Your Guide to Buying a Used Stainless Steel Table

Share

Picking up a used stainless steel table isn't just a cost-cutting measure; it's a strategic move that lands you professional-grade gear for a fraction of the price. You get a work surface that's built to last, which means more cash in your pocket for other critical parts of your business. It's really a low-risk, high-reward play for any setup.

Why Buying Used Is a Smart Move

Going for a used stainless steel table is about more than just saving a few bucks. It’s a savvy choice that banks on the material's legendary toughness. Stainless steel is famous for its ability to take a beating for decades in tough spots like restaurants, labs, and workshops. Unlike wood or plastic, it doesn’t easily scratch, warp, or stain, so a pre-owned table often works just as well as a brand-new one.

This incredible durability translates directly into outstanding value. A shiny new table carries a premium price tag, but a used model gives you the exact same core benefits—a hygienic, non-porous surface and rock-solid construction—for a much lower upfront cost. This makes it a perfect fit for startups, small businesses, or anyone trying to stretch a budget without skimping on quality.

Unlocking Immediate Value and Long-Term Performance

The biggest win is obvious: instant savings. The numbers back this up. The global stainless steel market was valued at USD 207.08 billion and is still growing, but you can often find used tables for 30-60% of the price of new ones. This huge discount happens because restaurants often upgrade equipment to meet new codes, which creates a steady stream of top-notch used tables for smart buyers.

Beyond the initial price drop, you’re investing in equipment that’s built to go the distance. Stainless steel has a neat trick up its sleeve: it's self-healing. A thin layer of chromium oxide on the surface naturally re-forms when it gets scratched, which keeps rust and corrosion at bay over time. With a little care, a used table can serve you well for years, if not decades.

If you're buying for a commercial operation, fitting a used table into your workflow might also mean thinking about storage. You can explore top storage solutions for businesses to get a handle on those logistics.

A used stainless steel table is more than a bargain; it’s an asset. Its proven durability means you're not just buying a piece of furniture, but a reliable workhorse that has already demonstrated its ability to perform.

Ultimately, choosing a used stainless steel table is a practical decision that balances smart spending with operational needs. It's one of the best ways to set your workspace up for success right from the get-go.

Navigating Different Types of Stainless Steel Tables

When you start shopping for a used stainless steel table, it’s easy to think they’re all the same: a slab of metal on four legs. That's like saying all cars are identical. Just as you wouldn't use a small sedan to do the job of a heavy-duty truck, different stainless steel tables are built for very different jobs.

Getting a handle on these differences is the key to finding a table that doesn't just fill a space, but actually makes your work easier. From the most basic flat tops to complex refrigerated units, each design has its own purpose. If you match the table to your actual needs, your used purchase will be a workhorse asset, not just another piece of furniture.

The Foundational Workhorse Tables

The most common used tables you'll come across are the versatile, all-purpose models that form the backbone of kitchens, labs, and workshops.

- Standard Flat-Top Tables: This is the classic prep table. It's a completely open, flat surface—a blank canvas for general food prep, assembly work, or any task that needs tons of elbow room. Its biggest strength is its simplicity.

- Tables with a Backsplash: Think of this as a standard table with a built-in guard rail. A raised lip, usually a few inches high, runs along the back. This simple feature is a lifesaver for messy jobs or when the table is up against a wall, as it stops liquids and food bits from splashing all over the place.

- Tables with an Undershelf: Being efficient is all about smart storage. Tables with a single or double undershelf give you instant, easy-to-reach space for equipment, containers, and supplies. It keeps essential gear off the floor and right where you need it.

These basic tables are everywhere on the used market and are the workhorses of many operations. To get an even better look at these core designs, check out our deep dive on the different types of stainless prep tables to help narrow down your choice.

Specialized Stations for Streamlined Workflows

Once you get past the basics, you'll find specialized workstations designed to make specific, high-volume tasks much faster. These aren't just tables; they often combine prep space, storage, and even refrigeration into one efficient unit. Finding one of these used can be a huge win.

A perfect example is the sandwich prep table. This is a full-on assembly line in a single piece of equipment. It has a refrigerated base to keep meats and cheeses cold, with a row of chilled wells on top for holding veggies and sauces. A cutting board usually runs along the front, making it a seamless flow from ingredient to finished product.

A specialized prep table turns a process with multiple steps into one smooth motion. By keeping everything chilled and organized in one spot, it skyrockets your speed and consistency—a massive advantage in any busy environment.

Another highly specialized unit is the pizza prep table. This station is built from the ground up for making pizzas. It has a refrigerated rail on top to hold pans of toppings like pepperoni, mushrooms, and cheese at safe temperatures. The work surface is often a big, durable cutting board, and the refrigerated base has plenty of room for dough boxes and other bulk items.

Deciding between a general-purpose table and a specialized one really comes down to what you do most. While a flat-top table gives you flexibility, a used pizza or sandwich prep station can give a massive productivity boost to businesses that churn out those items. Finding one in good shape on the used market is a smart, strategic move for any high-volume kitchen.

Decoding Stainless Steel Grades and Finishes

Not all stainless steel is the same. When you're eyeing a used stainless steel table, understanding the metal itself is just as critical as checking for dents and wobbles. Think of it like buying a coat: you wouldn't grab a light windbreaker for a blizzard. The grade, thickness, and finish of the steel dictate how and where the table will truly shine.

Making the right call here means your investment will hold up for years, giving you a work surface you can count on. The most common grades you’ll run into are 304 and 430, and knowing the difference is key.

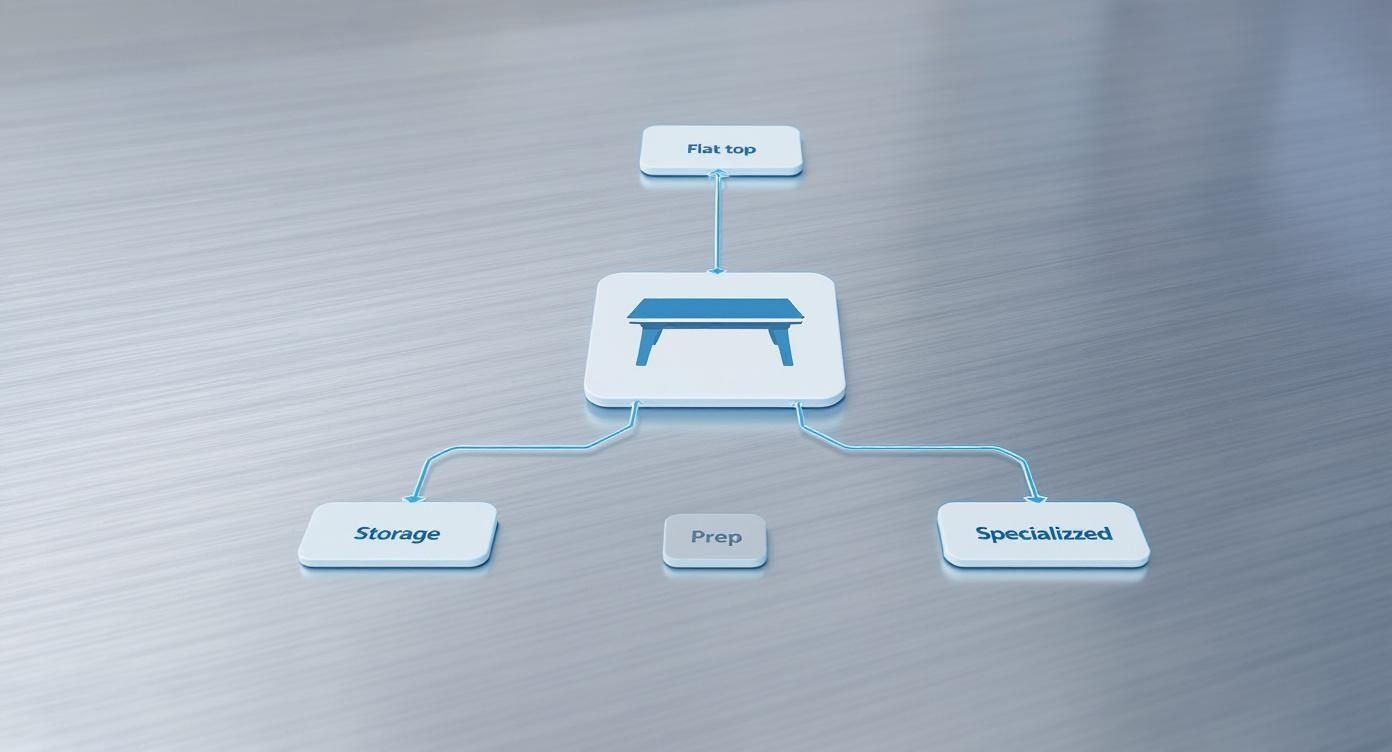

This diagram breaks down how different tables are built for specific jobs, from basic prep work to more specialized refrigerated units.

As you can see, even though they're all "stainless steel tables," their roles can be worlds apart. This is why picking the right material for the job is so important.

Understanding Steel Grades 304 vs 430

The grade of stainless steel tells you its chemical makeup, which directly affects how well it stands up to rust and corrosion.

-

304 Grade (The All-Weather Jacket): This is the gold standard for kitchens, labs, and any wet environment. It has more chromium and nickel, giving it top-notch protection against rust from water, cleaning chemicals, and acidic foods. A used stainless steel table made from 304 grade is exactly what you want for a dishwashing area, a fish prep station, or any spot that's constantly damp.

-

430 Grade (The Durable Work Shirt): This one is easier on the wallet and works great for dry tasks. It has less nickel, so it's a bit less corrosion-resistant but still incredibly tough. A 430-grade table is a smart, cost-effective choice for dry storage, holding equipment, or as a general-purpose workbench.

This blend of durability and hygiene is why these tables are so popular. The global market for them was valued at around USD 1.2 billion and is expected to grow at a compound annual rate of 5.5% through 2033. That growth shows just how essential they are in places like healthcare and food service where cleanliness is non-negotiable.

To help you decide, here's a quick comparison of the common steel grades you'll find when shopping for used tables.

Stainless Steel Grade Comparison for Used Tables

| Grade | Key Characteristics | Corrosion Resistance | Best For | Typical Cost |

|---|---|---|---|---|

| 304 | "18/8" (18% chromium, 8% nickel). Excellent rust and corrosion resistance. | High | Wet environments, food prep, dishwashing areas, medical settings. | Higher |

| 430 | Magnetic, lower nickel content. Good durability and strength. | Moderate | Dry storage, equipment stands, general-purpose workbenches. | Lower |

| 201 | Lower nickel, higher manganese. Strong and durable but less corrosion-resistant than 304. | Low to Moderate | Dry, low-impact applications. Budget-friendly choice for light duty. | Lowest |

| 316 | "Marine grade," includes molybdenum for enhanced resistance to chlorides (salt). | Very High | Coastal areas, labs with harsh chemicals, processing salted foods. | Highest |

This table should give you a solid starting point for matching the steel grade to your specific needs, ensuring you don't overpay for features you don't need or underbuy for a demanding environment.

The Importance of Gauge and Finish

Beyond the grade, two other details matter a lot: the steel's thickness (gauge) and its surface finish.

The gauge is simply how thick the sheet of steel is. Here’s the trick: the lower the gauge number, the thicker and stronger the steel. A 14-gauge table is a heavy-duty beast built to hold equipment or take a serious daily beating. On the other hand, an 18-gauge table is thinner and better suited for light prep work or storage. When you're inspecting a used table, a thicker gauge usually signals a longer life and more stability.

The gauge of a stainless steel table is its backbone. A thicker gauge (like 14 or 16) provides the structural integrity needed for heavy tasks, preventing bowing and ensuring stability for years of hard work.

Finally, take a look at the finish. Most tables have a brushed finish, which does a nice job of hiding minor scratches and fingerprints. A polished or mirrored finish looks sharp, but it will show every single smudge and needs constant wiping to keep it looking good.

If you want to dig deeper into the material specifics, you can learn more about what to look for in a commercial stainless steel prep table. By putting together your knowledge of grades, gauges, and finishes, you can confidently pick out a used table that’s a perfect match for your work.

Your Hands-On Used Table Inspection Checklist

So, you’ve found a promising used stainless steel table, and the price looks good. Now for the most important part—the in-person inspection. This is where you’ll separate a fantastic deal from a future headache. Think of yourself as a detective looking for clues; every little detail tells a story about the table's past life and its future in your workspace.

A thorough inspection doesn't have to be complicated. If you know what to look for, you can quickly size up a table's true value by focusing on a few key areas: its structure, the surface condition, and any special features it might have. This checklist will walk you right through it.

Assessing Structural Integrity

The foundation of any good table is stability. A wobbly or weak frame isn't just annoying; it’s a genuine safety hazard in a busy kitchen. Always start your inspection here, because major structural problems are often the most difficult and expensive to fix.

Give the table a firm push from the top and then from the sides. Does it sway or rock? A little wobble can sometimes be fixed by adjusting the feet, but if you feel any serious give, it’s a red flag for a problem with the legs or where they connect to the top.

You might find a table that’s not perfectly steady. You can learn how to fix a wobbly table quickly and permanently to see if it’s a simple fix you’re willing to tackle. But if the frame itself is bent or the joints are shot, it’s best to just walk away.

Next, get down low and take a close look at the welds, especially where the legs and undershelf connect.

- Look for Cracks: Even tiny hairline fractures in a weld are a sign of failure. Under the stress of daily use, they will only get worse.

- Check for Rust: While stainless steel is great at resisting corrosion, the welds can be weak spots, particularly on lower-grade steel. Heavy rust here compromises the strength of the joint.

- Examine the Feet: Make sure all the adjustable feet (often called bullet feet) are there and that you can actually turn them. If they’re missing or seized up with rust, leveling the table on an uneven floor will be next to impossible.

A table's stability is non-negotiable. If it doesn't feel solid and secure during your inspection, it won't perform safely when loaded with heavy equipment or during vigorous prep work.

Examining the Tabletop Surface

The surface is where all the action happens, so its condition is critical for both hygiene and function. You're looking for damage that goes beyond typical wear and tear.

Carefully run your hand across the entire tabletop. Can you feel any deep gouges, pitting, or major dents? Minor surface scratches are totally normal for a used table, but deep crevices are a real problem.

- Deep Scratches and Gouges: These are a nightmare to clean properly and can become a breeding ground for bacteria—a huge concern in any food prep environment.

- Pitting and Corrosion: Tiny pits or rust spots signal that the steel's protective layer is breaking down. This is often caused by long-term exposure to harsh chemicals or acidic foods.

- Dents and Bowing: Grab a straight edge, like a ruler or a level, and lay it across the surface. A noticeable dip or bow in the middle means the table was likely overloaded, and it’s not going to give you a flat, reliable work surface anymore.

Inspecting Specialized Components

If you’re looking at something more specialized, like a sandwich or pizza prep table, you have a couple more things to check. These units often have built-in refrigeration, which absolutely must be working perfectly to be a good deal.

The very first thing you should do when you arrive is plug the unit in. Pop a thermometer inside and let it run while you inspect everything else. For food safety, the refrigerated section has to get down to—and hold—a temperature below 40°F (4°C).

- Test the Cooling: Check the thermometer after 30-45 minutes. If the unit isn't getting cold, you could be looking at a failing compressor or refrigerant issue, which is a very expensive repair.

- Check the Gaskets: Look at the rubber seals around the doors and lids. They should be soft and create a tight seal. If they’re cracked, brittle, or torn, cold air is just going to leak out, making the compressor work overtime and driving up your energy bill.

- Listen to the Compressor: Pay attention to the sound it makes. A quiet hum is normal. Loud banging, clanking, or constant cycling on and off could mean it's on its last legs.

By methodically working through this checklist, you can confidently evaluate any used stainless steel table. This careful inspection ensures you're not just buying equipment, but investing in a reliable tool that will serve you well for years to come.

Finding Your Table and Nailing the Price

Okay, you've got your checklist and you know what to look for. Now for the fun part: the hunt. Finding the right used stainless steel table without getting ripped off is all about knowing where to look and understanding what things are really worth.

The world of used gear is pretty big, stretching from pro dealers to some guy on Facebook Marketplace. Each has its pros and cons. A dealer gives you a bit more safety, but a private seller might offer a killer deal. Your best bet depends on your budget, how much risk you're willing to take, and how fast you need that table.

Top Spots to Score a Used Stainless Steel Table

The search for the perfect table can take you to a few different places, both online and in the real world. I'd suggest checking out a mix of these to give yourself the best shot at finding a quality piece at a fair price.

- Used Restaurant Equipment Dealers: These guys are the specialists. They usually inspect, clean, and sometimes even touch up the equipment they sell. You might pay a little more, but you're also buying their expertise and maybe even a limited warranty. That peace of mind can be worth a lot.

- Restaurant Auction Houses: When a restaurant shuts down or renovates, its gear often hits the auction block. You can find some absolute steals here, but it’s a high-risk, high-reward game. You’ll have to inspect things on the fly and be ready to buy "as-is."

- Online Marketplaces (Facebook, Craigslist): These platforms put you right in touch with sellers. The big plus here is the potential for rock-bottom prices and direct haggling. The catch? Quality is all over the map, so that hands-on inspection we talked about becomes non-negotiable.

You'll find a ton of tables out there, largely because of massive global production. In fact, the worldwide market for stainless steel kitchen goods hit 3.9 billion units, with the U.S. being a major player. This scale keeps the secondhand market full of inventory as businesses upgrade. If you're curious about the global trends that affect used equipment, you can dive into some insights on stainless steel article consumption on indexbox.io.

A Simple Guide to Pricing

So you've found a table. How do you know if the asking price is fair? There's no magic number, but a good rule of thumb is that a used table should go for 30% to 60% of what it cost new. Where it lands in that range comes down to a few key things.

A fair price is the sweet spot between what the seller wants and what the table is actually worth. Use its condition, brand, and features as your bargaining chips to land on a number that makes sense.

To figure out a fair offer, size up the table using these four points:

- Condition: This is the big one. A table with just a few scratches and a solid frame? That’s closer to the 60% mark. But if it's got big dents, rust on the welds, or is missing its feet, you should be pushing for a price closer to 30% to make up for the work it needs.

- Brand Recognition: Big names in the commercial kitchen world like Advance Tabco, John Boos, or Regency just hold their value better. They have a reputation for solid construction, so a table from a known brand can justify a slightly higher price than a generic one.

- Steel Grade and Gauge: Like we covered earlier, a 304-grade stainless steel table is worth more than a 430-grade one, especially if it's going to get wet. The same goes for thickness—a beefy 14-gauge top is more valuable than a flimsy 18-gauge one.

- Special Features: Extras add to the cost. A built-in sink, a working refrigerated base, or extra undershelves all bump up the value. If there's a refrigeration unit involved, make absolutely sure it works. A dead compressor can turn a bargain into a very expensive headache.

Armed with this know-how, you can walk into any negotiation feeling confident, spot a good deal from a mile away, and bring home the perfect workhorse for your kitchen.

Keeping Your Stainless Steel Table Looking New

So you've brought home a used stainless steel table. This thing is a workhorse, but a little bit of care will go a long, long way in protecting your investment. Proper upkeep isn't just about looks; it keeps the surface hygienic and ensures your table performs like new for decades to come.

The secret isn't complicated. It really boils down to a simple, consistent routine and knowing which products to use—and more importantly, which ones to avoid.

The magic behind stainless steel's durability is an invisible, paper-thin layer of chromium oxide that naturally forms on the surface. Think of it as the steel's built-in bodyguard, fighting off rust and corrosion. Keeping your table clean is all about protecting this layer from things that can break it down, like caked-on grime or harsh chemicals.

Your Daily Cleaning Routine

Honestly, the best thing you can do for your table is a quick, daily wipe-down. This simple step prevents food bits and liquids from sitting around and causing trouble, which is a big deal with acidic stuff like tomato sauce or citrus juice that can tarnish the finish.

For most daily cleaning, a soft, damp cloth and a little mild detergent are all you need.

- Wipe with the grain: Get up close and you'll see faint lines in the metal. That's the "grain." Always wipe parallel to these lines. Going against them can create tiny scratches that make the surface look dull over time.

- Rinse thoroughly: After you've wiped it with detergent, go over it again with a clean, damp cloth to get rid of any soap residue.

- Dry immediately: Grab a soft, dry towel and wipe away every last drop of moisture. This is key to preventing those annoying water spots, which are just mineral deposits left behind by hard water.

This whole process takes maybe a minute, but it’s the single most effective way to keep your used stainless steel table in prime condition.

Tackling Tougher Stains and Spots

Every now and then, you'll run into something more stubborn, like baked-on grease or even a few small rust spots. Whatever you do, don't reach for steel wool or an abrasive scrubber! There are much better—and safer—ways to get that shine back.

For tough, greasy messes, a simple paste of baking soda and water works wonders without scratching the surface. Just apply the paste, let it sit for a few minutes, and gently work it in with a soft nylon brush or sponge, making sure to move with the grain. If you spot any minor rust, it can often be handled with a specialized cleaner made just for stainless steel.

Proper care is less about heavy scrubbing and more about using the right techniques. Gentle, consistent cleaning protects the steel's natural defenses, whereas harsh chemicals and abrasive tools create damage that invites corrosion.

If you want a deeper dive into safe and effective cleaning methods, you can learn more about how to properly clean stainless steel to make sure you're protecting its finish for the long haul. The goal is always to address spills and stains quickly, before they get a chance to set and compromise that all-important protective layer.

Got Questions About Used Tables?

Alright, so you've found a promising used stainless steel table, but a few nagging questions are holding you back. That's smart. Getting these last few details ironed out is what separates a great buy from a future headache.

Let's walk through some of the most common questions that pop up right before pulling the trigger. Think of this as your final gut-check on everything from cosmetic issues to critical safety certifications.

Can I Get Deep Scratches Out of a Used Table?

For minor scuffs and surface-level marks, you might have some luck. Grab a non-abrasive stainless steel cleaner and a microfiber cloth, and gently rub with the grain. This can sometimes make those lighter scratches blend in a bit better.

But let's be realistic—deep scratches or gouges are there to stay. While they probably won’t affect the table's sturdiness, they can be a real problem in a food prep setting. A deep gouge is a perfect hiding spot for bacteria, making it tough to sanitize properly. Before you buy, run your hand over any major scratches. If they're deep enough to catch your fingernail, think twice if you're using it in a commercial kitchen.

Is Buying a Used Prep Table With Refrigeration a Good Idea?

It absolutely can be, but you have to be extra careful here. A used refrigerated prep table—like those for sandwiches or pizzas—can save you a ton of money, but only if the cooling system is solid. This is where you need to do more than just kick the tires.

Insist on plugging it in and letting it run for at least 30 to 60 minutes. Don't just trust the display; stick a reliable thermometer inside to see if it actually gets down to a food-safe temperature (below 40°F or 4°C) and stays there. While it's running, take a close look at the gaskets on the doors or lids. If they're cracked, brittle, or don't seal tightly, walk away. A bad seal makes the compressor work overtime, which burns electricity and leads to a much shorter lifespan.

What’s "NSF Certified" and Does It Really Matter?

NSF stands for the National Sanitation Foundation. When you see that NSF mark on a piece of equipment, it means it’s been rigorously tested to meet strict public health and safety standards. It’s designed to be easily and thoroughly cleaned.

For anyone running a commercial food business—a restaurant, café, or food truck—NSF certification isn't just a nice-to-have. It’s a deal-breaker. Your local health inspector will be looking for it, and you simply won't pass inspection without it.

Now, if you’re just looking for a heavy-duty table for your garage, workshop, or a non-food lab, you don't need to worry about the NSF mark. But for any professional kitchen, it's non-negotiable.

Are There Specific Brands I Should Hunt For?

While the table's actual condition is always king, some brands just have a reputation for building gear that can take a beating. Finding a used table from one of these names is usually a good sign that it was built with quality materials and solid construction from the start.

Keep an eye out for these brands:

- Advance Tabco

- John Boos

- Regency

- Metro

Seeing one of these names can give you a bit more confidence, but don't let it be the only factor. Your own hands-on inspection is what truly matters. A well-cared-for table from a lesser-known brand is always a smarter purchase than a trashed table from a big-name manufacturer.

Ready to find the perfect workhorse for your kitchen or workspace? At PrepTables.com, we offer a huge selection of new stainless steel tables and commercial equipment built to last. Explore our collection and find the ideal table for your needs today!