A Practical Guide to Top Rated Commercial Refrigerators

Share

When you're shopping for top rated commercial refrigerators, it's easy to get fixated on the price. But the real value isn't in the upfront cost—it's in the features that keep your business running smoothly day in and day out. A truly 'top rated' unit delivers in four key areas: hardcore durability, the right certifications (like NSF and Energy Star), rock-solid cooling, and a smart design that actually helps your kitchen flow.

What Makes a Commercial Refrigerator Top Rated

Think of a commercial refrigerator as more than just a cold box. It’s a workhorse that has a direct line to your profits and how efficiently your kitchen operates. The big difference between a basic unit and a top-rated one is its ability to take a beating in a pro kitchen while putting money back in your pocket. A great refrigerator means less food spoilage, lower energy bills, and no headaches with the health inspector, making it one of the smartest investments you can make.

This is more important than ever, given how much the market for these appliances is growing. The commercial refrigeration scene in the U.S. is set to jump from USD 8.3 billion in 2025 to a massive USD 12.2 billion by 2035. That boom tells you just how much restaurants, delis, and food trucks are relying on high-quality units. You can dive deeper into the data on the U.S. commercial refrigeration market to see how these trends are playing out.

The Four Pillars of a Top Rated Unit

To spot a commercial refrigerator that’s truly a cut above the rest, you need to check for four things. These are the pillars that separate the dependable workhorses from the ones that will let you down. Each one plays a direct role in making your kitchen more efficient, compliant, and profitable.

- Robust Durability: It all starts with the steel. You want a unit made from a lower gauge of stainless steel—18-gauge or lower is ideal. A lower number means the metal is thicker and tougher, so it can stand up to the dents, dings, and spills of a hectic kitchen without rusting or falling apart.

- Essential Certifications: These are not optional. An NSF (National Sanitation Foundation) seal means the unit is designed for easy cleaning and meets strict public health standards. At the same time, an Energy Star logo confirms it meets federal efficiency guidelines, which translates directly to savings on your utility bill.

- Consistent Performance: The compressor is the heart of the machine. A top-tier unit will have a powerful, high-quality compressor that holds a steady temperature, even when the doors are swinging open and shut during a dinner rush. That reliability is what keeps your food out of the temperature "danger zone."

- Intelligent Design: The little things make a big difference in a busy workflow. Look for features like self-closing doors, adjustable shelves that fit your specific products, easy-to-read digital temperature controls, and simple-to-clean parts like removable door gaskets. They save time and cut down on staff headaches.

In the end, a top-rated commercial refrigerator isn't just another piece of equipment; it's a strategic part of your business. When you invest in a unit that nails these four areas, you're setting your kitchen up for success, keeping your food safe, and protecting your profits from waste and high energy costs.

Comparing The Core Commercial Refrigerator Types

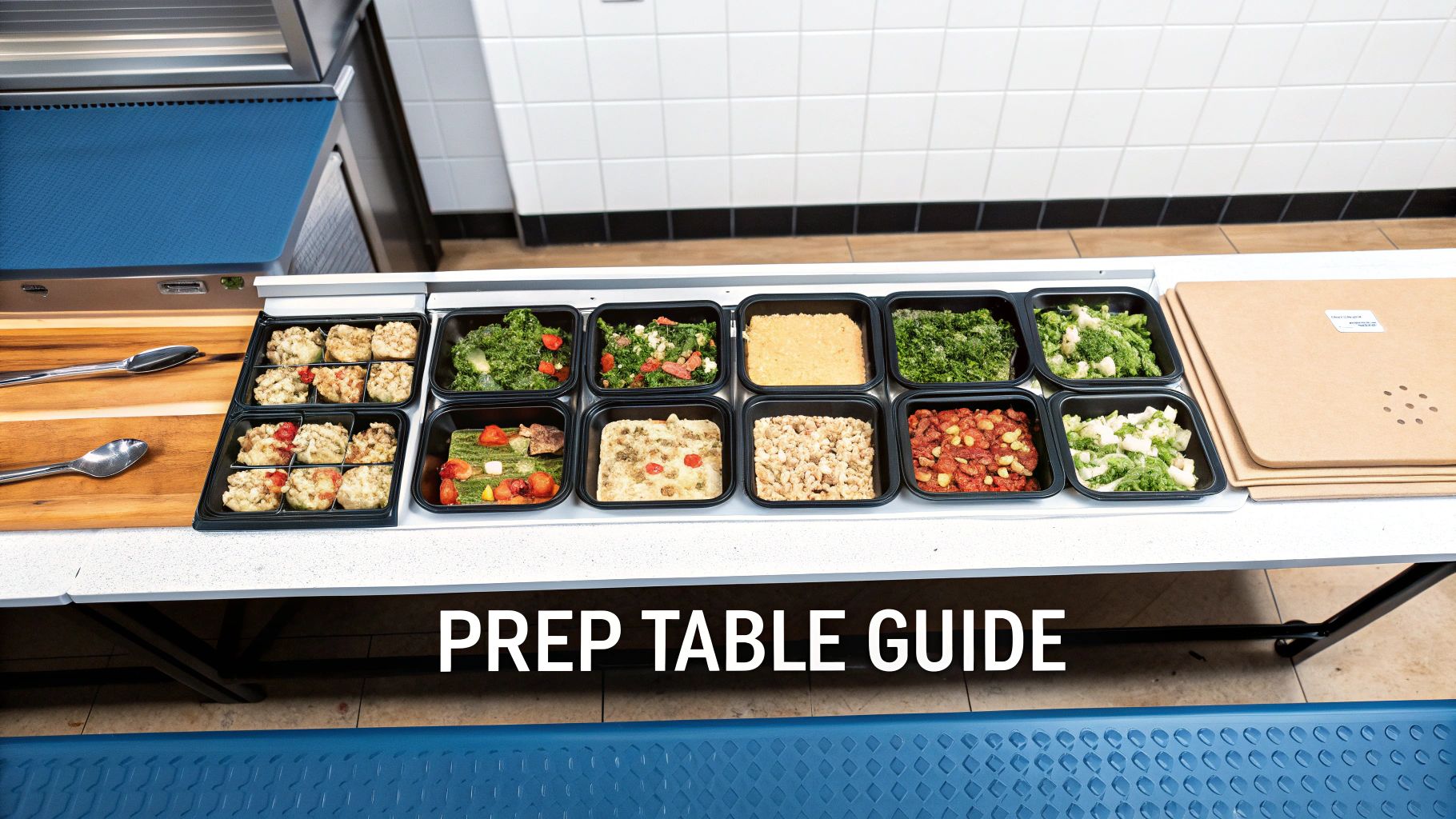

Choosing the right commercial refrigerator isn’t just about finding a cold box; it’s about making a strategic investment in your kitchen’s workflow. The perfect unit for your business comes down to your menu, your kitchen’s layout, and how fast you need to serve customers. Getting a handle on the key differences between reach-ins, undercounter models, and specialized prep tables is the first real step to picking a workhorse that actually helps your team, not hinders it.

The North American market for this gear is enormous, commanding a massive 50% of the global share. It's projected to hit a value of USD 40.89 billion by 2034, which tells you just how vital these investments are for anyone in the foodservice game. This trend really drives home the need to choose durable, top-rated stainless steel units built to withstand the pressure.

The infographic below breaks down what really matters—durability, certifications, and solid performance—when we talk about a "top-rated" commercial refrigerator.

As you can see, things like high-grade steel and the right certifications aren't just details; they're the foundation of a unit's long-term value and reliability.

To give you a clearer picture, this table compares the main refrigerator types side-by-side, helping you match the right equipment to your specific operational needs.

Commercial Refrigerator Comparison Framework

| Refrigerator Type | Primary Use Case | Ideal Environment | Typical Capacity Range | Workflow Integration |

|---|---|---|---|---|

| Reach-In | Bulk cold storage for ingredients and prepared foods. | Back-of-house, walk-in overflow, general storage areas. | 20-70+ cu. ft. | Central storage hub; requires staff to walk to it. |

| Undercounter | Point-of-use refrigeration for frequently accessed items. | Underneath counters at bars, coffee stations, or small prep areas. | 2-15 cu. ft. | Decentralized; puts cold items right where they're needed. |

| Prep Table | Integrated prep surface and ingredient refrigeration. | Assembly lines for sandwiches, salads, pizzas, and burritos. | 7-30+ cu. ft. | The ultimate workflow tool; combines prep and storage. |

| Walk-In | High-volume storage for bulk inventory, cases, and boxes. | Dedicated space, typically in the back-of-house. | 100-1000+ cu. ft. | The kitchen's main inventory hold; feeds all other units. |

Each type serves a distinct purpose. The key is understanding how they fit together to create a smooth, efficient kitchen.

The Power Of Stainless Steel Prep Tables

When you need to get food out fast, stainless steel prep tables are an absolute game-changer. These units are a hybrid, combining a tough work surface with other functionalities to streamline kitchen workflow. While some are simple, non-refrigerated work surfaces, many integrate refrigeration, making them indispensable for high-speed service. This simple but brilliant design puts ingredients and workspace in one spot, cutting out wasted steps. The result? Faster service, more consistent dishes, and tighter food safety.

A strategically placed refrigerated prep table can slash assembly time for items like salads and sandwiches by up to 30%. That translates directly to faster ticket times and happier customers during a chaotic lunch rush.

These units are mission-critical for any business that relies on quick, on-demand assembly. They aren't one-size-fits-all, either. They're engineered for specific menus, making sure the layout and features are a perfect match for the job at hand. For a deeper dive, check out our guide on the best commercial refrigerators for your business.

Sandwich and Salad Prep Tables: The Versatility Kings

Sandwich and salad prep tables are all about instant ingredient access. What makes them unique is the refrigerated top rail designed to hold multiple food pans, usually standard 1/6 or 1/9 sizes. This layout lets your crew grab dozens of different toppings, sauces, and proteins without ever taking a step.

These units almost always come with a cutting board that runs the full length of the table, creating a self-contained assembly line. If you see a "mega-top" model, that just means it has a deeper rail, often with three rows of pans instead of two. It's a lifesaver for high-volume delis or build-your-own concepts. The refrigerated base underneath is there for bulk storage, so you can keep the line stocked and moving during your busiest hours.

Pizza Prep Tables: Built for Dough and Toppings

At a glance, pizza prep tables look similar, but they’re built differently to handle the specific needs of a pizzeria. The main difference is the top rail. It's raised and refrigerated, but it's designed to hold larger, deeper food pans. That extra depth is crucial for bulky ingredients like mounds of shredded cheese, vats of sauce, and other core pizza toppings.

On top of that, the cutting board on a pizza prep table is much deeper than what you’ll find on a sandwich unit. This gives you plenty of real estate to stretch and top large pizza doughs, from personal pies all the way up to an extra-large. The refrigerated base is also set up differently, often configured to hold stacks of dough boxes and full-size sheet pans. It’s a complete, all-in-one pizza station that any serious pizzeria can't live without.

A Closer Look at Refrigerated Prep Tables

When it comes to kitchen efficiency, refrigerated prep tables are the undisputed champions. They merge cold storage and a dedicated workspace into a single, compact unit that can transform your entire operation. For any business that relies on rapid assembly—think delis, pizzerias, or fast-casual salad spots—these tables aren't just a convenience. They're essential for maintaining speed, consistency, and most importantly, food safety.

The genius is in the hybrid design. You get a refrigerated base for bulk storage, a tough cutting board surface right on top, and a refrigerated rail to hold pans of ingredients right at your fingertips. This all-in-one station turns a potentially chaotic prep process into a streamlined assembly line, which is exactly what you need to survive a lunch or dinner rush.

But it's crucial to understand that not all prep tables are built the same. The small design differences between a sandwich prep table and a pizza prep table are significant, with each one fine-tuned for a specific menu and workflow. Getting this choice right is key to buying a unit that will actually help your team, not hinder it.

Sandwich and Salad Prep Tables for Diverse Ingredients

Sandwich and salad prep tables are engineered for menus that juggle a wide variety of fresh, smaller-portioned ingredients. Their defining feature is a refrigerated rail built to hold multiple rows of standard food pans, usually 1/6-size or 1/9-size. This setup gives chefs instant access to dozens of different toppings, proteins, and sauces without taking a single step.

These tables almost always come with a full-length cutting board, creating a single, dedicated space for building out orders. You'll also see "mega-top" models on the market. These feature an extra-deep rail that can hold three rows of pans instead of two, giving high-volume shops maximum ingredient capacity.

The layout of a sandwich prep table directly impacts order accuracy and speed. When every topping is visible and within arm's reach, kitchens see fewer mistakes and can push orders out the door faster. That leads directly to happier customers.

The refrigerated cabinet below provides the backup storage you need to quickly restock the top rail during peak hours. This ensures the assembly line never has to grind to a halt—a vital detail for any busy restaurant.

Pizza Prep Tables for High-Volume Dough Work

At first glance, pizza prep tables look similar, but they're fundamentally different beasts. They are built specifically for the unique demands of a pizzeria. The most critical distinction is the raised, refrigerated rail, which is designed to hold larger, deeper food pans for bulky items like shredded cheese, gallons of sauce, and other core pizza toppings.

Another key difference is the cutting board. On a pizza prep table, the cutting board is much deeper—often 19 inches or more. This gives you plenty of space to stretch, sauce, and top large pizza doughs, which is non-negotiable for any shop handling everything from personal pies to extra-large family pizzas.

The refrigerated base is also configured differently, typically designed to hold full-size sheet pans and stacks of dough boxes. This keeps every essential component for pizza-making in one consolidated station. For a deeper dive, you can learn more about commercial refrigerated prep tables and their specific features.

Key Features That Define Performance

Beyond the basic type, a few key features determine how well a refrigerated prep table will actually perform in a real kitchen. Paying attention to these details can be the difference between a reliable workhorse and a constant headache.

- Cutting Board Material: Most units come with a standard polyethylene cutting board, which is durable and easy on your knives. However, composite boards are gaining popularity for being even more durable and stain-resistant, though they usually cost a bit more.

- Rail Design: A raised rail, common on pizza tables, often provides better airflow and keeps pans at a more consistent temperature. A flush rail on a sandwich table creates a seamless workspace but needs a well-designed lid to maintain food-safe temperatures.

- Stainless Steel Gauge: Just like with any other top rated commercial refrigerators, the steel gauge matters. A lower gauge (like 18-gauge) means the steel is thicker and more durable. It'll stand up to the dents and dings of a busy kitchen, ensuring a longer life for your investment.

Matching Refrigerator Features to Your Kitchen Needs

Choosing one of the top rated commercial refrigerators isn't about finding the "best" one on the market. It's about finding the right one for your specific kitchen. The perfect refrigerator for a massive hospital kitchen is completely wrong for a tiny food truck, and vice versa.

When you match key features to the real-world demands of your space, you're investing in a tool that actually makes your kitchen more efficient, protects your inventory, and supports your team. A common mistake is getting hung up on capacity alone. A much smarter way is to look at your daily workflow and figure out which features solve your biggest headaches. This means going beyond cubic feet and looking at things like compressor power, ventilation design, and shelving.

Scenario One: The Compact Food Truck

A food truck kitchen is a masterclass in organized chaos. Space is incredibly tight, and the operating conditions can be brutal. Ambient temperatures can soar during a summer lunch rush, putting a massive strain on any refrigeration system. Here, an undercounter unit is usually the only practical choice, but you can't just grab any model off the shelf.

The number one priority has to be raw cooling power and sheer durability. The compressor’s ability to handle high ambient heat is non-negotiable. You need a unit with a beast of a compressor and excellent insulation to hold safe temperatures when the world outside is working against it. This is what prevents food spoilage and keeps you serving safely all day.

Food Truck 'Must-Have' Feature Checklist:

- High-BTU Compressor: This is your first line of defense against the high ambient heat inside the truck. A powerful compressor ensures the unit won't burn itself out trying to keep up.

- Durable Stainless Steel Exterior (18-Gauge or Lower): The fridge has to survive constant vibration, movement, and the inevitable bumps and dings that come with working in a cramped space.

- Front-Breathing Ventilation: With zero clearance on the sides and back, a front-venting design is a must. It lets the unit be installed flush against walls without the risk of overheating.

- Heavy-Duty Casters: Being able to move the unit is key for deep cleaning and service in such a confined kitchen.

Scenario Two: The Bustling Sandwich Shop

For a busy deli or sandwich shop, the entire game is about speed and instant access to ingredients. Every single second you can shave off during the lunch rush means more sales and happier customers. The right refrigerator here isn't a storage box in the back—it's a mega-top prep table that acts as the command center for the whole assembly line.

The single most important feature is maximizing the number of cold ingredient pans right on the prep line. A mega-top design gives you an entire extra row of pan storage compared to standard models, which is a huge advantage. It lets you offer a more diverse menu and cuts down on how often you have to restock ingredients during your busiest hours.

By keeping dozens of ingredients perfectly chilled and within arm's reach, a mega-top prep table can reduce order assembly time by 20-30%. This efficiency gain is crucial for maximizing throughput during the busiest parts of the day.

The focus here is purely on optimizing workflow. The unit has to create a seamless, non-stop flow from the ticket printer to the finished sandwich.

Scenario Three: The Large Institutional Kitchen

An institutional kitchen, like one in a hospital or university, operates on a totally different scale. The main goal here is massive, organized bulk storage. In this world, a multi-door reach-in refrigerator is the undisputed workhorse, responsible for safely holding thousands of dollars worth of diverse inventory.

The most critical feature is adjustable, heavy-duty shelving. Your staff has to be able to reconfigure the interior on the fly to fit everything from giant stockpots and full-size sheet pans to small containers of prepped produce. Another vital feature is a digital temperature alarm, which provides an immediate alert if the internal temperature drifts out of the safe zone—an absolute necessity in environments where food safety is the highest priority. To ensure your chosen refrigerator integrates seamlessly, consider its role within the broader setup of an essential coffee shop equipment list, as the principles of workflow and integration apply across many foodservice settings.

How to Maximize Your Refrigerator's Lifespan and Efficiency

Choosing one of the top-rated commercial refrigerators is a solid first move, but protecting that investment is where you really impact your bottom line. A smart purchase is just the start; proper maintenance and daily operational habits are what turn a great appliance into a long-term asset. This means you can't just "set it and forget it"—you need a proactive plan for upkeep.

Consistent care doesn't just extend your unit's life. It also keeps it running at peak efficiency, which helps control your energy bills and keeps your food inventory safe. Simple, routine tasks can prevent most common equipment failures, saving you the headache and expense of emergency repairs down the road.

Routine Maintenance Checklist

Following a straightforward maintenance schedule is the secret to getting the most out of your refrigerator's lifespan. These tasks are simple enough for any kitchen staff to handle and are your best defense against costly breakdowns. Making these checks part of your weekly and monthly routines is absolutely crucial.

- Clean Condenser Coils Monthly: The condenser coils are what release heat from the unit. When they get clogged with dust, grease, and grime, the compressor has to work much harder, wasting energy and leading to early failure. A quick brushing once a month is all it takes.

- Inspect Door Gaskets Weekly: A worn or cracked door gasket is a major energy drain, allowing cold air to escape and forcing the unit to run constantly. Wipe them down daily and check for a tight seal by closing the door on a piece of paper—if it slides out easily, it's time for a replacement.

- Adhere to Sanitation Protocols: Regular cleaning of the interior and exterior not only stops bacteria growth but also helps you maintain that all-important NSF certification. This includes wiping up spills immediately and sanitizing surfaces according to health code standards.

For a more detailed breakdown, you can learn more about a complete commercial kitchen equipment maintenance plan that covers all your bases.

Analyzing the Total Cost of Ownership

The sticker price of a refrigerator is just one part of the story. The total cost of ownership (TCO) includes the initial purchase price plus all the energy and maintenance costs over the unit's entire life. This is where an Energy Star certified model really proves its worth, showing how a slightly higher upfront investment can lead to significant long-term savings.

An Energy Star certified commercial refrigerator can be 10-20% more efficient than a standard model, potentially saving a business hundreds of dollars per year on utility bills. Over a decade, these savings can easily surpass the initial price difference.

Let's look at a practical example. Imagine Unit A costs $2,500 and uses $600 in electricity annually. Unit B, an Energy Star model, costs $3,000 but uses only $450 per year.

While Unit A is cheaper at first, Unit B saves you $150 every single year. In just over three years, the energy savings completely pay back the initial $500 price difference. After that, it’s pure savings in your pocket.

Understanding how to select and maintain equipment for optimal energy consumption is crucial. For general insights on cutting energy costs, you might find this guide on efficient equipment choices useful. This long-term financial view empowers you to make a sound decision that benefits your bottom line for years to come.

Answering Your Top Questions About Commercial Refrigerators

Picking out the right commercial refrigerator is a big decision, and it’s normal to have a few questions. Getting straight answers is key to making an investment you’ll be happy with for years to come. We’ve gathered some of the most common technical and practical questions we hear from business owners just like you.

Think of this as your quick-reference guide to clearing up those final details. Our goal is to help you feel confident that the unit you choose is a perfect match for your kitchen and your business.

What Is the Difference Between a Top-Mount and Bottom-Mount Compressor

Where the compressor sits on your refrigerator really changes how it performs and how you maintain it. A top-mount compressor is located at the very top of the unit. This placement is great because it keeps the compressor away from all the dust, grease, and debris that collects on a kitchen floor, which can improve its efficiency and mean you don't have to clean the coils as often.

On the other hand, a bottom-mount compressor is at the base. This design usually makes it easier for technicians to get to for routine service. It also raises the bottom shelf to a more comfortable, ergonomic height for your staff. The downside? It can pull in more floor dirt and might vent warm air right into your kitchen, which is something to think about in already hot environments.

Why Is NSF Certification Crucial for Kitchen Equipment

When it comes to kitchen equipment, NSF (National Sanitation Foundation) certification isn’t just a nice-to-have—it’s a must. Nearly every local health department will look for that NSF seal. It's your guarantee that the refrigerator was designed from the ground up with food safety in mind.

This certification means the unit is made from materials that are non-porous, resist corrosion, and are easy to clean. The whole design is checked to make sure there are no little cracks or gaps where bacteria could hide and grow. Seeing that NSF logo is your assurance that you're set up to meet health codes and run a safe, clean kitchen.

How Do I Choose the Right Size Refrigerator for My Business

Figuring out the right size is about more than just the exterior dimensions. It’s really a three-step check to make sure the unit works for your space and your workflow.

- Calculate Your Inventory Needs: Start by thinking about your typical cold storage volume. A good rule of thumb is to have enough space to hold two or three days' worth of inventory, especially for your busiest times.

- Measure Your Physical Space: Get out the tape measure and check your available kitchen footprint. Don't forget this critical step: you absolutely must leave at least 2-3 inches of clearance on all sides for proper air circulation. Without it, the compressor can overheat.

- Confirm Delivery Path: Lastly, measure all your doorways, hallways, and tight corners on the delivery route. This final check saves you from the headache and cost of realizing the unit won't fit through the door on installation day.

What Are the Main Benefits of an Integrated Prep Table

A unit like a sandwich prep table or a pizza prep table is a game-changer for kitchen efficiency. Its biggest advantage is that it combines three essential stations into one: a refrigerated base, an ingredient rail, and a workspace.

This all-in-one design keeps every cold ingredient your staff needs right at their fingertips. It cuts down on wasted steps running back and forth to the main fridge and helps speed up order prep times significantly. Plus, it’s a big win for food safety, since ingredients spend less time out in the open. By merging two key pieces of equipment, you save a ton of floor space, which is pure gold in any commercial kitchen.

At PrepTables.com, our specialty is providing the durable, high-quality stainless steel prep tables and commercial refrigeration that efficient kitchens are built on. Our team of experts is here to help you find the perfect equipment that fits the unique way you work.

Explore our full range of NSF-certified refrigerated prep tables and commercial refrigerators at https://preptables.com.