Under Counter Fridge Size Guide: Find the Right Fit for Your Kitchen

Share

Choosing the right under counter fridge size is the very first step toward a kitchen that just works. Getting it right means a smoother workflow and less frustration. Thankfully, most standard models are designed to slide neatly under a 36-inch countertop, with widths ranging anywhere from a slim 24 inches to a spacious 72 inches or more. There’s a perfect fit for almost any commercial space.

Decoding Standard Under Counter Fridge Dimensions

When you start looking at under counter refrigerators, the first numbers you’ll run into are the exterior dimensions: height, width, and depth. These are the make-or-break specs that determine if a unit will even physically fit into your designated spot.

Think of it this way: the dimensions are the foundation of your decision. If the unit doesn’t fit, all its fancy features and capacity don't matter. The goal is to find a fridge that slots into your line without causing traffic jams or forcing you into expensive countertop modifications. Getting this right from the start saves a world of headaches, time, and money.

Height The Universal Fit

Height is the most consistent dimension you'll find with under counter fridges, and for good reason. Most commercial models are built to a height between 32 and 34 inches. This isn't a random number—it’s specifically designed to let them slide comfortably under a standard 36-inch high commercial countertop.

That little bit of extra space leaves a crucial one-to-two-inch gap for the countertop material itself and any leveling adjustments you need to make. A perfectly level fridge is non-negotiable; it ensures the door seals tight, preventing energy waste and keeping those internal temperatures rock steady.

Width Tailoring to Your Space and Needs

Width is where you have the most variety, and it’s the dimension that most directly affects your storage capacity. Standard widths for under counter models can swing wildly, starting at a compact 24 inches and stretching all the way to 72 inches or more for the big three-door units.

The width you ultimately choose boils down to two things: how much physical space you have in your kitchen line and how much product you need to keep cold.

- Single-door units (24-30 inches): These are perfect for small cafes, coffee shops, or as a dedicated prep station with limited needs.

- Two-door units (48-60 inches): This is the sweet spot for many delis and mid-sized restaurants that need more chilled storage right at their fingertips.

- Three-door units (72+ inches): You’ll see these in high-volume kitchens where chefs need to grab large quantities of ingredients without missing a beat.

Depth Maximizing Workspace

When it comes to depth, most under counter refrigerators fall between 24 and 32 inches. This range is designed to align with standard commercial counter depths, creating that clean, flush workspace every chef loves.

The shallower models (around 24-27 inches) are great for saving precious floor space in tighter kitchens. On the other hand, deeper units (30-32 inches) give you a significant boost in internal storage. For a deeper dive, check out our complete guide to undercounter refrigerator dimensions.

The real appeal of these standard sizes is how easily they integrate into an existing kitchen. It’s no accident that these dimensions are so common; since around 2010, industry norms have pushed for sizes that fit into about 90% of base cabinets, making installation a breeze.

How to Measure Your Space for a Perfect Fit

Picking the right under counter fridge size is a lot like getting a custom suit made—if it's off by even a little bit, it just won't work. Before you get anywhere near clicking "buy," you need to grab a tape measure. It's the most important first step, and skipping it can lead to a massive headache of returns, restocking fees, and a completely messed-up workflow.

Think of it this way: measure twice, order once. This old saying will save you from the nightmare of trying to jam a fridge into a space it was never designed for. Let's walk through a simple checklist that covers more than just the basic height, width, and depth.

The Essential Measurement Checklist

First things first, measure the actual opening where the fridge is going to live. Don't eyeball it. You need exact numbers.

- Measure the Height: Run your tape measure from the floor to the bottom of the countertop. Do this in three different places—the left, the center, and the right. Floors and countertops are almost never perfectly level, so use the smallest measurement you get.

- Measure the Width: Next, do the same thing for the width of the opening, measuring from one side to the other. Again, take this measurement at the top, middle, and bottom, and use the narrowest figure you find.

- Measure the Depth: Finally, measure from the back wall to the front edge of the cabinets next to the opening. This is key to making sure your new fridge won't stick out and block a busy walkway.

Once you have these three numbers, you've got your starting point. But don't stop there. The next step is the one most people forget, and it's what keeps your fridge from burning out.

Crucial Insight: You absolutely have to account for ventilation. A fridge's compressor creates heat, and if that heat can't escape, the unit will overwork itself. That leads to a shorter lifespan and expensive repairs down the road. A little breathing room makes all the difference.

Planning for Ventilation and Delivery

Ventilation is the lifeblood of any refrigeration unit. It's one of the most common—and most costly—mistakes I see people make.

- Rear-Breathing Models: Most standard under counter fridges are rear-breathing. They absolutely need at least 1-2 inches of clearance on the sides and another 2-3 inches at the back to get rid of heat. You have to add these buffer inches to the fridge's listed dimensions to know the true amount of space you need.

- Front-Breathing Models: These units are the go-to for seamless, built-in looks. They pull in cool air and push out hot air through a grille right on the front, so they don't need clearance on the sides or back. They cost a bit more, but they’re perfect for tight spots and custom cabinetry.

Beyond the spot where it will be installed, you have to measure the entire path the delivery team will take. Can the fridge actually make it into your kitchen? Measure the width of every doorway, hallway, and any tight corners it has to get around. There’s nothing worse than having a shiny new appliance stuck in your lobby.

For those of us working in tighter quarters, making every inch count is a big deal. A good guide to renovating small space kitchens for maximum efficiency can be a lifesaver. Taking these extra steps ensures your installation is smooth sailing, from the delivery truck all the way to its new home under the counter.

Translating Cubic Feet into Real-World Storage

The manufacturer's spec sheet will give you the external dimensions, telling you if a fridge will physically slide into your kitchen line. But the number that really matters for your business is the internal capacity, measured in cubic feet. That number can feel a bit abstract, but getting it right is the key to an efficient kitchen and avoiding daily inventory headaches.

Think of it like the trunk of a car. A number tells you the space, but it doesn't tell you how many bags of groceries or suitcases you can actually fit inside. It’s the same with your fridge. A 7 cu. ft. model might sound tiny, but it could be the perfect workhorse for a small coffee shop's milk and cream supply. On the flip side, a busy deli will need something closer to 15 cu. ft. just to handle their bulk meats and cheeses.

Visualizing Your Storage Needs

The trick is to stop thinking in cubic feet and start thinking in food pans, sauce bottles, and tubs of prepped ingredients. The under counter fridge size you choose directly impacts how much product you can keep chilled and ready to go when the orders start flying in.

Here’s a practical breakdown:

- Small Capacity (5-7 cu. ft.): Perfect for holding a few full-size hotel pans of prepped veggies, a solid selection of sauces, or backup beverages. This size is a champion for a dedicated prep station.

- Medium Capacity (8-12 cu. ft.): This range gives you more breathing room. It can handle multiple stacks of food pans, larger dairy containers, and all the fixings for a busy sandwich or salad station.

- Large Capacity (13-19+ cu. ft.): Built for high-volume kitchens. These units can hold bulk items, entire cases of drinks, and numerous full-size pans, which means fewer trips to the walk-in during a chaotic service.

One of the most common mistakes I see is chefs buying a fridge based on the empty floor space they have, not the volume of food they actually need to store. A fridge that's too small gets over-stuffed, and that blocks airflow, leading to dangerous temperature fluctuations.

Before you buy, map out your daily inventory. How many pans of chopped lettuce, sliced tomatoes, or portioned proteins do you go through during a lunch rush? Answering that question will give you a much clearer idea of the capacity you truly need.

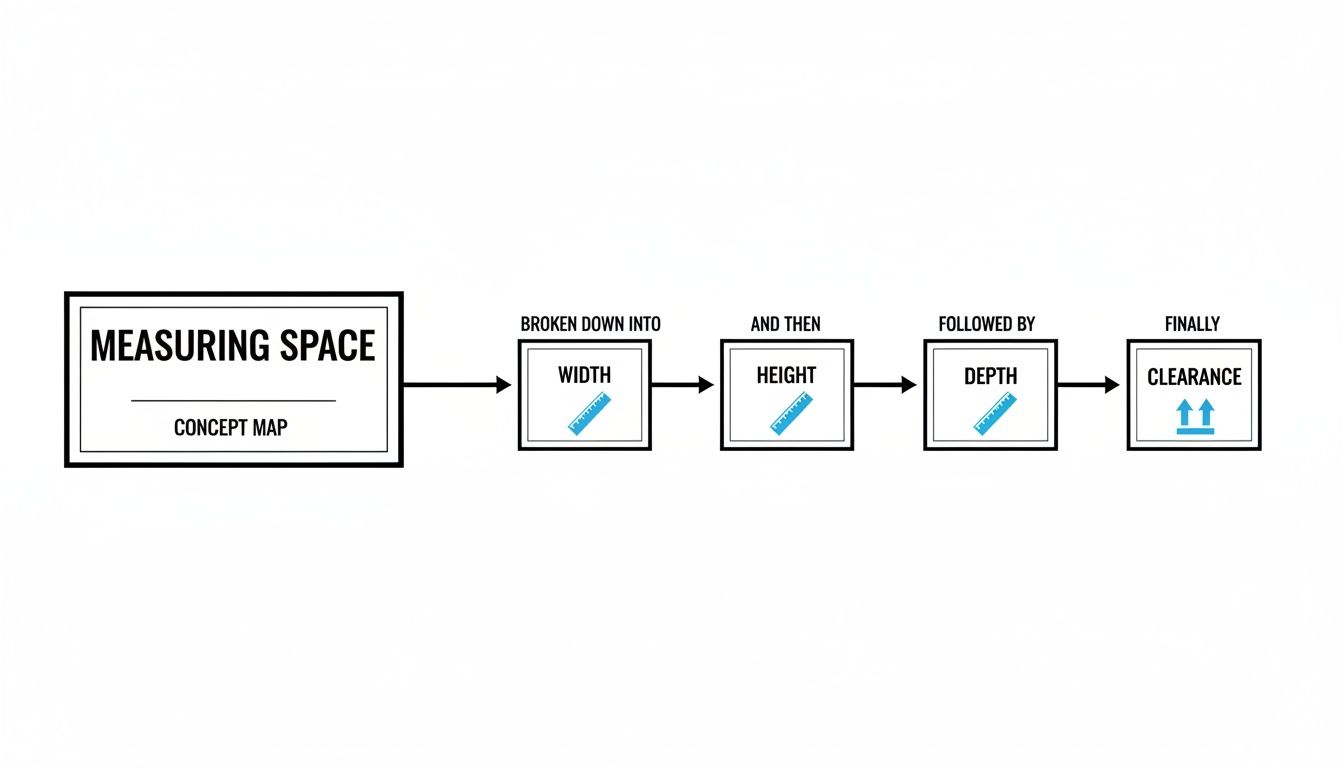

This quick guide covers the basics of measuring your space—something you have to get right before you even think about capacity.

As you can see, getting the width, height, and depth is just the start. That extra clearance for ventilation is non-negotiable for a successful installation.

Matching Capacity to Modern Kitchen Trends

Picking the right capacity isn't just about your menu today; it’s about keeping up with where the industry is headed. Across North America and Europe, kitchens are getting smaller. This has made compact, efficient refrigeration more popular than ever, especially in the US and Germany where operators want smart features and energy-saving designs.

It’s no surprise that models in the 5-10 cubic feet capacity range are dominating the market, pulling in about 50% of the revenue share. They hit that sweet spot between providing enough storage and fitting into tight spaces.

But capacity is only part of the puzzle. Think about how the unit fits into your kitchen's overall workflow. A great under-counter fridge should make your life easier, not harder. It’s always a good idea to look into smart kitchen storage solutions for small spaces to see how you can maximize every square inch.

Ultimately, you want an under counter fridge size that supports your operation. By visualizing your inventory and understanding the trends, you can land on a choice that boosts both your efficiency and your bottom line.

From Simple Coolers to Specialized Stainless Steel Prep Tables

The term "undercounter" isn't just about simple chilled boxes anymore. It’s grown to include a whole family of specialized stainless steel workstations that blend refrigeration with vital prep space, turning a single footprint into an efficiency powerhouse.

While a standard undercounter fridge is a versatile workhorse for general storage, you need something more when you’re assembling sandwiches, salads, or pizzas at lightning speed. That's where specialized prep tables come in. They're not just built for cold storage; they're engineered for workflow. These units are almost universally constructed from stainless steel for its durability, ease of cleaning, and resistance to corrosion—a must-have in any commercial kitchen.

Standard Undercounter Fridges and Freezers

This is the foundation of the category. A standard undercounter refrigerator or freezer offers a chilled stainless steel cabinet with solid or glass doors. Their main job is straightforward: bulk storage. They keep ingredients cold and ready right where you need them.

Their dimensions are usually what you'd expect, fitting neatly under commercial countertops with typical widths from 24 to 72+ inches and depths between 24 to 32 inches. The real decision here is balancing capacity against your available footprint. You’re giving up a bit of floor space to gain immediate access to ingredients, which means fewer trips to the walk-in.

Sandwich and Salad Prep Tables

A sandwich prep table (often called a salad prep table) is a complete stainless steel workstation. It combines a refrigerated base with a cutting board surface and a refrigerated rail on top to hold all your food pans. This design keeps everything from sliced meats and cheeses to fresh veggies chilled and within arm's reach.

The dimensions are perfectly tailored for the job.

- Depth: These tables are usually a bit shallower than their pizza-making cousins, with depths typically between 27 to 30 inches. This makes it easy for staff to reach ingredients at the back of the topping rail without straining.

- Width: They come in a wide range of widths, from 27 to 72 inches, so you can find one that fits a small deli just as well as a massive institutional kitchen.

- Topping Rail: The top rail is built to hold standard hotel pans (like 1/6-size pans), which makes swapping out ingredients and managing inventory a breeze.

Key Takeaway: A sandwich prep table is all about minimizing movement. By putting storage, prep space, and ingredients in one spot, you can slash assembly times and boost order accuracy during the lunch rush.

Pizza Prep Tables

Pizza prep tables are the heavy-duty relatives of sandwich tables, built from durable stainless steel to withstand the demands of a high-volume pizzeria. The concept is the same—refrigerated base, topping rail—but everything is scaled up.

Here’s how their sizing is different:

- Deeper Work Surface: This is the biggest giveaway. Pizza prep tables have a much deeper work surface, often from 32 to 36 inches. That extra real estate is crucial for stretching and saucing large pizza pies without feeling cramped.

- Raised Topping Rail: The refrigerated rail is often raised higher than on a sandwich table. This creates a more comfortable angle for working on the main surface below.

- Dough-Friendly Refrigeration: Many models feature refrigeration systems designed to keep humidity a bit higher, which is perfect for storing pizza dough without it drying out.

Understanding these key differences is essential. For a deeper dive into these specialized units, check out our guide on commercial refrigerated prep tables.

Comparing Undercounter Prep Table Sizes and Features

To make it even clearer, let's break down how these stainless steel units stack up. Seeing the specs in one place can really help you visualize which one fits your kitchen's needs.

| Unit Type | Common Widths (Inches) | Common Depths (Inches) | Key Features | Primary Use Case |

|---|---|---|---|---|

| Standard Undercounter | 24 - 72+ | 24 - 32 | Basic refrigerated cabinet, solid or glass doors | General bulk ingredient storage at point-of-use |

| Sandwich/Salad Prep Table | 27 - 72 | 27 - 30 | Integrated cutting board, top rail for food pans | High-speed assembly of sandwiches, salads, bowls |

| Pizza Prep Table | 44 - 100+ | 32 - 36 | Extra-deep work surface, raised topping rail | Prepping large pizzas with numerous toppings |

Ultimately, the choice boils down to your menu and your workflow. If you just need cold storage, a basic undercounter fridge is a great choice. But for any kind of high-volume assembly line, investing in a specialized stainless steel prep table with the right under counter fridge size will pay you back every single shift.

Installation Tips for Peak Performance and Longevity

Getting the right under counter fridge size is half the battle, but a perfect installation is what makes sure that investment pays off for years to come. A sloppy setup is a one-way ticket to an overworked compressor, shaky temperatures, and a fridge that dies way too soon. This is where we go from planning on paper to getting it right on the kitchen floor.

Think of it like laying the foundation for a house. If it’s not level, solid, and given space to breathe, you’re just asking for trouble down the road. Nail these next steps, and you’ll be rewarded with a longer-lasting unit, a smoother workflow, and lower energy bills.

The Critical Role of Ventilation

If you only remember one thing from this guide, make it this: ventilation is everything. Your fridge's compressor is constantly working to pump heat out of the cold box, and that hot air has to go somewhere. Block the airflow, and you’re essentially forcing your fridge to run a marathon in a winter coat. It’s going to overheat, burn out, and fail.

This is why you have to know what kind of model you're dealing with. There are two main designs, and getting them mixed up is a costly mistake.

-

Front-Breathing Models: These are the pros of tight-squeeze installations. They pull in cool air and push out hot air through a grille right on the front, usually near the floor. This clever design means you can slide them flush into cabinetry without worrying about leaving a gap on the sides or back.

-

Rear-Breathing Models: These are the more traditional—and often more affordable—workhorses. They get rid of heat through coils on the back. For these models, open space is non-negotiable. If that hot air gets trapped, the compressor will run nonstop, sending your energy bills through the roof before it eventually gives up for good.

Expert Tip: Don't guess—check the manufacturer's spec sheet. As a rule of thumb, a rear-breathing fridge needs at least 1-2 inches of breathing room on the sides and another 2-3 inches at the back. Skimping on this can easily void your warranty.

Achieving a Perfectly Level Surface

A wobbly fridge isn't just an eyesore; it's a mechanical problem waiting to happen. When the unit isn't perfectly flat, the door gaskets won't create a tight seal. Even a tiny gap lets cold air seep out and warm, humid air sneak in. This creates a double-whammy of trouble.

First, your compressor has to work overtime to fight the warm air, which is a massive waste of energy. Second, all that moisture coming in condenses and forms ice, which can ruin your ingredients and make you defrost the unit way more often.

Grab a spirit level and place it on top of the fridge. Tweak the adjustable feet until that little bubble is dead center, checking both front-to-back and side-to-side. It’s a five-minute job that will save you countless headaches.

Electrical and Placement Considerations

Finally, let’s talk power and position. These are the last pieces of the puzzle, but they’re just as important. Commercial fridges are powerful beasts that pull a lot of juice, especially when the compressor cycles on.

-

Dedicated Circuit: Your under-counter fridge needs its own dedicated electrical circuit. Period. If you plug it into a circuit shared with a microwave, blender, or toaster, you're risking an overload. A tripped breaker means a dead fridge, which is the last thing you need during a busy service.

-

Avoid Heat Sources: It sounds obvious, but you’d be surprised. Keep your fridge away from heat-generating equipment like ovens, fryers, and griddles. The hotter the air around the fridge, the harder it has to work to stay cool. Smart kitchen design is your first line of defense for equipment longevity.

A proper installation is the first and most important step in taking care of your equipment. To keep everything in your kitchen running smoothly, check out our guide on commercial kitchen equipment maintenance for more pro tips.

Common Questions About Under Counter Fridge Sizing

Picking out an under counter fridge size always brings up a bunch of questions. Getting the right answers upfront is the key to avoiding a costly headache and making sure your new cooler fits right into your kitchen's flow. We've rounded up the questions we hear most often from operators to help you make a decision you'll be happy with.

Think of this as your cheat sheet. We're covering the big questions about sizing, installation, and daily use to solve those little problems before they turn into big ones.

What Is the Standard Height of an Under Counter Fridge?

Most commercial undercounter refrigerators are built to stand between 32 and 34 inches tall. This isn't a random number—it's designed that way so the unit can slide perfectly under a standard 36-inch commercial countertop.

That little bit of wiggle room accounts for the thickness of your countertop and gives you space to make any leveling adjustments. It's always a smart move to pull out the tape measure and check your actual counter height before you buy. Custom kitchens or older spots can sometimes have funky dimensions that'll trip you up.

How Much Ventilation Space Does My Undercounter Fridge Need?

The breathing room your fridge needs comes down to its design, and it’s a detail you can’t afford to ignore. Some models are "front-breathing," meaning they have grilles on the front to pull air in and push it out. These are great because you can build them right into your cabinetry or push them flush against a wall.

But the more common "rear-breathing" units need space to work properly. They need room to get rid of heat so the compressor doesn't burn itself out.

As a rule of thumb, plan on leaving at least 1-2 inches of space on the sides and another 2-3 inches at the back. But always, always check the manufacturer’s spec sheet for the exact numbers. Following their guide keeps your unit running efficiently and keeps your warranty valid.

Skimping on ventilation is one of the top reasons these units fail early. It makes the compressor work way too hard, which means higher energy bills and a much shorter life for your fridge.

Can I Use a Residential Undercounter Fridge in a Commercial Kitchen?

Putting a residential fridge in a commercial kitchen is something we strongly advise against. While the under counter fridge size might look about the same on the outside, what’s going on inside is a completely different story.

Commercial units are built tough, with things like high-grade stainless steel and compressors that are absolute workhorses. They’re designed to handle the heat and chaos of a professional kitchen, where doors are constantly flying open during a busy service. A residential model just can't keep up; it will likely die a quick death, your warranty will be void, and you could even get hit with a health code violation for using non-NSF-certified gear.

Should I Choose a Solid Door or a Glass Door Fridge?

Deciding between a solid and a glass door is really a choice between energy savings and workflow speed. It’s a strategic call that affects how your team uses the cooler every single day.

- Solid Doors: These are the champs of insulation, which makes them much more energy-efficient. They’re the perfect pick for back-of-house storage where you don't need to see what's inside all the time. They do a fantastic job of holding a steady temperature, even in a hot kitchen.

- Glass Doors: These are ideal for your front-of-house area or busy prep lines where your crew needs to spot ingredients in a split second. Being able to see inside before opening the door cuts down on how long it's open, which is a huge help for keeping things cool during a rush.

Just think about what you're using it for. If it’s for stocking up on bulk items, a solid door is probably the smarter, more economical choice. But if it's for a fast-paced prep station where every second matters, the visibility of a glass door can make your whole line more efficient.

How Do I Know if I Need a Specialized Prep Table?

If your menu is heavy on things that need assembly—like sandwiches, salads, or pizzas—a standard undercounter cooler just isn't going to cut it. That's your cue to look at a specialized prep table, which combines refrigeration with a workspace right on top.

- Sandwich Prep Tables: These come with a cutting board and a refrigerated rail on top to hold all your pans of ingredients. They're usually around 27-30 inches deep, making everything easy to reach.

- Pizza Prep Tables: These are built bigger for obvious reasons. They have a deeper work surface, often 32-36 inches, to handle large pizza doughs, and the rail is set up for all your toppings.

The choice is all about your workflow. If your team is constantly grabbing things from a regular fridge, walking them over to a counter, and then putting it all together, a prep table streamlines that entire dance into one station. It’s a real investment in making your kitchen run smoother.

Ready to find the perfect fit for your kitchen? The experts at PrepTables.com offer a wide selection of undercounter refrigerators and specialized prep tables to meet any commercial need. Explore our collection and enhance your kitchen's efficiency today at https://preptables.com.