’re working with a larger kitchen that needs more sprawling surfaces, it's worth checking out specialized options. You can learn more about how to choose a large work table in our dedicated guide.

Understanding NSF Certification and Proper Maintenance

In any professional kitchen, cleanliness isn't just a nice-to-have; it's the bedrock of your entire operation. This is where you'll notice a small but mighty seal of approval on quality gear: NSF certification. Seeing that mark on your work table kitchen setup is the single best way to know it’s built to meet strict public health and safety standards.

The National Sanitation Foundation (NSF) is the organization that sets the gold standard for equipment design. When a table is NSF-certified, it means it’s made from food-safe materials and—this is the important part—designed without any cracks, crevices, or seams where nasty bacteria can set up camp. This smart design makes the surface a breeze to clean and sanitize, protecting your customers and your hard-earned reputation.

What That NSF Seal Really Means

You can think of the NSF seal as a promise. It’s a clear signal to health inspectors, your staff, and even your customers that your equipment is built from the ground up for total hygiene.

- Food-Safe Materials: The steel and other parts won’t ever leach anything funky or harmful into the food you're prepping.

- Hygienic Design: Every surface is smooth, non-porous, and totally free of those tiny gaps that love to trap food particles.

- Easy to Sanitize: The way it's built allows for a truly deep clean, leaving absolutely no place for pathogens to hide.

This isn't just a sticker. It's a critical feature that confirms your investment is safe, compliant, and ready for the daily grind of a commercial kitchen. Want to dive deeper? You can learn more about what NSF certification means for your equipment in our full guide.

A Step-by-Step Cleaning and Maintenance Guide

Keeping your stainless steel table looking and performing its best all comes down to a consistent cleaning routine. Nail these steps, and you'll prevent cross-contamination, bust through grime, and get years more life out of your table.

- Clear and Scrape: First things first, get all the loose food bits and equipment off the surface. A soft plastic or rubber scraper is your best friend here for lifting any stuck-on gunk without scratching.

- Wash with Mild Soap: Mix up a simple solution of mild dish soap and warm water. Grab a soft cloth or a non-abrasive sponge and wash the whole surface, always wiping with the grain of the steel. This little trick helps prevent tiny scratches.

- Rinse Thoroughly: Use a fresh, damp cloth to wipe away every last bit of soap. Any residue left behind can create a dull film that actually attracts more dirt.

- Sanitize Effectively: Now, apply a food-safe sanitizer, making sure to follow the manufacturer's directions to the letter. Let it sit for the required contact time—that's when the magic happens and bacteria are eliminated.

- Dry Completely: Don't skip this last step! Use a clean, dry microfiber cloth or a squeegee to get the surface bone-dry. This stops water spots in their tracks and makes it harder for new bacteria to grow.

Preventing Scratches and Rust

To keep your table gleaming, always use cutting boards for chopping and dicing. And whatever you do, steer clear of abrasive tools like steel wool or harsh chemical cleaners that contain chlorine.

If you get a minor scratch, a specialized stainless steel cleaner or a simple paste made from baking soda and water can often help buff it out. A little bit of care goes a long way, ensuring your table remains a safe, shiny workhorse in your kitchen for years.

Customizing Your Workstation for Peak Efficiency

Getting a great work table kitchen setup is really just the starting point. Think of that basic stainless steel table as a blank canvas. The real magic happens when you start customizing it to turn that simple surface into a high-performance workstation built around your kitchen's unique rhythm.

The right accessories can completely change your game. Simple add-ons solve those little everyday headaches, shaving precious seconds off tasks that add up to hours saved over a week. When you think beyond the basic slab of steel, you can build a station that makes every single movement more efficient.

Essential Accessories for Your Work Table

Some add-ons are so effective they’ve practically become standard issue in professional kitchens. These are the workhorses that tackle common problems like storage, organization, and mobility, making your whole space more flexible and productive.

-

Caster Wheels: Slap a set of these on, and your static table is suddenly a mobile command center. Casters give you incredible flexibility to rearrange your kitchen for deep cleaning, special events, or just a workflow that needs to change on the fly. Just make sure to get locking casters so the table stays put when you're working.

-

Overshelves: An overshelf, sometimes called a double-tier shelf, is the fastest way to double your storage without eating up more floor space. They’re perfect for keeping frequently used spices, tools, or small appliances right where you need them but off the main prep surface.

By adding just one or two key accessories, kitchens can often reclaim valuable workspace and reduce staff movement by up to 20%. That means less fatigue and higher output, especially when you're in the weeds.

Advanced Customization Options

Once you've covered the basics, you can get into features that are designed for specific tasks. These are the accessories that help you create a mini assembly line right at your workstation—a must-have for any high-volume operation.

Think about how drawers or specialized rails could tighten up your process:

-

Drawers: Adding a set of drawers gives you enclosed, organized storage for all those essential tools like knives, whisks, and thermometers. It keeps them clean, safe, and exactly where you need them, so nobody wastes time digging around for the right utensil.

-

Bin Rails: If you run a salad, sandwich, or pizza line, these are a total game-changer. Bin rails are mounted to the edge of the table and are designed to hold all your ingredient bins. This turns a standard table into a dedicated assembly station and keeps the main surface clear for actually building orders.

Answering Your Top Work Table Questions

Choosing the right work table can feel overwhelming with all the options out there. We get it. To help you cut through the noise, we’ve put together some straightforward answers to the questions we hear most often from chefs and kitchen managers. Think of this as your cheat sheet to making a smart investment for your work table kitchen.

What Are the Main Types of Stainless Steel Prep Tables?

You might think a table is just a table, but in a professional kitchen, the right design can make a world of difference. The classic flat-top is the foundation, but a few specialized models are built to solve specific problems and streamline your workflow.

Here’s a breakdown of the most common types you’ll run into:

- Standard Prep Tables: These are the dependable all-rounders of the kitchen. They give you a simple, tough surface for everything from chopping veggies to plating entrees. Most come with options like an undershelf for extra storage or a backsplash to keep your walls clean.

- Mobile or Portable Tables: Slap some caster wheels on a standard table, and you’ve got a flexible powerhouse. You can roll them out of the way for deep cleaning or rearrange your kitchen on the fly for a special event. They're a lifesaver in tight spaces.

- Equipment Stands: These aren’t your average tables. Built with heavier gauge steel and beefed-up legs, they’re designed to safely hold your heavy hitters—think big mixers, griddles, or meat slicers. They provide a rock-solid base you can count on.

What’s the Deal with Pizza and Sandwich Prep Tables?

This is where things get really interesting. Some of the most valuable tables out there are the ones with built-in refrigeration. By putting cold storage right where the action is, these units completely change the game for any kitchen that does assembly-line prep.

Pro Tip: A specialized refrigerated prep table can slash the number of steps a cook takes by more than 50% when making pizzas or sandwiches. No more walking back and forth to the fridge—it's a massive time-saver.

Pizza Prep Tables are purpose-built for slinging pies. They usually have a wide workspace (sometimes marble, to keep the dough from sticking) and a refrigerated rail up top. That rail holds all your toppings—sauce, cheese, pepperoni—right at your fingertips, keeping everything cold and safe while you work.

In the same way, Sandwich Prep Tables are engineered to make the lunch rush feel less like a panic attack. They feature a cutting board that runs the length of the unit, sitting right in front of a series of cold wells for your meats, cheeses, veggies, and condiments. Everything is laid out for an ergonomic, efficient flow, so your team can build orders faster than ever. For a deli, pizzeria, or cafe, adding one of these to your work table kitchen isn't just an upgrade; it's a total game-changer.

Ready to find the perfect foundation for your culinary creations? At PrepTables.com, we offer a vast selection of professional-grade stainless steel work tables, specialized prep stations, and commercial equipment to fit any kitchen's demands. Explore our collection and build a more efficient workspace today at https://preptables.com.