Choosing Your Stainless Steel Shelf Unit

Share

A stainless steel shelf unit is more than just a place to put things. It’s the workhorse of any space where durability, hygiene, and rust resistance are top priorities. Think of commercial kitchens, medical labs, or even a hard-working home garage—these are the environments where this kind of tough, easy-to-clean storage really shines.

Why Stainless Steel Is the Smart Choice for Shelving

Before you pick out any shelving, it’s worth taking a moment to understand why stainless steel is so often the best material for the job. It's not just about looks; it's a long-term investment in a clean, organized, and safe space. Its unique properties give you real-world benefits you won't get from wood or plastic.

The demand for this kind of quality is growing. The global market for stainless steel shelving was valued at roughly USD 5.2 billion in 2023 and is expected to climb to around USD 8.1 billion by 2032. This isn't just a trend; it's a clear signal that more businesses and homeowners are choosing durable, low-maintenance storage. You can dig into more of these market insights on Dataintelo.com.

To give you a clearer picture, here’s a quick rundown of what makes stainless steel the go-to material for shelving.

Key Benefits of Stainless Steel Shelving at a Glance

| Benefit | Description | Ideal For |

|---|---|---|

| Unmatched Durability | Built from an iron alloy with chromium, it resists bending, buckling, and cracking under heavy loads. | Storing bulk ingredients, heavy equipment, and dense materials. |

| Corrosion Resistance | A natural, self-healing layer of chromium oxide prevents rust, even in damp or steamy conditions. | Commercial kitchens, laboratories, basements, and garages. |

| Superior Hygiene | The non-porous surface is easy to clean and sanitize, preventing bacteria from finding a place to hide. | Food service environments, medical facilities, and cleanrooms. |

| Professional Look | Maintains a clean, modern aesthetic for years without chipping, warping, or discoloring. | Any space where appearance and cleanliness are important. |

This table just scratches the surface. Let's dive a little deeper into what makes these benefits so crucial.

Unmatched Durability and Strength

At its heart, stainless steel is an iron alloy beefed up with chromium and nickel. This blend creates a material that’s built to take a beating day in and day out. Plastic can crack under a heavy load, and wood can warp or splinter over time, but a stainless steel shelf unit holds its ground.

This toughness is exactly why you see it in demanding environments. It can easily handle the weight of heavy mixers, stacks of canned goods, or boxes of tools without breaking a sweat. You get a reliable storage platform you can count on.

A key advantage of stainless steel is its non-porous surface. This means liquids, food particles, and contaminants cannot penetrate the material, preventing stains and bacterial growth.

Superior Corrosion and Rust Resistance

The real magic behind stainless steel's long life is its chromium content. When air hits the surface, the chromium creates a super-thin, invisible shield of chromium oxide. If it gets scratched, it "heals" itself, constantly protecting the steel underneath from rust and corrosion.

This makes it the perfect choice for places with a lot of moisture:

- Commercial Kitchens: It holds up against steam from dishwashers, constant spills, and frequent deep cleaning.

- Laboratories: It stands strong against chemical splashes and harsh sterilizing agents.

- Garages and Basements: It won't break down or rust away in damp, humid air.

This resistance means your investment stays looking professional and functions perfectly for years, without the ugly decay that ruins other materials.

The Gold Standard for Hygiene

In any setting where sanitation is everything, the non-porous surface of stainless steel is a lifesaver. Wood has tiny cracks and grains where bacteria love to hide, but stainless steel offers a perfectly smooth surface that’s incredibly easy to clean and disinfect.

This is exactly why it’s a requirement in so many food service and medical industries. A quick wipe-down is all it takes to remove germs and grime, helping you keep your space safe and sterile without a ton of effort. Choosing a stainless steel shelf unit isn't just about storage; it's a smart move for better efficiency and cleanliness.

Understanding Stainless Steel Grades and Finishes

Not all stainless steel is the same, and picking the right type is a big deal for the lifespan and performance of your stainless steel shelf unit. Think of steel grades like different jackets in your closet. One is a versatile raincoat perfect for wet weather, while another is a tough work jacket meant for dry, demanding jobs. Knowing these differences ensures you get a unit that's perfectly suited for its task.

This isn't just a technical detail—it affects everything from rust resistance to your budget. The global stainless steel market, valued at USD 106.51 billion in 2023, is expected to hit USD 150 billion by 2035 because industries like food service and construction need specific material properties. You can learn more about these trends in this detailed report on the stainless steel industry.

Decoding Stainless Steel Grades

When you see numbers like "Type 304" or "Type 430," you're essentially looking at the steel's recipe. These grades tell you the specific mix of metals in the alloy, mainly chromium and nickel, which dictates how it will perform.

Here’s a look at the two most common grades you’ll run into when shopping for shelving.

Comparing Common Stainless Steel Grades for Shelving

| Feature | Type 304 Stainless Steel | Type 430 Stainless Steel | Best Use Case |

|---|---|---|---|

| Composition | Contains 18% chromium and 8% nickel. | High chromium content, but very little nickel. | |

| Corrosion Resistance | Excellent. The high nickel content makes it the top choice for preventing rust. | Good, but not as robust as Type 304 in wet conditions. | |

| Best For | Wet or humid environments like walk-in coolers, kitchens, and dishwashing areas. | Dry storage areas like pantries, stockrooms, and garages. | |

| Cost | More expensive due to the higher nickel content. | More affordable and budget-friendly. | |

| Magnetic? | No | Yes |

Ultimately, choosing the right grade is a practical decision. If you need shelving for a prep area where spills and steam are a daily reality, Type 304 is a non-negotiable investment. But for storing dry goods in a back room, the cost savings of a Type 430 unit just make sense. Our guide to commercial stainless steel tables dives even deeper into selecting materials for professional kitchen environments.

The Impact of Finishes on Appearance and Maintenance

Beyond the grade, the finish on your stainless steel shelf unit affects both its look and how easy it is to keep clean. The finish is simply the texture applied to the steel's surface during manufacturing.

You'll typically find two main options: brushed and polished.

Brushed Finish: This finish has a dull, satin-like look created by fine parallel lines. It's a workhorse finish, great at hiding fingerprints, smudges, and minor scratches, making it a smart choice for busy, high-traffic areas.

Polished Finish: A polished finish is smooth, reflective, and almost mirror-like. It delivers a striking, high-end look but will show every fingerprint and water spot. This finish is usually reserved for front-of-house applications where appearances are a top priority.

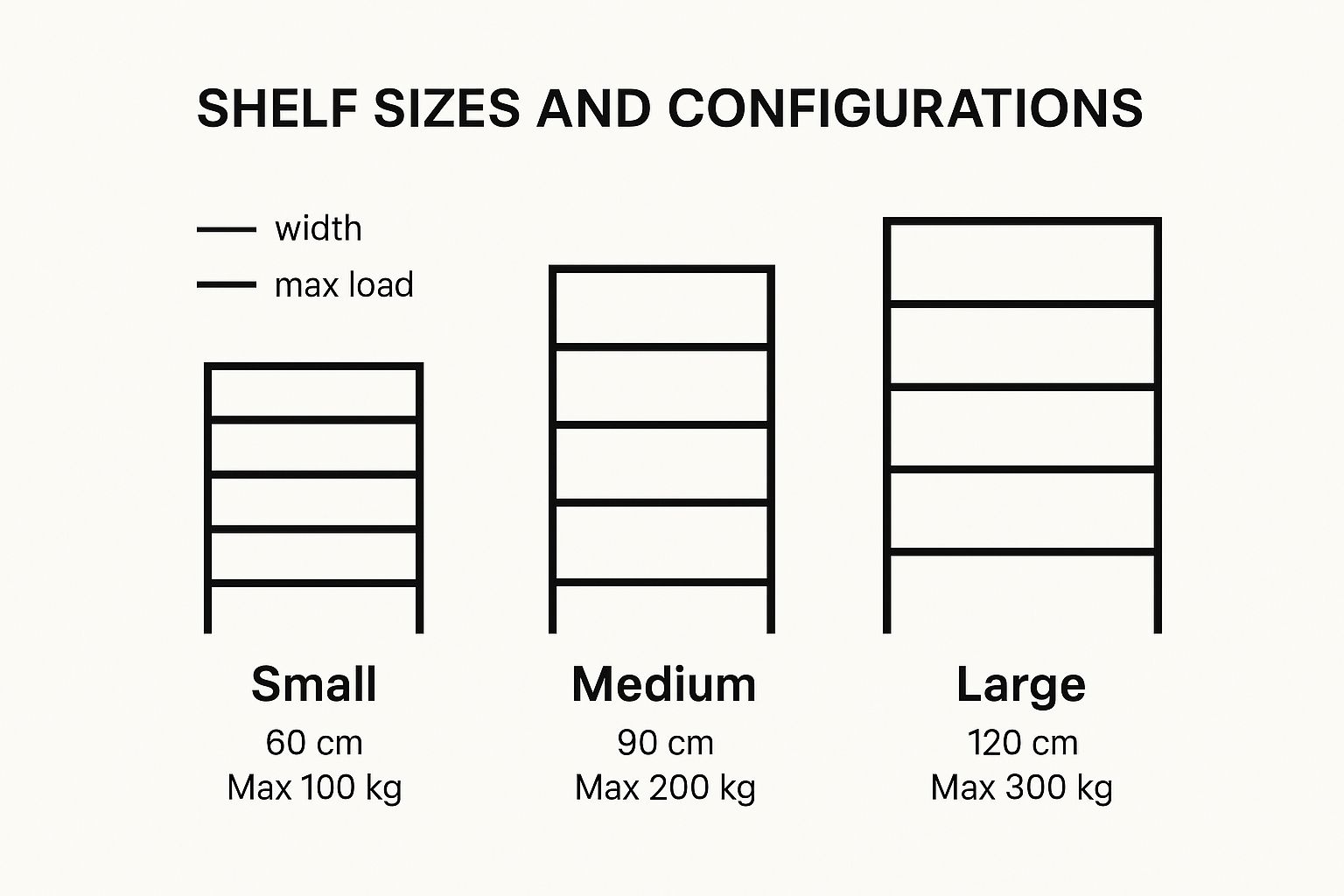

The infographic below shows how a unit's physical size relates to its strength.

As you can see, there’s a direct link between a shelf's width and the weight it can safely hold—another key factor to consider alongside the material grade and finish.

Finding the Right Stainless Steel Prep Table

While a standalone stainless steel shelf unit is a must-have for vertical storage, the real heart of any busy kitchen is the prep table. This piece of equipment is a hybrid, blending a tough workspace with built-in storage to create the command center for your entire operation. Picking the right one isn't just about getting a flat surface; it's about choosing a station that makes your whole workflow smoother.

Stainless steel prep tables aren't one-size-fits-all. They range from simple workbenches to highly specialized stations, and understanding the differences is the key to creating a more organized, functional kitchen. Each design is built to solve specific problems, making sure every tool and ingredient is right where you need it, when you need it.

The Foundation: Workbenches with Undershelves

The most common and flexible option you'll find is the standard stainless steel workbench. Think of it as the basic building block of kitchen organization. It gives you a clean, tough surface for all your chopping, mixing, and plating, while the open undershelf offers easy-to-access storage for high-volume items.

That undershelf is a complete game-changer for kitchen efficiency. Instead of trekking back and forth to a separate stainless steel shelf unit, you can keep bulky items right under your workspace. This setup is perfect for:

- Bulk Ingredients: Storing heavy bags of flour, sugar, or potatoes just an arm's length away.

- Large Equipment: Tucking away big mixers, food processors, or stock pots that would otherwise eat up valuable counter space.

- Nesting Containers: Stacking those large prep containers and mixing bowls neatly out of sight.

By merging active prep space with immediate storage, these tables cut down on wasted steps and save precious time when you're in the middle of a rush. They really are the backbone of a well-designed kitchen.

Specialized Stations: Sandwich Prep Tables

When speed and consistency are everything, a basic workbench just won't cut it. That's where specialized units like the sandwich prep table shine. Engineered for high-volume sandwich or salad lines, these tables are all about peak efficiency.

A sandwich prep table has refrigerated compartments built right into the work surface. It features a refrigerated rail across the top holding multiple food pans, keeping your sliced meats, cheeses, and veggies perfectly chilled and ready to go. This layout means your crew can build orders in record time without ever having to leave their station.

The real genius of a sandwich prep table is its ability to maintain the cold chain. By keeping perishable ingredients at a safe temperature right where they're being used, it dramatically cuts the risk of foodborne illness and protects the quality of your product.

These tables almost always come with a cutting board running the full length of the unit, giving you a dedicated, food-safe surface for assembly. Below, you’ll find refrigerated cabinets or drawers for backup ingredients, creating a completely self-contained workstation.

Purpose-Built for Perfection: Pizza Prep Tables

Much like sandwich tables, pizza prep tables are fine-tuned for a very specific job. Their standout feature is a wide, cool work surface—often marble or granite, though stainless steel is also an option—that’s perfect for stretching and handling dough. The cool surface keeps the dough from getting sticky or overworked.

Just like their sandwich-making cousins, these tables have a refrigerated rail for all the toppings. This gives a pizza maker instant access to sauce, cheese, pepperoni, and veggies, all held at the right temperature. This all-in-one design is a lifesaver in a busy pizzeria, where one station has to handle the entire assembly process. For a deeper look into selecting the right materials and configurations, you can explore this detailed guide on the essential stainless steel prep table.

Key Features That Enhance Functionality

Beyond the main type of table, a few key features can make a huge difference in how useful and safe your prep table is. Paying attention to these small details will help you pick a unit that truly meets your kitchen's needs.

- Backsplashes: A backsplash is simply a raised lip along the back of the table. Its job is to keep food, liquids, and utensils from falling down behind the unit. This not only keeps your walls clean but also prevents food scraps from piling up in hard-to-reach spots—a big win for hygiene.

- Marine Edges: A marine edge, sometimes called a raised or anti-drip edge, is a raised perimeter around the main work surface. This feature is designed to contain spills, keeping liquids from running onto the floor. It’s an incredibly valuable feature in wet prep areas, as it boosts safety by reducing slip hazards.

- Ergonomic Height: Most commercial prep tables are set at a standard height of 34-36 inches, which works well for most people. However, looking for tables with adjustable legs or feet lets you customize the height for your staff, which can reduce back strain and improve posture during those long shifts.

Decoding Load Capacity and NSF Certification

Beyond the type of steel and its finish, there are two details you absolutely can't ignore when picking a stainless steel shelf unit: load capacity and NSF certification. These aren't just minor specs on a product page; they are the core of what makes a shelf safe, functional, and compliant.

Getting these right means you're buying a unit that's not only strong enough to do the job but also meets critical health standards. Think of load capacity as the muscle and NSF certification as the clean bill of health—you need both for a truly reliable storage system.

Understanding Shelf Load Capacity

Load capacity is simply the maximum weight one shelf can handle without buckling, as long as that weight is spread out evenly. This is often called the "uniformly distributed load." It's a huge deal. Overloading a shelf is a classic mistake and a primary cause of collapses, which can destroy inventory and, worse, cause serious injuries.

It’s all about matching the shelf's strength to what you're storing. A shelf holding a heavy-duty 60-quart commercial mixer has to be far stronger than one holding a few boxes of disposable gloves or spice containers.

Not sure what capacity you need? It's pretty straightforward to figure out:

- Make a list. Jot down everything you plan to put on a single shelf.

- Do the math. Add up the total weight of those items. It's smart to round up or add a little extra to give yourself a safety buffer.

- Find your shelf. Choose a stainless steel shelf unit with a per-shelf capacity that easily handles your heaviest estimated load.

For instance, if you're storing two 50-pound bags of flour on one shelf, you need a capacity of at least 100 pounds. But honestly, a shelf rated for 200 or 300 pounds is a much safer, smarter choice. For an even deeper dive into heavy-duty storage, especially how weight distribution works, you can find great info on long span shelves.

What Is NSF Certification

The other make-or-break factor is the NSF mark. NSF International (which used to be the National Sanitation Foundation) is a respected, independent organization that tests and certifies products to make sure they meet strict public health and safety standards. When you see that NSF logo on a stainless steel shelf unit, it's a rock-solid guarantee of quality and hygiene.

This isn't just a fancy sticker. It means the product went through a battery of tough tests to prove its mettle.

An NSF-certified shelf is a promise of safety. It tells health inspectors, employees, and customers that your equipment is designed for a sanitary environment, with no hidden crevices where bacteria can grow and a surface that is easy to clean and sanitize.

For any commercial kitchen, food processing plant, or medical setting, NSF certification isn't optional—it's a requirement. Health codes demand NSF-listed equipment to prevent foodborne illness and keep things sterile.

Why NSF Standards Matter

To earn that NSF logo, a shelving unit must meet some very specific design and material rules. These standards are all about knocking out hygiene risks before they start.

Here’s what NSF certification actually guarantees:

- Hygienic Materials: The stainless steel is non-porous, corrosion-resistant, and non-toxic. It won’t leach anything into food or other sensitive items.

- Smooth and Cleanable Design: The unit is built without cracks, sharp corners, or tiny gaps where food bits and germs can hide. Every surface is smooth and a breeze to wipe down.

- Durability and Performance: The shelf is tough enough for a demanding commercial environment. It won't chip, pit, or break down in a way that could compromise its sanitary surface.

When you invest in an NSF-certified stainless steel shelf unit, you're getting a product that's not only built to last but also designed to meet the highest public health standards. It makes health inspections smoother and gives you one less thing to worry about.

Assembling Your Stainless Steel Shelf Unit

Turning that box of steel parts into a sturdy, reliable stainless steel shelf unit might seem like a headache waiting to happen, but it’s actually a pretty straightforward job if you know what you’re doing. This guide will walk you through it, making the process simple and ensuring your new shelving is built right for maximum stability.

Before you start tearing open the box, grab a rubber mallet and a level. The mallet is perfect for tapping shelves into place without denting the steel, and the level is your best friend for getting everything perfectly balanced. Having these on hand will save you a ton of frustration later.

It's no surprise that stainless steel furniture is becoming more popular. People want stuff that lasts. In fact, the global market for stainless steel furniture hit about USD 3.35 billion in 2024 and is projected to climb to USD 5.66 billion by 2032. You can dig into the specifics of these market growth trends on seelteen.com.

A Step-by-Step Assembly Guide

Most freestanding units go together the same way. Always give the manufacturer's instructions a once-over, but here’s the general game plan for a solid build.

- Prepare the Posts: First things first, screw the adjustable feet into the bottom of the four vertical posts. If your kit has plastic clips, snap them onto the posts where you want your first shelf to sit. Just make sure they're all at the exact same height.

- Build on Its Side: Here’s a little trick that makes life easier—assemble the unit on its side. Lay two posts on the floor, parallel to each other. Slide the first shelf down over them until it’s resting snugly on the clips. Do the same for the second shelf.

- Attach the Other Side: Now, grab the other two posts and slide them onto the open corners of the shelves you just attached.

- Complete the Shelves: With the main frame together, you can slide the rest of your shelves into place. Make sure each one clicks firmly onto its clips.

- Secure and Level: Time to get it on its feet. Carefully stand the unit upright. Use your rubber mallet to give the corners of each shelf a gentle tap to make sure everything is tight. Last, grab your level and adjust the feet to kill any wobble.

Addressing Common Installation Hurdles

Even the best plans can hit a snag. Knowing how to handle these common issues will keep your project moving smoothly.

Dealing with Uneven Floors Those adjustable feet on your stainless steel shelf unit are a lifesaver for wonky floors. Once the unit is where you want it, check it with a level. If it’s rocking, just twist the feet clockwise or counter-clockwise to raise or lower each corner until it stands perfectly still.

Anchoring Wall-Mounted Shelves For wall-mounted shelves, stability is everything. You absolutely have to mount the support brackets directly into wall studs. Use a stud finder to locate them, then drill your pilot holes. This is the only way to ensure the shelf can safely hold its rated weight. For more general advice and to sidestep common assembly mistakes, check out these helpful tips for assembling storage shelves.

Maintaining Your Shelving for Lasting Performance

A stainless steel shelf unit is built to last, but the secret to keeping that polished, hygienic surface for years is consistent care. Think of it as protecting your investment. A simple maintenance routine is all it takes to keep your shelving a reliable workhorse and prevent grime from building up.

The goal is to protect the steel's natural "passive layer," which is its built-in defense against rust. This means getting into a good rhythm with daily wipe-downs, weekly cleanings, and the occasional deeper scrub. And having the right tools on hand is just as important as the schedule itself.

Your Essential Cleaning Toolkit

You don’t need an arsenal of harsh chemicals or a ton of elbow grease to clean stainless steel effectively. In fact, going too aggressive can backfire, stripping away the protective chromium oxide layer that keeps rust at bay.

Your go-to supplies should be simple and gentle:

- Soft Cloths or Microfiber Towels: Perfect for wiping down surfaces without leaving a single scratch.

- Mild Soap or Detergent: A little bit of dish soap in warm water is usually all you need for daily gunk and grime.

- Specialized Stainless Steel Cleaner: For those times you want to do a deeper clean or really make the surface shine, a dedicated cleaner is your best friend.

On the flip side, some common cleaning tools are enemies of stainless steel. Never use steel wool, abrasive scouring pads, or any chlorine-based cleaners like bleach. These are notorious for scratching the surface and introducing tiny iron particles that can kickstart rust and corrosion.

Keeping your stainless steel pristine is all about consistency. Regular, gentle cleaning is far more effective than occasional, aggressive scrubbing. This approach maintains the material's natural defenses against corrosion and wear.

Practical Cleaning Routines

A simple, structured cleaning schedule will keep your stainless steel shelf unit looking brand new. For daily upkeep, a quick wipe with a damp cloth is often all it takes to handle fingerprints and small spills. For anything tougher, a weekly clean with soapy water should do the trick.

Here’s a pro tip: always wipe in the direction of the steel’s grain. You can see the faint lines in the finish. Following them helps prevent streaks and keeps the surface looking smooth and uniform. After washing, always rinse with clean water and dry it completely with a soft towel to prevent water spots from forming.

For a complete breakdown of the best techniques, check out our in-depth guide on how to clean stainless steel the right way.

Finally, get in the habit of giving your unit a quick check-up every few months. Make sure all the hardware is tight and the shelf feels stable and secure. A little preventative maintenance goes a long way in ensuring your shelving is safe for years to come.

Common Questions About Stainless Steel Shelving

Picking out the right stainless steel shelf unit usually brings up a few questions. Getting the right answers means you’ll end up with a setup that’s perfect for your space, whether it's a hectic commercial kitchen, a clean lab, or just your home garage. This section covers the most frequent queries to help you feel confident about your choice.

We’ll look at everything from using them outdoors to understanding certifications, making sure you have what you need to pick a unit that's safe, tough, and right for the job.

Can I Use a Stainless Steel Shelf Unit Outdoors?

Stainless steel is famous for resisting rust, but not all grades handle the great outdoors equally well. If you’re planning to put shelving outside, you absolutely need a unit made from Type 304 or, for even better protection, Type 316 stainless steel.

Type 316 has an extra ingredient, molybdenum, which gives it superior defense against corrosion from rain and salty air. A lower-grade option like Type 430 will almost certainly start to rust if left outside. Always double-check the manufacturer's specs to see the steel grade before you buy it for outdoor use.

How Do I Calculate the Load Capacity I Need?

First off, make a list of everything you want to store on a single shelf and guess the total weight. It’s always a good idea to aim high with your estimate to give yourself a safety buffer. For instance, a restaurant kitchen shelf might need to hold heavy mixers, while a garage shelf might just have tools and paint.

Choose a shelving unit with a uniformly distributed load capacity that’s comfortably above your heaviest estimated shelf weight. This one simple step prevents the shelves from dangerously sagging or breaking and keeps everything safe for the long haul.

Is an NSF Certified Shelf Necessary for My Home?

For home use, NSF certification isn't a legal must-have, but it's a solid indicator of quality and safety. An NSF-certified shelf has a guaranteed smooth, non-porous surface, which means it’s a breeze to clean and sanitize and won’t harbor bacteria.

Putting an NSF-rated stainless steel shelf unit in your home kitchen or pantry gives you the same kind of assurance professional chefs rely on. It means your storage is built to top-tier standards for both cleanliness and durability—a smart move for any health-conscious home.

Ready to find the perfect storage solution for your space? At PrepTables.com, we offer a wide selection of NSF-certified stainless steel shelving and prep tables designed for durability and hygiene. Explore our collection at PrepTables.com and build a more organized, efficient workspace today.