Choosing Your Commercial Stainless Steel Prep Table

Share

Not all stainless steel surfaces are created equal, and when you step into the world of commercial prep tables, you’ll find a surprising amount of variety. Each type is designed to solve a specific problem in the kitchen. Understanding these differences is your first step toward a more efficient kitchen.

Choosing the right commercial stainless steel prep table is all about matching its design to what your team does day in and day out.

Decoding the Different Types of Prep Tables

When you hear “commercial stainless steel prep table,” you probably picture one thing: a simple, flat-topped table. And while that classic design is definitely a kitchen workhorse, it’s only the beginning of the story. The truth is, there's a whole world of prep tables out there, and not all of them are built for the same job.

Choosing the right one isn't just about buying a piece of equipment; it's about designing a smarter, more efficient workflow.

Think about it like this: a carpenter doesn’t just have “a saw.” They have a specific tool for every task—a miter saw for perfect angles, a handsaw for quick cuts, a table saw for ripping long boards. A well-run kitchen is no different. It needs a variety of prep tables to handle everything from basic chopping to high-speed assembly. The global market for these tables, valued at over USD 1.2 billion, keeps growing for this exact reason. Kitchens need durable, hygienic surfaces that are also adaptable. You can explore more data on this market growth to see just how essential they've become.

The Foundation: Standard Work Tables

The most common table you'll see is the standard work table. This is the all-purpose hero of any commercial kitchen. It’s the blank canvas where you dice vegetables, knead dough, mix sauces, and plate your final dishes.

These tables generally come in two main styles, each solving a different kitchen challenge:

- Open Base Tables: These are exactly what they sound like—a tabletop supported by legs, with nothing underneath. Their biggest advantage is the wide-open access to the floor, which makes sweeping and mopping a breeze. This design is perfect if you prioritize floor hygiene or need to tuck large, mobile ingredient bins out of the way.

- Tables with Undershelves: If your kitchen is tight on space, an undershelf is a game-changer. That simple addition turns unused space into valuable, easy-access storage. It’s the perfect spot to stash mixing bowls, small appliances, or stacks of pans, keeping your main work surface clear and organized.

Specialized Tables for Peak Efficiency

While standard tables are great for general prep, specialized tables are engineered to streamline specific, repetitive tasks. They are designed around a single principle: minimizing movement. When a chef has every tool and ingredient they need within arm's reach, their speed and consistency skyrocket. This is where you see a huge jump in productivity during the dinner rush.

A specialized prep table can turn a chaotic process into a well-oiled machine. By consolidating tasks into a single station, you cut down on foot traffic, reduce the risk of cross-contamination, and seriously speed up order times.

The best examples are sandwich prep tables and pizza prep tables. These units aren't just tables; they're complete, self-contained workstations. They combine a stainless steel work surface with refrigerated cabinets below for backup ingredients. More importantly, they feature a rail of chilled pans right on top, keeping everything from sliced meats and cheeses to veggies and sauces at a safe, consistent temperature. Many even come with a built-in cutting board. For any busy pizzeria, deli, or fast-casual spot, this all-in-one design is what makes a high-volume lunch rush possible.

If you want to dive deeper into all the configurations, check out our complete guide on the types of stainless steel prep tables.

Finding the Right Prep Table for Your Workflow

Stepping into the world of commercial kitchen equipment can feel like a lot, but picking the right commercial stainless steel prep table is simpler than you think. The trick is to stop looking for a one-size-fits-all solution. Instead, you need to match the table's design to the actual, day-to-day jobs your team is doing. Your kitchen’s unique rhythm is the best guide you’ll have.

Think about it. A high-end steakhouse needs something completely different from a bustling corner deli. The steakhouse crew might want long, wide-open surfaces for butchering whole primals and meticulously plating dishes. The deli, on the other hand, needs a compact station built for speed, cranking out sandwiches like an assembly line. Each kitchen’s menu and flow will point you to the perfect table.

Knowing the basic types is the first step to making your space work smarter, not harder.

Standard Work Tables: The Kitchen's Foundation

The most basic and flexible choice is the standard work table. This is the blank canvas of your kitchen—the all-purpose hero where you chop vegetables, portion out proteins, mix ingredients, and plate your masterpieces. They’re absolutely essential, but even these fundamental pieces come in a few different styles to solve specific problems.

-

Open-Base Tables: These are as simple as it gets: a sturdy top on four legs, with nothing underneath. The big win here is total access to the floor, which makes sweeping and mopping a breeze. This design is a favorite in kitchens where floor hygiene is a top priority or where large, rolling ingredient bins need to be tucked away.

-

Tables with Undershelves: When every square inch of storage counts, an undershelf is a must-have. It turns that empty space under the work surface into prime real estate for storage. It’s the perfect spot to stash mixing bowls, small appliances, or frequently used pans, keeping your main workspace clear and ready for action.

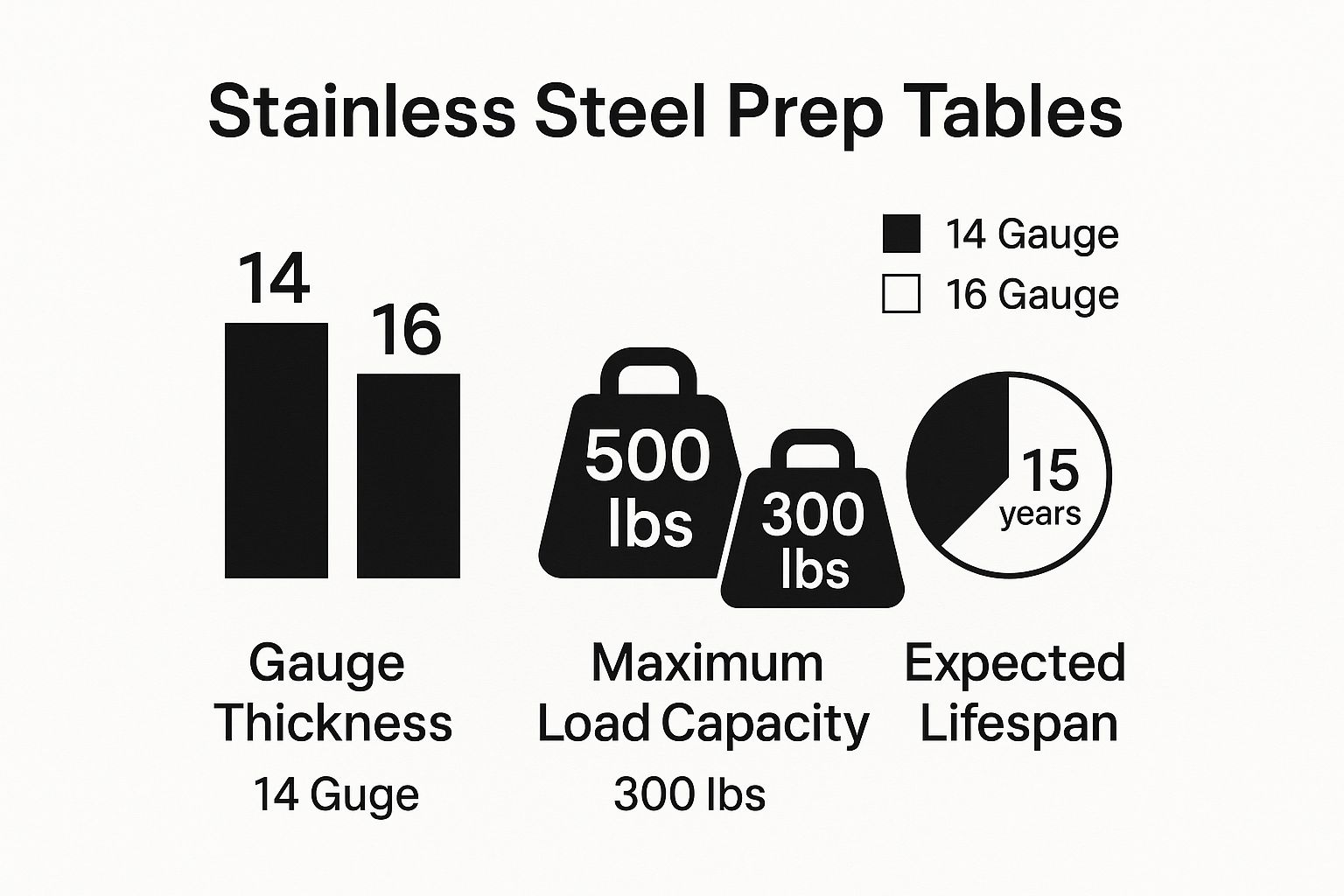

Choosing between a beefier table and a standard one often comes down to budget versus durability. This chart breaks down how different steel gauges stack up.

As you can see, a lower gauge number means thicker, tougher steel. This translates directly to a higher load capacity and a longer lifespan, making it a smart investment for any high-volume, heavy-duty kitchen.

Specialized Tables for High-Volume Tasks

While standard tables are great all-rounders, some jobs are so repetitive and high-volume that they demand a specialized tool. These tables are engineered around one core idea: keeping your chefs in one spot. When every tool and ingredient is within arm’s reach, efficiency skyrockets.

A specialized prep table can be the difference between a chaotic, messy service and a smooth, seamless one. By putting an entire workflow into one station, you cut down on foot traffic, slash order times, and create a safer, more organized kitchen.

To make it easier to see how these different types fit into a real kitchen, here's a quick comparison.

Which Prep Table Type Fits Your Kitchen?

| Table Type | Best For | Key Features |

|---|---|---|

| Open-Base Work Table | General prep, easy cleaning, storing mobile bins | Simple four-leg design, maximum floor access |

| Work Table with Undershelf | Kitchens needing extra storage for tools or dry goods | Adds a fixed shelf below the work surface |

| Pizza/Sandwich Prep Table | High-volume pizzerias, delis, and cafes | Refrigerated rail for toppings, cold storage base, integrated cutting board |

Each of these designs serves a very specific purpose. Your job is to match the table's features to your menu's demands.

Pizza and Sandwich Prep Tables

Built for pure speed, these units combine a tough stainless steel workspace with refrigerated cabinets below for backup ingredients. But the real game-changer is the refrigerated "rail" up top, which holds an array of chilled food pans. This keeps everything from pepperoni and cheese to lettuce and tomatoes at a safe, consistent temperature, ready to go.

Many models even have a built-in cutting board, creating a truly all-in-one station. For any busy pizzeria or deli, this setup is what makes a slammed lunch rush not just manageable, but profitable.

The market shows just how critical these units have become. The refrigerated prep table market was recently valued at an impressive USD 3.12 billion. This huge number highlights just how much modern kitchens rely on equipment that combines workspace with essential temperature control for speed and food safety.

Choosing the right commercial stainless steel prep table is one of the biggest levers you can pull to boost your kitchen's productivity. By taking a hard look at your menu and workflow, you can find a table that doesn't just sit there—it actively helps you succeed. To see how different setups can transform various restaurant concepts, check out our guide on how to choose the right restaurant stainless steel tables.

Key Features That Elevate Your Workstation

The real difference between a decent commercial stainless steel prep table and a truly great one lies in the details. Once you've sorted out the steel grade and basic size, it's the specific features that turn a simple surface into the workhorse of your kitchen. These aren't just bells and whistles; they have a direct impact on safety, cleanliness, and how comfortable your staff is during a long shift.

Think of it this way: buying a table with the right features is a direct investment in your team's efficiency. A well-designed table means less strain, quicker cleanup, and a more organized space where your chefs can really hit their stride.

Safety and Ergonomics First

Kitchens are fast-paced environments, and let's be honest, accidents can happen. But smart design choices can go a long way in preventing common injuries and cutting down on physical fatigue. The best prep tables are built with the user in mind, making those long hours on the line safer and more comfortable.

Here are two of the most critical features for safety and ergonomics:

-

Rounded 'Bullnose' Edges: A table with sharp, squared-off edges is just a hazard waiting for someone to bump into it. This can lead to anything from a nasty bruise to a torn apron. A bullnose edge, on the other hand, is rounded and smooth, drastically cutting down the risk of injury when someone inevitably brushes past it in a hurry.

-

Adjustable Legs or Feet: Your kitchen staff aren't all the same height, and I'd bet your kitchen floors aren't perfectly level either. Adjustable legs are the simple solution to both problems. They let you dial in a comfortable working height for your team, which helps prevent back and shoulder pain. Plus, you can level the table on uneven ground to stop that annoying wobble that makes precise knife work a nightmare.

Cleanliness and Protection Features

In any food business, hygiene is everything. Certain features are designed specifically to make this critical task easier and more effective, protecting both your food and your building.

A backsplash is a must-have for any table that will be pushed up against a wall. It's a simple raised lip at the back that acts as a barrier, stopping water, food bits, and cleaning sprays from splashing onto the wall. This doesn't just keep your kitchen looking tidy—it prevents moisture from soaking into drywall, which can cause mold and other headaches down the road.

A table with an integrated backsplash creates a self-contained, sanitary workspace. It streamlines cleanup by keeping the mess on the easy-to-sanitize steel surface, saving your team valuable time and protecting your building's integrity.

This demand for smart, integrated features is a huge reason why the food prep tables market is growing. The sector was valued at USD 1.18 billion and is projected to climb to USD 1.62 billion by 2029, all because modern kitchens need these kinds of adaptable, efficient solutions. You can read more about the food prep table market trends to see how these innovations are shaping what's available.

Customizations for Peak Efficiency

Beyond the standard stuff, you can customize your table to fit your kitchen’s workflow like a glove. These add-ons transform a basic piece of equipment into a workstation perfectly tailored to your menu and processes.

Mobility with Casters

Adding a set of casters (heavy-duty wheels) to your table's legs gives you incredible flexibility. A mobile table can be rolled out of the way for deep cleaning, rearranged for different prep tasks, or moved to create more floor space when needed. Just make sure you get at least two locking casters to hold the table firmly in place when it’s being used.

Tailored Storage Solutions

Making the most of your table's storage can be a game-changer for organization.

- Undershelves: As we've mentioned, these are fantastic for bulk storage. Some models even offer adjustable undershelves, so you can change the height to fit specific containers or small appliances perfectly.

- Drawers: Adding a drawer gives you secure, enclosed storage for all those small hand tools—peelers, thermometers, whisks, and plating spoons. It keeps your main work surface clear and your essential gear right where you need it.

- Overshelves: An overshelf, sometimes called a double-tier shelf, adds storage above the work surface. This is the perfect spot for holding spices, organizing plating dishes, or staging finished orders under heat lamps.

By carefully considering these features, you can build a commercial stainless steel prep table that truly works for your kitchen, boosting safety, cleanliness, and your team's overall efficiency.

Proper Assembly and Strategic Kitchen Placement

There's a certain satisfaction that comes with unboxing a brand new commercial stainless steel prep table. It’s a clean slate, a promise of a smoother, more efficient kitchen. But before you can get to chopping, mixing, and plating, you have to get two things right: assembly and placement.

A rushed setup can leave you with a wobbly, unstable surface—a frustrating and frankly dangerous problem. And putting it in the wrong spot can jam up your whole kitchen's flow, creating bottlenecks that kill your ticket times. Nailing these two steps from the get-go is the key to making sure your investment starts paying off immediately.

A Frustration-Free Assembly Guide

Putting a stainless steel table together is usually pretty straightforward, but a few pro tricks can save you a world of headaches. The goal here is simple: a rock-solid, perfectly level workstation that can take whatever your kitchen throws at it.

Just follow these steps for a secure, wobble-free setup:

- Work Upside Down: This is the single best piece of advice I can give. Don't try to wrestle with the legs while the heavy top is upright. Instead, lay the tabletop upside down on a protected surface, like the cardboard box it came in. This gives you wide-open access to the leg sockets.

- Attach Legs and Undershelf: Go ahead and insert the legs into their sockets. If your table has an undershelf, now is the time to slide it down over the legs. Use the set screws and Allen wrench that came with it to loosely secure the shelf at your preferred height.

- Tighten Evenly: With everything in position, go back and tighten all the set screws properly. Make sure you work in a crisscross pattern, just like you would when tightening lug nuts on a car tire. This distributes the pressure evenly and prevents any warping.

- Flip and Level: Now, carefully flip the table over onto its feet. Grab a small level and place it on the tabletop. Check it, then adjust the individual feet at the bottom of each leg until that bubble is dead center. This final tweak is what gets rid of any lingering wobble for good.

Strategic Placement for Maximum Workflow

Where your prep table lives is every bit as important as how it’s built. A well-placed table is a command center, linking different kitchen zones and cutting down on wasted steps for your crew. Bad placement just creates chaos.

A strategically placed prep table supports a logical kitchen workflow, reducing foot traffic and saving precious seconds on every order. Think of it as the bridge connecting your cold storage, cooking line, and washing stations.

To really dial in your layout, think about the classic kitchen triangle concept. Your prep station should be the hub, with easy access to your most-visited areas:

- Refrigeration: The table needs to be close to your fridges and freezers. This lets chefs grab ingredients without having to trek across the kitchen floor.

- Sinks: Having a prep sink nearby is non-negotiable for washing produce and for quick hand washes, which is critical for food safety.

- Cooking Line: Your table should be just a few steps from the range or ovens, creating a seamless path from preparation to cooking.

Follow these simple assembly and placement tips, and your new commercial stainless steel prep table won’t just be another piece of equipment. It will be a core part of a productive, efficient, and safer kitchen right from day one.

Maintaining Your Table for a Lifetime of Use

Think of your commercial stainless steel prep table as more than just a piece of kitchen equipment; it's a real investment in your kitchen's workflow and cleanliness. And like any smart investment, it needs a little care to give you a lifetime of solid service. A simple, consistent maintenance routine is all it takes to protect that investment, keep it looking sharp, and make sure you always have a safe, sanitary surface ready to go.

This isn't about some complicated, time-sucking process. The best strategy is built on easy, daily habits that stop problems before they even have a chance to start. Once you understand what helps and what hurts that steel surface, you'll find it incredibly easy to keep your table in top shape for years—or even decades.

Your Daily Cleaning Protocol

The absolute foundation of good maintenance is cleaning your table every single day. This isn't just for appearances. It gets rid of tiny food particles and spills that could slowly eat away at the steel's protective layer if you let them sit.

For daily cleaning, all you need is a soft cloth, some warm water, and a bit of mild soap or detergent. Just gently wipe down the entire surface. Here's a pro tip: always wipe in the direction of the steel's grain, those faint polish lines you can see. If you scrub against the grain, you can create tiny scratches that dull the finish.

A core rule for stainless steel care: deal with spills right away. Acidic stuff like lemon juice, vinegar, or tomato sauce can start to compromise the steel's protective chromium layer if left sitting. This can lead to stains or even corrosion down the line. A quick wipe with a damp cloth is all it takes to prevent this.

After washing, give it a quick rinse with clean water to get rid of any soap residue. The last step is the most important one: dry the table completely with a soft, dry cloth. This simple action prevents those annoying water spots from hard water, which can actually etch the finish over time.

Weekly and Monthly Maintenance Tasks

While daily wipedowns handle the everyday mess, a slightly deeper clean on a regular basis is what really ensures long-term sanitation and durability.

- Sanitizing: At least once a week, you'll need to sanitize the table to stay on the right side of the health department. Use a food-safe sanitizer, like a quaternary ammonium compound, and just follow the product's directions for dilution and how long it needs to sit.

- Deep Cleaning: Got some stubborn, baked-on grease or grime? A simple paste made from baking soda and water works wonders and won't scratch the steel. Slap the paste on, let it sit for a minute, then gently scrub with a soft nylon brush before rinsing and drying.

- Passivation: If you ever spot a tiny rust spot or a deep scratch, you might need to "passivate" the steel. This sounds technical, but it just means using a special stainless steel cleaner to remove any contaminants and help that invisible, self-healing protective layer reform itself.

What to Avoid to Prevent Damage

Knowing what not to do is just as critical as your cleaning routine. Some cleaners and tools can do permanent damage to your commercial stainless steel prep table.

Absolutely Never Use:

- Chlorine Bleach: Any cleaner with chlorine will attack the steel’s protective layer, causing rust and pitting. It’s the enemy of stainless steel.

- Steel Wool or Abrasive Pads: These will absolutely scratch the surface, creating little crevices where bacteria can hide and rust can start.

- Harsh Abrasive Powders: Scouring powders are too aggressive and will permanently dull and scratch up your table's finish.

By following these straightforward guidelines, you can make sure your stainless steel prep table stays a clean, reliable workhorse in your kitchen. For a closer look at what makes these tables so tough in the first place, you can explore our guide to stainless steel prep table basics. Proper maintenance is simply how you protect that built-in quality for its entire lifespan.

Common Questions About Stainless Steel Prep Tables

So, you're getting close to picking out a new commercial stainless steel prep table, but a few questions might still be nagging at you. That's completely normal. Getting clear answers is what turns a good purchase into a great one, giving you the confidence that you've made the right call.

Let's walk through the most common questions we hear from chefs and kitchen managers. Think of this as the final check-in before you pull the trigger, making sure you sidestep the usual mistakes and get a table that will be a reliable workhorse for years.

What Is the Best Stainless Steel Grade for a Food Prep Table?

When it comes to the tabletop—the surface your food will actually touch—there’s really only one answer: 304-grade stainless steel. This is the undisputed industry standard for a reason. It has more chromium and nickel, which gives it top-tier resistance to rust and corrosion, especially from acidic stuff like lemon juice or tomato sauce, and the sanitizers you use every day.

For the parts that don't touch food, like the legs, base, or undershelf, 430-grade steel is a smart and common choice. It’s plenty durable for structural support and helps keep the overall cost down without compromising on the quality of your main work surface.

Can I Put Hot Pans Directly on a Stainless Steel Table?

I know it's tempting, but you really want to avoid placing a screaming hot pan straight from the range onto your table. While stainless steel handles heat well, an extreme, sudden temperature change can cause what’s called thermal shock. This can lead to warping or even permanent discoloration.

A warped table isn't just an eyesore. It makes your work surface uneven and wobbly, which is a real pain for precise knife work and can even be a safety hazard.

The best practice is simple: always use a trivet or a silicone mat. It’s a small habit that will keep your tabletop perfectly flat and protect your investment for the long haul.

Why Is NSF Certification Important for a Prep Table?

Think of the NSF (National Sanitation Foundation) certification as a guarantee. It’s your proof that a piece of equipment meets strict public health standards. An NSF-certified table is built to be cleaned thoroughly and easily, with smooth welds and sealed corners where gunk and bacteria can't hide.

More than just being a good idea, most local health departments require NSF-certified equipment in commercial kitchens. Choosing a table with that seal is often a critical requirement for passing your health inspections and running a compliant, professional operation.

How Do I Clean and Sanitize My Stainless Steel Prep Table?

For daily cleaning, just stick to the basics: a soft cloth, warm water, and a mild detergent. A key tip is to always wipe with the grain of the steel—those faint lines in the metal. This helps prevent tiny scratches. For sanitizing, grab a food-safe solution (like a quat sanitizer) and follow the directions for proper contact time.

Here’s what you absolutely must never use: steel wool, abrasive pads, or any cleaners that contain chlorine bleach. These will scratch the finish and destroy the steel’s natural protective layer, which opens the door for rust and permanent damage.

Ready to find the perfect foundation for your kitchen's workflow? At PrepTables.com, we offer a wide selection of NSF-certified commercial stainless steel prep tables designed for durability, hygiene, and efficiency. Explore our collection and find the right table for your business today!