Your Guide to Refrigerated Sandwich Prep Tables

Share

Think of a refrigerated sandwich prep table as the central nervous system of your kitchen's assembly line. It’s not just a piece of equipment; it’s where speed, food safety, and consistency all come together in one efficient hub.

Like a pilot’s cockpit, it keeps every essential ingredient perfectly chilled and within easy reach, cutting down on wasted time and motion. This one unit is a game-changer because it combines three critical kitchen stations into one.

The Essential Hub of a Modern Kitchen

At its heart, a refrigerated sandwich prep table is a masterclass in efficiency, merging three distinct workstations into a single, seamless unit. This integration is precisely what makes it a must-have in any fast-paced kitchen.

It’s a powerful combination of:

- Refrigerated Storage: The spacious, chilled base keeps all your backup ingredients—from meats and cheeses to sauces—at ideal, food-safe temperatures.

- Hygienic Prep Surface: A durable, easy-to-clean cutting board runs along the top, giving you a dedicated space to build sandwiches, salads, and wraps.

- Organized Ingredient Rail: A row of pans, often called an ingredient rail, sits right at the work surface, holding every topping and filling you need for instant access.

This all-in-one design means your chefs aren't constantly walking back and forth between a separate fridge, a prep counter, and various ingredient bins. The result is a massive drop in wasted steps and a huge boost in how quickly you can get orders out the door.

Why Prep Tables Are More Vital Than Ever

The need for these units is skyrocketing across the entire foodservice industry. For busy kitchens, especially in the QSR world, an efficient prep area is non-negotiable. Exploring specialized quick service restaurant solutions can take your workflow optimization even further.

This unified workstation ensures every sandwich or salad is made with ingredients held at a consistent, safe temperature. This drastically cuts down the risk of foodborne illness while guaranteeing a high-quality, consistent product every single time.

The market numbers back this up. The global market for refrigerated sandwich prep tables is expanding fast, with valuations already sitting somewhere between USD 850.5 million and USD 3.2 billion. This incredible growth is being driven by the boom in quick-service restaurants, the rise of delivery and takeout, and increasingly strict food safety rules that favor NSF-rated gear.

Whether you're running a busy deli, a high-volume cafeteria, a ghost kitchen, or even a food truck, these tables are no longer a luxury—they're a core piece of a successful operation. They give your team the power to handle huge order volumes with speed and precision, making them a true cornerstone of any modern, efficient kitchen.

Let's break down exactly what these tables bring to the table.

Core Benefits of a Refrigerated Prep Table

| Benefit | How It Improves Your Kitchen |

|---|---|

| Increased Efficiency | Keeps all ingredients chilled and within arm's reach, drastically reducing prep time and staff movement. |

| Improved Food Safety | Maintains consistent, safe temperatures for all ingredients, minimizing the risk of bacterial growth and spoilage. |

| Enhanced Consistency | An organized ingredient rail ensures every item is made with the same fresh components, leading to a uniform final product. |

| Space Optimization | Combines three separate stations (refrigerator, prep counter, ingredient storage) into one compact footprint. |

By understanding these immediate advantages, you can start to see just how much the right unit can transform your day-to-day operations and, ultimately, your bottom line.

Deconstructing Your Refrigerated Prep Table

Choosing the right refrigerated prep table feels a bit like picking the perfect engine for a race car. What’s under the hood is what dictates its performance, how long it'll last, and ultimately, whether it helps you win the dinner rush. To make a smart investment, you've got to understand the anatomy of these kitchen workhorses.

From the specific grade of stainless steel to the design of the ingredient rail, every single component plays a part in your day-to-day workflow. Think of the materials and construction as the unit's DNA—this is where you separate a table that will last for years from one that will buckle under pressure.

The Foundation: Stainless Steel Grades and Types

Stainless steel is the undisputed champion for commercial kitchen equipment. It’s tough, resists corrosion, and is easy to keep sanitary. While all prep tables are made of stainless steel, they come in different grades and types tailored for specific tasks and budgets. The two grades you’ll see most often are 304 and 430 stainless steel.

- 304 Stainless Steel: This is the premium choice. It has more chromium and nickel, which gives it top-tier resistance to rust and corrosion. It’s the ideal material for tabletops, interiors, and any surface that’s constantly exposed to acidic foods like tomatoes or vinaigrettes.

- 430 Stainless Steel: A more budget-friendly option, this grade is still plenty durable for most uses. While it holds up well, it's a bit more vulnerable to damage from certain acids and salts over time. You'll often see it used on the exterior sides and back of a unit where there’s no direct food contact.

Beyond the grade of steel, refrigerated prep tables are specialized for different menu items. The two most common types are sandwich/salad prep tables and pizza prep tables.

Sandwich Prep Tables vs. Pizza Prep Tables

At first glance, they might look like twins, but sandwich and pizza prep tables are specialized tools built for very different menus. Grabbing the wrong one will absolutely create frustrating bottlenecks in your assembly line. The real difference is all in the workspace design.

A refrigerated sandwich prep table is built for linear assembly—think subs, wraps, and salads. Its cutting board is on the narrower side, usually 8 to 12 inches deep. This is perfect for laying out a long sub roll or a tortilla and adding ingredients down the line. The ingredient rail is also set up for smaller, shallower pans holding sliced meats, cheeses, and veggies.

On the other hand, a pizza prep table is designed to handle the wide, round shape of pizza dough. Its defining feature is an extra-deep cutting board, often 16 to 20 inches or even more. This gives a chef plenty of room to stretch dough, add sauce, and pile on toppings without making a mess. The ingredient rail also uses deeper, larger pans to hold bulky items like pepperoni and sausage.

Understanding this distinction is key. A unit built with a 304 stainless top and interior is a long-term investment in durability, while the choice between a sandwich or pizza layout ensures your equipment supports your menu. For a deeper dive, exploring a dedicated guide to the nuances of a stainless steel prep table can give you even more insight.

Choosing the Right Size and Layout

Picking the perfect refrigerated prep table isn't just about finding a unit that fits an empty spot in your kitchen. It's about designing a workstation that truly performs. Simply measuring your floor space is step one, but a unit that’s actually going to help your business needs to be matched to your menu complexity, your daily order volume, and the natural flow of your kitchen.

The first big decision is always size. A small, 27-inch single-door unit could be the perfect workhorse for a food truck or a coffee shop with a simple sandwich menu. On the flip side, a sprawling 72-inch, three-door beast is absolutely essential for a bustling deli or a chain restaurant that pushes out hundreds of orders a day.

Think about your scale. Commercial refrigerated prep tables usually run anywhere from 36 to 108 inches wide. The ingredient pan capacity grows right along with the width, starting with small units holding just 2-6 pans and scaling up to massive models that can support over 20. The market for these units is pretty strong, especially in North America, with prices starting around a few thousand dollars and climbing past $12,000 for the big, feature-packed models. You can see for yourself what’s driving the sandwich preparation refrigerators market and its growth.

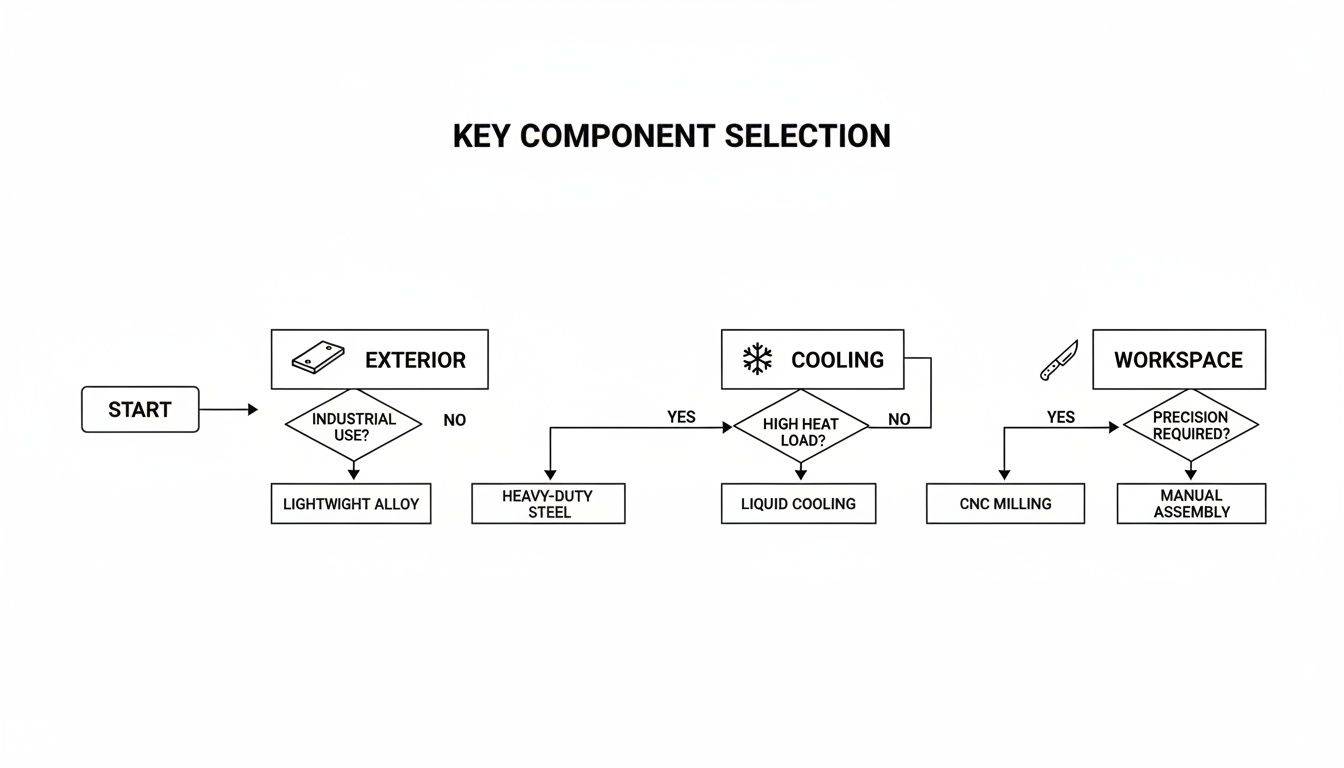

This decision tree can help you visualize how to narrow down your options based on key factors like construction, cooling needs, and workspace.

As you can see, choosing the right table is all about finding the sweet spot between a durable exterior, a powerful cooling system, and a workspace that actually makes your team faster.

Doors vs. Drawers: Which Is Right for You?

Once you've got a size in mind, you need to decide how you'll configure the refrigerated base. This choice directly affects how your crew gets to backup ingredients and how organized your cold storage stays during the lunch rush.

- Doors: The classic choice, doors give you the most flexibility. They open up to a wide, cabinet-style space with adjustable shelves. This is perfect for storing bulky or odd-sized things like big tubs of pickles, whole heads of lettuce, or tall squeeze bottles.

- Drawers: Drawers, on the other hand, are built for pure organization. They are designed to hold food pans perfectly, keeping ingredients neatly separated and easy to grab. This setup can seriously speed up restocking the top rail and helps you enforce a first-in, first-out (FIFO) system for your inventory.

The trade-off is pretty straightforward: doors are for adaptable bulk storage, while drawers are for lightning-fast organization. A lot of kitchens find a hybrid model—a unit with both doors and drawers—gives them the best of both worlds.

Standard Top vs. Mega Top Designs

The last major layout decision is all about the top ingredient rail—the heart and soul of your prep station. What you choose here comes down to the variety on your menu.

A standard-top model has a single row of ingredient pans. This setup works great for straightforward menus with a core group of toppings. A mega-top unit, however, adds a second and sometimes even a third row of pans.

That extra capacity is a game-changer for places with complex menus. A mega-top lets you keep a much wider variety of fresh ingredients—different cheeses, meats, veggies, and sauces—all right at your fingertips. This not only makes assembling diverse orders way faster but also helps prevent cross-contamination by giving every ingredient its own home. For many growing businesses, a versatile unit like a 48-inch sandwich prep table hits that perfect balance between footprint and capacity.

Ultimately, if you take the time to think through your kitchen's size, menu, and volume, you can set up a prep table that’s not just another piece of equipment, but a true asset that makes your line more efficient and kills operational bottlenecks.

Mastering Temperature Food Safety and Efficiency

Beyond the shiny stainless steel and different layouts, the real job of a refrigerated sandwich prep table is to keep your food, your customers, and your business safe. The technical details might seem a little overwhelming, but getting a handle on temperature control and energy use is the foundation of any safe and profitable kitchen. It’s not just a good idea—it’s an absolute must for running a professional foodservice operation.

It all comes down to avoiding the temperature danger zone. Foodborne pathogens love to multiply between 41°F and 135°F, so precise temperature control is your first and best defense. A quality prep table is more than just a cold box; it’s engineered to hold a consistent, safe temperature for every ingredient, from the base cabinet all the way up to the top rail.

The Gold Standard of Food Safety Temperatures

Modern prep tables are built to keep ingredients in a very specific—and very important—temperature range: 34°F to 41°F (1°C to 5°C). This is the sweet spot that slows down bacterial growth without freezing your fresh produce.

Holding that temperature steady, especially during a chaotic lunch rush with lids opening and closing, is what separates a reliable piece of equipment from a major health code risk.

These units use powerful, forced-air refrigeration systems to push cold air evenly around the cabinet and food pans. This gets rid of any warm spots where bacteria could start to grow. The system is also designed to recover its temperature quickly after a door is opened, keeping everything inside safe. To dive deeper into this critical topic, check out our guide on food safety temperature control and how it affects your kitchen.

Decoding the NSF Certification

When you see that little NSF logo on a prep table, it’s not just a sticker. It's a seal of approval that guarantees the equipment meets strict public health and safety standards set by NSF International, an independent testing organization.

For a refrigerated prep table, an NSF certification means:

- Hygienic Design: The unit is built with materials that are smooth, non-porous, and resist corrosion, leaving no nooks or crannies for germs to hide.

- Easy to Clean: It's designed with rounded corners and removable shelves, making daily sanitizing routines much simpler.

- Safe Materials: Any part that touches food has been tested and proven to be non-toxic and safe for a commercial kitchen.

In many places, NSF certification isn’t optional—it’s required to pass your health inspection. Choosing an NSF-certified unit is a smart investment in your kitchen’s safety and compliance. It shows inspectors and customers you’re serious about doing things right.

Balancing Performance with Energy Efficiency

While food safety always comes first, keeping operational costs down is a close second. Refrigeration is a huge energy user in any commercial kitchen, and an inefficient prep table can send your utility bills through the roof.

Luckily, modern engineering helps you get a great return on your investment. In a typical commercial kitchen, refrigeration can make up 20–30% of total electricity use, so efficiency really matters.

Many new prep tables are designed with high-grade insulation, energy-efficient compressors, and eco-friendly refrigerants. These features cut down on power use without compromising on cooling performance. It’s all about finding that perfect balance.

How Key Features Impact Cost and Performance

Understanding the trade-offs between initial price and long-term savings can help you make a smarter purchase. This table breaks down how key technical features affect your upfront cost and your operational budget over time.

| Feature | Initial Cost Impact | Long-Term Benefit |

|---|---|---|

| Standard Compressor | Lower | Basic performance, higher energy consumption during peak use. |

| Energy-Efficient Compressor | Higher (5–20%) | Reduces electricity use by 10–30%, leading to significant savings on utility bills over the unit's lifespan. |

| Standard Insulation | Lower | Less effective at holding temperature, causing the compressor to work harder and use more energy. |

| High-Density Insulation | Higher | Maintains cold temperatures more effectively, reducing compressor run-time and lowering energy costs. |

| Older Refrigerants (HFCs) | Lower | Less environmentally friendly and being phased out, potentially leading to higher service costs in the future. |

| Eco-Friendly Refrigerants | Higher | Lower environmental impact and better efficiency, ensuring compliance with new regulations. |

By prioritizing a unit that excels in both temperature stability and energy efficiency, you're making a choice that protects your bottom line while upholding the highest standards of food safety.

Protecting Your Investment with Proper Care

A high-quality refrigerated sandwich prep table is a serious investment in your kitchen's speed and efficiency. But just like any heavy-duty equipment, its performance and how long it lasts comes down to one thing: how well you take care of it. Being proactive about installation and staying on top of maintenance isn’t just about ticking boxes—it's about protecting that investment, avoiding disastrous downtime, and making sure your unit runs safely for years to come.

Thinking about long-term care from day one is the secret to avoiding major headaches down the road. A few simple, routine habits can be the difference between a workhorse that lasts a decade and one that’s bleeding you dry with emergency repair bills.

Essential Installation Practices

Getting the setup right from the start is your first line of defense against an early breakdown. The single most important factor? Proper ventilation. The compressor, which is the heart of the whole refrigeration system, throws off heat as it runs. If that heat gets trapped, the compressor has to work overtime, jacking up your energy bills and heading straight for a total burnout.

When you install your unit, always stick to the manufacturer's clearance guidelines. This usually means leaving a few inches of open space around the back and sides of the table. It’s a simple step, but it gives the system the airflow it needs to breathe, keeping everything cool and running efficiently from the get-go.

A Practical Maintenance Checklist

Regular, preventative maintenance is how you get the most out of your refrigerated prep table. A simple, consistent routine helps you spot small issues before they blow up into big, expensive problems. For a wider view on keeping all your kitchen gear in top shape, these general preventive maintenance best practices are a great resource.

Here’s a straightforward checklist to get you started:

- Clean Condenser Coils (Monthly): Dust and grease are the enemies of an efficient cooler. When coils get clogged, they can't release heat, forcing the compressor to overwork. A quick brush-down once a month keeps them clean.

- Inspect Door Gaskets (Weekly): A worn or cracked gasket is like leaving the door open—it lets cold air pour out, causing temperature swings and wasting energy. A quick test is to close a piece of paper in the door. If it slides out easily, it’s time for a new gasket.

- Sanitize All Surfaces (Daily): This one's non-negotiable for food safety. Wipe down the cutting board, interior, and exterior with a food-safe sanitizer to prevent bacteria from growing.

- Check and Clear Drain Lines (Monthly): Make sure the drain lines are clear of any gunk. A clog can cause water to back up, leading to nasty frost buildup inside the unit.

Think of this routine as a regular health check-up for your equipment. A few minutes of prevention each week can save you from thousands of dollars in emergency service calls and lost inventory.

Troubleshooting Common Issues

Even with the best maintenance, things can still go wrong. Knowing how to spot common problems can help you figure out if it's a quick fix you can handle yourself or if you need to call in a pro.

If you're seeing temperature fluctuations, the first thing to check is the condenser coil—is it clean? Are the door gaskets creating a tight seal? Also, make sure your team isn't overloading the unit with warm food or propping the doors open for too long.

Dealing with frost buildup? The usual suspects are a bad door seal or a blocked drain line. Both problems let too much moisture into the system, which then freezes. Fixing these simple issues can often get your unit back to peak performance without having to call for service.

Common Questions About Prep Tables

As you get ready to choose your new refrigerated prep table, a few questions always seem to pop up. Here’s a quick rundown of the most common ones to help you keep your unit running safely and smoothly.

How Often Should I Clean The Condenser Coils?

You’ll want to clean the condenser coils at least every 90 days to keep things running efficiently. If your kitchen sees a lot of airborne grease, flour, or dust, it’s a good idea to check and clean them every month.

When coils get dirty, the compressor has to work much harder. This not only spikes your energy bills but also dramatically increases the chances of a breakdown you really don’t have time for.

Can I Put Hot Food Directly Into The Refrigerated Base?

The short answer is no. You should never place hot food directly into any refrigerated unit. Putting hot items inside can quickly raise the internal temperature into the food safety "danger zone" (above 41°F), which puts every other ingredient in there at risk.

Always let cooked food cool down to a safe temperature before you store it in your prep table. It’s a simple step, but it’s absolutely critical for stopping bacterial growth and keeping all your products safe.

What Is A Front-Breathing Refrigeration System?

This term just describes how the unit pulls in and pushes out air for the refrigeration system. Most prep tables are rear-breathing, which means they need a few inches of open space behind them to get proper airflow.

A front-breathing unit, on the other hand, does all its air circulation through a grille on the front. This design is a lifesaver in tight spaces because you can push it right up against a wall or snug it in next to other equipment. It gives you a lot more flexibility with your kitchen layout without compromising on cooling power.

At PrepTables.com, we focus on providing durable, high-performance equipment that helps you streamline your kitchen's workflow and safety. Take a look at our wide selection of refrigerated sandwich prep tables to find the perfect match for your business.