Your Guide to Stainless Steel Commercial Tables

Share

When you're outfitting a commercial kitchen, few choices are as fundamental as your work surfaces. And in this world, there's one clear winner: the stainless steel commercial table. It’s the undisputed champion, loved for its raw durability, easy-to-clean surface, and sharp, professional look. This isn't just a slab of metal to chop vegetables on—it's the very foundation of an efficient, safe, and productive kitchen.

Why Stainless Steel Is the Kitchen Workhorse

Picture a commercial kitchen as a high-performance engine. Every single part has to stand up to intense heat, pressure, and constant, grueling use. Stainless steel is the material purpose-built for this environment, which is why it has become the gold standard for professional kitchens everywhere.

Choosing steel isn't just a matter of convenience; it's a smart business move. Its global demand tells the whole story. The market for stainless steel tables hit a value of roughly USD 1.2 billion in 2024 and is only expected to climb, all thanks to its vital role in foodservice and other industries. If you're curious, you can explore more data on the stainless steel tables market to see just how critical these tables are.

Built for Unmatched Durability

Commercial kitchens are a battlefield. We're talking sharp knives, heavy pots, and sizzling temperatures. A stainless steel work table is engineered to take all of it in stride. Unlike a wooden butcher block that can warp, split, or harbor germs, or plastic that can melt and stain, steel gives you a rock-solid, stable surface day in and day out.

This material also shrugs off corrosion from acidic foods like tomatoes and lemon juice, not to mention the aggressive cleaning chemicals used to keep things sanitary. You can slide a hot pan straight from the stovetop onto its surface without a second thought. That's a huge advantage when you're in the weeds during a dinner rush and every second counts.

The Gold Standard for Hygiene

In a professional kitchen, food safety is everything. The physical makeup of stainless steel makes it the most hygienic choice you can make. Its surface is completely non-porous, meaning there are no microscopic nooks or crannies for bacteria, mold, or other nasty pathogens to hide and grow.

A non-porous surface is your first line of defense against cross-contamination. It means that once you've cleaned and sanitized the table, it's truly clean and ready for the next task. This simple fact makes hitting—and exceeding—health code standards so much easier.

This quality makes daily sanitation a breeze, saving you precious time and labor. A quick wipe-down with the right cleaner is all it takes to maintain a sterile workspace, which is absolutely essential for preventing foodborne illness and keeping your customers safe.

A Professional and Timeless Aesthetic

Beyond all the practical perks, stainless steel just looks the part. It has a sleek, clean appearance that instantly signals professionalism and high standards. It also reflects light, which can make a busy kitchen feel brighter and more open.

This clean look isn't just for show, either. It helps your team spot spills or stray bits of food right away, leading to a safer and more organized workspace. It’s a timeless look that will keep your kitchen looking sharp for years, never going out of style.

Decoding Steel Grades and Gauges for Your Kitchen

When you start shopping for a stainless steel prep table, you’ll quickly come across terms like “grade” and “gauge.” These aren't just technical jargon; they are the two most critical factors that determine how long your table will last, how much abuse it can take, and whether it’s the right fit for your kitchen. Getting this right is the key to a smart purchase.

Think of it like choosing tires for a truck. You wouldn’t put regular highway tires on a heavy-duty rig that’s going to be slogging through mud and rocks. In the same way, the steel you pick for your table has to be tough enough for the job you’re going to throw at it.

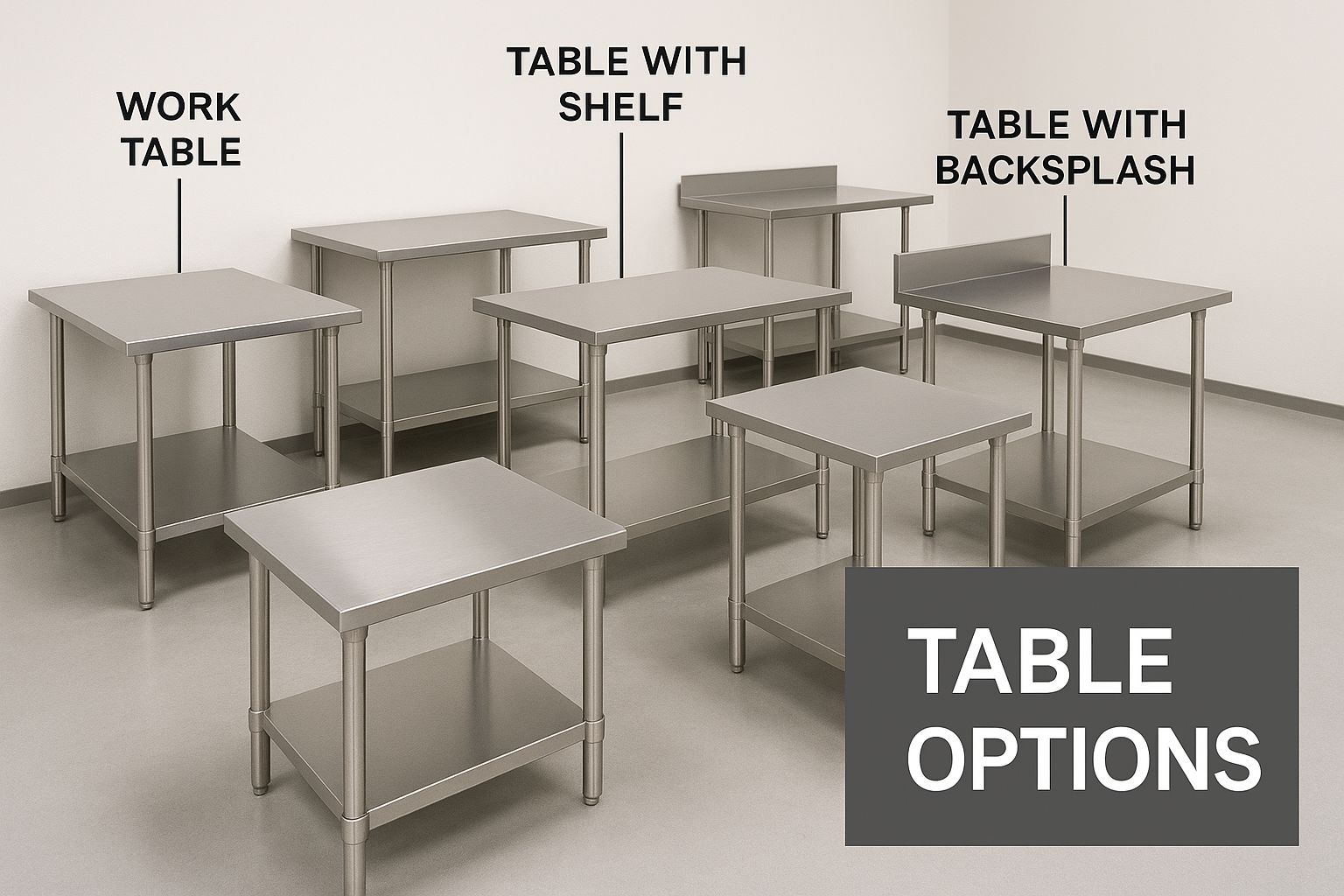

To give you a better sense of what's out there, here's a look at the different kinds of tables you'll find in a professional kitchen.

As you can see, they range from basic flat-top surfaces to specialized tables with all sorts of built-in features, each designed for a specific role in the kitchen's daily grind.

The Two Main Types of Steel Grade

In the commercial kitchen world, you'll mainly be choosing between two grades of stainless steel: Type 304 and Type 430. Each one has its own purpose and price tag, so your choice really comes down to where and how you plan to use the table.

Type 304 stainless steel is your all-terrain, premium tire. It has more nickel in its makeup, which gives it fantastic protection against rust and corrosion. This makes it the only real choice for any surface that touches food directly or gets wet constantly—think your main prep station, the dishwashing area, or a table for mixing acidic sauces. It’s the gold standard for hygiene and durability.

Type 430 stainless steel is more like a reliable, everyday tire. It's a great, budget-friendly choice for dry, less intense situations. Because it has less nickel, it's more likely to corrode if it’s always wet. But for equipment stands, dry storage shelves, or prep tables in areas far from the sink, it's a perfectly smart and cost-effective option.

A good strategy is to match the steel grade to the job. Splurge on Type 304 where food safety and moisture are a big deal, and save some money with Type 430 for dry storage and equipment support.

To make this even clearer, here's a quick comparison table to help you decide.

Comparing Stainless Steel Grades and Gauges

This quick-reference guide will help you choose the right stainless steel type and thickness for different commercial kitchen applications.

| Specification | Type 304 (18/8) | Type 430 (18/0) | Ideal Use Cases |

|---|---|---|---|

| Corrosion Resistance | Excellent; high nickel content prevents rust | Good; less nickel makes it more prone to rust with moisture | 304 for wet areas & food contact; 430 for dry storage & equipment stands |

| Durability | High; stands up to acidic foods and cleaning chemicals | Moderate; best for low-impact, dry environments | 304 for heavy prep; 430 for light-duty tasks like holding appliances |

| Cost | Higher initial investment | More budget-friendly and economical | Invest in 304 for critical areas; save with 430 for secondary uses |

Ultimately, choosing between Type 304 and Type 430 is about balancing performance and budget based on the table's specific role in your kitchen.

Understanding Steel Gauge: The Lower The Better

While the grade tells you about the steel’s chemical makeup, the gauge tells you how thick it is. This is where things can feel a bit backward: the lower the gauge number, the thicker and stronger the steel. When it comes to the tabletop, a lower number is always a better sign.

Here’s a quick rundown of what you’ll typically see:

- 14-Gauge: This is the heavyweight champion. It’s the thickest, most durable option out there, built to handle heavy equipment like commercial mixers, meat slicers, or non-stop chopping. If you're doing serious butchering or high-impact prep, this is what you want.

- 16-Gauge: This is the popular all-rounder. A 16-gauge table strikes a great balance between strength and price, making it perfect for general food prep, assembly lines, and most everyday kitchen tasks.

- 18-Gauge: This is the most economical choice, often found on entry-level tables. It's perfectly fine for lighter work, like holding small appliances or storing dry goods, but be aware that it will dent more easily if something heavy is dropped on it.

Nailing the right combination of grade and gauge means your prep table won’t just be another piece of equipment—it will be a long-lasting workhorse built for its job. To see how these specs translate into actual products, check out our guide on the different types of stainless steel prep tables. It will help you connect the dots between the material and the real-world application in your kitchen.

Finding the Right Style of Prep Table

Once you've nailed down the right material, the next challenge is matching the table's design to its real-world function in your kitchen. Stainless steel commercial tables aren't a one-size-fits-all product; they're specialized tools built to solve specific problems and make distinct tasks flow better.

Choosing the right style is a lot like picking the perfect knife for a job. You wouldn't use a paring knife for butchering, and a cleaver is just overkill for peeling an apple.

The layout of your kitchen and the unique demands of your menu will ultimately point you to the best table for your operation. From simple, open-base work surfaces to complex, refrigerated prep stations, every model is engineered to boost your workflow. Let's break down the most common and effective styles you'll find in modern commercial kitchens.

Foundational Work Table Designs

At the heart of every kitchen, you'll find the basic work tables. These are the versatile, everyday surfaces where most of the chopping, mixing, and general prep happens. But even these fundamental models have key variations that can make a huge difference in how they're used.

- Standard Work Tables: This is the most straightforward design—a flat top with four legs. Its open base is perfect for sliding trash cans or ingredient bins right underneath, keeping your floor space clear and easy to navigate. These often serve as central islands where staff can work from all sides.

- Tables with Undershelves: This is probably the most popular setup out there. An integrated undershelf gives you immediate, easy-to-reach storage for small appliances, mixing bowls, or bulk ingredients. This simple addition transforms a basic surface into a self-contained workstation, cutting down on trips across the kitchen for supplies.

- Tables with Backsplashes: A small but critical feature, a backsplash is just a raised lip along the back of the table. Its whole job is to protect your walls from splashes, spills, and food debris. This is a must-have for any table pushed against a wall, especially in wet prep or dishwashing areas. It makes cleanup faster and helps maintain a more hygienic space.

The long-standing popularity of these designs comes down to one thing: practicality. In fact, by 2025, stainless steel tables are projected to make up 48.5% of the total market revenue in the commercial foodservice equipment world. Their dominance comes from their ability to handle the heat, moisture, and intense cleaning protocols of a pro kitchen, making them a solid investment.

Specialized Prep Tables for High-Volume Tasks

Moving beyond the basics, you'll find specialized stainless steel commercial tables built to master specific culinary jobs. These units often integrate refrigeration and other features to create an all-in-one station for complex menu items, which can drastically improve your speed and consistency during a hectic service.

Think of these specialized tables as mission control centers for your most popular dishes. They pull every tool, ingredient, and surface needed for a specific task into one compact, ergonomic space, eliminating wasted steps and maximizing output.

Two of the best examples are pizza and sandwich prep tables, each tailored to the unique demands of its craft. Looking at these options can help you spot workflow bottlenecks you might not have even known existed. For a deeper dive into what makes a great workstation, our guide on choosing a commercial stainless steel prep table offers even more valuable tips.

The Pizza Prep Table: A Pizzeria's Best Friend

Anyone who's worked a pizzeria line knows that speed and organization are everything. A dedicated pizza prep table is built from the ground up for this high-speed environment.

These units typically feature:

- Refrigerated Rails: A line of cold wells sits at the top of the table, holding all your essential toppings—pepperoni, mushrooms, cheese, sauces—at a safe, cool temperature and right at your fingertips.

- A Cold Work Surface: Many models come with a marble or granite slab for stretching dough. These materials stay naturally cool, which keeps the dough from sticking or getting overworked.

- Refrigerated Base: Underneath the work surface, you'll find refrigerated cabinets or drawers for bulk storage of backup ingredients, pizza screens, and dough trays.

This all-in-one design means a pizza maker can build an entire pizza from start to finish without ever having to leave their station.

The Sandwich and Salad Prep Table: Efficiency for Delis and Cafes

In the same way, sandwich and salad prep tables are the backbone of delis, cafes, and quick-service spots. Their design is all about the rapid assembly of fresh, made-to-order items.

Key features include:

- Cold Wells: Just like a pizza table, these units have refrigerated pans for holding sliced meats, cheeses, veggies, and dressings.

- Integrated Cutting Board: A full-length cutting board runs along the front of the unit, giving you a dedicated space to slice and build sandwiches or salads directly in front of the cold wells.

- Refrigerated Storage: The base provides plenty of cold storage for backup ingredients, making sure you can restock your line in a flash during a lunch rush.

By combining cold storage with an immediate prep surface, these tables ensure ingredients stay fresh while enabling a smooth, assembly-line workflow that gets orders out the door fast. Choosing the right style isn't just about filling a space; it's about investing in a more efficient, organized, and profitable kitchen.

Choosing the Correct Size and Load Capacity

Getting the size and load capacity right for your stainless steel prep table isn't just a detail—it's fundamental to running a safe and efficient kitchen. A table that fits perfectly can make prep work feel smooth and organized, while the wrong one creates chaos.

Let's break down how to get it right.

Measuring Your Kitchen Space

Before you even look at tables, grab a measuring tape and some graph paper (or a digital tool if you prefer). Sketch out your work area, paying close attention to how your team moves. You need to account for foot traffic, door swings, and clearance around other equipment. The last thing you want is a bottleneck during a busy dinner service.

- Give yourself at least 36 inches of clear space around the table. This is non-negotiable for safe movement.

- Think about height. A table that’s too low or too high will lead to back pain and fatigue for your staff.

- Check the dimensions for anything you plan to store underneath. Will your ingredient bins or rolling carts actually fit?

Understanding Load Capacity

Load capacity is simply how much weight your table can safely hold, both on the main work surface and on the undershelf. Think of it like a weight rack at the gym—you wouldn't put heavy plates on a lightweight bar. The same principle applies here. Overloading a table is a recipe for disaster.

- A heavy-duty 14-gauge table can typically handle 500+ pounds on top and another 250+ pounds below.

- A standard 16-gauge table usually supports around 350 pounds on the top surface and 150 pounds on its undershelf.

- Lighter-duty 18-gauge tables are best for simple tasks, holding about 200 pounds on top and 80 pounds underneath.

Types of Stainless Steel Prep Tables

Not all prep tables are created equal. Different styles are designed for specific workflows, so picking the right one ensures your equipment and ingredients fit seamlessly into your process.

Standard Work Tables

These are the workhorses of most kitchens. A simple, flat-topped table is incredibly versatile for general chopping, mixing, and staging. They come in a huge range of sizes, from a compact 24x24 inches to a massive 96x30 inches. A 16-gauge top strikes a great balance between durability and cost for everyday use.

Pizza Prep Tables

Designed specifically for pizzerias, these units often feature refrigerated rails to keep toppings perfectly chilled and within reach. They’re typically 48 to 72 inches wide and need a heavy-duty frame to support over 400 pounds of dough, ingredients, and tools.

Sandwich Prep Tables

A must-have for delis and sandwich shops, these tables combine cold wells for ingredients with a built-in cutting board. Spanning 36 to 60 inches, they usually have an undershelf load capacity of around 150 pounds, perfect for keeping backstock close at hand.

| Table Type | Typical Dimensions | Top Load Capacity |

|---|---|---|

| Standard Work Table | 24x24 to 96x30 inches | 350–500 lbs |

| Pizza Prep Table | 48–72 x depth | 400–600 lbs |

| Sandwich Prep Table | 36–60 x depth | 200–300 lbs |

Matching the table's dimensions and load specs to your specific menu and kitchen layout is the key to avoiding safety risks and maximizing efficiency.

When you’re ready to choose, bring your spatial measurements and your load requirements together. If you have staff members of different heights using the same station, look for models with adjustable-height legs. It’s a small feature that makes a big difference in comfort.

- Map out clearance zones around refrigerators and oven doors to keep the workflow moving.

- Don’t guess. Match the table’s gauge and grade to the actual work it will be doing.

- Re-evaluate your layout once a year. Your needs can change as your menu evolves.

A properly sized and rated prep table is the unsung hero of a productive kitchen. It keeps your equipment safe, your ingredients protected, and your team moving with confidence.

Key Takeaways

- Start with precise measurements of your space, always planning for clearance.

- Use the load specs to match the table to your heaviest equipment and ingredients.

- Choose specialized tables, like pizza or sandwich units, based on your menu's workflow.

- Revisit your needs annually to keep up with any changes in your menu or staff.

Taking the time to measure your space and match load limits will pay off every single day in safety and speed. Your prep table is where productivity happens—make sure it's built on a solid foundation.

Key Features That Maximize Your Workspace

A simple slab of steel is just a surface. The right features, however, turn that surface into a high-performance workstation that works with you, not against you. Once you’ve sorted out the size and the steel grade, the specific add-ons are what really dial a table into your kitchen’s unique rhythm. These are the details that make the difference.

Thinking through these features helps you build a table that doesn't just fit your floor plan but actively makes your team faster and safer. From containing spills to setting the perfect prep height, every little thing plays a part.

The Non-Negotiable Mark of Safety: NSF Certification

Before we get into anything else, let's talk about the big one: NSF certification. This isn't just some sticker they slap on the leg. It's your guarantee that the table meets incredibly strict public health and safety standards. An NSF-certified table is built smart—no cracks, no crevices, and no porous materials where bacteria can throw a party. It’s designed to be cleaned and sanitized, period.

For any commercial kitchen, this is non-negotiable. It’s what health inspectors look for, and it’s what keeps your food safe. The proof is in the numbers; NSF-certified stainless steel prep tables are consistent top sellers, with popular models on major retail sites often moving over 400 units a month. You can explore detailed sales data on commercial kitchen equipment to see just how essential this certification is in the market.

Ergonomics and Flexibility in Design

A happy cook is a productive cook, and a comfortable one is even better. Features that focus on good ergonomics and a flexible layout are crucial for cutting down on fatigue and helping your kitchen adapt on the fly.

- Adjustable Legs: Your team isn't one-size-fits-all, so your tables shouldn't be either. Adjustable legs, often called "bullet feet," let you set the table height just right for your crew, saving backs during those long shifts.

- Mobile Casters: For kitchens that need to be nimble, tables with casters (wheels) are a game-changer. They make it easy to roll the table out of the way for a deep clean or reconfigure the line for a special event. Just make sure you get locking casters so the table stays put when you're working.

Think of these features as an investment in your team's well-being and your kitchen's agility. A table on wheels can become an extra plating station in a pinch, while an ergonomically set table helps prevent the kind of aches and pains that wear people down.

Smart Features for a Cleaner Workspace

Keeping messes contained is half the battle in a busy kitchen. A few clever design elements can make a world of difference, keeping your prep areas cleaner, safer, and more efficient. Our guide on choosing the right restaurant stainless steel tables gets into more detail on how these features create a smoother workflow.

One of the most important choices is the table's edge style. You’ll generally see two types:

- Rolled Edges: These are smooth, rounded, and comfortable to lean on. They’re simple and make wiping down the table a breeze.

- Marine Edges: You'll know these by the small raised lip running around the edge. This simple feature is a lifesaver for containing spills, stopping liquids from dripping onto the floor and creating a dangerous slip hazard.

Customization Options for All-In-One Stations

To really get the most out of every square foot, look for tables with built-in components. These options can turn a standard prep surface into a specialized, all-in-one station that saves time and steps.

Some of the most popular customizations include:

- Cabinet Bases: Instead of an open shelf underneath, an enclosed cabinet gives you protected storage. It's perfect for keeping equipment and supplies out of sight, making your kitchen look instantly more organized.

- Integrated Sinks: A table with a built-in prep sink is a massive time-saver. No more walking across the kitchen to rinse vegetables or wash hands. Everything you need is right there.

- Overshelves: Adding a tier or two of shelving above the work surface puts spices, tools, and small containers within easy reach, keeping your main prep area clear and ready for action.

Taking Care of Your Table to Protect Your Investment

Think of a good stainless steel table as a long-term partner in your kitchen. It’s a serious purchase, and if you treat it right, it’ll easily last a lifetime. Proper care isn't rocket science, but it's absolutely vital for keeping that protective layer on the steel strong, ensuring the surface stays hygienic, and making sure it looks sharp for years.

The steel's surface has a natural shield—a layer of chromium oxide that fights off rust and corrosion. Your main job is to keep that shield intact. That means avoiding anything that could scratch or weaken it and sticking to a simple, consistent cleaning routine.

Your Daily Cleaning Routine

For day-to-day upkeep, the simpler, the better. A quick wipe-down after every shift is all it takes to stop food gunk from hardening and keep the surface ready for action. The key is to be gentle but thorough.

First, clear off any debris. Then, grab a soft cloth or sponge, some mild soap, and warm water. Here’s a pro tip: always wipe in the direction of the steel’s grain—those faint lines you can see on the surface. Following the grain helps you avoid creating tiny new scratches and keeps the finish looking great. Once it's clean, rinse it well with fresh water and dry it completely with a soft cloth to stop water spots from forming.

One of the biggest mistakes people make is letting water or cleaners just air-dry on the table. This leaves behind mineral deposits that will dull the steel’s natural shine. That final wipe-down? It’s not optional.

Deep Cleaning and Polishing

Every so often, your tables will need a bit more attention to cut through stubborn grime or bring back that original gleam. For a deeper clean, you can use a cleaner made specifically for stainless steel or even make a simple paste with baking soda and water. Just apply it with a soft cloth—again, moving with the grain—then rinse and dry it completely.

To really make it pop, a good stainless steel polish or a little bit of mineral oil on a clean, dry cloth works wonders. This doesn't just make it shiny; it also adds a temporary barrier that helps repel fingerprints and smudges.

What to Absolutely Avoid

Protecting your stainless steel is as much about what you don't do as what you do. Some tools and chemicals are the mortal enemies of stainless steel and will cause permanent damage.

Keep these far away from your tables:

- Abrasive Stuff: Things like steel wool, scouring powders, and stiff brushes are a big no-no. They’ll scratch the surface, creating little nooks where rust can start to form.

- Chlorine-Based Cleaners: Bleach and any cleaner with chlorides in it will chew right through the steel's protective layer, which can lead to pitting and corrosion.

- Oven Cleaners: These are incredibly harsh and can cause staining and damage that you just can't fix.

By following these simple rules, you’ll make sure your stainless steel commercial tables stay a hygienic, tough, and good-looking asset in your kitchen. A little consistent care goes a long way in protecting your investment and keeping your workspace looking professional.

Of course. Here is the rewritten section, crafted to sound completely human-written and natural, following the provided style guide.

Common Questions About Commercial Prep Tables

When you're outfitting a kitchen, a few common questions always pop up about stainless steel commercial tables. Getting the right answers from the start means you can invest with confidence, knowing you’ve chosen a piece of equipment that will serve your crew well for years.

One of the first things people ask is about the different kinds of tables out there. It's not just about a flat surface to work on. Many kitchens get a ton of value from more specialized models. For instance, a simple table with an undershelf immediately becomes a self-contained station, giving you a convenient spot to stash mixing bowls or small appliances. And if you’re placing a table against a wall, one with a backsplash is a must-have to keep food and splashes contained, which makes cleanup way easier.

Specialized Prep Table Varieties

For certain high-volume tasks, a specialized table isn't just a nice-to-have—it’s a total game-changer.

Think about a busy pizzeria. A dedicated pizza prep table is designed with refrigerated rails right on top, keeping all your toppings like pepperoni and cheese perfectly chilled and within easy reach. Many even feature a marble top, which is ideal for stretching dough because it stays cool and prevents sticking.

It's a similar story for delis and cafes. A sandwich prep table is built to streamline the whole assembly process. These units have cold wells for meats, veggies, and cheeses, all right next to an integrated cutting board. This setup keeps everything fresh, organized, and ready to go, so your team can build orders fast. Both of these designs are all about combining refrigeration and workspace to boost speed and consistency. The right one for you really just boils down to your menu and how your kitchen flows.

At PrepTables.com, we stock a huge variety of professional-grade tables built to handle the demands of any kitchen. Explore our collection of stainless steel commercial tables and find the perfect foundation for your culinary workspace.