Top Stainless Steel Shelf Options for Your Space

Share

Walk into any professional kitchen, and you'll see it everywhere: the unmistakable gleam of stainless steel. It’s not just a trend; it's the undisputed champion for shelving, tables, and just about every other surface. A stainless steel shelf is more than just storage—it's a critical piece of equipment built for durability, hygiene, and the relentless pace of a commercial environment.

This blend of sheer toughness and easy sanitation is exactly why pros swear by it. It’s the kind of reliable, no-fuss gear that lets you focus on the food, not on whether your storage can handle the heat.

Why Stainless Steel Is the Professional Standard

There's a reason stainless steel has become the backbone of functional, safe, and efficient workspaces. It’s not just about looks. Its unique properties are perfectly matched for places where cleanliness and resilience are everything.

Think of a stainless steel shelf as a long-term partner in your kitchen's success. Its non-porous surface is a game-changer. Unlike wood, which can soak up bacteria in its grain, or plastic that easily scratches and stains, stainless steel creates a smooth, solid barrier. Nothing gets in, making it incredibly simple to wipe down and sanitize.

Unmatched Durability and Resilience

A busy kitchen is a battlefield for equipment. Things get dropped, slammed, and exposed to wild temperature swings from hot ovens to walk-in freezers. Stainless steel takes all of it in stride, resisting dents and impacts without breaking a sweat. This means your shelves stay stable and secure, whether they’re holding a heavy stockpot or a 50-pound bag of flour.

On top of that, its natural resistance to rust and corrosion is a must-have. Kitchens are full of moisture, acidic spills, and tough cleaning agents. A stainless steel shelf shrugs it all off, keeping its integrity and professional look for years. That kind of longevity is smart business.

The Foundation of Kitchen Hygiene

Good sanitation is the heart of food safety, and stainless steel is the perfect material to build on. With no tiny cracks or pores for germs to hide in, cleaning is fast and effective, helping you breeze through health inspections. This same principle of cleanability applies to bigger surfaces, too. To see how it scales up, check out our guide on commercial stainless steel tables.

It's no surprise that demand for this kind of reliable equipment is booming. The market for stainless steel shelves hit about USD 5.2 billion in 2023 and is expected to climb to USD 8.1 billion by 2032. This isn't just a trend in restaurants; it reflects a growing need for durable, low-maintenance gear in all kinds of professional settings.

Let's break down why stainless steel is such a powerhouse in any professional setting.

Key Benefits of Stainless Steel Shelving at a Glance

| Feature | Primary Benefit | Ideal Application |

|---|---|---|

| Non-Porous Surface | Prevents bacteria and mold growth, making it easy to sanitize. | Food prep areas, walk-in coolers, medical labs. |

| Corrosion Resistance | Withstands moisture, acids, and harsh cleaning chemicals without rusting. | Dishwashing stations, chemical storage, high-humidity areas. |

| High Durability | Resists dents, scratches, and impacts from heavy daily use. | Bulk storage, high-traffic kitchens, industrial workshops. |

| Temperature Tolerance | Remains stable in both extreme heat and cold without warping or cracking. | Near ovens and grills, inside freezers and refrigerators. |

| Professional Aesthetic | Provides a clean, modern, and uniform look that signals quality. | Open kitchens, customer-facing prep areas, cleanrooms. |

Ultimately, choosing stainless steel isn't just about buying a shelf; it's about investing in a system that promotes safety, efficiency, and long-term value. It’s a choice that pays for itself over and over again.

Choosing the Right Stainless Steel Grade

Not all stainless steel is created equal. Picking the right grade is like picking the right knife for the job—you wouldn't use a butter knife to break down a side of beef, right? The specific alloy, or "grade," of your stainless steel shelf determines everything: its strength, how well it resists rust, and ultimately, how long it will last in your kitchen.

Getting a handle on the technical side of things means you're making a smart investment. You don't need a degree in metallurgy, just a clear idea of how different grades actually perform. This way, you’ll get a shelf that perfectly balances durability, performance, and your budget.

The Most Common Steel Grades Explained

When you're shopping for a stainless steel shelf, you'll almost always see three numbers pop up: 304, 430, and 201. Each number is basically a different recipe, giving the steel unique properties.

-

304 Grade (The Premium Workhorse): Often called "food-grade" stainless steel, 304 is the gold standard for most kitchens. It has a high amount of chromium and nickel, which gives it top-notch resistance to rust and corrosion. Think of it as an all-weather jacket; it can handle the constant moisture from a dish pit, acidic spills from a marinade, and the general humidity of a busy kitchen without breaking a sweat.

-

430 Grade (The Budget-Friendly Choice): This grade is more magnetic and has less nickel than 304, making it a more affordable option. It’s still durable, but it doesn't fight off corrosion quite as well. It’s a great, cost-effective choice for dry storage areas like pantries or equipment closets where it won't be constantly exposed to moisture. It’s like a reliable windbreaker—perfect for mild conditions, but not what you want in a downpour.

-

201 Grade (The Light-Duty Option): Type 201 is another wallet-friendly choice, but it’s the least resistant to corrosion of the three. It's best kept for completely dry, low-impact environments. While it gives you the look of stainless steel for less, it's far more likely to rust if it gets wet or comes into contact with corrosive stuff.

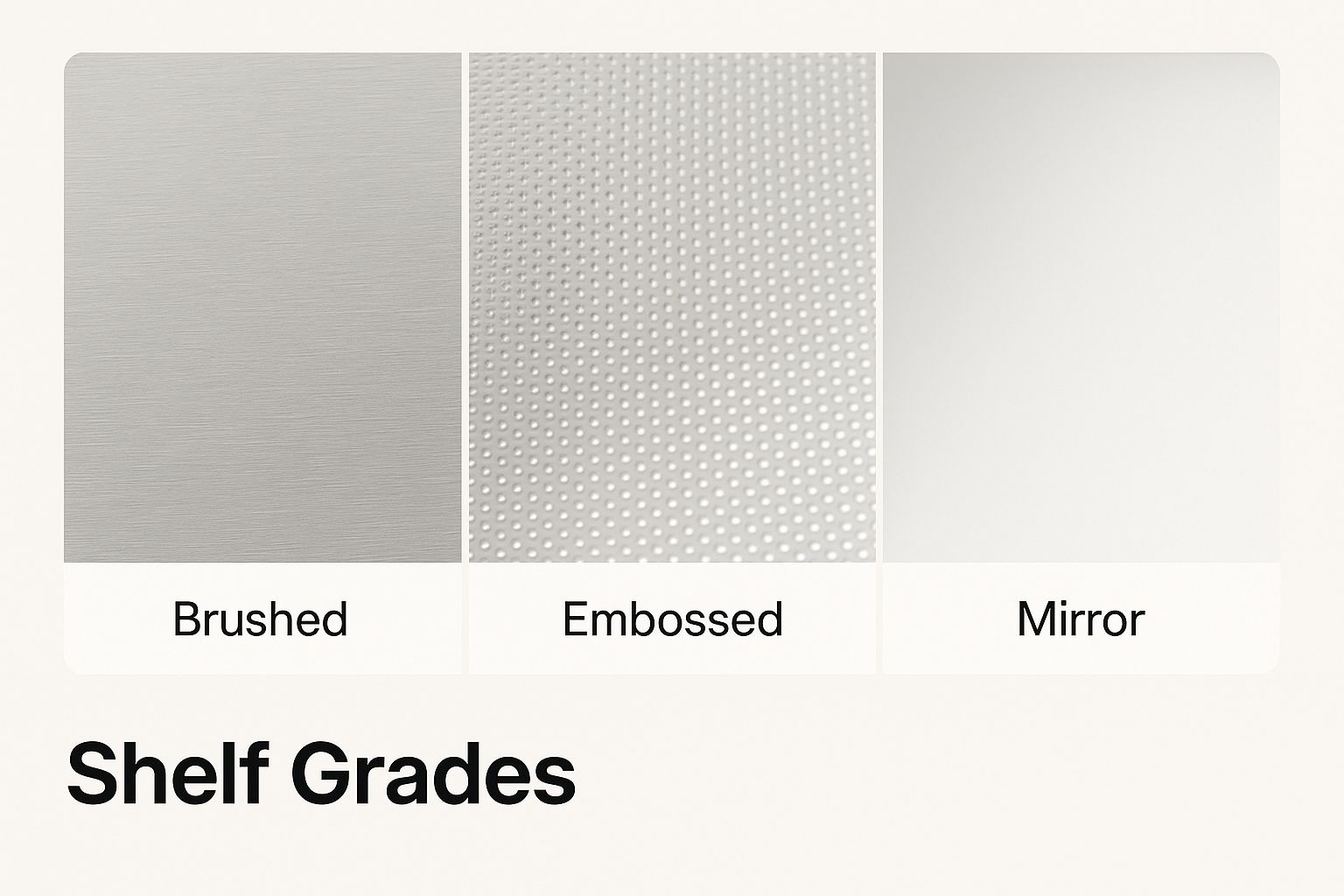

This visual guide can help you see the different finishes and grades you'll come across.

The image really shows how different grades might look similar but are worlds apart in function. It's a good reminder to choose based on what you need it for, not just how it looks.

Decoding Steel Gauge: The Secret to Strength

Besides the grade, the other critical number you need to know is the gauge. This is all about the thickness of the steel. It works on a reverse scale, which can throw people off at first.

A lower gauge number means thicker, stronger, and more durable steel.

For example, a 16-gauge stainless steel shelf is much thicker and can hold more weight than an 18-gauge shelf. Most commercial shelves fall somewhere between 14-gauge (the really heavy-duty stuff) and 18-gauge (standard duty). For general storage like dishes or small appliances, an 18-gauge shelf is usually fine. But if you’re storing heavy equipment like a stand mixer or big bags of flour, you'll want to invest in a sturdier 16-gauge or even 14-gauge shelf.

This incredible strength is a big reason why stainless steel is everywhere. The market for it is massive and projected to hit USD 348.95 billion by 2034. Within that market, austenitic steels like the popular 304 grade are the go-to for high-quality shelves because they fight corrosion so well and are easy to work with. You can dig into more of the details in these stainless steel market trends.

Making the Right Choice for Your Environment

So, how do you put it all together? It really just comes down to matching the grade and gauge to where the shelf is going and what it’s going to hold.

Use this simple checklist to guide your decision:

- High-Moisture or High-Spill Areas: For dish pits, prep stations, or walk-in coolers where water and acidic liquids are a daily reality, 304 grade is non-negotiable. Its superior corrosion resistance will stop rust in its tracks and make your shelf last so much longer.

- Dry Storage and General Use: For pantries, storage rooms, or even retail displays, 430 grade is a fantastic sweet spot between durability and cost. You get that professional look without paying the premium for 304.

- Heavy Loads and Equipment: No matter the grade, always check the gauge. If you're planning to store bulk ingredients or heavy machinery, spend the extra money on a lower gauge (14 or 16) for maximum strength and peace of mind.

By thinking through both the grade and the gauge, you can pick a stainless steel shelf that doesn’t just fit your space, but also delivers the kind of performance and longevity your kitchen demands.

Exploring Different Types of Shelves and Prep Tables

While the material gives you a solid foundation, the real magic of a stainless steel shelf is in its design. These aren't just one-size-fits-all pieces of metal; they're specialized tools engineered to solve specific storage and workflow problems. Picking the right type of shelving is just as critical as choosing the right grade of steel.

Think of it like putting together a custom toolbox. You wouldn't just throw in one kind of wrench. You'd pick different tools for different jobs to work as efficiently as possible. That's the exact same logic you should apply when outfitting a professional kitchen.

From space-saving wall units to mobile carts and heavy-duty floor models, every style has a unique job. Getting a handle on these differences lets you create a storage system that isn't just tidy, but one that feels completely intuitive for your team to use.

Maximizing Space with Wall-Mounted Shelves

Wall-mounted stainless steel shelves are the undisputed champions of vertical space. In cramped kitchens where every square foot of the floor is prime real estate, getting shelves up on the wall is a game-changer. They keep essential ingredients, spices, and small tools right where you need them—above a prep station, sink, or the main cooking line.

Typically, these shelves are best for lighter-duty storage and items you need to grab in a hurry. You might use one to hold your most-used saucepans, another for stacking plates ready for service, or one just for organizing your spice containers. The key is to place them strategically to cut down on wasted steps and make the whole cooking process smoother.

The Versatility of Freestanding Shelving Units

When it comes to bulk storage, freestanding units are the workhorses. These heavy-duty racks are what you'll find holding down the fort in pantries, walk-in coolers, and back storage rooms. They can handle way more weight than their wall-mounted cousins, making them perfect for heavy sacks of flour, cases of produce, or bulky equipment.

Their biggest plus is their versatility. You can set them up in countless configurations, with adjustable shelf heights to fit items of all shapes and sizes. Many units even have optional casters, which instantly turns a stationary rack into a mobile cart you can roll out of the way for cleaning or rearrange as your kitchen layout changes.

A well-organized freestanding unit is like the central library for your kitchen's inventory. When bulk goods are clearly visible and easy to get to, it slashes search time and helps with accurate stock-taking, which directly boosts efficiency and cuts down on food waste.

From Storage to Workspace: The Role of Prep Tables

Beyond just holding things, stainless steel is the heart of the most important piece of furniture in any kitchen: the prep table. A stainless steel prep table isn't just a surface; it's the command center for chopping, mixing, assembling, and plating. These tables usually have shelves built in underneath the main work surface, giving you integrated storage for mixing bowls, cutting boards, and ingredient bins.

The standard work table is a simple, flat-topped surface with an undershelf. It's the all-purpose MVP of the kitchen, ready for just about any task you throw at it. But for more specialized jobs, prep tables have evolved into highly specific machines designed to perfect a single workflow.

Specialized Tables for Peak Efficiency

When a kitchen is churning out a high volume of something specific, like sandwiches or pizzas, a standard table can slow things down. This is where specialized prep tables step in, combining refrigeration and custom layouts to put production into overdrive.

-

Sandwich Prep Tables: These units are built for the art of sandwich making. They feature a long cutting board that runs alongside a series of refrigerated wells. These cooled compartments hold standard-sized food pans filled with sliced meats, cheeses, veggies, and condiments, keeping everything fresh and right at the chef's fingertips. This setup lets a cook build sandwiches assembly-line style, often without taking a single step.

-

Pizza Prep Tables: A pizza prep table is engineered for one thing: dough. It often has a raised, refrigerated rail that holds ingredient pans at an ergonomic angle for quick topping. The main work surface itself is often made of chilled marble or extra-thick stainless steel to help keep the pizza dough cool and stop it from sticking. The whole design keeps the pizza-making process contained in one efficient, temperature-controlled station.

By understanding the distinct roles of a simple stainless steel shelf, a freestanding unit, and specialized prep tables, you can design a workspace that doesn't just look organized—it actively makes your team more productive.

Understanding Load Capacity and NSF Certification

When you're outfitting a professional kitchen, two things are absolutely non-negotiable for your shelving: safety and sanitation. Once you’ve settled on the right material grade, you have to get real about the daily demands of a busy kitchen. A shelf has to do more than just look the part; it needs to perform under pressure and meet tough health codes.

This is where load capacity and NSF certification enter the picture. These aren't just specs on a product sheet. They’re the two most critical indicators of a shelf's reliability and its fitness for a food-safe environment, making sure your kitchen runs smoothly and passes inspection.

Calculating Your Needs: Load Capacity Explained

Load capacity is simply the maximum weight a shelf can safely hold when that weight is spread out evenly. Think of it as the shelf's structural speed limit. Pushing past that limit doesn't just mean you'll get a sagging shelf—it can lead to total collapse. That means lost inventory, damaged equipment, and a serious risk of injury.

Manufacturers will always give you a weight rating, but it’s on you to figure out how much your stuff actually weighs. Don't eyeball it. A 50-pound bag of flour is easy enough, but what about a stack of heavy ceramic plates or a few stockpots brimming with liquid? A single case of canned goods can hit 40-50 pounds, and a stack of just a dozen large dinner plates can weigh over 25 pounds.

As a simple rule of thumb for kitchen safety, always pick a shelf with a load capacity at least 25% higher than what you think you'll need. This buffer gives you a margin for error and prevents long-term metal fatigue.

Taking this extra step ensures your shelving stays solid and dependable, even when the dinner rush hits and things are getting put away in a hurry.

The Gold Standard: NSF Certification

While load capacity is all about structural safety, NSF (National Sanitation Foundation) certification is all about sanitation. Seeing that NSF seal on a stainless steel shelf is your guarantee that it’s been through the wringer and meets strict standards for public health.

For a shelf to earn that mark, it has to be:

- Easy to Clean: The design can't have any cracks, tight corners, or crevices where bacteria and food particles can hide.

- Non-Porous Surface: The material itself won't absorb grease, moisture, or food, which stops mold and bacteria from growing.

- Durable and Corrosion-Resistant: It has to be made from materials that won't rust, chip, or break down from contact with food and cleaning chemicals.

Honestly, passing a health inspection often comes down to using NSF-certified gear. If you want to get into the nitty-gritty, our guide on What is NSF Certification explains it all. That little seal tells inspectors—and your customers—that you take food safety seriously.

The demand for high-quality, certified equipment is a big deal. The wider metal retail shelving market, which includes stainless steel, is expected to jump from USD 6.27 billion to USD 9.16 billion between 2024 and 2030. This trend just highlights how critical durable, hygienic storage has become. You can read more about this growing market on Research and Markets.

At the end of the day, understanding both what a shelf can hold and what the NSF seal means will empower you to make a smart, safe, and compliant investment for your kitchen.

Installation and Maintenance Best Practices

Buying a top-notch stainless steel shelf is a great start, but getting the most out of it comes down to one thing: proper installation and regular care. When you mount a shelf securely and keep it clean, it’s no longer just a piece of equipment. It becomes a reliable part of your kitchen's daily rhythm—safe, sanitary, and professional-looking for years.

Think of it like a new car. The performance you get depends just as much on that first tune-up and regular oil changes as it does on the engine itself. These simple practices are what protect your investment and ensure your shelves stay in pristine shape.

Secure Installation for Maximum Stability

How you install your shelving directly impacts its safety and how much weight it can actually hold. A shelf that's poorly mounted is a disaster waiting to happen, while a unit that’s properly assembled gives you total peace of mind.

For Wall-Mounted Shelves:

The most critical step is to find the wall studs. Drywall alone is nowhere near strong enough to support the weight of a commercial shelf loaded with supplies. You absolutely must use a stud finder to locate the wooden supports behind the wall.

- Locate and Mark: Find the studs where you want to mount the shelf and clearly mark their centers.

- Use Appropriate Hardware: Always use the heavy-duty screws and mounting gear that the manufacturer recommends. Standard drywall screws just won't cut it.

- Level and Secure: Grab a level to make sure the shelf is perfectly horizontal before you start drilling. Fasten the brackets securely into the center of the studs for rock-solid stability.

For Freestanding Units:

Putting together a freestanding unit is usually more straightforward, but you still need to be precise.

- Build on a Level Surface: Make sure the floor is even to stop the unit from wobbling.

- Secure Shelves Firmly: Before you load anything on, double-check that each shelf is seated properly on its clips or collars. A common mistake is not pushing them down firmly enough, which can create a wobbly, unstable unit.

- Check for Stability: Once it’s all put together, give the unit a gentle shake. If it moves, go back and re-check that every component is tight and the legs are level. Most units come with adjustable feet to help you compensate for uneven floors.

A Simple Routine for Long-Term Maintenance

Stainless steel is famous for being low-maintenance, but "low" doesn't mean "no" maintenance. A consistent cleaning routine is the key to preventing grime, grease, and water spots from building up, keeping your shelves hygienic and looking sharp.

A little attention each day goes a long way. At the end of a service, a quick wipe-down with a soft, damp cloth and some mild detergent is usually all it takes to handle fresh spills and fingerprints. This simple step stops food residue from hardening and makes your deeper cleans so much easier.

Pro Tip: Always wipe and scrub in the direction of the steel's grain, not against it. This little trick helps prevent tiny scratches and keeps the original finish looking smooth and clean.

To make sure nothing gets missed, a simple cleaning schedule can work wonders. Once a week, you should do a more thorough cleaning with a dedicated stainless steel cleaner to cut through any tough grease and bring back that shine. For a complete guide with step-by-step instructions, check out our post on how to clean stainless steel and keep it looking brand new.

To make things even easier, here's a simple schedule you can follow to keep your stainless steel shelves in top-notch condition.

Stainless Steel Cleaning and Maintenance Schedule

| Frequency | Task | Recommended Cleaner | Pro Tip |

|---|---|---|---|

| Daily | Wipe down surfaces | Mild soap & warm water | Clean up spills immediately to prevent them from drying and staining. |

| Weekly | Deep clean & polish | Commercial stainless steel cleaner | Wipe with the grain to avoid micro-scratches and enhance shine. |

| Monthly | Inspect for damage | Water & soft cloth | Check brackets and connections to ensure everything is still tight and secure. |

| As Needed | Remove tough spots | Baking soda paste | For stubborn grime, let the paste sit for a few minutes before scrubbing gently. |

Sticking to a schedule like this makes maintenance a manageable part of your routine rather than a major chore.

Safe and Effective Cleaning Practices

Choosing the right cleaning products is absolutely critical. Using harsh chemicals can permanently strip away the protective layer on your stainless steel, which will lead to ugly discoloration and even corrosion.

What to Use:

- Mild soap or detergent mixed with warm water.

- A simple paste of baking soda and water for stubborn spots.

- Specialized, non-abrasive stainless steel cleaners.

What to Avoid:

- Bleach and chlorine-based cleaners: These are the enemies of stainless steel and will cause rust-like pitting.

- Abrasive powders: Scouring powders will scratch the surface, creating tiny grooves where bacteria can build up.

- Steel wool or steel brushes: These will not only scratch the finish but can also leave behind tiny iron particles that will eventually rust.

By following these straightforward tips for installation and maintenance, your stainless steel shelf will continue to be a safe, dependable, and hygienic workhorse in your kitchen for its entire lifespan.

Got Questions? We’ve Got Answers.

When you’re outfitting a professional kitchen, having questions is a good sign. It means you’re thinking past the price tag and considering quality, performance, and how this investment will hold up over the long haul. We get a lot of the same questions, so we’ve gathered the most common ones right here to help you get the practical details you need.

Think of this as your field guide to making a smart purchase. These are the real-world concerns that separate a simple transaction from a savvy investment that serves your kitchen for years.

How Do I Choose Between Wall-Mounted and Freestanding Shelves?

The best choice really boils down to one thing: what do you value more, floor space or sheer storage muscle? Your kitchen’s layout and what you plan to put on the shelves will point you to the right answer.

Wall-mounted shelves are the ultimate space-savers. By using that empty vertical real estate, they keep your most-used spices, ingredients, or small tools right where you need them, often above a prep area. They're a lifesaver in smaller kitchens where every square foot is precious. The trade-off? They generally hold less weight and need to be securely anchored into wall studs.

Freestanding shelving units are the workhorses. These are your heavy lifters, built with much higher load capacities and incredible flexibility. You can set them up in a dry pantry for bulk goods, slide them into a walk-in for cases of produce, or completely reconfigure them as your menu changes. They do take up floor space, but they provide the strength you need for your heaviest inventory.

What Is the Best Way to Remove Rust Spots from a Stainless Steel Shelf?

Seeing a rust spot can be a little jarring, but don't panic. It's usually a simple fix if you catch it early. The trick is to be gentle and clean the spot without scratching the shelf's protective layer.

For minor spots, a simple paste of baking soda and water often does the trick. Just apply it to the rust, let it sit for about 30 minutes, and then gently scrub with a soft cloth. Always scrub in the direction of the steel's grain to avoid creating tiny scratches.

If you’re dealing with a more stubborn spot, a dedicated stainless steel cleaner containing oxalic acid is your next best bet. No matter what you use, always rinse the area thoroughly with clean water afterward and dry it completely. This prevents water spots and helps stop future rust from forming.

Crucial Tip: Whatever you do, never use steel wool, abrasive scouring pads, or harsh scrubbers. They will permanently scratch the surface, creating little grooves where rust and bacteria can hide and making the problem much worse down the line.

Can I Cut Directly on a Stainless Steel Prep Table?

While stainless steel is tough as nails, you should absolutely never use its surface as a cutting board. There are two big reasons why.

First, you'll destroy your knives. That steel-on-steel contact will dull a razor-sharp blade in seconds, making your prep work harder and more dangerous. Second, even the best knife will leave micro-scratches on the tabletop. These tiny grooves become breeding grounds for food particles and bacteria, making the table much harder to sanitize and potentially compromising food safety.

Always, always use a dedicated, NSF-certified cutting board on your stainless steel prep table. It’s the only way to protect your knives, your table, and your customers.

Is There a Difference Between a Sandwich Prep Table and a Pizza Prep Table?

Yes, and the difference is huge! While they both look similar, they are highly specialized pieces of equipment, each engineered for a completely different workflow.

-

Sandwich Prep Tables: These are built for the fast-paced assembly line of a deli or café. They almost always have a deep, full-length cutting board running right in front of a series of refrigerated wells. These wells are made to fit standard-sized food pans, keeping your sliced meats, cheeses, veggies, and condiments perfectly chilled and right at your fingertips.

-

Pizza Prep Tables: These units are all about the dough. They feature a raised, refrigerated rail that holds ingredient pans at a perfect ergonomic angle for topping pies quickly. More importantly, the main work surface is often a thick, chilled slab of marble or granite. This is critical for keeping pizza dough cool, which stops it from getting sticky and makes it much easier to stretch and work with.

Knowing these design differences is the key to picking the right table. Each one is a purpose-built machine designed to make a high-volume task faster, easier, and more consistent.

Ready to build a more efficient and hygienic workspace? The team at PrepTables.com has the expertise and the equipment to help you find the perfect stainless steel solutions for your needs. Explore our extensive collection of shelves, prep tables, and more at https://preptables.com today.