Your Guide to Selecting a Refrigerated Sandwich Prep Table

Share

Picture a kitchen where every last topping, sauce, and slice of meat is perfectly chilled, neatly organized, and always within reach. That's the reality a refrigerated sandwich prep table brings to the table. It’s a single, brilliant piece of equipment that combines a sanitary workspace with easy-access cold storage, completely changing the game for food safety and speed.

The Secret To A Faster And Safer Kitchen

Think of a refrigerated sandwich prep table as your kitchen's command center. It elegantly merges two critical functions—prep and refrigeration—into one compact footprint. This setup is absolutely vital for maintaining the cold chain, which is the unbroken journey of keeping food at a safe, cold temperature from the moment it arrives to the second it's served.

By keeping all your ingredients chilled and right in front of the chef, these tables slash the time food spends in the dreaded "temperature danger zone" (41°F to 135°F), where bacteria can multiply in a flash. This isn't just about moving faster; it's about embedding a core food safety practice right into your workflow. For a deeper dive, check out our guide on restaurant food storage guidelines.

Boosting Efficiency and Reducing Waste

A well-organized prep table means your team isn't constantly running back and forth to the walk-in cooler. Those saved seconds on every single order add up, leading to faster ticket times and happier customers, especially when the lunch rush hits. Every motion is streamlined, making the assembly line smoother and far more consistent.

This efficiency also has a direct impact on your bottom line by helping to control food costs. When ingredients are stored correctly and used systematically, you'll see a noticeable drop in spoilage and waste. The organized layout naturally encourages a first-in, first-out (FIFO) system, ensuring older ingredients get used up first.

In a fast-paced kitchen, every second saved is a victory. A refrigerated prep table provides the ultimate advantage by placing everything a chef needs right at their fingertips, turning potential chaos into a seamless production line.

The growing market for these units says it all. The sandwich and salad prep table industry was valued at a whopping USD 1.2 billion in 2024 and is expected to climb to USD 1.71 billion by 2032, all thanks to the increasing demand for top-notch food safety and freshness.

More Than Just a Table

At the end of the day, this piece of equipment is an investment in quality and consistency. It’s your guarantee that the last sandwich of the night is just as fresh and safe as the first one you made. For an even more streamlined operation, you can pair it with other cold storage solutions, like refrigerated food lockers, to elevate your kitchen's safety and efficiency. By building a smarter, more organized kitchen, you’re setting yourself up for success.

Finding the Right Prep Table for Your Menu

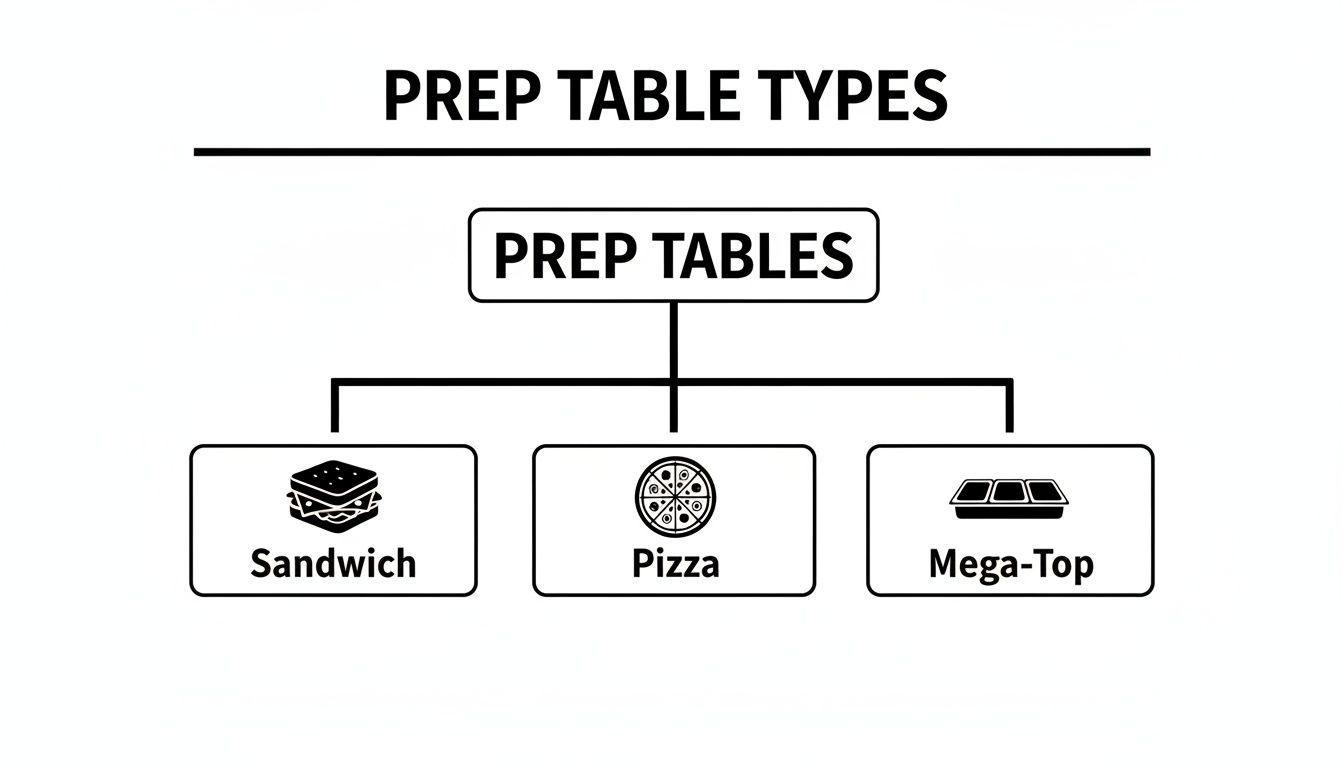

Choosing the right stainless steel prep table is a lot like picking the right knife for a specific task—the best one depends entirely on what you’re making. Not all prep tables are created equal, and matching the equipment to your menu is the first step toward a smoother, more efficient kitchen. Let's break down the most common types you'll run into.

Sandwich and Salad Prep Tables

The refrigerated sandwich prep table is the classic workhorse. You’ll find it in delis, cafes, and quick-service spots everywhere. Its design is straightforward and incredibly effective: a flat cutting board runs the length of the unit, right in front of refrigerated wells that hold your food pans. This layout is perfected for the assembly line-style creation of sandwiches, salads, and wraps. Your ingredients stay perfectly chilled and are just inches away from the prep surface, allowing your staff to build orders in a flash without taking a single extra step. It’s the gold standard for any operation that needs to crank out high volumes with speed and consistency.

Pizza Prep Tables

At first glance, a pizza prep table might look similar, but it’s engineered specifically for the unique demands of a pizzeria. The biggest difference is its cutting board, which is much deeper than what you’ll find on a standard sandwich unit. That extra real estate gives you plenty of room to stretch and work with large pizza doughs without making a mess. Another key feature is the raised pan rail. The ingredient wells are elevated above the work surface, a design that stops flour, cheese, and other toppings from falling into your cold ingredients and accommodates deeper pans for bulkier items.

Mega-Top Units for Maximum Ingredients

What happens when your menu is packed with dozens of toppings and condiments? You bring in a mega-top refrigerated sandwich prep table. Think of these as a direct upgrade to the standard sandwich model, built for kitchens that need more ingredient variety right on the line. The defining feature of a mega-top is its expanded pan capacity. Instead of the usual two rows of pans, a mega-top table has three rows, giving you about 50% more cold storage space at your fingertips. This is a game-changer for businesses with complex menus, like gourmet sandwich shops, burrito bars, or salad chains offering tons of customization.

The ability to hold more ingredients directly on the line isn't just a convenience—it's a strategic advantage that reduces ticket times and increases order accuracy by minimizing staff movement and confusion.

The overall demand for these versatile stations is on the rise. The food prep tables market, which includes all these types, was valued at USD 1.18 billion in 2023 and is projected to climb to USD 1.62 billion by 2029. This growth shows just how critical these units have become in modern foodservice. You can explore more data on this expanding market to understand the trends. Learn more about the food prep tables market growth on arizton.com.

Worktop and Undercounter Models

Finally, for kitchens with tight layouts or a need for secondary prep stations, worktop and undercounter refrigerators offer a compact solution. A worktop model gives you a flat, durable stainless steel surface for general prep work, with refrigerated cabinets tucked underneath. It doesn't have the top-mounted pan rail but serves as an excellent multi-purpose station. Undercounter models are even more space-conscious, designed to slide neatly under an existing counter. They provide easy-to-access cold storage without a dedicated work surface on top. These units are perfect for adding extra refrigeration to specific stations, like a beverage or dessert area, without messing up your kitchen's flow.

Decoding the Features That Truly Matter

When you're ready to invest in a refrigerated sandwich prep table, it’s easy to get lost in a sea of spec sheets. A few core features, however, really separate a workhorse unit from one that will fail you mid-service. Understanding these is the key to choosing a table that will become a reliable backbone for your kitchen.

Just like a chef knows the difference between a high-carbon and a standard stainless steel knife, you need to know your materials. This is especially true when it comes to the construction of your prep table, where stainless steel is king for both durability and hygiene.

The Power of Stainless Steel

Not all stainless steel is created equal. For commercial kitchens, 304-grade stainless steel is the gold standard for any surface that touches food. It has a higher nickel and chromium content, making it incredibly resistant to rust and corrosion from acidic things like tomato sauce or salad dressing.

While 304-grade is what you want for the top and interior, you’ll often find 430-grade stainless steel on the sides and back. This is a smart way to manage costs in areas less exposed to food and moisture, giving you a good mix of durability and value.

The steel's thickness, or gauge, is another huge factor. It’s a bit backward: a lower gauge number actually means thicker, stronger steel.

- 16-Gauge: This is the heavy-duty choice, built for high-volume kitchens where equipment takes a beating. It’s much better at resisting dents and dings.

- 18-Gauge: A very common and dependable standard, 18-gauge steel gives you a great balance of toughness and affordability for most commercial kitchens.

- 20-Gauge or higher: While it's cheaper, this thinner steel dents easily and is really only suitable for light-duty use.

Think of a lower gauge number on your prep table as a thicker shield for your investment. It ensures the unit can handle the daily chaos of a busy kitchen without looking beat up.

Here’s a quick breakdown to help you compare the most common options you'll encounter.

Stainless Steel Type and Gauge Comparison

| Feature | 304 Series Stainless Steel | 430 Series Stainless Steel | 16-Gauge Thickness | 18-Gauge Thickness |

|---|---|---|---|---|

| Corrosion Resistance | Excellent; ideal for food contact surfaces and high-moisture areas. Resists acids and salts well. | Good; suitable for exterior panels, sides, and back where food contact is minimal. | Superior dent and impact resistance. | Standard durability for most commercial applications. |

| Durability | Very high. Resists scratches and maintains its finish over time. | High, but more susceptible to dents and scratches than 304. | Built to withstand heavy use, impacts from pans, and constant wear. | Offers a solid balance of strength and cost-effectiveness. |

| Cost | Higher initial cost due to nickel and chromium content. | More budget-friendly, making it a common choice for non-critical parts. | Higher price point, reflecting its premium strength and longevity. | More affordable than 16-gauge, representing the industry standard. |

| Best For | Tabletops, food wells, interior walls, and any surface directly touching ingredients. | Exterior body panels, backsplashes, and structural components not exposed to food. | High-volume delis, institutional kitchens, and any environment where equipment sees heavy abuse. | Most restaurants, cafes, and sandwich shops with standard daily prep needs. |

Understanding these differences helps you make a smarter choice, ensuring you’re paying for durability where it counts the most.

This image helps you see where a standard sandwich prep table fits in, and how other models like pizza or mega-tops are just specialized variations on the same core idea.

Essential Certifications and Controls

Beyond the metal, a few features are absolute must-haves for safety and performance. The most important one is NSF certification. This seal from NSF International means the unit meets strict public health standards. It's built from food-safe materials and designed to be cleaned easily. Operating without NSF-certified gear is a quick way to get a health code violation.

Of course, the whole point of a refrigerated sandwich prep table is precise temperature control. Look for units that have:

- Digital Temperature Controls: These let you set and see the internal temperature accurately, making sure your ingredients stay safely chilled between 33°F and 41°F.

- Front-Breathing Refrigeration: This is a lifesaver in tight kitchens. The unit pulls air in and pushes it out from the front, so you can push it right up against a wall or other equipment without choking the compressor.

- Rear-Breathing Systems: These are also common but need a few inches of clearance at the back and sides to breathe properly.

The Workspace Cutting Board

The cutting board is where the magic happens, so its material is a big deal. High-density polyethylene (HDPE) is the industry standard for good reason—it’s non-porous, tough, and simple to sanitize. They’re usually white, but you can find color-coded versions to prevent cross-contamination between things like raw meat and veggies. To see a more detailed comparison, check out our complete guide to commercial refrigerated prep tables.

You might love wood cutting boards at home, but they’re a no-go here. They're porous and a nightmare to maintain, which makes them impractical and often a health code violation in a commercial setting. Stick with a good polyethylene board to keep your line safe, efficient, and clean, shift after shift.

Choosing the Right Size for Your Kitchen Workflow

Picking a refrigerated sandwich prep table is about more than just filling a space—it’s about dialing in your kitchen’s rhythm. The right unit should feel like a natural extension of your workflow, not a clunky obstacle in the way. It's a critical decision that hinges on balancing your available space, how much food you push out, and your staff's comfort.

First things first: grab a tape measure. Size up the spot where the table will live, but don't stop there. You absolutely have to account for clearance space, especially for ventilation. Most units, particularly the rear-breathing models, need at least a few inches of open air behind and on the sides to keep the compressor from working itself to death.

Also, think about the full swing of the refrigerator doors and any nearby drawers. Your staff needs to be able to open everything completely without crashing into other equipment or each other. A cramped workspace is a recipe for inefficiency and accidents, quickly turning your shiny new investment into a production bottleneck.

Matching Unit Size to Production Needs

The width of your prep table is directly tied to your output. A great way to narrow down your options is to think about how many sandwiches you’re building during your busiest hour. That number will point you toward the perfect size.

-

Compact Models (27 to 36 inches): These are the go-to for food trucks, small cafes, or any kitchen where space is at a premium. A 27-inch unit can usually hold eight 1/6-size pans, making it perfect for a simple menu or as a dedicated station for things like desserts or salads.

-

Mid-Size Workhorses (48 to 60 inches): This range is the sweet spot for most delis and restaurants. A 48-inch sandwich prep table is a fan favorite because it balances footprint and capacity beautifully. It often holds a dozen or more pans and gives one or two chefs enough elbow room to work together during a rush. To see if this size is right for you, check out our guide on the 48-inch sandwich prep table.

-

High-Volume Giants (72 inches and up): For the big players—institutional cafeterias, large catering operations, or the busiest sandwich shops—these beasts are non-negotiable. They offer maximum ingredient storage and a massive work surface that can handle multiple staff at once, ensuring your line never misses a beat.

A table that’s too small means your team is constantly running back to the walk-in, killing their momentum. On the flip side, a unit that’s too big just eats up valuable floor space and burns extra energy. The goal is to find that perfect sweet spot between capacity and efficiency.

Ergonomics and Strategic Placement

Beyond just the dimensions, you have to think about the people using the table. The ergonomics of your prep station can literally make or break your kitchen's flow. The standard work surface height is around 34-36 inches, which is a comfortable level for most people and helps reduce back strain over a long shift.

Accessibility is a huge deal, too. Can your staff easily reach all the pans without awkward stretching? Is the cutting board deep enough for what you’re making? A standard 8-10 inch deep cutting board works well for most sandwiches, but you might want something deeper for large wraps.

Finally, think about where this unit is going to live. Placing your refrigerated sandwich prep table in a logical spot is crucial for a smooth workflow. It should minimize the steps your staff takes to grab ingredients, build orders, and pass them down the line. A well-placed table gets rid of wasted motion and prevents kitchen traffic jams, keeping the whole operation running like a well-oiled machine.

Mastering Installation and Long-Term Maintenance

Your new refrigerated sandwich prep table is a long-term investment. How you treat it from day one will directly impact its performance for years to come. Getting the installation right is about more than just plugging it in—it’s about laying the groundwork for a long, efficient life.

After you've rolled the unit into place (making sure to leave enough room for ventilation!), the first job is to get it perfectly level. Grab a level, place it on the main work surface, and tweak the casters or legs until that bubble is dead center. A wonky table can cause doors to hang open, gaskets to leak cold air, and condensation to pool up, creating a whole mess of problems you don't need.

Here’s the most important tip: once the table is in place, let it sit unplugged for at least 24 hours. Shipping can jostle the refrigerant and compressor oil, and this waiting period allows everything to settle back where it belongs. Firing it up too early can starve the compressor of oil and cause catastrophic damage to the heart of the system.

Creating a Daily Cleaning Routine

In a professional kitchen, a spotless prep table is non-negotiable. A simple daily cleaning habit is your best defense against bacteria and keeps your equipment running smoothly. This isn't a deep scrub, just a solid wipe-down of every surface that touches food or hands.

Your end-of-day checklist should look something like this:

- Empty and Clean Pans: Pull all food pans from the rail. They need to be properly washed, rinsed, and sanitized before you even think about refilling them for the next service.

- Wipe Down the Interior: Clear out the storage cabinet below and give the interior walls and shelves a good wipe with a food-safe cleaner. Get any spills or crumbs out of there.

- Sanitize the Cutting Board: Scrub the board with hot, soapy water, then hit it with a food-safe sanitizer. Stay away from abrasive pads that can carve grooves into the board—that’s just asking for bacteria to move in.

- Clean the Gaskets: Gently wipe down the door gaskets with warm water and a mild soap. Spills and gunk can make them sticky, causing them to rip over time and leak precious cold air.

Essential Preventative Maintenance Habits

Going beyond the daily wipe-down with a few key maintenance tasks can save you a fortune in emergency repair calls. These simple habits are all about protecting your table's cooling power and keeping your energy bills in check.

The single most important job is cleaning the condenser coils. Think of these coils as the unit's radiator; they release all the heat pulled from inside the cooler. Over time, they get caked with a nasty blanket of dust, grease, and kitchen grime.

Clogged condenser coils force the compressor to work overtime, jacking up your energy use and eventually causing it to burn out. Cleaning them every 90 days with a stiff brush and a vacuum is the best thing you can do to prevent a complete system failure.

Also, get in the habit of checking your door seals for cracks or tears. A bad gasket is like leaving the fridge door open. You can do a quick check with a dollar bill: close the door on it, and if you can pull the bill out with no resistance, the seal is weak and it’s time for a replacement. A few minutes of prevention will keep your refrigerated sandwich prep table a reliable kitchen workhorse for the long haul.

Why a Refrigerated Prep Table is a Kitchen's Secret Weapon

Think of a refrigerated prep table as more than just a piece of stainless steel. It's the central nervous system of a high-volume kitchen. This is where your operation’s speed, consistency, and food safety all come together. It's a direct investment in keeping your line moving smoothly and your customers happy.

By putting cold storage right at your prep crew’s fingertips, these units slash the time it takes to build a sandwich, salad, or burrito. This isn't just a small perk; it’s a game-changer for your ticket times, customer satisfaction, and even your food costs. Less waste and faster service mean a healthier bottom line.

What's Next in Prep Table Tech?

The food service world never stands still, and prep tables are no exception. We’re seeing a big push toward smarter, more sustainable models built for the demands of a modern kitchen.

Here’s what’s gaining traction:

- Eco-Friendly Models: Look for units using green refrigerants like R290. It has a much lower environmental footprint than older chemicals. Combine that with better insulation and high-efficiency compressors, and you've got a machine that seriously cuts down your energy bill.

- Smart Features: The next wave of prep tables comes with digital temperature monitoring and alert systems. This tech gives you real-time data, making it easier to stay on top of food safety and spot potential equipment issues before they turn into a full-blown crisis.

You can see this trend in the market numbers, too. The global market for these tables was valued at USD 3.2 billion in 2024 and is expected to climb to USD 5.4 billion by 2033. This growth is all about the demand for energy-saving tech that meets new environmental standards. If you're a data geek, you can find more details on the refrigerated prep table market growth on verifiedmarketreports.com.

Picking the right prep table isn't just a purchase—it's a foundational decision. It’s the kind of investment that pays you back with every single plate that leaves your kitchen, setting you up for success today and for years to come.

Frequently Asked Questions

Got questions about refrigerated sandwich prep tables? You're not alone. Figuring out the details is how you make a smart buy that actually fits your kitchen. Let's dig into some of the most common things operators ask.

What Is the Ideal Temperature for a Refrigerated Prep Table

You want to keep your unit between 33°F and 41°F (0.5°C and 5°C). This isn't just a suggestion—it's the sweet spot for keeping ingredients fresh and safely out of the "temperature danger zone" where bacteria loves to grow.

Get yourself a good, calibrated thermometer and check it regularly. Staying in that range isn't just smart, it's a must-have for passing your health inspection and serving safe, quality food.

Can I Use a Pizza Prep Table for Making Sandwiches

Technically, yes, but think about the workflow. A pizza prep table has a much deeper cutting board because you need room to stretch out large pizza dough. That extra space can feel awkward and clunky when you're just assembling a club sandwich.

Their pan rails are also raised higher to fit big, deep pans for bulky toppings. While you can make it work, a dedicated sandwich prep table is designed for the job. Everything is closer, more compact, and just plain faster for making sandwiches, wraps, or salads.

The right tool for the job always improves workflow. Using a sandwich prep table for sandwiches ensures every movement is optimized for speed and comfort, reducing strain on your staff during a busy shift.

How Often Should I Clean the Condenser Coils

Make it a habit to clean the condenser coils at least every 90 days. If your kitchen is a magnet for grease and dust—and let's be honest, most are—you should probably bump that up to once a month. Dirty coils are the worst enemy of any refrigeration unit.

When the coils get clogged, they can't push heat out, which makes the compressor work overtime. That means higher energy bills and a ton of extra stress on the system, which is a fast track to expensive breakdowns. Seriously, this one simple task will do more to extend the life of your unit than anything else.

What Does NSF Certified Mean and Why Is It Important

When you see that NSF seal, it means the unit has been put through the wringer by NSF International and meets their tough standards for public health. For a piece of commercial kitchen equipment, this is non-negotiable.

It's your guarantee that:

- The materials touching your food are safe.

- The entire unit is designed to be cleaned and sanitized properly, with no hidden nooks for gunk to build up.

- It actually performs the way the manufacturer claims it will.

Choosing an NSF-certified refrigerated sandwich prep table is how you know you're getting a professional-grade piece of gear built for the real world of a commercial kitchen.

At PrepTables.com, we offer a wide selection of NSF-certified refrigerated prep tables to meet the demands of any commercial kitchen. Explore our collection at PrepTables.com to find the perfect unit to enhance your workflow and food safety standards.