Finding the Best Commercial Refrigerators for Your Kitchen

Share

Picking the right commercial refrigerator isn't just about finding a cold box; it's about matching the machine to your kitchen's rhythm, your menu, and your workflow. The best units—whether a durable reach-in, a space-saving undercounter model, or a specialized prep table—strike the perfect balance between capacity, efficiency, and design to keep your business humming.

Decoding Commercial Refrigerator Types

Choosing your primary refrigeration is one of the most foundational decisions you'll make for your food service operation. It's a choice that directly impacts how smoothly your kitchen runs, how safe your food is, and what your utility bills look like every month. The market is huge for a reason. The global commercial refrigeration sector hit USD 85.6 billion in 2024 and is expected to soar to USD 161 billion by 2034, which just shows how vital these workhorses are in every corner of the food industry.

Before you even think about specific models, you need to understand the main categories. Each type is built for a specific job, from holding bulk ingredients in a bustling restaurant to displaying drinks in a small café. The size of your kitchen, its layout, and the kind of food you're serving will all point you toward the right starting place. Getting this right from the beginning saves you from expensive mistakes and ensures your team has the tools they need.

A Quick Comparison of Refrigerator Categories

To make that first big decision a little easier, let's break down how the main types stack up. Each one has a distinct role to play in a professional kitchen.

Commercial Refrigerator Types at a Glance

This table gives a quick overview of the primary types of commercial refrigerators and where they shine.

| Refrigerator Type | Primary Use | Best For | Key Feature |

|---|---|---|---|

| Reach-In Refrigerator | General bulk ingredient storage | High-volume restaurants, cafeterias, and institutional kitchens needing accessible cold storage. | High capacity with adjustable shelving for versatile inventory management. |

| Undercounter Unit | Point-of-use refrigeration | Cafes, bars, and food trucks where space is limited and ingredients must be kept at hand. | Compact design that fits under standard countertops, maximizing workspace. |

| Refrigerated Prep Table | Food assembly and preparation | Pizzerias, delis, and sandwich shops that require immediate access to chilled ingredients during prep. | Integrated refrigerated wells and a dedicated cutting board surface. |

| Walk-In Cooler | Large-scale bulk storage | Large restaurants, catering companies, and grocery stores managing substantial inventory. | Maximum storage capacity, allowing for pallet-sized deliveries and organized stock rotation. |

At the end of the day, the best commercial refrigerators are the ones that feel like a natural part of your daily grind. This means looking past the initial price tag to consider long-term reliability. A smart move is to factor in the availability of local appliance repair and maintenance services, because minimizing downtime is crucial.

Once you’ve settled on the right type of unit, you can dig into the specifics of different models. For a deeper dive into who makes the most reliable gear, check out our guide on the https://preptables.com/blogs/prep-tables/best-commercial-refrigerator-brands.

Comparing Standard Commercial Refrigerator Types

Choosing the right commercial refrigerator isn't just about storage; it’s a core decision that dictates how your whole kitchen operates. The choice you make impacts how your team gets to ingredients, how you track inventory, and ultimately, how you maintain food safety. The three main players are reach-in units, undercounter models, and walk-in coolers, and each one is built for a different kind of kitchen demand.

You have to think about how each type works in the real world. A busy café could get completely bogged down by a massive reach-in, but a high-volume restaurant would grind to a halt without the sheer space of a walk-in. Nailing this choice from the start saves you from a world of workflow headaches and makes sure your equipment works for you, not against you.

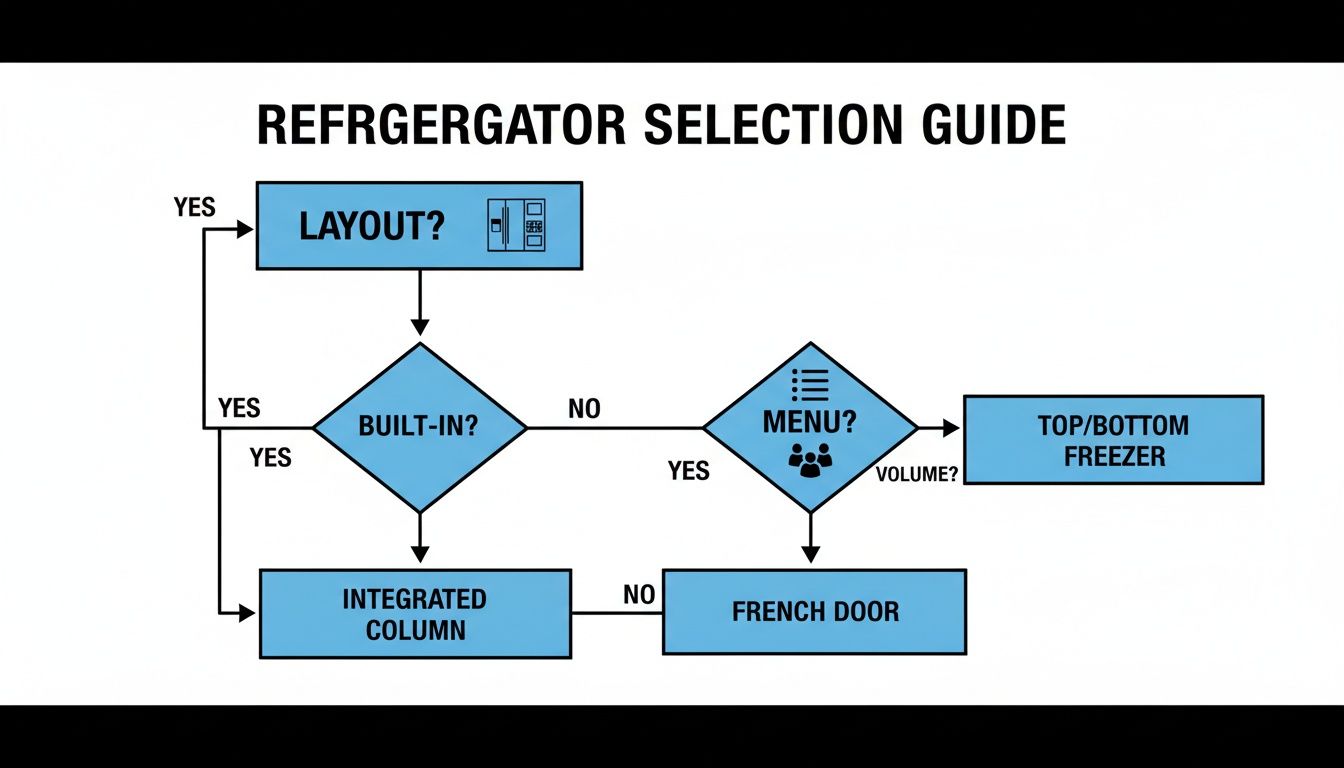

This decision tree helps visualize how your business’s specific situation—things like your layout, menu, and how many customers you serve—points you toward the right refrigeration setup.

As the chart makes clear, there's no single "best" answer. The right refrigerator is always the one that fits your specific operation like a glove.

Reach-In Refrigerators: The Kitchen Workhorse

You’ll find reach-in refrigerators in almost every commercial kitchen, and for good reason. They're the versatile backbone for daily operations. These upright units give you a ton of storage that’s easy to grab during a chaotic service, making them perfect for holding prepped ingredients, sauces, and anything else you’re pulling from constantly. They typically come in one, two, or three-door models to fit different volume needs.

The biggest fork in the road with a reach-in is the door type: solid or glass. This isn't just about looks—it directly affects your energy bill and how smoothly your kitchen runs.

Solid Door vs. Glass Door: A Critical Comparison

- Solid Door Reach-Ins are the champs of energy efficiency. Their insulated doors are much better at trapping cold air, meaning the compressor doesn't have to kick on as often. That translates to lower utility bills over the life of the unit. These are best for back-of-house storage where your staff already knows what they're grabbing.

- Glass Door Reach-Ins are all about visibility. Sometimes called merchandisers, they let staff spot items without opening the door, which can really speed up service and make inventory checks a breeze. But that convenience has a price; glass just isn't a great insulator, leading to higher energy consumption.

Here’s the trade-off in a nutshell: Glass doors speed up the workflow because you can see everything at a glance, but solid doors save you money on energy bills in the long run. For a fast-paced line, the visibility from glass doors might be worth the extra cost. For bulk storage in the back, solid doors are the smarter economic choice.

Undercounter and Worktop Units: Maximizing Space

When every square inch of your kitchen is prime real estate, undercounter and worktop refrigerators are lifesavers. These compact units are designed to slide right under standard countertops, putting chilled storage exactly where you need it in a prep station. For businesses like cafes, bars, and food trucks, this kind of integration is a game-changer.

Worktop models push this idea even further by adding a durable, food-safe stainless steel work surface on top. You get a combination prep area and refrigerator in one footprint. It’s the perfect setup for building salads, sandwiches, or mixing cocktails without having to trek across the kitchen for ingredients.

The main win here is a streamlined workflow. By keeping cold storage right at the point of use, these units cut down on staff movement, shave time off tickets, and just create a more organized, efficient kitchen. They are the go-to solution for adding refrigeration without eating up precious floor space.

Walk-In Coolers: The Ultimate Bulk Storage Solution

Once your inventory needs grow beyond what a few reach-ins can handle, it's time to think about a walk-in cooler. These are basically refrigerated rooms that offer the most storage capacity possible. For large restaurants, catering operations, hotels, and institutions, they are absolutely essential.

Walk-ins let you store whole cases of produce, giant buckets of prepped sauces, and even full-sized sheet pans on rolling racks. This is crucial for any business that buys in bulk to keep food costs down or that serves a high volume of customers every single day.

Beyond just sheer space, walk-in coolers offer incredible organizational potential. With the right shelving, you can implement a strict "First-In, First-Out" (FIFO) system, which is a must for cutting down on food waste and keeping ingredients fresh. A walk-in is a long-term investment in serious inventory control and the ability to scale your operation.

A Deep Dive into Refrigerated Prep Tables

In countless kitchens, the refrigerated prep table isn't just another piece of equipment; it's the command center. These powerhouse units fuse cold storage with a dedicated workspace into one efficient station, completely changing the rhythm of a busy kitchen. Unlike your standard reach-in or undercounter, the best commercial refrigerators built for prep are all about speed. They keep your most important ingredients chilled and literally at your fingertips.

It’s this marriage of chilling and assembly that makes them so critical in fast-paced spots. Whether you’re running a slammed deli, a high-volume pizzeria, or a cafe known for its fresh salads, the right prep table will slash ticket times and boost order accuracy. By cutting out the constant back-and-forth between a separate fridge and a cutting board, these tables create a self-contained workflow where everything happens in one fluid motion.

Common Types of Stainless Steel Prep Tables

While they all combine chilling and prep space, stainless steel prep tables are not a one-size-fits-all solution. They are specialized tools designed for specific menus and workflows. The three most common categories you'll encounter are sandwich/salad prep tables, pizza prep tables, and mega-top units.

- Sandwich/Salad Prep Tables: The versatile workhorse of delis, cafes, and salad bars. These tables typically feature a cutting board between 10 to 12 inches deep, providing ample room for assembling subs, sandwiches, and salads. The refrigerated wells are flush with the countertop, designed to hold standard-sized food pans filled with everything from sliced meats and cheeses to chopped vegetables.

- Pizza Prep Tables: A specialized unit built for the linear process of pizza making. Their standout feature is an extra-deep cutting board, often 19 inches or more, to accommodate large pizza doughs. Crucially, they have a raised ingredient rail that lifts the cold pans above the work surface. This ergonomic design allows pizza makers to grab and sprinkle toppings like pepperoni and mozzarella without awkwardly reaching over the dough.

- Mega-Top Prep Tables: This is essentially a supercharged sandwich table. Mega-top units add a third row of food pans, increasing ingredient capacity by about 30% compared to a standard model. This is ideal for kitchens with extensive menus or those needing a wider variety of ingredients immediately accessible, such as build-your-own-bowl concepts or high-volume sandwich shops.

Workflow and Design Considerations

The physical layout of each table has a direct impact on how efficiently your kitchen runs. Your menu should be the ultimate guide in this decision.

Key Differences at a Glance:

| Feature | Sandwich/Salad Prep Table | Pizza Prep Table | Mega-Top Prep Table |

|---|---|---|---|

| Cutting Board Depth | Standard (10-12 inches) | Extra-Deep (19+ inches) | Standard (10-12 inches) |

| Ingredient Rail | Flush with the work surface | Raised above the work surface | Flush with the work surface |

| Ingredient Capacity | Standard (2 rows of pans) | Standard (2 rows of pans) | High (3 rows of pans) |

| Ideal Use Case | Delis, cafes, salad bars | Pizzerias, flatbread shops | High-volume delis, custom bowl shops |

| Workflow Focus | Versatile assembly | Linear, high-volume production | High-variety, quick assembly |

For a bustling deli, the flush rail on a sandwich table is perfect. A line cook can slide a finished sandwich from the board to a wrapping station without having to navigate around a raised barrier. A pizzeria, however, depends on the ergonomic edge of the pizza table's raised rail. This design reduces physical strain and speeds up the topping process because the chef's movements are more direct and natural.

Material Quality and Food Safety Standards

Beyond the workflow, the actual construction of a prep table is crucial for both durability and hygiene. The best commercial refrigerators and prep tables are made from high-quality stainless steel, but not all stainless steel is the same. You’ll want to look for units built from 304-grade stainless steel on food-contact surfaces and 430-grade stainless steel for the exterior.

Why Stainless Steel Grades Matter

304-grade stainless steel has more chromium and nickel, giving it superior resistance to corrosion—a must-have for surfaces that constantly touch acidic ingredients like tomato sauce or vinaigrettes. 430-grade is a solid, more budget-friendly option that's perfect for the unit's sides and back.

Making sure your prep table is NSF (National Sanitation Foundation) certified is also non-negotiable. This certification is your guarantee that the unit is designed for food safety, with smooth, easy-to-clean surfaces that won't harbor bacteria in tiny cracks. To get a better handle on what makes these units so essential, you can find detailed information about different types of commercial refrigerated prep tables and their benefits. This knowledge is key to making a smart, long-term investment in your kitchen’s most important infrastructure.

Understanding Key Technical Specifications

Diving into the world of commercial refrigeration can feel like you're trying to decipher a foreign language. But don't get bogged down in the technical jargon. Once you get a handle on a few core specifications, you'll be able to choose a unit that works hard, keeps your energy bills down, and meets all the necessary safety standards.

Getting these details right from the start means your investment will pay off for years to come. The choices you make—like where the compressor sits or what kind of refrigerant it uses—have a direct impact on your kitchen’s workflow, how often you’ll need to schedule maintenance, and your monthly utility costs. These aren't just minor details; they define how the best commercial refrigerators perform day in and day out.

Compressor Placement: Top Mount vs. Bottom Mount

One of the first big decisions you'll run into is where the compressor is located. This single design choice affects everything from your kitchen's ambient temperature to how simple (or difficult) the unit is to service.

-

Top-Mount Compressors: These units have the compressor positioned at the very top. Since heat naturally rises, this setup is smart—it lets the hot air from the compressor dissipate towards the ceiling, away from your food and your staff. It also keeps the sensitive condenser coils away from the floor, where dust and grease love to accumulate, meaning you won't have to clean them as often. The only real downside is that their height can sometimes make maintenance a bit more awkward for technicians.

-

Bottom-Mount Compressors: By placing the compressor at the bottom, manufacturers make it incredibly easy for service techs to access everything for cleaning and repairs. This design also lifts the bottom shelf up, so your staff doesn't have to bend down as far to grab ingredients. The main trade-off is that these units tend to suck in more dust, grease, and debris from the floor, so you'll need to clean the coils more frequently to keep them running efficiently. They also vent heat at floor level, which can make a tight kitchen feel a bit warmer.

Situational Recommendation: For hot, busy kitchens with a lot of frying and grilling, a top-mount compressor is almost always the better bet to protect the coils from grease. But if easy maintenance is your top priority and a little extra floor-level heat isn't a dealbreaker, a bottom-mount unit offers a real advantage in ergonomics and serviceability.

Refrigerants and Environmental Impact

As you dig into the specs, pay close attention to the type of refrigerant a unit uses. This is the lifeblood of your refrigerator, and it directly affects your energy costs and your business's environmental footprint. The industry has thankfully moved on from older, ozone-depleting refrigerants. To get the full picture, it helps to understand the evolution of refrigerants like R22 and see why today's alternatives are so much better.

The new gold standard is R290 (propane), which is a natural and non-toxic hydrocarbon refrigerant. It has a very low Global Warming Potential (GWP) and is a powerhouse when it comes to energy efficiency. A unit running on R290 can slash energy use by up to 25%, which translates directly into lower electricity bills every month.

Critical Industry Certifications

Those little stickers you see on the side of a machine? They're not just for decoration. Certifications are your guarantee of safety, quality, and efficiency. The two most important ones you should never compromise on are NSF and ENERGY STAR.

Key Specifications and Their Real-World Impact

Let's break down what these technical features actually mean for your kitchen's performance, safety, and bottom line.

| Specification | What It Means | Impact on Your Business | Recommendation |

|---|---|---|---|

| NSF Certification | The unit meets strict standards for public health, ensuring it’s built with food-safe materials and is easy to clean properly. | Guarantees you'll pass health inspections and drastically cuts the risk of foodborne illness. | This is non-negotiable. Only buy equipment that is NSF certified for commercial food service. |

| ENERGY STAR | The unit has been certified by the EPA as being significantly more energy-efficient than standard models, often by 20% or more. | Directly lowers your monthly utility bills and reduces the total cost of ownership over the unit's lifespan. | Highly recommended for long-term savings, especially for a machine that will be running 24/7. |

| Refrigerant Type | The chemical compound that actually cools the unit. | Directly impacts energy efficiency and your environmental footprint. R290 is the leading modern choice. | Make it a priority to choose units running on R290 refrigerant for lower energy costs and greener operation. |

| Compressor Mount | The location of the compressor—either at the top or bottom of the refrigerator. | Affects maintenance access, ambient kitchen temperature, and how often you need to clean the coils. | Choose based on your kitchen: top-mount for hot/greasy areas, bottom-mount for easier service access. |

At the end of the day, these specifications are all about ensuring your equipment is reliable and safe. A great refrigerator is central to maintaining consistent holding temperatures, which is the absolute cornerstone of food safety. For a deeper dive into this critical topic, you can learn more about the principles of food safety and temperature control in commercial kitchens.

Optimizing Sizing and Placement for Kitchen Workflow

Choosing the right commercial refrigerator is only half the battle. Where you put it and how big it is can either make your kitchen a model of efficiency or grind it to a halt. Even the best unit, if stuck in the wrong spot, will create bottlenecks, add unnecessary steps for your staff, and slow down service. The real goal is to think about sizing and placement as part of a seamless workflow, where every move is logical.

It all starts with a tape measure and a good, hard look at your kitchen's natural rhythm. Before you even think about buying, you need to map out the physical space. Don't just measure the unit's footprint; you have to account for clearance. A refrigerator needs room to breathe—typically 2-3 inches on the sides and back—for proper ventilation. If you skip this, the compressor will constantly overwork, jacking up your energy bills and setting itself up for an early death.

Creating Efficient Kitchen Layouts

The gold standard in kitchen design has always been the work triangle. This is a simple concept that minimizes the steps between the three key zones: storage (your refrigerator), preparation (prep tables and sinks), and cooking (your range or oven). When you place your refrigerator strategically within this triangle, your chefs can grab ingredients, prep them, and hit the cooking line with zero wasted motion.

In a busy restaurant, this might mean a large reach-in refrigerator sits near the receiving door to make restocking a breeze. At the same time, you’d have smaller undercounter units right on the prep line for quick access to high-use items. This hybrid setup keeps bulk storage organized and out of the way while giving your line cooks exactly what they need during a chaotic dinner rush.

Sizing for Your Menu and Volume

Sizing is a tricky balance. You have to consider what you need now and what you might need a year from now. A unit that's too small inevitably leads to overstuffing, which kills airflow and creates dangerous temperature inconsistencies. On the flip side, a massive, half-empty refrigerator is just wasting energy cooling empty air.

So, how do you find that sweet spot? Start by analyzing your inventory.

- Assess Your Menu: If your menu is heavy on fresh produce, you're going to need a lot more refrigerated space than a kitchen focused on dry goods and frozen items.

- Track Your Volume: Think about your busiest service. Your fridge needs to hold enough stock to get you through that peak period without someone having to run to the walk-in every five minutes.

- Plan for Deliveries: Make sure the unit can handle your typical delivery size while still leaving room for proper organization.

A common rule of thumb is to plan for 1.5 to 2 cubic feet of refrigeration space per restaurant seat. But treat this as a starting point. A place with a huge takeout or catering business will need way more storage than its seating capacity suggests.

Maximizing Functionality in Limited Spaces

When every inch is precious—think food trucks, cafes, or ghost kitchens—smart placement isn't just a good idea, it's a must. This is where specialized units like undercounter and worktop refrigerators really prove their worth. By tucking cold storage directly under your prep surfaces, you create incredibly efficient, compact workstations.

Here’s a practical example: A small sandwich shop can stick an undercounter refrigerator right below the assembly station. This simple move means the employee doesn't have to walk back and forth to a reach-in, saving a few seconds on every single order. During a packed lunch rush, those seconds add up to faster ticket times, more orders out the door, and much happier customers. The trick is to think vertically and combine functions wherever you can. You can turn a space problem into a major workflow advantage.

Calculating the True Cost of Your Refrigerator

The sticker price on a commercial refrigerator is just the beginning of its financial story. To find the best unit for your bottom line, you have to look past the initial purchase and calculate the Total Cost of Ownership (TCO). This isn't just about treating the equipment as a one-time expense; it's about viewing it as a long-term asset with real, ongoing costs.

Thinking in terms of TCO completely shifts your focus from "what's cheapest today?" to "what offers the best value over its entire lifespan?" This bigger picture includes the initial price, day-to-day energy use, scheduled maintenance, and even the potential cost of surprise repairs. A cheaper unit might feel like a win upfront, but it can quickly become a financial headache if it’s inefficient and unreliable.

Breaking Down the Total Cost of Ownership

To really compare models accurately, you need to break down a few key financial factors. Each one plays a big part in the final cost you’ll pay over the typical 10-year lifespan of a commercial unit.

-

Initial Purchase Price: This is the most obvious cost, but it's only the starting point. A higher initial investment in a quality, efficient model almost always leads to bigger savings down the road.

-

Daily Energy Consumption: Refrigeration runs 24/7, making it one of the biggest energy hogs in any commercial kitchen. An inefficient model can easily tack on hundreds, if not thousands, of dollars to your utility bills every year. A large commercial refrigerator can burn through up to 17,000 kWh annually—a massive operational expense.

-

Projected Maintenance Costs: Every refrigerator needs regular upkeep, from cleaning condenser coils to checking door seals. Budgeting for professional service is the best way to prevent expensive breakdowns and get the most life out of your unit.

-

Potential Repair Costs: Let's be honest, lower-quality units are just more likely to fail. Factoring in the potential cost of emergency repairs—which includes spoiled product and business downtime—is a critical part of a realistic TCO calculation.

The ENERGY STAR Advantage: A Financial Comparison

This is where the long-term value really clicks. Let’s compare two hypothetical refrigerators over a decade of use to see how it plays out.

A standard commercial refrigerator might cost $3,000, while a comparable ENERGY STAR certified model costs $4,000. The cheaper unit seems like the smart choice, right? But its higher energy consumption adds an extra $300 to your utility bill each year.

Over a 10-year period, that extra energy cost adds up to $3,000. Suddenly, the "cheaper" unit has actually cost you $2,000 more than the energy-efficient model, and that's only factoring in energy use. This quick math doesn’t even touch on the higher likelihood of repair costs that often come with less robust equipment.

By looking at the full picture, you can make a financially sound decision that supports your business's profitability for years. The true cost is never just what’s on the price tag.

Your Questions, Answered

When you're about to invest in a piece of equipment as critical as a commercial refrigerator, a few last-minute questions always pop up. Getting those final details sorted is what turns a good purchase into a great one. Let's tackle some of the most common queries we hear from buyers.

Can I Just Use a Residential Refrigerator in My Kitchen?

In a word: no. It might look like an easy way to save a few bucks upfront, but putting a home fridge in a commercial kitchen is asking for trouble. Residential units simply don't have the muscle to keep up with the constant door openings and high heat of a professional kitchen, which puts your food—and your customers—at risk.

On top of that, they aren't built for the daily grind of a busy operation, so they'll burn out fast. Most importantly, a residential fridge won't have an NSF certification. That's an instant health code violation, which can lead to hefty fines or even get you shut down.

What’s the Big Deal with Compressor Mounts?

Where the compressor sits—either on top or on the bottom—makes a huge difference in day-to-day use and maintenance.

A top-mount compressor is your best bet for hot or dusty spots, like a pizzeria or a bakery with flour in the air. Since heat naturally rises, the compressor pushes hot air up and out, away from the unit. This also helps keep the coils from getting gunked up with grease and dust.

A bottom-mount compressor, on the other hand, is much more user-friendly. It lifts the bottom shelf up to a more comfortable height, saving your staff from constantly bending over. It's also a dream for service techs to access. The downside? It tends to suck in more dust from the floor and vents warm air right into your workspace, which isn't ideal in a tight kitchen.

How Often Do I Really Need Professional Service?

Think of it like a car's oil change—it's non-negotiable if you want it to last. Your commercial refrigerator should get a professional check-up at least twice a year. This isn't just a deep clean; a technician handles the critical stuff you can't, including:

- Scrubbing the condenser and evaporator coils clean.

- Checking refrigerant levels for any potential leaks.

- Inspecting all the electrical connections and fan motors.

- Calibrating the thermostat to make sure it's dead-on accurate.

Here's a pro tip: Regular professional maintenance is the single best thing you can do for your refrigerator's lifespan. It catches the small problems before they snowball into a catastrophic failure that costs you thousands in spoiled food and lost business.

What’s the Right Way to Clean Stainless Steel?

Keeping your stainless steel looking good is all about technique. To avoid tiny scratches, always clean with the grain of the metal, not against it. For daily wipe-downs, a soft cloth with a bit of mild detergent and warm water is all you need.

When you're dealing with tougher grime, grab a dedicated stainless steel cleaner. Whatever you do, never reach for steel wool, bleach, or any chlorine-based cleaners. They will absolutely destroy the protective finish on the steel and open the door for rust to set in.

Ready to find the perfect refrigeration solution for your professional kitchen? At PrepTables.com, we offer a wide range of NSF-certified refrigerators and prep tables designed for durability and efficiency. Explore our collection and upgrade your kitchen today.