A Guide to Warming Tables Food Service

Share

Ever wonder how a buffet keeps dozens of different dishes perfectly hot for hours on end? The secret weapon is the food warming table. You can think of it as a climate-controlled waiting room for food, engineered to hold every meal at that just-right temperature from the moment it leaves the stove until it hits the plate.

The Secret to Great Food Service: Keeping It Hot

In any food service operation, whether it’s a high-volume commercial kitchen or an elegant catered event, the final impression is what counts. A dish that’s cooked to perfection but arrives at the table lukewarm is a letdown for everyone. This is precisely where warming tables become absolute game-changers.

Their most critical job is to ensure food quality and safety. By keeping dishes above the dreaded temperature "danger zone" (40°F - 140°F or 4°C - 60°C), these tables stop harmful bacteria from growing, making sure every bite is a safe one.

More Than Just Heat

But it's not just about safety. Warming tables are essential for protecting the entire sensory experience of a meal. They preserve the exact texture, flavor, and aroma the chef worked so hard to achieve. Without one, delicate sauces can separate, crispy coatings can turn soggy, and hot entrees can become disappointingly cool.

The industry certainly recognizes their value. The global market for food holding and warming equipment was pegged at USD 5.2 billion back in 2025 and is on track to hit USD 7.2 billion by 2035. You can get a closer look at these market trends and growth projections from industry analysis reports.

At its core, a food warming table is the bridge between the kitchen's peak output and the guest's dining schedule. It makes sure the first plate served is just as delicious as the last.

The Two Fundamental Approaches

To pull this off, warming tables rely on one of two basic heating methods. Getting a handle on the difference is the first real step in picking the right unit for your menu and your kitchen's workflow.

- Wet Heat: These are often called steam tables for a reason. They use a bath of hot water to create a gentle, moist heat that wraps around the food pans.

- Dry Heat: This method is more direct, using heating elements to radiate warmth without any water or steam involved.

Each style has its own clear advantages depending on what you're serving. This sets the stage for figuring out which technology is going to be the best fit for your operation.

Choosing Your Method: Wet Heat vs. Dry Heat

When you’re picking out a warming table, the biggest decision you'll make is about the heating technology. Whether you go with wet or dry heat will make all the difference in your food's texture, moisture, and overall quality. It's all about matching the gear to your menu.

Why Steam (Wet Heat) is Your Best Friend for Moist Foods

The most common kind of wet heat warmer is the steam table. Think of it as giving your food a gentle, warm sauna. A water reservoir, called a spillage pan, sits below your food pans and is heated from underneath. This creates a consistent cloud of steam that keeps everything humid.

This steamy environment is perfect for foods that absolutely must stay moist. We're talking delicate sauces that could break, creamy mashed potatoes that might otherwise form a crust, or rich stews that need to stay tender. The moist heat wraps around the food pans, stopping them from drying out during a long service. This is how you make sure dishes that are meant to be juicy stay that way.

To get the most out of your steam table, you'll want to use the right pans. You can learn more in our detailed guide on different types of steam table pans and how to use them.

The Case for Dry Heat

On the flip side, we have dry heat warming tables. These work a lot more like an oven. They use heating elements to radiate warmth directly onto the food pans—no water, no humidity. This approach is the only way to go for anything that needs to stay crispy.

Fried chicken, crunchy french fries, or roasted vegetables would turn into a soggy mess in a steam table. Dry heat is what preserves that satisfying crunch and golden-brown finish your customers are looking for. It's a simple, reliable method that delivers consistent warmth, making it a go-to for a huge range of popular dishes.

A simple rule of thumb: If the food was cooked with moisture (like anything steamed, boiled, or sauced), hold it with wet heat. If it was cooked with dry heat (fried, baked, or roasted), hold it with dry heat.

A Quick Comparison

To make the choice crystal clear, let's break down the core differences between these two heating methods.

| Feature | Wet Heat (Steam) Tables | Dry Heat Tables |

|---|---|---|

| Heating Method | Uses heated water to create steam | Uses heating elements for direct radiant heat |

| Best For | Moist foods: stews, sauces, pasta, mashed potatoes | Crispy foods: fried chicken, fries, roasted items |

| Moisture Level | High humidity; prevents food from drying out | Low humidity; preserves crispness and texture |

| Key Advantage | Maintains moisture and tenderness over time | Keeps fried and baked goods from getting soggy |

| Consideration | Requires water management (refilling, cleaning) | Can dry out certain foods if held for too long |

Ultimately, the right choice depends entirely on your menu. Many kitchens use a combination of both to keep every single dish at its peak quality.

Specialized Warming Solutions

Beyond the standard steam and dry heat tables, you'll find specialized gear designed for specific jobs. Heated display shelves, for example, are a must-have for many buffet lines and grab-and-go spots. These units keep packaged or plated foods at the perfect serving temperature while they're on display.

This part of the market is definitely growing. In 2025, the global heated shelf food warmer market was valued at around USD 4.9 billion and is expected to hit nearly USD 7.4 billion by 2035. You can get more details on this market expansion to see where the industry is heading.

For any off-site events, portable food warmers are a lifesaver. These are essentially insulated cabinets built for catering, letting you transport and hold food safely at the right temperature, so you can deliver quality service absolutely anywhere.

Getting a handle on these different technologies is the first step. It's how you build a solid hot-holding strategy that keeps every dish tasting like it just came out of the kitchen.

Beyond Warming: Specialized Prep Tables

Holding food at the perfect temperature is one thing, but a modern kitchen is a multitasking beast. Real efficiency demands more than just warming; it calls for smart, integrated workstations. This is where specialized prep tables come into play, combining different functions into a single, seamless unit. But before we get to the fancy stuff, let's start with the foundation: the classic stainless steel prep table.

Famous for its incredible durability and non-porous surface, stainless steel is the undisputed king of hygiene in professional kitchens. It laughs off corrosion, stands up to aggressive cleaning, and gives bacteria nowhere to hide. This simple, sturdy workhorse provides the essential space for all your chopping, mixing, and assembling—it’s the true backbone of any food prep area. You can find these tables in various configurations, from simple flat-top surfaces to models with integrated backsplashes to protect walls, or undershelves for convenient storage.

Sandwich Prep Tables: The Deli Workhorse

Now, let's move beyond a basic flat surface to the highly specialized sandwich prep table. Picture a stainless steel workstation that's been fused with a refrigerated unit. The top is lined with a row of chilled wells, or pans, perfectly designed to hold all your fresh ingredients—lettuce, tomatoes, cheeses, and meats—right at your fingertips.

Underneath the workspace, you’ll find a reach-in refrigerator for bulk storage of backup ingredients. This brilliant design means a line cook can build dozens of sandwiches without ever taking more than a step or two. It slashes food handling time, keeps ingredients safely chilled, and ensures a fast, consistent workflow. You can see why it's an indispensable piece of gear in delis and cafes.

Pizza Prep Tables: For Perfect Pies

In the same vein, the pizza prep table is engineered for one specific, high-volume job. Just like its sandwich-focused cousin, it combines a refrigerated base with a top rail of chilled ingredient pans. The key difference? It has a much deeper work surface, often made of marble or another material that stays cool—perfect for stretching and working with pizza dough.

This setup allows a pizzaiolo to have sauce, cheese, and a huge array of toppings all within arm's reach. The integrated design is absolutely crucial for maintaining the speed needed to survive a dinner rush, ensuring every pizza is built quickly with the freshest ingredients possible.

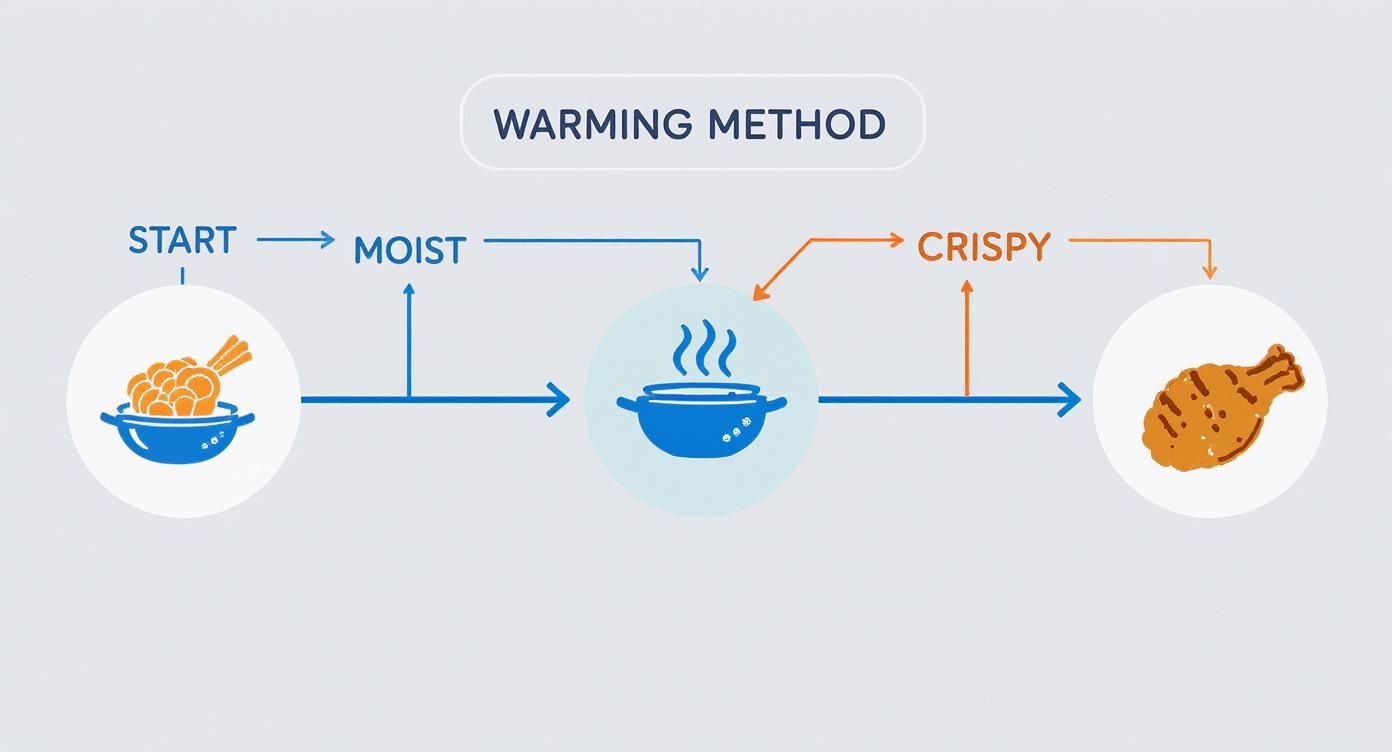

This visual decision tree can help you decide which primary heating method is right for different food types.

As the infographic shows, it’s all about a simple principle: moist foods need wet heat to keep from drying out, while crispy foods need dry heat to maintain their texture.

By combining preparation space with cooling or holding functions, specialized tables become the heart of an efficient assembly line. They turn a series of separate tasks into one fluid motion.

While these tables are all about cold holding, the same principles of workflow efficiency apply to hot food. For any operation that needs to hold large quantities of prepared hot food ready for service, understanding the benefits of a dedicated hot holding cabinet is just as important. These integrated solutions are what truly power a modern, high-speed food service operation.

How to Select the Right Warming Table

Ready to bring a warming table into your kitchen? Picking the right one isn't just about price—it's about finding the perfect fit for how you actually work. Everything from your kitchen's layout to the specific demands of your menu plays a part in choosing a unit that will be a reliable partner for years to come.

The first big question usually comes down to controls. Think of it as the difference between a scalpel and a sledgehammer. Thermostatic controls are your scalpel, giving you the power to dial in an exact temperature. This is non-negotiable for delicate items like a hollandaise sauce or a custard that will break if it gets even slightly too hot.

On the other hand, you have infinite controls. These are the simple, rugged "low-medium-high" knobs. They're built like tanks, making them perfect for chaotic, high-volume spots where durability trumps pinpoint precision.

Power Source and Construction

Next up, you have to consider what your kitchen can support. Electric models are the crowd favorite; they're essentially plug-and-play and deliver steady, even heat. Gas-powered units, running on natural gas or propane, often heat up faster and might be cheaper to run depending on your local utility rates. The catch? You'll need a proper gas line hookup.

The build material is just as critical. Stainless steel is the gold standard in commercial kitchens, and for good reason. It’s tough, hygienic, and a breeze to wipe down. But not all stainless steel is created equal. You'll want to pay attention to the grade, usually 304 or 430.

- 304 Stainless Steel: This is the premium stuff. It has top-tier corrosion resistance, making it the only real choice for wet-heat steam tables that are constantly exposed to moisture.

- 430 Stainless Steel: A more wallet-friendly grade, 430 stainless steel is perfectly fine for dry-heat tables where moisture isn't a daily battle.

Your choice of warming table impacts more than just food temperature; it affects workflow, utility costs, and even food safety compliance. A well-chosen unit should seamlessly integrate into your kitchen's daily rhythm.

Size, Capacity, and Practical Add-Ons

Finally, get out the measuring tape and look at your menu. How many pans do you need to hold at peak service? Warming tables are sized based on the number of full-size hotel pans they can fit. A small cafe might get by with a two-pan unit, while a sprawling buffet line could easily need a five-pan table or larger.

Don't forget the little things that make a big difference. Built-in cutting boards can add precious prep real estate. Sneeze guards are an absolute must for any self-serve line to keep things hygienic. And if your kitchen layout changes, models with casters offer the flexibility to roll the unit wherever it's needed most.

The market for warming tables food service professionals use is packed with options, from electric and gas to newer induction models, all pushing for better energy efficiency and safety. You can even see how top brands are innovating in this catering food warmers market overview. By weighing all these factors, you can land on a warming table that truly works for your menu, your space, and your budget.

Best Practices for Daily Operation and Safety

Owning a high-quality warming table is just the start. If you want to guarantee food quality and keep your customers safe, you have to use it correctly. Mastering a few daily habits turns that piece of equipment into a true cornerstone of your kitchen's safety and service.

The first step, and one that gets skipped more often than you'd think, is a proper preheat. Never, ever place cold pans of food into a cold warming table. Think of it like preheating your oven—you have to get the table up to the target temperature before the food goes in.

For steam tables, this also means filling the wells with hot water first. This simple step is your first line of defense against food lingering in the temperature "danger zone."

Maintaining Ideal Conditions

Once you're preheated and running, daily management becomes all about consistency. With steam tables, water levels are everything. If you let the water evaporate completely, you risk damaging the heating elements and getting nasty hot and cold spots.

Train your staff to keep an eye on the water and top it off with hot water throughout the service.

For any type of warming table, how you arrange the food is also critical. Give the pans some breathing room to allow for even air circulation. Overcrowding the table is a surefire way to create cold spots where temperatures can dip to unsafe levels, killing both the safety and the quality of your food.

Food safety isn't a single action but a continuous process. Consistent temperature monitoring is the most reliable way to ensure every dish served is both delicious and safe for consumption.

The Golden Rule: Temperature Checks

The single most important daily task is checking the food's temperature. Hot food absolutely must be held at or above 135°F (57°C) to stop harmful bacteria from growing. This is not a "set it and forget it" situation.

- Use a Calibrated Thermometer: Don't just trust the table's dial. Get in there with a good food thermometer and check the internal temperature of the food itself.

- Check Regularly: You should be checking and logging temperatures at least every two hours. This vigilance helps you spot a problem long before it becomes a real crisis.

Nailing these operational basics is fundamental. For a deeper look at keeping your kitchen compliant and your customers safe, our guide to food safety temperature control has all the essential info you need.

Cleaning and Maintenance for Long-Term Performance

A high-performance warming table is a serious investment in your kitchen's quality and safety. But just like any other workhorse piece of equipment, it needs regular care to keep doing its job right. A solid cleaning and maintenance routine is the best way to protect that investment, sidestep surprise breakdowns, and make sure your warming tables food service is always safe and on point.

Think of it like a simple checklist broken down into daily, weekly, and monthly jobs. This kind of structure makes it a breeze for staff to follow and stops tiny issues from blowing up into big, expensive problems.

Your Essential Cleaning Checklist

The real secret to making your equipment last is consistency. Wiping it down every day stops food from getting caked on, while a deeper clean once a week gets rid of tougher grime and any mineral buildup.

Daily Tasks (End of Day):

- Wipe Down All Surfaces: Grab a soft cloth and a food-safe sanitizer to clean the outside of the unit, the control panel, and any nearby surfaces.

- Empty and Clean Wells: If you have a steam table, drain all the water. Pull out the food pans and wash them on their own. Give the inside of each well a thorough cleaning to get rid of any spills or residue.

- Sanitize Inserts: Make sure all food pans and utensils are cleaned and sanitized based on health code rules before you put them away for the night.

Weekly Tasks:

- Descale Water Pans: If you're in an area with hard water, mineral buildup (limescale) is going to happen. Once a week, use a commercial-grade descaling solution to dissolve these deposits in your steam table wells. This is crucial for efficient heating.

- Inspect Heating Elements: For dry heat tables, check the elements for any cooked-on food or grease. Once they are completely cool, carefully clean them with a non-abrasive brush.

Preventative maintenance isn’t just about being clean; it’s about keeping the machine working properly. A well-cared-for unit runs more efficiently, uses less energy, and is way less likely to quit on you during a busy service.

Simple Preventative Maintenance Checks

Beyond just cleaning, a few quick monthly look-overs can really stretch the life of your warming table. These checks only take a few minutes but can spot wear and tear before it turns into a call for a repairman.

At least once a month, give the whole unit a quick inspection. Check the power cord for any frays or damage. Give the control knobs and legs a little wiggle to make sure they’re tight and not stripped. If you have a mobile unit, check the casters to see that they roll smoothly and lock properly. Working these simple steps into your routine helps you maintain the highest kitchen hygiene standards and keeps your equipment running like it's brand new.

Common Questions About Food Warming Tables

As you bring a warming tables food service into your operation, a few questions always seem to pop up. Let's clear the air on some common points so your team can use your new equipment safely and effectively from day one.

Can You Cook Food in a Warming Table?

Let's get this one out of the way first: absolutely not. This is a huge safety issue and a surprisingly common misunderstanding. Warming tables are built for one job and one job only: hot-holding. They're designed to keep already cooked food at a safe temperature, holding it above that critical 135°F (57°C) danger zone where bacteria love to grow.

These units simply don't have the muscle to cook raw food. Trying to do so will give you undercooked, unsafe meals and could even damage the equipment itself. Stick to what they do best.

What Is the Difference Between a Steam Table and a Dry Warmer?

The real difference comes down to how they keep food warm. A steam table, which you'll also hear called a wet warmer, uses a bath of hot water to create steam. That steam provides a gentle, moist heat perfect for things that can dry out easily, like pasta, mashed potatoes, or saucy dishes.

A dry warmer, on the other hand, works more like your oven. It uses heating elements to send out dry, radiant heat. This is exactly what you want for keeping crispy foods crispy—think fried chicken, french fries, or anything roasted. You wouldn't want those getting soggy.

The right choice isn't about which is better overall, but which is better for the specific food you're holding. Using the wrong method can ruin the texture and quality your chefs worked hard to create.

How Often Should You Check Food Temperatures?

This is non-negotiable for food safety. You need to be checking the internal temperature of every single food item with a properly calibrated thermometer at least once every two hours.

Keeping a consistent log of these temperature checks is your best defense. It ensures every dish stays safely above that 135°F (57°C) minimum, keeps the health inspector happy, and, most importantly, protects your customers.

Can You Place Food Directly into a Warming Table Well?

No, never put food directly into the wells. You must always use food-safe metal pans, like standard hotel pans, to hold the food. There are a few key reasons for this: it's basic sanitation, it stops flavors from mixing and prevents cross-contamination, and it makes swapping, refilling, and cleaning a thousand times easier and safer for your crew.

For durable, high-quality stainless steel prep tables, refrigerated workstations, and other essential kitchen equipment, explore the extensive collection at PrepTables.com. Find the perfect solutions to optimize your kitchen's workflow and hygiene at https://preptables.com.