Choosing Stainless Steel Tables with Wheels

Share

Picture a bustling restaurant kitchen or a busy workshop where your workspace moves with you, not against you. That’s exactly what you get with stainless steel tables on wheels. They're a simple concept—marrying industrial strength with easy mobility—but their impact is huge. This combination can turn a rigid, static room into a dynamic space that’s flexible, efficient, and clean.

The Modern Workstation Reimagined

In places where speed and cleanliness are everything—think commercial kitchens, labs, or medical clinics—fixed equipment can really slow things down. A stationary prep table means staff are constantly walking back and forth, wasting precious time and energy. And we all know the headache of trying to clean underneath and behind heavy, immovable furniture. Traditional layouts lock you into one way of working, making it tough to adapt when things change, like for a big catering job or a new lab experiment.

This is exactly where stainless steel tables with wheels come in and save the day. They aren't just pieces of furniture; they're tools that actively solve these everyday problems. Think of them like Lego blocks for your workspace—you can reconfigure the entire room on the fly to fit whatever you're doing right now.

Key Advantages of Mobile Workstations

The perks of bringing these tables into your space are immediate and incredibly practical. They hit on the most common frustrations in professional settings.

- Enhanced Workflow Efficiency: You can roll the work surface right where the action is. This cuts out all those wasted steps and just makes everything faster.

- Improved Hygiene and Sanitation: Cleaning becomes a breeze. Just roll the tables out of the way for a thorough sweep and mop of the floors and walls. This is non-negotiable for maintaining sanitary standards.

- Maximum Space Optimization: One room can suddenly wear many hats. What was a prep area moments ago can become a serving line, or you can push everything aside to create a wide-open space.

By combining the non-porous, corrosion-resistant surface of stainless steel with the flexibility of casters, these tables offer a simple yet powerful solution for boosting productivity and cleanliness.

At the end of the day, these mobile workstations give businesses the power to build more responsive, adaptable environments. They free you from the constraints of fixed furniture, opening the door to smarter workflows and much better control over your operations.

Exploring Different Types of Mobile Prep Tables

When you hear “stainless steel table with wheels,” you probably picture a simple, flat-topped cart. And while that’s a great starting point, the world of mobile prep tables is way more diverse and specialized than you might think. From basic work surfaces to complex refrigerated units, there are various types of stainless steel prep tables designed for specific tasks.

Picking the right one is like choosing the perfect tool for a job—it makes a huge difference in your workflow and overall efficiency. These tables aren't one-size-fits-all. They run the gamut from basic, multipurpose workhorses to highly specialized units built for the rigors of high-volume food production, like pizza prep tables and sandwich prep tables.

Getting a handle on these differences is the first real step toward optimizing your space for maximum productivity.

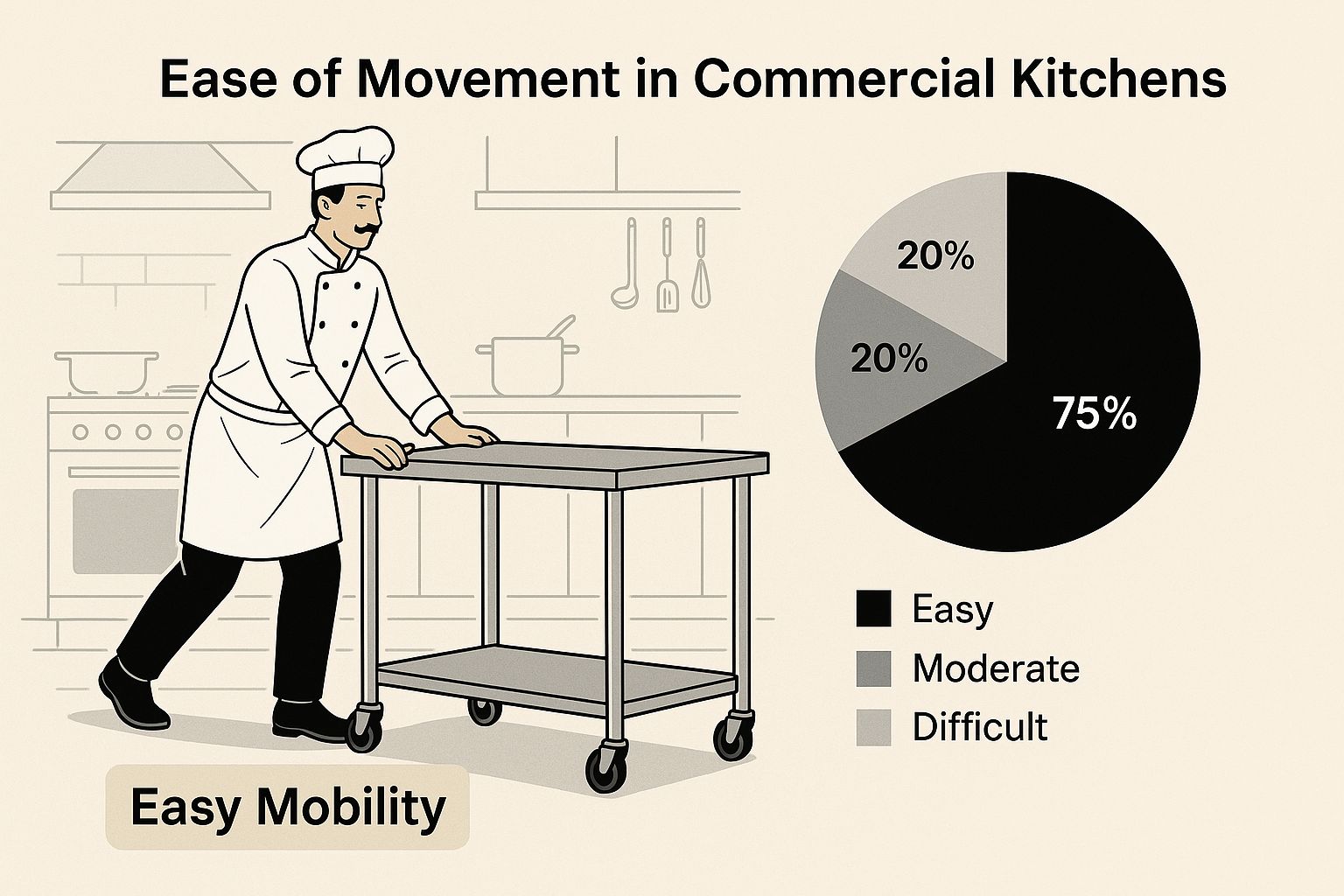

The image above says it all. The ability to just roll your prep surface wherever you need it transforms a static workstation into a dynamic asset. You can adapt your kitchen layout on the fly, bringing the table to the task instead of the other way around.

General-Purpose Mobile Work Tables

The most common and flexible option out there is the general-purpose mobile work table. You can think of this as the jack-of-all-trades in any professional kitchen or workshop. It’s defined by a flat, tough work surface that’s perfect for a whole range of jobs, from chopping vegetables to assembling parts.

Where these tables really start to differ is underneath the tabletop. The design of the undershelf has a direct impact on both your storage capacity and how easy it is to clean.

- Solid Undershelf: This gives you a stable, flat surface for stashing heavy boxes, small appliances, or ingredient containers. It’s fantastic for organization, but you’ll have to put in a little more elbow grease to clean underneath it.

- Wire Undershelf: A slatted or wire shelf is great for air circulation, which is ideal if you’re storing things like potatoes or onions. It’s also a breeze to clean, since crumbs and debris can fall right through to the floor for a quick sweep.

- Open Base: This design ditches the undershelf entirely. You get maximum legroom and a super simple way to store bulky items like stock pots or rolling bins directly underneath.

Specialized Food Service Prep Tables

Once you move past the basics, you get into the really interesting stuff: specialized stainless steel tables with wheels engineered for specific culinary tasks. These units have built-in features that streamline high-volume jobs, turning what could be a chaotic process into a smooth, assembly-line-style workflow. The two most common examples are pizza prep tables and sandwich prep tables.

The true magic of a specialized prep table is its ability to consolidate multiple steps into a single, organized station. This cuts down on wasted movement, minimizes cross-contamination risks, and seriously speeds up service.

In a busy deli or pizzeria, having everything you need within arm's reach isn't just a nice-to-have—it's absolutely essential for keeping up with customer demand during a rush.

Sandwich and Salad Prep Tables

A sandwich or salad prep table is a command center for creating fresh, made-to-order meals. More than just a table, it’s a hybrid workstation and refrigeration unit rolled into one. They almost always feature a refrigerated base to keep ingredients like deli meats and cheeses at safe holding temperatures. Up top, you’ll find a row of chilled wells for toppings, often protected by a lid. A cutting board typically runs along the front, providing a dedicated space for assembly. This all-in-one design is a game-changer for food safety and efficiency.

Pizza Prep Tables

Similarly, a pizza prep table is built from the ground up for the unique demands of a pizzeria. These tables feature a wide, deep work surface—often made of marble or refrigerated stainless steel—that gives chefs plenty of room to stretch dough. Above the work surface sits a raised, refrigerated rail packed with ingredient pans for toppings like pepperoni and cheese. This setup keeps everything perfectly chilled and organized for lightning-fast access, making the pizza-building process fast, clean, and consistent.

Each design is a purpose-built solution. Choosing the right one means you’re not just buying a table; you’re investing in a more efficient, safer, and faster operation. For a deeper dive into the variety available, you can learn more about different types of stainless prep tables in our detailed guide.

How to Choose the Right Mobile Stainless Steel Table

Picking the right stainless steel table with wheels is more than just buying another piece of equipment. It’s an investment. You're choosing a tool that needs to stand up to the daily grind, keep your workspace safe, and genuinely make your workflow smoother.

Let's walk through the key factors to look for. This isn't about complicated specs; it's a practical guide to help you make a smart, confident decision that you'll be happy with for years to come.

Decoding Stainless Steel Grades

The first thing to tackle is the grade of the stainless steel. This choice is a big deal—it directly affects how long the table will last, how well it resists rust, and how much it costs. Think of it like buying tires for your car: some are perfect for city driving, while others are built to handle rough weather and terrain.

-

Grade 304 Stainless Steel: This is the gold standard for kitchens, labs, and any place that gets wet. It's made with both chromium and nickel, a combination that gives it fantastic protection against rust and corrosion from water, cleaning solutions, and even acidic foods. If your table is going to see any moisture or food prep, 304 grade is the way to go.

-

Grade 430 Stainless Steel: This is a more wallet-friendly option. It has chromium but not the nickel, which makes it less resistant to corrosion. A 430-grade table is a perfectly fine choice for dry storage, holding equipment, or as an assembly surface in a non-humid area.

Matching Load Capacity to Your Workload

Next up: how much weight can it actually hold? This is the table's load capacity. A table meant for dicing vegetables has completely different strength needs than one that has to support a 200-pound commercial mixer. Simple as that.

Always look for the manufacturer's official load capacity and think about the absolute heaviest thing you might ever put on it. It’s always a good idea to pick a table that can handle more weight than you think you need. An overloaded table isn't just unstable; it's a serious safety risk.

A table's true strength isn't just in the top shelf. It comes from the combination of thick legs, quality wheels, and solid overall construction. A higher load capacity usually means you're getting a much more durable piece of kit.

Evaluating Casters and Mobility

The wheels—or casters—are what put the "mobile" in your mobile table. Their design is what determines how smoothly it rolls, how safe it is, and whether it will scuff up your floors.

-

Swivel vs. Rigid Casters: Most tables have four swivel casters, letting you spin and maneuver in any direction. This is great for tight spots. Some heavy-duty models use two swivel and two rigid (fixed) casters, which makes steering it in a straight line much easier.

-

Locking Mechanisms: This is non-negotiable. At least two of the wheels must have reliable locks. You need to be able to park the table and know it’s not going to roll away mid-task.

-

Caster Material: Polyurethane wheels are a fantastic all-around choice. They don't leave marks on the floor, they're quiet, and they glide easily over most surfaces.

The move toward this kind of flexible equipment is a major trend. By 2025, it’s expected that stainless steel tables will make up around 48.5% of all money spent on commercial foodservice equipment worldwide. Adding wheels just makes them that much more useful, giving kitchens and cleanrooms the ability to rearrange their space on the fly. You can dive deeper into commercial table trends on Preptables.com.

What Are the Real-World Benefits of Putting Your Workspace on Wheels?

So, what happens when you actually bring a mobile table into your setup? It's more than just a convenience. Investing in stainless steel tables with wheels delivers some serious, practical advantages that you'll notice on day one. We're talking about core improvements to your productivity, cleanliness, and how you use your space.

The growing demand for these tables tells the story. The global market for stainless steel tables hit around USD 1.2 billion in 2024 and is on track to reach USD 1.8 billion by 2033. This isn't surprising when you see how heavily industries like foodservice and healthcare rely on them. You can dig deeper into these numbers over at Verified Market Reports.

A Smoother Workflow with Less Wasted Motion

The first thing you'll see is a huge jump in efficiency. In a kitchen with fixed stations, think about all the time and energy spent walking back and forth. A mobile table cuts out all that wasted motion.

Imagine wheeling your entire prep station right up to the walk-in cooler or pulling it next to the stove. This simple move creates a logical, assembly-line flow, shaving minutes off complex tasks. Fewer steps mean less fatigue for your team and more focus on what matters.

Seriously Better Hygiene and Easier Cleaning

Keeping things sanitary is non-negotiable, especially in a professional kitchen or medical setting. Heavy, stationary tables are a nightmare to clean around, creating a perfect hiding spot for dirt and grime to build up.

Mobile tables make this a non-issue.

- Total Floor Access: Just unlock the casters and roll the table out of the way. Suddenly, you have a clear shot for sweeping, mopping, and deep cleaning.

- No More Grimy Corners: You can get right up to the walls and baseboards, preventing that gross, long-term buildup.

- Easier Inspections: It's so much easier to spot spills or deal with pest control when you can see everything clearly.

The ability to effortlessly move a workstation for a thorough cleaning is a game-changer. It turns a dreaded chore into a simple, routine task, making it way easier to keep your space up to code.

Ultimate Flexibility and Smarter Use of Space

Finally, stainless steel tables on wheels give you the power to create a truly dynamic workspace. A single room can transform to meet different needs throughout the day, letting you get the most out of every square foot.

A kitchen, for example, can be set up for morning prep, quickly reconfigured into serving lines for the lunch rush, and then cleared out for a deep clean at night. In a lab, a mobile workstation can be shuttled between different instruments or rearranged to support a new project. This kind of adaptability is pure gold for any operation looking to be more agile and do more with the space they've got.

Keeping Your Table in Top Shape: Assembly and Maintenance

Think of your new stainless steel table with wheels as a long-term partner in your workspace. Just like any good partnership, it needs a solid start and a little ongoing care to perform at its best. Nailing the assembly and sticking to a simple maintenance routine will ensure your table stays safe, sturdy, and reliable for years.

Assembling Your Mobile Table for Peak Performance

A solid assembly is the bedrock of your table’s stability. While most tables come with pretty clear instructions, the single most important step is getting the casters installed correctly. A loose or improperly attached wheel is a recipe for wobbles, poor mobility, and can even become a serious safety hazard.

The good news is that the process is usually quick and painless.

- Get Positioned: Start by flipping the tabletop upside down on a soft, protected surface to avoid any scratches.

- Attach the Legs: Go ahead and secure the legs to the tabletop using the hardware provided. Most use simple screws or set screws that are easy to tighten.

- Install the Casters: Now for the critical part. Push the caster stems all the way into the bottom of each leg. They need to be fully seated to prevent any rocking. If you have threaded casters, grab a wrench and tighten them down until they’re completely secure.

- The Stability Test: With everything attached, carefully turn the table upright. Lock the casters and give it a firm push. It should feel like a single, solid unit. No wiggle, no wobble.

A correctly assembled table feels completely solid. If you notice any movement at all, it's time to double-check that every piece of hardware is fully tightened and that the casters are seated properly in the legs.

Creating a Long-Term Maintenance Routine

Consistent care is what keeps your stainless steel looking great and functioning perfectly. A simple daily wipe-down and a quick periodic check-up can prevent rust, corrosion, and other issues, dramatically extending the life of your table.

Daily cleaning is your first line of defense. All you need is a soft cloth, some warm water, and a mild detergent. The key is to always wipe in the direction of the steel's grain—this little trick helps you avoid creating tiny scratches on the surface. For a full rundown of the best cleaning techniques, check out our guide on how to clean stainless steel.

Just as important is knowing what not to use. Stay away from harsh abrasives like steel wool, which will definitely scratch the finish. You'll also want to avoid any chlorine-based cleaners like bleach, as they can cause pitting and leave behind permanent rust spots.

Your Periodic Inspection Checklist

Beyond the daily wipe-down, setting aside a few minutes each month for a quick inspection can help you catch small problems before they turn into big headaches.

- Check All Hardware: Give all the bolts and set screws on the legs and undershelf a once-over to make sure they’re still tight.

- Inspect and Lube the Casters: Clear out any gunk or debris that has built up in the wheels and swivels. A little food-safe lubricant on the swivel bearings will keep them rolling smoothly.

- Test the Brakes: Engage and disengage the caster locks a few times. You want to be sure they are still functioning correctly and holding the table firmly in place.

Common Questions About Stainless Steel Tables with Wheels

Let's dig into some of the most common questions people have about these mobile workstations. Think of this as the practical advice you'd get from someone who's spent years working with this equipment. We'll clear up any lingering doubts so you can choose the right table and keep it in top shape.

Can I Replace or Upgrade the Wheels on My Table?

Absolutely. In fact, it's one of the best things about them. Most stainless steel tables are designed with replaceable casters, which makes repairs and upgrades a breeze.

The single most important thing to check is the stem size and type. You need to make sure the new wheels will fit snugly and securely into the table's legs. Many people upgrade from the standard casters to get specific perks, like switching to non-marking polyurethane wheels to save their floors from ugly scuff marks. If your table is always loaded down, a better set of casters with high-quality bearings will make it glide across the floor instead of fighting you every step of the way. Just be sure the new set's total weight capacity is higher than the table plus whatever you plan to load onto it.

What Is the Best Way to Clean and Sanitize the Surface?

Keeping your stainless steel table clean and hygienic is straightforward if you stick to a simple routine. For daily wipe-downs, all you need is a soft cloth, warm water, and a bit of mild detergent. Here’s a pro tip: always wipe in the same direction as the steel’s grain. It’s a small detail that goes a long way in preventing micro-scratches.

When it's time to sanitize, stick to a food-safe solution and—this is crucial—stay away from anything with chlorine, like bleach. Chlorine is the enemy of stainless steel; it can cause pitting and permanent damage. After cleaning or sanitizing, give the table a good rinse with clean water and dry it completely.

A common mistake is letting moisture sit on the surface. Thoroughly drying your stainless steel table after cleaning is the single best way to prevent rust and maintain its protective layer.

Are These Tables Certified for Commercial Kitchen Use?

This is a fantastic and critical question. For a table to be used in a professional kitchen, it isn't enough for it to just look the part—it has to meet strict public health and safety standards.

In the United States, the gold standard for certification comes from NSF International. If a table has the NSF mark, it means it's been put through rigorous testing to prove it's non-porous, a snap to clean, and built to resist corrosion. When you're shopping, always keep an eye out for that NSF logo. It's your guarantee that the equipment is ready for a demanding food service environment. To get the full story, you can read our detailed article on what NSF certification means.

Are There Specialized Mobile Tables for Other Industries?

You bet. While they’re a staple in foodservice, these tables are incredibly versatile. The same qualities that make them great for kitchens—hygiene, durability, and mobility—are in high demand across many other fields. Healthcare and childcare are perfect examples.

Specialized stainless steel changing tables with wheels are indispensable in places where cleanliness is non-negotiable. It's a surprisingly large market, with an estimated global size between USD 300 million to USD 500 million. You can see more on this niche at Market Report Analytics. It just goes to show how adaptable these simple, sturdy workstations really are.

Ready to find the perfect mobile workstation for your space? At PrepTables.com, we offer a wide selection of high-quality, NSF-certified stainless steel tables with wheels designed for durability and efficiency. Explore our collection today at https://preptables.com.