Undercounter Freezer Refrigerator Combo Guide

Share

In a busy professional kitchen, every single move and every inch of space matters. An undercounter freezer refrigerator combo isn't just another appliance; it's a strategic tool designed to put chilled and frozen storage right where the action is. By integrating both into one compact unit, you streamline the entire workflow, cutting down on wasted movement and seriously boosting your team's efficiency. It's the perfect answer for making the most out of a tight kitchen layout.

How a Combo Unit Can Transform Your Kitchen Workflow

When you're in the middle of a service rush, seconds count. The biggest challenge is often just getting ingredients quickly without disrupting the flow. How do you keep the pace up without having your staff run laps around the kitchen? A combo undercounter unit tackles this head-on by putting two of your most-used appliances into a single footprint.

Think about a coffee shop during the morning madness. Baristas are churning out smoothies and lattes as fast as they can. With a combo unit right at their station, they’ve got refrigerated milk for steaming and frozen fruit for blending within arm's reach. That quick trip to a separate freezer might only take 10 seconds, but multiply that by hundreds of orders, and you're looking at a major bottleneck.

The Power of Proximity

Placing cold storage directly under the prep surface creates a super-efficient "work cell." You're essentially eliminating the constant back-and-forth that breaks a chef's focus and slows down the line. It's more than just convenience; it's a fundamental upgrade to how your kitchen operates.

This isn't just about speed, either. The benefits ripple through your entire operation:

- Less Kitchen Congestion: Fewer people crisscrossing the floor means a safer, less chaotic workspace for the whole team.

- Better Ergonomics: Staff can grab what they need with a simple reach, which reduces physical strain over a long, demanding shift.

- Tighter Organization: Ingredients are stored exactly where they're used, creating a more organized and predictable prep process.

To help you see the value at a glance, this table breaks down the core benefits these integrated units bring to the table.

At-a-Glance Benefits of a Combo Unit

| Benefit | Impact on Kitchen Operations | Ideal For |

|---|---|---|

| Space Optimization | Frees up valuable floor space by combining two appliances into one footprint. | Small kitchens, bars, cafes, or any space where square footage is at a premium. |

| Workflow Efficiency | Keeps chilled and frozen ingredients at the point of use, minimizing staff movement. | High-volume prep stations, salad/sandwich lines, and barista counters. |

| Reduced Traffic | Fewer trips to walk-in coolers or upright freezers mean less congestion on the line. | Busy, fast-paced kitchens where staff need to move quickly and safely. |

| Improved Ergonomics | Reduces physical strain by placing essentials within easy reach, minimizing bending and walking. | Any kitchen focused on staff well-being and reducing fatigue during long shifts. |

As you can see, the impact goes far beyond just saving space; it's about creating a smarter, more productive kitchen environment.

A Growing Trend in Commercial Kitchens

This push for efficiency is why these units are becoming so popular. The global undercounter freezer market is expected to jump from roughly USD 2.9 billion in 2023 to about USD 4.5 billion by 2032. That's not just a small bump—it shows a real shift in the foodservice industry toward smarter, more versatile equipment. As kitchens get more compact and menus become more diverse, the value of a multi-functional undercounter freezer refrigerator combo is impossible to ignore. You can discover more insights on the growing undercounter freezer market on dataintelo.com.

Ultimately, by bringing one of these units into your kitchen, you’re doing more than just adding an appliance. You're fundamentally redesigning your workflow for peak productivity and turning your busiest station into the efficient heart of your operation.

Choosing the Right Configuration for Your Needs

Once you realize just how valuable an undercounter freezer refrigerator combo can be, the next challenge is picking the right layout for your kitchen's unique rhythm. These units aren't a one-size-fits-all solution; the mix of doors and drawers can make or break your team's efficiency during a busy service.

Think of it like choosing a chef's knife. A paring knife is perfect for delicate work, while a cleaver handles the heavy-duty jobs. You need the right tool for the task. The same logic holds true for your refrigeration. Matching the unit's design to your kitchen's daily workflow is what turns a good piece of equipment into an indispensable one.

Doors vs. Drawers: What Works Best?

The first decision you'll likely face is whether to go with classic swing doors or convenient sliding drawers. Each has its own strengths, and the best choice really depends on what you're storing and how you need to grab it.

A unit with side-by-side doors is the undisputed champion of bulk storage. It gives you a wide-open space, perfect for stashing bigger items like Cambro containers, full-size hotel pans, or cases of ingredients. If your station needs to hold large batches of prepped food or backup stock, the unobstructed access of a door model is tough to beat.

On the flip side, drawer models are masters of organization and speed. They're ideal for holding smaller, portioned items that need to be accessed in a flash. Picture a busy sandwich or salad station where cooks are grabbing pre-sliced meats, cheeses, and veggies. Drawers keep everything neatly separated and within easy reach, creating a smooth, assembly-line-style process.

Key Takeaway: It's not about which is "better"—it's about which is better for the job. Doors are for bulk. Drawers are for speed and organization.

The Best of Both Worlds: Door and Drawer Combos

For many kitchens, the smartest play is a hybrid model that gives you both doors and drawers in one undercounter freezer refrigerator combo. This setup is the ultimate in versatility, letting you tailor your storage to a varied menu and workflow.

Imagine a busy pastry station. The refrigerated door section can hold big mixing bowls of batter or full sheet pans of dough. At the same time, the freezer drawers below can store perfectly portioned fruit purees or individual desserts ready for plating. This layout supports both high-volume prep and the quick-grab needs of finishing a dish, all from a single, compact footprint. You can explore more on how these units fit into different kitchen designs in our complete guide to under-counter refrigerators.

The Importance of Stainless Steel Construction

No matter what door-and-drawer configuration you land on, there's one thing that is absolutely non-negotiable in a professional kitchen: stainless steel. It’s the industry standard for good reason. Its non-porous surface is a breeze to clean and sanitize, which is essential for passing health inspections and keeping your food safe.

Beyond hygiene, stainless steel is just plain tough. It stands up to the dings, scratches, spills, and harsh cleaning chemicals that are part of daily life in a commercial kitchen. This durability means your investment will last for years, all while keeping your kitchen looking sharp and professional. It’s no surprise that the demand for these durable, space-saving units is on the rise. More and more businesses are seeing the value in consolidating refrigerated and frozen storage into one efficient footprint.

Must-Have Features for Performance and Reliability

Beyond just the arrangement of doors and drawers, the true worth of an undercounter freezer refrigerator combo comes from the features quietly doing the heavy lifting. These aren't just specs on a product page; they're the engine parts that drive performance, safeguard your inventory, and ultimately protect your profits. Choosing the right features is like picking a seasoned line cook over a rookie—one just gets the job done, while the other delivers consistent, top-notch results shift after shift.

Think of these features as your insurance policy against spoiled food and late-night maintenance headaches. A unit that holds its temperature isn't a luxury; it's a critical tool for keeping food safe and your business in the black.

Precision Temperature Control

The most basic job of any commercial fridge or freezer is holding a steady, precise temperature. In a professional kitchen, even a few degrees of drift can ruin food quality and open the door to safety violations.

Modern units use digital temperature controls, which are lightyears ahead of old-school analog dials in terms of accuracy. This level of precision is essential for anyone following a Hazard Analysis and Critical Control Points (HACCP) plan. It guarantees your refrigerated items stay in the safe zone (usually 33°F to 38°F) and your frozen goods stay rock solid (around 0°F to -5°F), stopping harmful bacteria in its tracks.

Keeping exact temperatures isn't just about compliance; it's about protecting thousands of dollars of product. A good digital controller is like having a guard on duty 24/7, making sure every ingredient is stored perfectly.

Energy-Efficient Compressors

The compressor is the heart of your refrigeration unit, and its efficiency has a direct impact on your monthly power bill. An energy-efficient compressor gets the unit cold fast while using less electricity, which adds up to serious savings over the life of the appliance.

Keep an eye out for units with an ENERGY STAR® certification. These models are, on average, 20% more energy-efficient than their standard counterparts, which means lower utility bills for you. That efficiency doesn't just help your wallet; it also shrinks your kitchen's carbon footprint.

The Non-Negotiable Auto-Defrost System

Frost buildup is the silent killer of freezer performance. It acts like a layer of insulation, forcing the compressor to run harder and longer to keep things cold. This wastes energy and can lead to a burnt-out motor. An auto-defrost system is the only real solution.

This feature automatically melts away ice on a regular schedule, keeping the unit running at peak efficiency without you having to lift a finger. It saves you from the tedious, time-consuming job of manual defrosting and prevents the operational downtime that comes with it. For an undercounter freezer refrigerator combo, this is a mission-critical feature.

Smart Connectivity and Alerts

In a busy kitchen, smart features can give you a major leg up. Smart connectivity is quickly becoming a game-changer for kitchen management. Units with this tech can connect to your network and shoot alerts straight to your phone or computer.

Imagine getting a text the second a freezer's temperature starts to climb. That early warning could be the difference between a quick fix and a dumpster full of spoiled product. It lets you tackle problems before they become catastrophes. For those who take quality seriously, it's also important that your equipment meets industry standards. You can learn more about what NSF certification is and see why it’s a vital seal of approval for commercial kitchen gear, confirming it's built for safety, durability, and easy cleaning.

When you prioritize these key features—from pinpoint temperature controls and efficient compressors to auto-defrost and smart alerts—you're not just buying another piece of equipment. You're investing in a dependable, money-saving tool that will be a cornerstone of your kitchen's success for years.

Creating the Ultimate Prep Station

An undercounter freezer refrigerator combo is the foundation of a hyper-efficient prep station, but the real magic happens when you pair it with the right work surface. By matching your combo unit to a specific type of stainless steel prep table, you create a powerful, self-contained "work cell" where every ingredient and tool is within arm's reach. This strategic pairing is what separates a good kitchen from a great one.

Standard Worktop & Chef Base Tables

The most straightforward pairing is sliding your combo unit under a standard stainless steel worktop table. This versatile setup creates an all-purpose prep station ideal for tasks like chopping vegetables, portioning proteins, or plating dishes. For heavier-duty needs, a chef base—which is essentially a reinforced worktop designed to hold countertop cooking equipment—can be paired with refrigerated drawers below, creating the ultimate cookline station.

Specialized Sandwich Prep Tables

For delis, cafes, and sandwich shops, a dedicated sandwich prep table is a game-changer. These specialized tables feature a raised, refrigerated rail on top to hold pans of fresh toppings and condiments, plus a built-in cutting board. Placing an undercounter freezer refrigerator combo underneath completes the station. The refrigerated drawers are perfect for organizing sliced meats and cheeses for rapid assembly, while the freezer side can store backup items like bacon or frozen bread, eliminating mid-rush trips to the walk-in.

High-Efficiency Pizza Prep Tables

Pizza kitchens thrive on speed and consistency, and their equipment must support that workflow. A pizza prep table is designed with a wide, chilled work surface (often marble or stainless steel) for dough work and refrigerated ingredient rails for toppings. Integrating an undercounter freezer refrigerator combo beneath this setup is a strategic power move. The refrigerator section holds extra dough, sauce, and high-volume cheese, while the freezer is crucial for storing bulk toppings and backup inventory. This all-in-one station keeps the pizza line moving without a single wasted step. If you want to dig deeper, our article on commercial refrigerated prep tables offers more great tips for maximizing their efficiency.

By integrating cold storage directly below the work surface, you dramatically reduce staff movement, minimize cross-traffic, and accelerate order fulfillment. It’s the simplest way to make your kitchen layout work for you, not against you.

This thoughtful approach to station design is driving the industry forward. The market for commercial undercounter refrigeration is expected to grow from USD 12.16 million in 2025 to USD 16.19 million by 2035. This growth is fueled by the demand for durable stainless steel units that make kitchens more efficient.

Prep Table and Combo Unit Pairing Guide

| Prep Table Type | Ideal Combo Unit Feature | Workflow Advantage |

|---|---|---|

| Standard Worktop Table | Split door/drawer access | General-purpose flexibility for varied tasks like plating or portioning. |

| Sandwich Prep Table | Multiple refrigerated drawers | Organizes sliced meats and cheeses for rapid sandwich assembly. |

| Pizza Prep Table | Large freezer compartment | Stores bulk toppings and extra dough, preventing mid-rush stockouts. |

| Salad Prep Station | All-refrigerator drawers | Keeps delicate greens and prepped vegetables crisp and easily accessible. |

Matching your equipment to the task at hand is the secret to a smooth-running kitchen. A thoughtful pairing turns a simple prep area into a high-output station that supports your team and your bottom line.

Installation and Maintenance That Protects Your Investment

Picking out the perfect undercounter freezer refrigerator combo is a huge first step, but the real win is making sure it runs like a champ for years to come. That’s where smart installation and a simple maintenance routine come in. This isn't just about dodging repair bills; it's about getting the best performance out of your unit and keeping your kitchen humming.

The whole process starts the second that unit rolls through your door. Where you put it and how you set it up has a massive ripple effect on its lifespan and how much energy it eats up. Get this part right, and you're paving the way for years of reliable service.

Proper Installation Foundations

If you remember one thing about installation, make it ventilation. The compressor is the engine of your unit, and it throws off a lot of heat while it's working to keep things cold. If that hot air has nowhere to go, the compressor has to work overtime, jacking up your energy bills and heading toward an early breakdown—a headache you definitely don't need.

To keep things cool, follow these non-negotiable rules:

- Check Clearance Requirements: Most brands will tell you to leave at least 2-3 inches of breathing room around the back and sides. Don't guess—always check the spec sheet for your exact model.

- Avoid Heat Sources: It might seem obvious, but never stick your unit right next to a griddle, fryer, or oven. The constant heat from the outside forces it to run nonstop, putting a ton of strain on the system.

- Ensure a Level Surface: A wobbly unit is bad news. It can stop the doors from sealing properly, which lets cold air escape and causes messy condensation to build up. Grab a level and make sure it’s perfectly flat.

Electrical safety is another area you can't cut corners on. Your undercounter freezer refrigerator combo needs its own dedicated circuit that matches the voltage and amperage on the spec sheet. Trying to share a circuit is a serious fire risk and can fry the unit’s sensitive electronics.

A Simple Preventative Maintenance Schedule

Once your unit is properly installed, a basic maintenance schedule is your best friend for preventing surprise meltdowns. These tasks are quick, easy, and make a world of difference in the long run. For more serious issues, like troubleshooting a fridge that's not cooling, knowing where to look for quick answers can save your inventory and your investment.

Here’s a straightforward checklist to get you started:

-

Clean Condenser Coils Monthly: Think of condenser coils as the unit's radiator—they release all the heat. When they get caked with dust and grease, the compressor can't cool down. A quick once-over with a stiff brush every month keeps them breathing easy and boosts efficiency big time.

-

Inspect Door Gaskets Weekly: Gaskets are what create that airtight seal. Every week, give them a quick look for any cracks, tears, or brittleness. A classic trick is to close the door on a dollar bill; if you can pull it out with no resistance, it's time for a new gasket.

-

Wipe Down the Interior Daily: A daily wipe-down keeps odors from building up and prevents cross-contamination. Just use a mild detergent with warm water to clean up any spills and keep the surfaces sanitized for safe food storage.

A well-maintained unit doesn't just last longer—it runs cheaper. Clean coils and tight seals mean the compressor runs less, directly lowering your electricity bill month after month.

By taking these proactive steps, you're not just looking after a piece of equipment; you're protecting one of your kitchen's most critical assets. This small investment of your time pays off big in reliability, efficiency, and peace of mind.

Making the Right Choice for Your Business

Alright, let's pull all these threads together. Choosing the perfect undercounter freezer refrigerator combo really comes down to understanding the unique DNA of your kitchen. If you take a hard look at your specific needs, you can pick a unit that becomes a strategic part of your team—not just another piece of equipment on the invoice.

Start by looking at your operation with fresh eyes. What's your menu like? How many customers are you serving on a busy day? How much floor space can you actually spare? And, of course, what's your budget? Each of these questions will start pointing you toward the right configuration and size.

Matching the Unit to Your Workflow

To make this real, let's picture two totally different kitchens. Each one has its own rhythm and priorities, which means they'll need different equipment.

First up, a small, bustling coffee shop. Their entire workflow is about speed and having a few key ingredients right at their fingertips. For them, a smaller combo unit is a perfect fit. They could have refrigerated drawers for milk and creamers and a compact freezer section for things like frozen pastries or smoothie ingredients. The name of the game here is easy access in a tight space.

Now, let's pivot to a high-volume deli. Their needs are completely different. They need a ton of refrigerated space for all their different meats, cheeses, and prepped veggies. Their ideal unit would probably have multiple refrigerated drawers to keep everything organized, plus a much larger freezer to hold backup inventory. For the deli, it's all about capacity and smart organization.

The right choice isn't about finding the 'best' unit on the market; it's about finding the unit that best serves your specific operational rhythm. Analyze your daily prep and service tasks to see where your biggest bottlenecks are.

This is especially true for businesses jumping into newer models like ghost kitchen operations, where a combo unit is a lifesaver for maximizing every square inch of space. It's the key to supporting a diverse menu from a tiny footprint.

A Framework for Your Decision

When you start connecting the technical features we've talked about—like digital controls, doors versus drawers, and energy ratings—to these real-world scenarios, the best path forward becomes pretty clear. You're no longer just comparing spec sheets; you're actually picturing how each unit will perform during the dinner rush.

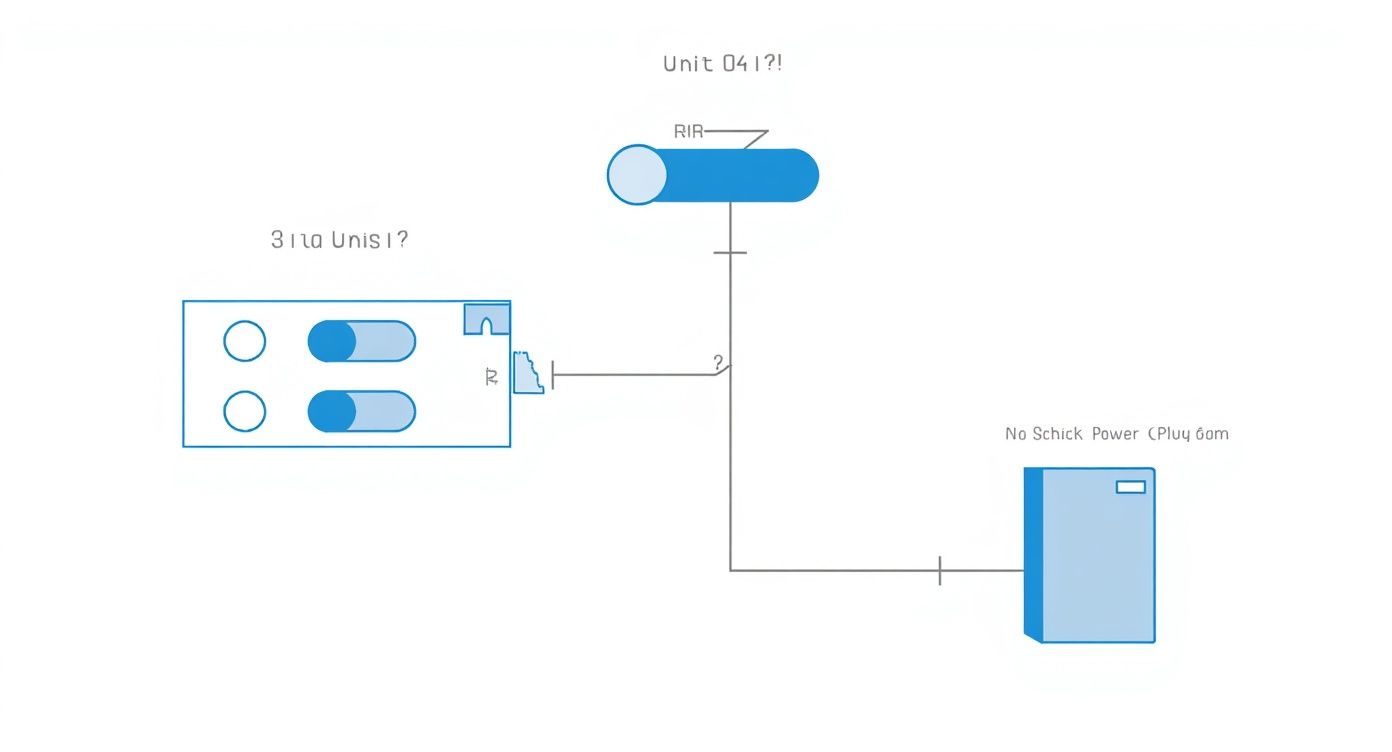

This simple decision tree can help you quickly diagnose common maintenance needs for your unit, starting with the most basic checks.

As you can see, troubleshooting often starts with the simplest stuff, like checking the power cord or inspecting the door gaskets, before you ever need to call a technician. A proactive approach to these small details will make sure your investment keeps working hard for your business, keeping your kitchen running smoothly day in and day out.

Frequently Asked Questions

When you're outfitting a commercial kitchen, the undercounter freezer refrigerator combo is your foundation for cold storage, but the stainless steel prep table you pair it with is what truly defines the workstation. Understanding the different types available is key to creating an efficient workflow.

What are the main types of stainless steel prep tables available?

In a professional kitchen, stainless steel prep tables are essential for their durability and hygiene. The most common is the standard worktop table, which offers a simple, flat surface perfect for general tasks like chopping vegetables or plating dishes. When you slide a combo unit underneath, you create a highly versatile prep station. For more specialized needs, there are also baker's tables, which may feature a wooden top for dough work, and chef bases, which are heavily reinforced low-profile tables designed to hold countertop cooking equipment while providing refrigerated storage below.

How do pizza prep tables differ from standard tables?

Pizza prep tables are specifically engineered for high-speed pizza assembly. Their defining feature is a raised, refrigerated rail on top, designed to hold pans of toppings like cheese, pepperoni, and vegetables, keeping everything chilled and within immediate reach. The main work surface is typically a wide expanse of marble or stainless steel, providing ample space for stretching dough. Placing an undercounter combo unit below—with the fridge holding backup sauces and dough and the freezer storing extra cheese and toppings—creates the ultimate pizza production line.

What makes sandwich prep tables unique?

Like pizza tables, sandwich prep tables are designed for assembly-line efficiency. They also feature a refrigerated top rail for condiments and fresh ingredients. The key difference is the integrated cutting board that often runs the full length of the table, providing a dedicated surface for slicing and building sandwiches. This setup is ideal for delis and cafes. Pairing it with an undercounter combo unit with multiple refrigerated drawers for organizing sliced meats and cheeses makes for an incredibly efficient workstation that can handle the busiest lunch rush.

Ready to build your ultimate prep station? At PrepTables.com, we offer a wide range of NSF-certified stainless steel prep tables and undercounter refrigeration to fit any kitchen's needs. Explore our collection and optimize your workflow today!