A Complete Guide to Stainless Steel Shelving Racks

Share

When it comes to outfitting a professional space, stainless steel shelving racks are pretty much the only game in town. Why? They bring a killer combo of hygiene, toughness, and rust resistance to the table, making them a smart investment in both safety and smooth operations.

Why Stainless Steel Is the Gold Standard for Professional Shelving

Picture a busy restaurant kitchen, a clean lab, or a warehouse with constant traffic. In places like these, regular shelves just don't cut it. Wood can warp and become a breeding ground for bacteria, plastic might crack under heavy boxes, and other metals are just waiting to rust. Stainless steel, on the other hand, is built for exactly this kind of punishment.

The numbers back it up, too. The market for these shelves was worth around USD 1.8 billion in 2023 and is only expected to grow. This boom is driven by huge demand from the foodservice world, where over 1 million commercial kitchens in the U.S. are swapping out old shelving for NSF-certified stainless steel. And for good reason—studies have shown these racks can slash bacterial growth by up to 99% compared to other materials.

The Core Strengths of Stainless Steel

So, what makes stainless steel so special? It all comes down to the metal itself.

- Unmatched Hygiene: The surface of stainless steel is non-porous. In simple terms, there are no microscopic nooks or crannies for germs, mold, or bacteria to hide in. This is a must-have feature for any place that handles food or requires a sterile environment.

- Incredible Durability: This stuff is tough. It can handle heavy loads and take a beating without denting or bending, which means it will last for years, even with constant use.

- Superior Corrosion Resistance: Thanks to the chromium mixed into the alloy, stainless steel naturally forms a protective layer that fights off rust and corrosion. That makes it perfect for humid environments like walk-in coolers or areas where spills are common.

Choosing stainless steel shelving isn't just buying a product; it's a foundational investment in your business's long-term safety, compliance, and efficiency.

Understanding Different Steel Grades

Here's something important to know: not all stainless steel is the same. The "grade" of the steel tells you what it's best at resisting.

Type 304 is the most common grade you'll find. It's a great all-rounder, perfect for most kitchens and dry storage areas because it holds up well against food acids and standard cleaning chemicals.

But for tougher environments, you'll want to look at Type 316. This grade has an extra ingredient—molybdenum—that seriously boosts its ability to resist salts and chlorides. Think about it: a pizzeria needs shelving that won't get ruined by acidic tomato sauce spills, while a restaurant near the coast needs racks that can handle the salty air without corroding. Picking the right grade is key to getting the most life out of your shelves.

To get a better handle on this, check out our guide where we have stainless steel grades explained in more detail.

Understanding the Anatomy of a Stainless Steel Rack

Picking the right stainless steel shelving racks goes way beyond just getting the dimensions right. To make sure your investment can actually handle the grind of a busy kitchen, lab, or warehouse, you need to look under the hood at the components that give it strength and longevity. Think of it like buying a truck—you wouldn't just look at the paint color; you'd check the engine and towing capacity.

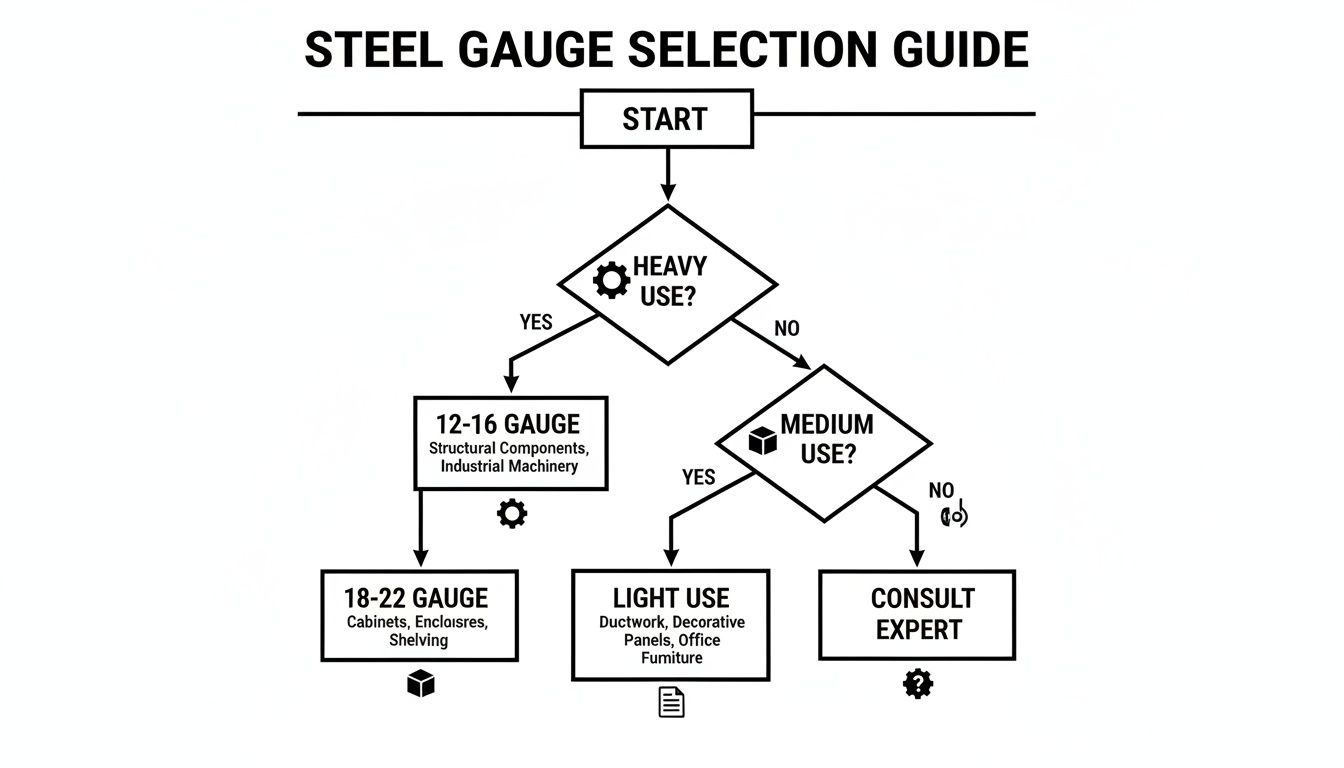

Let's dive into one of the most critical specs: steel gauge.

Simply put, steel gauge is just a number that tells you how thick the steel is.

The whole thing is a bit counterintuitive, though. A lower gauge number actually means thicker, stronger steel. It works just like electrical wiring—a heavy-duty 12-gauge wire can handle a lot more power than a flimsy 18-gauge wire. It's the exact same principle with your shelving.

Decoding Steel Gauge and Strength

A rack's gauge is the number one factor determining how much weight it can hold before it starts to bend, buckle, or warp. For example, a heavy-duty 14-gauge shelf is in a completely different league of strength compared to a standard 18-gauge one.

- 14-Gauge Steel: This is the heavyweight champ. It’s built for storing serious weight like 50-pound sacks of flour, bulky kitchen equipment, or full stockpots. You'll see this in high-volume restaurant kitchens and warehouses where failure is not an option.

- 16-Gauge Steel: This is the all-rounder, offering a fantastic balance of strength and affordability. It's perfect for most general storage needs, like holding stacks of dinner plates, countertop appliances, or cases of canned goods.

- 18-Gauge Steel: Best for lighter-duty jobs. An 18-gauge shelf is great for storing your dry goods, small utensils, or even office supplies in the back office.

If you really want to get a feel for how these components come together, checking out a practical guide on building custom shelving units can be a huge help. It helps you visualize how each part works together to create a sturdy, reliable structure.

To make this a little easier to digest, here's a quick reference table.

Steel Gauge and Load Capacity Guide

| Steel Gauge | Common Applications | Typical Load Capacity (per shelf) |

|---|---|---|

| 14-Gauge | Heavy equipment, bulk ingredients, full stockpots | 600 - 800 lbs |

| 16-Gauge | General storage, appliances, cases of goods, dishware | 400 - 600 lbs |

| 18-Gauge | Light dry goods, small utensils, office supplies | 250 - 400 lbs |

Remember, these are just general guidelines. Always check the manufacturer's specific load ratings before you buy.

Understanding Finishes and Their Impact

The finish on stainless steel isn't just for show—it plays a big role in how easy the rack is to keep clean. The most common you'll run into is a brushed finish. It has that classic satin look with fine parallel lines, which does a fantastic job of hiding minor scratches and fingerprints. It's the practical choice for busy, high-traffic work areas.

On the other hand, you might see a polished finish, which gives you a shiny, mirror-like surface. While it looks sharp, it's a magnet for smudges and fingerprints and will take a lot more wiping to keep it looking pristine.

Calculating Your Load Capacity Needs

Load capacity is the magic number that tells you the maximum weight a single shelf can hold safely when that weight is spread out evenly. Pushing past this limit is asking for trouble. You risk bent shelves, a full-on rack collapse, and some serious safety hazards.

Before you add anything to your cart, take a minute to do some quick math. What are the heaviest things you plan on putting on a single shelf? For a bakery, that could be several sacks of flour and sugar. For a lab, it might be a few pieces of dense equipment. Always, always pick a rack with a load capacity that gives you a comfortable buffer over your heaviest estimated load.

History shows why durable materials matter. During the 2008 recession, there was a 15% shift away from aluminum to stainless steel because it's more cost-effective in the long run, lasting three times longer under typical loads of 2,000 to 5,000 pounds. For a modern pizzeria, using undercounter stainless racks with adjustable heights (usually 28-36 inches) isn't just about storage; it helps with ergonomics and has been shown to cut injury claims by 20%, according to OSHA data. You can find more warehouse racking insights on Future Market Insights.

When in doubt, always overestimate your weight requirements. A stronger rack is a safer and more reliable long-term asset for your operations.

Finding the Perfect Stainless Steel Shelving Configuration

Okay, so you’ve got the basics down—steel gauge, load capacity, all that good stuff. Now for the fun part: picking the actual shape and style of shelving that will work best in your space. This isn't just about finding something that fits; it’s about choosing a configuration that makes your whole operation run smoother.

Think of it like picking the right tool for a job. Sure, you could use a wrench to hammer a nail, but a hammer works a whole lot better. The same logic applies here. The world of stainless steel shelving racks is surprisingly diverse, going way beyond a simple set of shelves. Let's break down the most common types so you can find the perfect fit.

Core Shelving Types for Every Need

Most kitchens, labs, or stockrooms can get by with one of four main types of shelving. Each one has its own strengths, depending on your layout and what you’re trying to accomplish.

-

Freestanding Units: These are the all-purpose workhorses of the storage world. They aren't bolted to anything, so you can stick them wherever you need them—smack in the middle of a room to create a new section, up against a wall, or inside a walk-in cooler. Their flexibility is a lifesaver for businesses whose needs change on the fly.

-

Wall-Mounted Shelves: When you're tight on floor space, the only way to go is up. Wall-mounted shelves are brilliant for keeping stuff you use all the time—spices, small tools, plates—right above a prep table or sink. They get things off your valuable counter space, making the whole area feel cleaner and more organized.

-

Dunnage Racks: These are the low-slung, heavy-lifters of the group. Their whole job is to keep bulk items safely off the floor, which is a non-negotiable health code rule in most places. Picture a bakery storing 50-pound bags of flour or a bar keeping cases of seltzer properly elevated. Dunnage racks are built to handle serious weight.

-

Mobile Racks (on Casters): Need ultimate flexibility? Get racks on wheels. A busy kitchen can roll ingredients from the fridge to the line in one go. A caterer can load up trays and wheel them right out to the van. They go where the work is, which is a massive advantage in any fast-paced environment. For really high-volume operations, you might even look into how systems like gravity flow racks can take this a step further.

This handy chart can help you connect the dots between what you're storing and the steel gauge you’ll need for these different setups.

As you can see, the heavier the load, the lower (and thicker) the gauge needs to be. Simple as that.

The Rise of Integrated Prep Tables

Sometimes, just having shelves nearby isn't enough. That's where integrated workstations come in. These genius pieces of equipment combine your prep surface, storage, and even refrigeration into one compact unit. It’s all about saving space and, more importantly, saving steps for your staff.

These aren't just tables with a shelf slapped on underneath. They are purpose-built to make a specific job as efficient as possible. The goal is to keep everything an employee needs right at their fingertips, which is a proven way to speed things up and reduce fatigue.

Specialized Workstations: Sandwich and Pizza Prep Tables

The sandwich and pizza prep tables are probably the best examples of this all-in-one approach. They look similar, but each is tweaked for its specific menu. A well-designed prep station isn't just a piece of equipment; it's the central nervous system of your production line, dictating the pace and efficiency of your entire operation.

A sandwich prep table is an absolute must for any deli or café. Here’s why they work so well:

- Refrigerated Top Rail: A row of chilled wells holds all your fresh ingredients—lettuce, tomatoes, onions, pickles—keeping them cold, safe, and ready to grab.

- Cutting Board Workspace: You get a full-length cutting board right in front, giving you a dedicated spot to build sandwiches and salads.

- Undercounter Refrigeration: The whole base is a refrigerated cabinet with its own stainless steel shelving. It’s the perfect place for backup pans of ingredients, deli meats, and sauces.

A pizza prep table follows the same concept but is built for the chaos of a pizzeria. It has a similar refrigerated rail, but it's usually raised and designed to hold deeper pans for sauce, mountains of cheese, and all your toppings. The refrigerated cabinet below is often configured to hold bulky pizza dough boxes right alongside everything else.

By marrying a tough work surface with easy-access cold storage right where you need it, these tables turn food assembly into a streamlined, highly efficient process.

Why NSF Certification Is a Non-Negotiable Requirement

When you're shopping for stainless steel shelving racks, you’ll probably see a small, circular blue seal on some products: the NSF logo. It’s easy to dismiss it as just another sticker. In a professional setting, though, that seal is one of the single most important things to look for.

Think of it as your guarantee. That little logo tells you the equipment has survived a whole battery of tough tests for safety and hygiene.

The National Sanitation Foundation (NSF) acts like a strict, third-party auditor for public health. When a shelving unit gets their stamp of approval, it means the product has been thoroughly evaluated from top to bottom. This isn't just a quick look-over; it's a deep dive.

NSF inspectors check that the materials are non-toxic and won't leach chemicals into your food. They make sure the design is completely smooth—no tiny cracks or crevices where bacteria could hide and throw a party. They also confirm the rack is built tough enough for a commercial environment without chipping, pitting, or falling apart.

The Real-World Impact of Certification

Having NSF-certified gear isn't just a "nice-to-have." It’s a critical part of running a safe, compliant kitchen or lab. Health inspectors are trained to spot that NSF seal on every food contact and storage surface. Using non-certified shelving is one of the fastest ways to get written up.

An NSF-certified rack isn't just a piece of metal; it's a piece of mind. It tells your staff, your customers, and health inspectors that you take food safety seriously.

Failing a health inspection can be devastating. We're talking fines, mandated closures, and a serious blow to your reputation. All that hard work you've put in can be undone by one failed inspection. That’s exactly why investing in certified shelving is a fundamental business need, not an optional upgrade. To get into the nitty-gritty, you can learn more about what NSF certification truly means and how the whole process works.

Why Non-Certified Racks Are a Liability

Sure, you might save a few bucks upfront by choosing non-certified shelving, but you’re taking on some serious risks. Those uncertified racks might be built with cheaper steel that can rust or corrode, contaminating your inventory. Their design could also have hard-to-clean corners or seams, creating the perfect breeding ground for mold and pathogens.

The recent focus on hygiene has only made this certification more important. In the U.S., where PrepTables.com operates, demand for certified stainless racks in commercial kitchens jumped 25% between 2020-2024. This change, driven by post-COVID hygiene standards, has been shown to cut cross-contamination risks by up to 90% when using high-quality Type 304 or 316 steel. This isn't just a local trend; it's part of a global move toward tougher food safety rules. You can find more insights on the growing stainless steel shelves market.

At the end of the day, NSF certification is your shield against health code violations and a cornerstone of a safe, professionally run operation.

Installation and Maintenance: Protecting Your Investment

You’ve invested in top-notch stainless steel shelving racks, but getting the most out of them boils down to two things: setting them up right and keeping them clean. A solid installation is all about safety and stability from day one. And a smart maintenance routine? That’s what keeps the steel looking pristine and doing its job for years, even decades. This isn't just about appearances; it's about protecting your investment.

A wobbly shelf is a dangerous shelf. That's why every good installation starts with the floor. Before you even think about putting pieces together, find a completely level spot. An uneven surface will cause the entire unit to lean or rock, which is a major hazard, especially when it’s loaded down with heavy equipment or supplies.

A Step-By-Step Guide to Secure Installation

Assembling your shelving is pretty straightforward, but it’s the details that matter. Always follow the manufacturer’s instructions to the letter, but here are a few universal tips that I’ve learned always make a difference.

- Check Your Parts: Do a quick inventory before you begin. Lay everything out and make sure all the components are there and in good shape. This simple step can save you a massive headache halfway through the build.

- Assemble on a Level Surface: If you can, build the rack right where it’s going to live. Use a level to double-check that the floor is flat before you start and then check the frame again once it’s assembled.

- Secure Wall-Mounted Units to Studs: This is absolutely non-negotiable for wall shelves. Use a stud finder to locate the solid wood beams behind your drywall. Anchoring directly into studs is the only way to get the support needed for heavy loads. Drywall anchors alone are just asking for trouble.

- Evenly Distribute Weight: When you start loading up the shelves, put your heaviest items on the bottom. Spread the weight evenly across each shelf. This simple trick lowers the unit's center of gravity and makes it much more stable.

Preserving the Protective Layer Through Proper Cleaning

What makes stainless steel so resistant to rust? It's all thanks to a super-thin, invisible shield on its surface called the passivation layer. This layer of chromium oxide forms naturally when the metal meets oxygen. Your entire cleaning goal is to get rid of grime without scratching or stripping away this crucial barrier.

Think of the passivation layer as the steel's immune system. Harsh chemicals and abrasive tools can weaken it, leaving the metal vulnerable to corrosion and rust.

I’ve seen more stainless steel ruined by incorrect cleaning than by anything else. The biggest myth is that you can grab steel wool or a scouring pad for tough, stuck-on messes. Never do this. These tools will shred the passivation layer and leave behind tiny iron particles that are guaranteed to rust, eventually compromising the whole shelf.

For a deep dive on the right way to clean, check out our guide on how to clean stainless steel for detailed, step-by-step instructions.

Your Go-To Cleaning and Maintenance Schedule

When it comes to keeping your stainless steel in perfect shape, consistency is everything. A simple, regular routine is the best way to prevent buildup and protect the metal's finish.

Here's a practical schedule that will keep your shelves looking and performing their best.

Stainless Steel Cleaning and Maintenance Schedule

| Frequency | Task | Recommended Cleaning Agent | Pro Tip |

|---|---|---|---|

| Daily | Wipe down spills and food debris | Warm water and a soft cloth | Clean spills right away to stop acids or salts from damaging the surface. |

| Weekly | Clean all surfaces thoroughly | Mild soap or detergent and warm water | Always wipe in the direction of the metal's grain to avoid streaks and smudges. |

| Monthly | Deep clean and inspect the entire unit | Specialized stainless steel cleaner | Look for any early signs of rust and treat small spots with a baking soda paste. |

Sticking to this routine is simple, but it makes all the difference.

By following these installation and maintenance tips, you’re ensuring your stainless steel shelving racks don’t just meet compliance standards. You're guaranteeing a safe, durable, and hygienic storage solution that will serve your business reliably for a long, long time.

Customizing Your Storage for Maximum Efficiency

A standard stainless steel shelving rack is a great starting point for any professional kitchen or lab, but its real power is revealed when you customize it. Think of the basic unit as a blank canvas. By adding the right accessories, you can turn a simple storage rack into a purpose-built system that solves your biggest organizational problems and makes daily routines faster.

This is the step where you go from just storing things to actively managing your workflow. The goal is a setup so perfectly matched to what you do that it feels like it was designed just for your business.

Tailoring Shelving with Practical Accessories

A small investment in the right add-ons can lead to big gains in efficiency. Instead of a one-size-fits-all approach, you can create specific zones for different items, making everything easier to find, grab, and put back. It’s all about cutting down on wasted time and movement.

Here are some of the most popular and effective accessories available:

- Shelf Dividers: These simple clip-on barriers are perfect for keeping smaller items in line. Think spice containers, condiment bottles, or lab vials—all neatly organized and standing upright. No more knocking things over like dominoes.

- Wine Rack Inserts: A must-have for restaurants and bars. These specialized inserts cradle wine bottles securely, packing them in tightly while protecting your valuable inventory from rolling around or falling.

- Security Cages: If you store high-value items like top-shelf spirits, specialty ingredients, or sensitive lab materials, a lockable security cage is a great solution. It keeps things ventilated while stopping unauthorized access.

- Tray Slides: Absolutely essential for cafeterias, bakeries, and caterers. Tray slides let you store and pull out sheet pans with no fuss. This organized system improves airflow for cooling and simplifies the entire process from prep to service.

Customization isn’t about making things more complicated; it’s about removing friction from your day-to-day work. The right accessory should make a task feel simpler, faster, and more natural.

Customization in Action

Let’s look at how this plays out in a real-world setting. Picture a busy catering company that uses mobile racks to transport food. By adding color-coded plastic bins to each shelf, they can separate ingredients for different events. This makes loading the truck faster and dramatically cuts down on packing mistakes.

In another example, a research lab could add under-shelf drawers to their stainless steel workstations. This one simple change creates a secure, organized spot for delicate instruments and tools. It keeps the main work surface clear and lowers the risk of contamination or damage. By tailoring your stainless steel shelving racks with these kinds of practical add-ons, you build a smarter, more productive workspace from the ground up.

Answering Your Top Questions About Stainless Steel Racks

Even with all the details, you probably have a few practical questions kicking around. Let's tackle some of the most common things buyers ask about stainless steel shelving racks so you can feel totally confident in your choice.

What Is the Difference Between 304 and 316 Grade Stainless Steel?

The easiest way to think about it is that Type 304 is the trusty workhorse for most situations. It's perfect for almost any commercial kitchen or dry storage area because it has fantastic, all-around resistance to corrosion. It handles the usual food acids and cleaning chemicals without breaking a sweat.

Type 316, though, has an extra ingredient: molybdenum. That addition gives it superior armor against things like chlorides and salts.

So, when should you spring for 316-grade steel? If your shelving is going in a coastal spot with salty air, near de-icing salts, or around harsh industrial chemicals. For just about everyone else, the more budget-friendly Type 304 is the way to go.

Can I Place Hot Pans Directly on Stainless Steel Shelves?

You absolutely can. One of the best things about stainless steel is its high tolerance for heat. You can move hot pots, pans, and baking trays right onto the shelf without worrying about melting, warping, or any other damage.

This is a huge plus in a fast-paced commercial kitchen. It means items can go straight from the oven or stovetop to the rack, keeping your workflow smooth and efficient when things get busy.

How Do I Remove Rust Spots from My Stainless Steel Rack?

While stainless steel is highly resistant, it isn't completely rust-proof. If you see little rust spots pop up, it’s almost always because of surface gunk or from using the wrong cleaning tool, like steel wool.

Here's how to safely get rid of them:

- Mix up a simple paste of baking soda and water.

- Gently rub the paste on the spot with a soft cloth. Always move in the same direction as the metal's grain.

- Rinse the spot completely with clean water and dry it thoroughly so you don't leave water spots.

This is critical: never use steel wool, abrasive scouring pads, or chlorine bleach. These will permanently scratch the steel's protective surface, which is like sending an open invitation for more rust to show up later.

At PrepTables.com, we focus on providing top-quality stainless steel solutions that keep your operation running safely and smoothly. Check out our full lineup of NSF-certified shelving, prep tables, and other commercial gear today. Find the perfect equipment for your professional space at https://preptables.com.