Your Guide to Stainless Steel Shelving Units

Share

When you hear the term stainless steel shelving unit, you're talking about more than just a place to put things. These are the heavy-duty, workhorse storage systems you see in bustling commercial kitchens, sterile medical labs, and busy industrial warehouses for a reason. Their incredible durability, resistance to corrosion, and hygienic qualities make them a cornerstone of professional environments. The non-porous surface is a breeze to clean and sanitize, making it easy to meet strict health and safety codes.

Why Stainless Steel Is the Industry Standard

From the controlled chaos of a restaurant kitchen to the quiet precision of a laboratory, stainless steel is the undisputed champion of professional storage. But what gives it this edge? It’s not just one thing, but a powerful combination of traits that other materials just can't touch.

Think of it as the ultimate utility player. It's tough enough for a high-traffic warehouse, clean enough for a sterile medical setting, and even sleek enough for a modern retail space. This amazing versatility is exactly why it has become the gold standard everywhere.

The Core Advantages of Stainless Steel

The fact that stainless steel shelving is so common is no accident. It’s a direct result of how well it performs and the real-world problems it solves for businesses every day.

- Unmatched Durability: Stainless steel is incredibly resistant to dents, scratches, and dings. It can take a beating in the most demanding environments and keep on going. It’s not going to chip like painted wood or rust like regular steel.

- Superior Hygiene: The surface of stainless steel is non-porous, which means there are no tiny crevices for bacteria, mold, or other nasty things to hide. This makes it incredibly easy to clean and sanitize to professional standards—a non-negotiable in food service and healthcare. To learn more about these standards, you can read up on what NSF certification is and why it's so important.

- Corrosion and Heat Resistance: This material naturally holds up against water, harsh cleaning chemicals, and high temperatures without breaking down. That makes it perfect for dishwashing areas, walk-in coolers, and hot kitchens.

The global market for stainless steel shelves was valued at around $5.2 billion in 2023 and is expected to grow to about $8.1 billion by 2032. This jump shows just how much demand there is for reliable, clean storage solutions across many different industries.

This guide will walk you through everything you need to know about choosing the right stainless steel shelving unit, helping you make a smart investment that will last for years to come.

Decoding The Right Stainless Steel Grade

Choosing a stainless steel shelving unit seems straightforward, but one of the most critical details is often overlooked: the grade of the steel itself. Not all stainless steel is created equal, and the type you pick directly affects your shelving's lifespan, durability, and ability to fight off rust.

Think of it like buying tires for your car. You wouldn't put summer tires on for an icy winter road, right? It’s the same principle here. The environment where you’ll place the shelving dictates which steel grade is the right tool for the job.

The secret is in the steel's chemical recipe, specifically how much chromium and nickel it contains. These two elements are the superheroes of stainless steel, giving it the strength and corrosion resistance that make it a staple in professional kitchens and storage areas.

The Workhorse: Type 304 Stainless Steel

When you absolutely cannot compromise on corrosion resistance and durability, Type 304 stainless steel is the undisputed industry champ. This grade is packed with both chromium (around 18%) and nickel (about 8%), a powerful combination that creates an incredibly tough, rust-proof surface.

The nickel is the real game-changer here; it dramatically boosts the steel's ability to stand up to harsh conditions. This makes 304-grade steel the only sensible choice for environments with high humidity, moisture, or exposure to corrosive cleaning chemicals.

- Walk-in Coolers and Freezers: The constant moisture and cold temperatures are no match for Type 304's protective qualities.

- Dishwashing Areas: This is the ultimate stress test, with constant exposure to water, steam, and detergents. Type 304 handles it without breaking a sweat.

- Outdoor or Marine Environments: For food trucks or coastal businesses, Type 304 offers vital protection against salt air and humidity.

While it does come with a higher price tag, investing in a 304-grade stainless steel shelving unit pays for itself with a much longer, hassle-free life in demanding spots.

The Economical Choice: Type 430 Stainless Steel

On the other side of the coin, we have Type 430 stainless steel. This grade still has a healthy amount of chromium (around 17%), which gives it solid durability and that clean, professional look.

The key difference? It contains a negligible amount of nickel. This makes it more vulnerable to rust and corrosion when it’s repeatedly exposed to moisture or harsh chemicals.

Because it lacks that superior nickel protection, Type 430 is best suited for dry storage applications where humidity isn't a factor. It’s an excellent, cost-effective option for places like:

- Dry Pantries and Storage Rooms: It's perfect for organizing canned goods, dry ingredients, and other packaged supplies.

- Linen Closets: Ideal for keeping towels, uniforms, and other textiles neatly stored.

- Retail Displays: The polished finish looks great for showing off merchandise in a controlled indoor setting.

The big takeaway is this: it’s not about which grade is "better" overall, but which one is better for your specific needs. Matching the steel grade to its environment is the smartest way to guarantee longevity and get the most value from your investment.

Comparing The Grades Side By Side

To make the decision even clearer, let's put these two common steel types head-to-head. Understanding these distinctions will help you look past the price tag and focus on what really matters: the long-term performance of your stainless steel shelving unit.

Here’s a simple table to help you compare the two most common grades at a glance.

Comparing Stainless Steel Grades 304 vs 430

| Feature | 304 Stainless Steel | 430 Stainless Steel |

|---|---|---|

| Corrosion Resistance | Excellent; ideal for wet, humid, or harsh environments. | Good; best suited for dry, low-moisture environments. |

| Key Alloy Element | High nickel content (approx. 8%) for superior rust prevention. | No significant nickel content, relying on chromium. |

| Ideal Use Cases | Walk-in coolers, dish rooms, chemical storage, outdoor areas. | Dry food pantries, equipment storage, retail, office supplies. |

| Cost | Higher initial investment due to nickel content. | More budget-friendly and economical for dry applications. |

| Magnetic Properties | Non-magnetic. | Magnetic. |

Ultimately, choosing the right grade is a practical decision. For wet or demanding areas, the upfront cost of 304 steel is a wise investment. For simple dry storage, 430 offers great value and gets the job done perfectly.

Finding Your Perfect Shelving Style

Once you've settled on the right grade of steel, the next job is picking the style that truly fits your workflow. A stainless steel shelving unit is never a one-size-fits-all solution; different designs are built for different tasks. It’s like putting together a custom toolkit—each style is a specialized tool made to solve a specific organizational headache.

Choosing the right style can make a huge difference in efficiency. It might mean faster prep times in the kitchen or quicker inventory checks in the stockroom. The goal is to match the shelf's design to its real-world job.

Wire Shelving The Open-Air Organizer

The most common style you'll see is wire shelving, and for good reason. Its open-grid design is a masterpiece of functional simplicity, offering huge advantages that solid shelves just can't touch. This is the go-to choice anywhere that airflow and visibility are king.

Picture a walk-in cooler full of fresh produce. Solid shelves would trap moisture and block air, creating little pockets where spoilage can start. But wire shelving lets cold air circulate completely, reaching every item from all sides. This simple feature helps keep temperatures consistent and makes your perishable goods last longer.

That open design is also a game-changer for keeping things clean in dry storage. Dust and small debris don't have a flat surface to pile up on—they just fall right through, which makes cleaning a whole lot easier.

- Improved Airflow: A must-have for walk-in coolers, freezers, and any ventilated area to keep products fresh and temperatures even.

- Enhanced Visibility: You can see what's on every shelf from almost any angle. This speeds up inventory counts and cuts down on time spent hunting for that one specific item.

- Fire Safety Compliance: In many commercial spaces, wire shelving is preferred because it allows water from sprinkler systems to pass through to lower levels, helping you meet local fire codes.

Solid Shelving The Spill Stopper

While wire shelving is all about airflow, solid shelving is the undisputed champ when it comes to containment and stability. That flat, unbroken surface is perfect for holding small or oddly-shaped items that would wobble or just fall right through a wire grid.

Think about storing small spice jars, bags of flour, or tiny mechanical parts. A solid stainless steel shelf gives them a secure, stable base, so you don't have to worry about things tipping over. That's why it's a favorite in bakeries, labs, and workshops.

But its greatest strength is spill control. If a bottle of sauce or a chemical container leaks, a solid shelf keeps the mess contained to that single level. It prevents drips from contaminating everything stored below, saving you from a massive cleanup and preventing product loss.

A solid stainless steel shelving unit acts as a built-in safety net. It contains messes, protects items on lower shelves, and provides a perfectly smooth work surface when you need one in a pinch.

Wall-Mounted Shelving The Space Saver

When your floor space is precious real estate, wall-mounted shelving is the brilliant answer. By using that empty vertical wall space, these units free up the floor for foot traffic, rolling carts, and other essential equipment. You’ll often see them mounted right above prep tables and sinks, keeping frequently used tools and ingredients right at arm's length.

This style of stainless steel shelving unit is perfect for:

- Creating an "active" storage zone in a busy prep area.

- Keeping cleaning supplies organized and off the floor in a utility closet.

- Displaying products in a retail shop without cluttering up the aisles.

Mobile Shelving The Flexible Solution

For dynamic spots where the layout needs to change on a dime, mobile shelving (units on casters) offers flexibility that nothing else can. These units give you the same sturdy storage as their stationary cousins, but you can roll them wherever they're needed most.

Imagine loading a mobile unit with ingredients in the pantry and wheeling it into the kitchen for prep, then moving it out of the way during service. That kind of adaptability is priceless for caterers, event spaces, and any multi-purpose room where the workflow is always changing. As you can see, the options for commercial kitchens are vast. Our detailed guide on commercial kitchen shelves can provide even more tailored advice.

This demand for versatility is a big reason the market is growing. The global stainless steel shelving market was valued at around $3.5 billion in 2025 and is projected to grow at a compound annual rate of about 6% through 2033. This growth is driven by the need for adaptable solutions in food service, retail, and warehousing. You can discover more insights about this growing market on datainsightsmarket.com.

Exploring Stainless Steel Prep Tables

A standard stainless steel shelving unit is a storage workhorse, but the real action in a commercial kitchen happens where storage meets workspace. That’s where prep tables come in. A stainless steel prep table with built-in shelving isn't just a piece of furniture—it’s the command center of your kitchen, bridging the gap between raw ingredients and the finished plate.

These hybrid units are all about cutting down on wasted motion and cranking up productivity. When you put storage right under the work surface, chefs can grab ingredients, tools, or pans without taking a single step. That seamless flow is the secret sauce for a fast-paced, efficient kitchen.

The Foundation: Standard Work Tables

The most common model is the standard stainless steel work table, often equipped with an undershelf or cabinet base. Its design is brilliantly simple but incredibly effective. You get a tough, flat top for chopping, mixing, and plating, while the storage below keeps essentials at your fingertips.

- Open Undershelf: An open shelf below offers easy access to mixing bowls, bulk ingredients, or small appliances, keeping the work surface clear.

- Enclosed Cabinet Base: A cabinet base provides concealed storage, perfect for keeping items protected from dust and splashes or simply for a cleaner look.

This design slashes the time spent running to the pantry or other shelving units. A chef can grab a fresh pan, pull down a bowl, and get to work in one fluid motion. It keeps the whole process contained, efficient, and focused.

Specialized Units: Refrigerated Prep Tables

For kitchens cranking out high volumes of specific items—think delis or pizzerias—a standard table isn't enough. That's where specialized, refrigerated prep tables come in. These units are engineered for a lightning-fast assembly line where every ingredient has its perfect, temperature-controlled home. They combine a work surface, refrigerated storage, and ingredient wells into one compact powerhouse.

Sandwich Prep Tables: The Cooled Command Center

A sandwich prep table is a masterclass in efficiency. The top section features a row of chilled pans, or wells, that hold all your fresh toppings—lettuce, tomatoes, onions, cheese—at the perfect, food-safe temperature. Right in front of these wells is a cutting board, creating an ergonomic assembly line. Below, a refrigerated cabinet stores backup supplies and larger items like meats and cheeses.

A well-designed sandwich prep station lets a cook build an entire order without moving their feet. This drastically cuts down ticket times, with some studies showing that an optimized layout can speed up order fulfillment by up to 25%.

Pizza Prep Tables: The Assembly Line Powerhouse

Pizza prep tables are built with one mission in mind: making the pizza-building process as smooth as possible. They use the same core concept as sandwich tables—refrigerated wells on a raised rail and an undercounter cabinet—but they're fine-tuned for pizza.

Many high-end models feature a wide marble or granite top because the cold stone is perfect for keeping dough from sticking and staying cool while you work it. The refrigerated ingredient wells are typically elevated and angled toward the chef, making it incredibly easy to grab and spread toppings. The refrigerated base cabinet is often designed to hold standard dough trays, keeping everything needed for service in one place.

Making an Informed Buying Decision

Picking the right stainless steel shelving unit is a big deal. It’s a decision that directly affects your workflow, safety, and overall efficiency. To make a smart investment, you have to look past the price tag and aesthetics. It's all about matching the shelf to the real-world demands of your space.

The whole process kicks off with the basics: load capacity, the dimensions of your room, whether you need it to move, and any essential certifications. Nail these factors, and your new shelving will be a long-term asset, not a short-term headache.

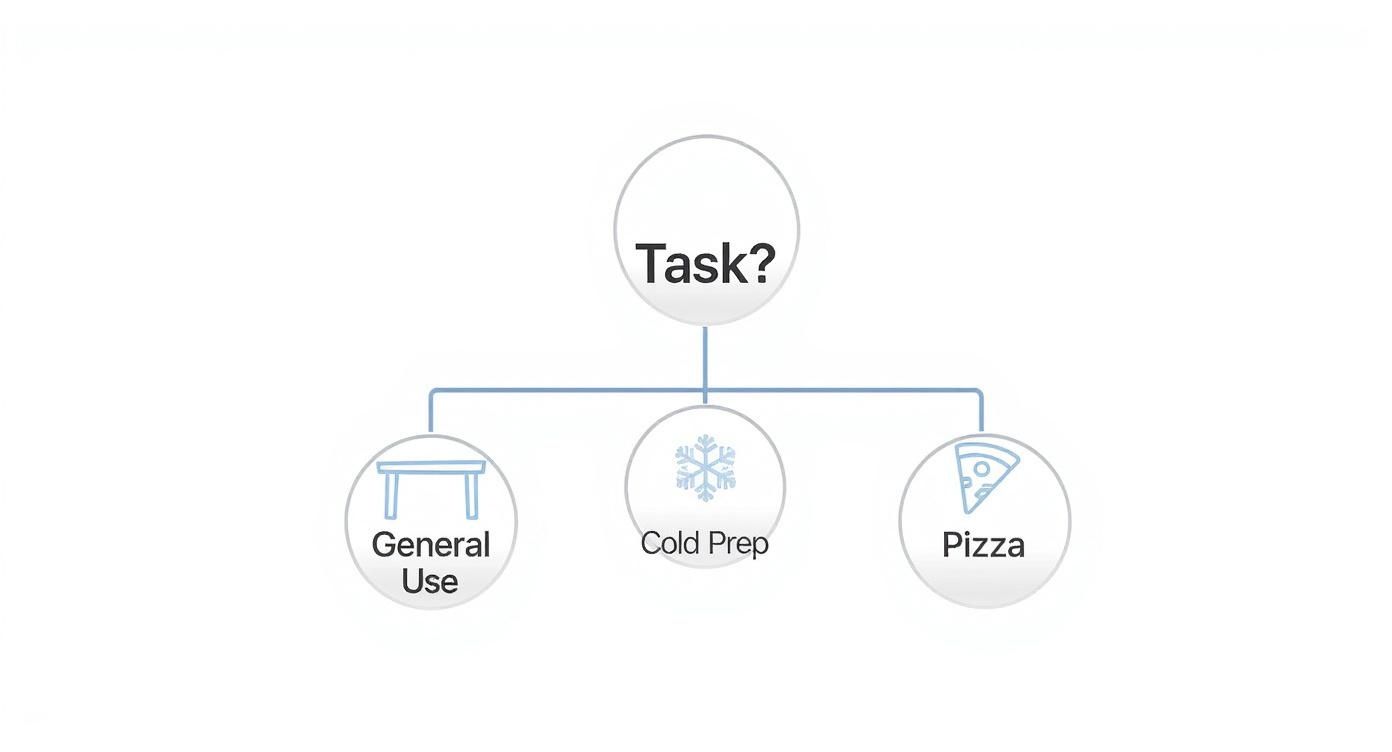

To give you an idea of how to think through this, here's a simple decision tree for a related piece of equipment, the prep table.

As you can see, the task at hand—whether it's general prep, working with cold ingredients, or making pizza—points you straight to the perfect table. This same logic applies to choosing any specialized equipment, including your shelving.

Calculate Your Load Capacity

Before you even think about anything else, you absolutely must figure out how much weight your shelves need to hold. The load capacity isn't just a friendly suggestion; it's a critical safety number. Think of it like a bridge—you have to know its weight limit before you start sending traffic over it.

Manufacturers usually list the capacity as "evenly distributed," which just means the weight is spread out nicely across the entire shelf. A shelf rated for 600 pounds can’t handle a single 600-pound object dropped right in the middle. Think about your heaviest items—are we talking bulk flour sacks, cases of canned goods, or heavy machinery? Whatever it is, choose a capacity that gives you plenty of breathing room.

Measure Your Space Accurately

Next up, get out the tape measure. Don't just eyeball it. You need the exact width, depth, and height of the spot where the unit is going to live.

And don't forget to think about how people move around the space. A shelf that technically fits but blocks a doorway or creates a traffic jam in a busy kitchen is a total failure. You need to leave enough clearance around the unit for your team to move, bend over, and grab things without bumping into everything. For a deeper look at picking storage solutions for different spaces, check out this expert guide to shelving and storage units.

Mobile vs. Stationary Units

Deciding between mobile units (on wheels) and stationary ones (on fixed feet) really comes down to how you operate day-to-day.

- Stationary Units: These are the workhorses for permanent storage. They’re super stable and can typically hold more weight, making them perfect for heavy equipment or bulk inventory that isn't going anywhere.

- Mobile Units: If you work in a dynamic environment where you need flexibility, casters are a game-changer. Imagine rolling a fully loaded unit from the stockroom to the prep line. This is a fantastic option for caterers, shared kitchens, or any space that needs frequent deep cleaning.

The Importance of NSF Certification

For any business in food service or healthcare, NSF Certification is something you can't skip. This little mark from NSF International is your proof that the equipment meets strict public health and safety standards.

An NSF-certified stainless steel shelving unit is a guarantee that its materials are non-toxic, won't corrode, and are designed to be cleaned easily and completely. It’s an independent stamp of approval saying the unit is safe for storing food and sterile supplies—which is crucial for passing those health inspections.

The need for high-quality, reliable shelving is growing worldwide, especially in developing markets. In fact, the Asia-Pacific region holds a massive 33% share of the global shelving market, a trend fueled by economic growth and rising commercial standards. This global demand just highlights how important it is to invest in certified, quality equipment.

Installation and Long-Term Maintenance Tips

Think of your stainless steel shelving unit as a long-term investment in your business’s efficiency and hygiene. To get the most out of it, proper care starts right from day one. A rock-solid installation guarantees stability and safety, while a simple, consistent maintenance routine will keep that pristine finish looking sharp and fighting off corrosion for years.

Of course, following the manufacturer’s assembly instructions is your first step. But in the real world, you'll often need to make a few tweaks. Getting the unit perfectly level and secure isn't just about looks—it's about preventing a wobble that could turn into a serious safety hazard down the line.

Achieving a Stable and Secure Installation

A solid foundation is everything. Even a tiny wobble can compromise the whole structure, especially when you've got it loaded down with heavy equipment or supplies. The trick is to tackle any unevenness from the get-go.

Most freestanding shelving units come with adjustable feet for this very reason. Grab a level and place it on each shelf as you're setting up. Turn the feet clockwise or counter-clockwise until that bubble is dead center. It's a simple step, but it's what prevents dangerous swaying and ensures weight is distributed evenly across the entire frame.

For wall-mounted units, safety is non-negotiable. Always anchor the shelves directly into wall studs. If studs aren't an option, use heavy-duty wall anchors rated for well beyond the shelf's maximum load capacity.

A securely mounted wall shelf is more than just convenient; it's a critical safety measure. An improper installation poses a huge risk of collapse, which can lead to injury, ruined inventory, and costly downtime.

If you want to dive deeper into the nuts and bolts of secure mounting, check out this ultimate guide to shelving brackets. The context is a bit different, but the core principles for a secure installation are universal.

Long-Term Care and Cleaning Best Practices

Keeping your stainless steel shelving looking good and staying hygienic is surprisingly simple if you stick to a routine. The main goal is to clean it effectively without accidentally damaging the passive layer of chromium oxide—that’s the invisible shield that protects the steel from rust.

Most of the time, a daily wipe-down is all you need. Use a soft cloth or microfiber towel with a bit of warm water and mild detergent (like dish soap). Always wipe in the direction of the steel's grain to avoid creating tiny scratches. Once you're done, rinse it with clean water and dry it completely with another soft cloth. This prevents those annoying water spots and mineral deposits.

Knowing what not to do is just as important. Here are the main things to keep away from your stainless steel:

- Abrasive Cleaners: Things like scouring powders or steel wool will leave permanent scratches on the surface.

- Chlorine-Based Cleaners: Bleach and any cleaners with chlorides will eat away at that protective layer, leading to pitting and rust.

- Hard Water: Don't let water air-dry on the surface. The mineral deposits left behind will dull the finish over time.

For a more detailed breakdown, you can read our complete guide on how to clean stainless steel for more step-by-step techniques. By following these straightforward tips for installation and maintenance, you'll make sure your stainless steel shelving unit stays a durable, safe, and valuable part of your workspace for a long, long time.

Frequently Asked Questions

Even after going through a guide, you'll likely have a few specific questions pop up when it comes to picking out and using your stainless steel shelving unit. We get it. Here are some straightforward answers to the questions we hear most often, so you can feel completely confident about your choice.

What Is The Best Way To Clean And Sanitize A Shelving Unit?

For everyday cleaning, a soft cloth with some warm water and a mild detergent is all you need. If you're using the shelves in a food prep area, you'll want to sanitize them with a food-safe, non-chlorinated sanitizer—just follow the directions on the bottle.

No matter what, always give the shelves a good rinse with clean water and wipe them completely dry. This simple step prevents those annoying water spots from forming. And please, stay away from harsh tools like steel wool or gritty cleaning powders. They will absolutely scratch the surface, which can eventually lead to rust.

Can I Use Stainless Steel Shelving In A Walk-In Freezer?

You bet. Stainless steel is a fantastic choice for cold, damp places like walk-in coolers and freezers. Its natural ability to resist corrosion is a huge plus in these environments.

For really demanding spots like freezers, we strongly recommend going with a 304-grade stainless steel unit. The extra nickel in its makeup gives it superior protection against rust, which means you'll get a long, hygienic life out of it, even in consistently moist and cold conditions.

How Do I Know The True Weight Capacity Of A Shelf?

This is a big one. The weight capacity you see from the manufacturer is almost always based on an evenly distributed load. Think of it like spreading a layer of butter on toast—you want the weight spread out across the whole shelf, not all clumped in one spot.

For instance, a shelf rated for 600 pounds can handle that weight just fine if it's distributed. But, if you were to place a single, heavy 600-pound object right in the middle, you risk the shelf bowing or even breaking. To play it safe, always try to spread your heavier items out as much as possible.

At PrepTables.com, we stock a huge selection of NSF-certified stainless steel shelving units and prep tables built for the demands of professional kitchens and workspaces. Find the perfect storage solution to optimize your workspace today!