Reducing Food Waste in Restaurants Profitably

Share

That little bit of daily food waste might seem like nothing, but it’s a quiet killer of your restaurant's profitability. Getting a handle on reducing food waste in restaurants isn't just a feel-good ethical goal—it's a core business strategy for protecting your margins and building a tougher, more profitable operation.

The Hidden Costs of Food Waste

Every single ingredient that ends up in the bin represents a whole chain of financial losses that go way beyond what you paid for it.

Think about a single spoiled tomato. You've lost the cost of the tomato, sure, but you've also lost the labor spent receiving and storing it, and all the potential revenue from the dish it was supposed to be in. When you multiply that across an entire year, these tiny losses snowball into thousands of dollars.

A mid-sized bistro, for example, might not even notice the daily cost of over-prepped garnishes or portions that are just a little too big. But those "minor" issues can easily bleed $5,000 to $10,000 out of the business annually, hitting the bottom line directly. This isn't just about tossing food; it's about throwing away invested capital, labor, and profit.

The financial drain is often much larger than operators realize. Food costs represent, on average, 30-50% of a restaurant's total spending. When waste occurs, you're not just losing ingredients—you're losing a substantial portion of your operating budget.

Understanding the Sources of Waste

To actually start reducing food waste in your restaurant, you have to know where it's coming from. The problem isn't one big leak; it's more like a dozen small drips that, together, create a flood of lost money. These issues usually fall into three main buckets.

- Ordering and Inventory Errors: Over-ordering perishables "just in case" is a classic, but costly, mistake. Without a solid handle on forecasting, kitchens are often stuck with extra ingredients that go bad before they ever see a plate.

- Kitchen Preparation Inefficiencies: This covers everything from improper trimming techniques that toss out perfectly usable product to prepping way too many ingredients for the day's service.

- Customer Plate Waste: Those unfinished meals coming back to the dish pit—often from oversized portions or unpopular menu items—represent a direct loss of perfectly good, prepared food.

In our industry, this is a massive economic and environmental problem. Full-service restaurants generate around 5.76 million tons of food waste every year worldwide. That's the largest share compared to other food service spots, and it's driven by these exact inventory, prep, and plate waste issues. You can dig into more restaurant waste statistics over on The Restaurant HQ. This waste chips away at profitability and is a huge missed opportunity for efficiency.

The True Financial Impact on Your Operations

The cost of food waste goes beyond just the price of the trashed ingredients. It also includes wasted energy for cooking and refrigeration, the water used for cleaning, and the labor costs of staff who handle food that just gets thrown away.

For instance, poor storage practices can lead directly to spoilage, which then inflates your utility bills from overworked refrigeration units. To get a better grip on this, you might find our guide on choosing your commercial refrigerator helpful—it’s all about making sure your equipment is working for you, not against you.

Ultimately, tackling food waste is one of the most direct paths to improving your restaurant's financial health. By putting real strategies in place to measure, track, and reduce waste, you can turn what was once a silent expense into a real, tangible boost to your profits.

Pinpointing Waste with a Practical Kitchen Audit

You can't fix what you don't measure. Before you can make any real headway in reducing food waste in restaurants, you first have to get a crystal-clear picture of what’s actually being tossed. A hands-on kitchen audit gives you this crucial data, and you don’t need to hire expensive consultants to get it done. It's really just about creating a simple, repeatable process to see exactly where your money is going.

This whole process is a lot simpler than it sounds. For one week, just set up separate, clearly labeled bins for the three main types of food waste. This one act of separation is the first step toward getting a real handle on your inventory and costs.

Setting Up Your Waste Tracking System

To get started, all you really need are three dedicated containers, a basic kitchen scale, and a simple spreadsheet or even a physical logbook. The goal here is to make tracking a normal part of your kitchen's daily routine, not some extra chore that everyone dreads.

- Spoilage Bin: This is for any ingredient that goes bad before you can use it. Think wilted greens, expired dairy, or moldy produce. This bin is a direct reflection of issues with your purchasing or storage methods.

- Prep Trim Bin: This bin is for all the unavoidable scraps from food prep, like vegetable peels, meat trimmings, and off-cuts. If this bin gets heavy, it might point to inefficient knife skills or a missed opportunity to repurpose those scraps.

- Plate Waste Bin: This one is for all the food that comes back from the dining room uneaten. It’s a direct signal of portion size problems, unpopular menu items, or recipes that just need a little tweaking.

At the end of each shift or day, simply weigh the contents of each bin and jot down the numbers. This small habit builds an incredibly valuable set of data over the course of a week.

Turning Data into Actionable Insights

Once you've got a week's worth of data, you can start connecting the dots. Your spreadsheet shouldn’t just track the weight; it should also track the estimated cost of what you're throwing away. Seeing that you tossed $150 worth of spoiled avocados is way more impactful than just seeing a number like 10 pounds.

This hard data takes all the guesswork out of the equation. You might think your biggest financial hit is from plate leftovers, but the numbers could show it’s actually from improper produce storage. I know a small café owner who did a week-long audit and found their biggest source of waste was salad greens wilting before they could be used.

By simply changing their storage containers and tweaking their order frequency, the café saved over $300 a month. It’s a perfect example of how a simple audit can lead to immediate and substantial savings.

The insights from your audit will shine a spotlight on specific problem areas, letting you roll out targeted solutions. For instance, a lot of plate waste from one particular dish might be a cue to reduce the portion size or rethink the recipe. This data-driven approach is the bedrock of effective inventory management best practices, which are all about preventing waste before it even happens.

The Bigger Picture of Restaurant Waste

Understanding your own kitchen’s waste is critical, but it’s also just one piece of a much larger industry-wide puzzle. Globally, it’s estimated that about 4% to 10% of food purchased by restaurants never even makes it to a customer's plate. Even more shocking, a staggering 31% to 40% of the food that is served gets left behind. This data from Hospitality Insights really underscores the urgent need for better tracking in every single professional kitchen.

Running a weekly or bi-weekly waste audit transforms an abstract problem into a concrete set of numbers you can actually do something about. It’s the foundational step for any restaurant that’s serious about plugging financial leaks, boosting efficiency, and building a more profitable, sustainable business.

Designing a Waste-Efficient Kitchen Workflow

An efficient kitchen is the heart of a successful restaurant, and frankly, it's where the battle against food waste is either won or lost. The right equipment and a smart layout do more than just speed up service—they actively prevent the spoilage and over-prepping that bleed profits. This whole process often starts with one of the most fundamental pieces of gear: the stainless steel prep table.

Choosing the right prep table isn't just about finding a surface to chop on. It's a strategic move that affects durability, hygiene, and the entire flow of your kitchen. Stainless steel tables come in various forms, each designed to optimize a specific part of your workflow. Key factors include the gauge (thickness) of the steel and the table's specific features.

- 18-Gauge Stainless Steel: This is your versatile workhorse. It's perfect for general prep, light-duty storage, and assembly stations. For most day-to-day kitchen tasks, it strikes the perfect balance between durability and cost.

- 16-Gauge Stainless Steel: If you're running a high-volume kitchen or need a spot for heavy equipment like a mixer or meat slicer, step up to 16-gauge. It's thicker, tougher, and won't dent or bow under the constant pressure of heavy use.

Spending a little more on a heavier gauge for those demanding areas means your tables will last longer and provide a stable, safe surface. That stability contributes to a smoother, less wasteful prep process.

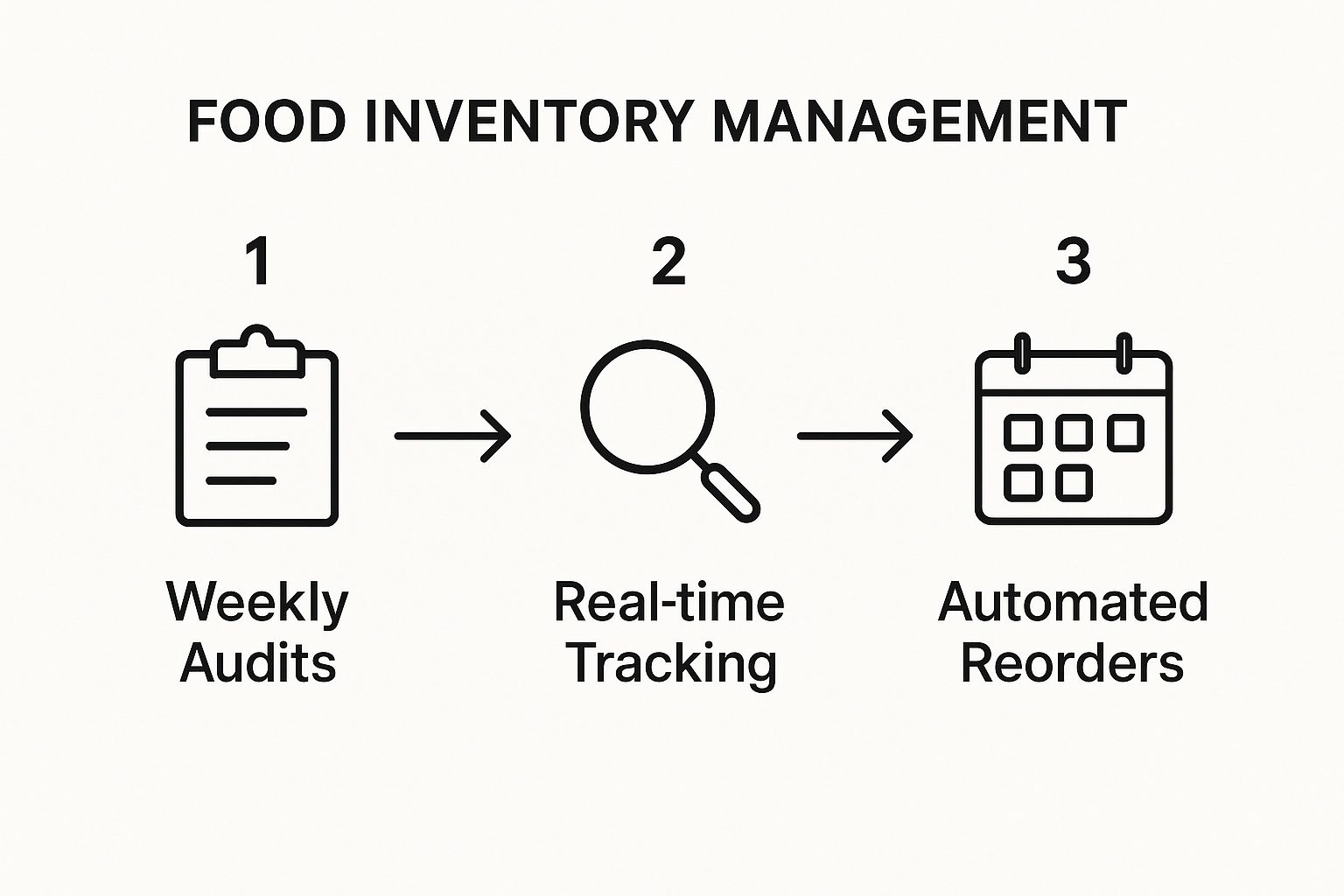

This process flow visualizes how a structured approach, starting with audits and moving to automated systems, can create a more efficient inventory management cycle. By systematically tracking what you have, you can prevent the over-ordering that leads directly to waste.

This workflow shows just how important it is to move from manual checks to more tech-driven solutions for a truly proactive approach. The right equipment is the foundation that makes this kind of systematic tracking even possible.

Specialized Prep Tables for Targeted Waste Reduction

Beyond your standard work surfaces, specialized prep stations are absolute game-changers, especially for specific menu types. These units are designed to keep perishable, high-use ingredients at the perfect temperature right where the action is, which drastically cuts down on spoilage and helps with portion control. Two of the most impactful options are sandwich prep tables and pizza prep tables, which combine workspace, storage, and refrigeration into one efficient unit.

A well-designed prep station is your first line of defense against waste. By keeping ingredients fresh, organized, and perfectly portioned, you're not just making food—you're protecting your profit margin with every single order.

These units have refrigerated storage built right in below the workspace, with cooled wells on top for holding food pans. This design means your staff isn't constantly running to the walk-in, which saves energy and keeps ingredients within arm's reach, ensuring they stay fresh throughout a busy service.

The Power of Refrigerated Sandwich Prep Tables

For any deli, café, or spot with a slammed lunch service, a sandwich prep table is non-negotiable. Its design is all about efficiency and freshness. The top section features refrigerated wells made to hold multiple pans of sliced meats, cheeses, lettuce, tomatoes, and all your sauces.

This setup brings some major benefits for cutting down on food waste:

- Temperature Control: Ingredients stay at a consistent, food-safe temperature, which extends their shelf life and stops the wilting or spoilage that happens when they sit out.

- Portioning Efficiency: With everything laid out in front of the chef, it’s so much easier to grab the right amount for each order, minimizing accidental over-portioning.

- Reduced Cross-Contamination: Separate pans for each ingredient help maintain quality and stop flavors from mixing, meaning fewer ingredients get tossed because of contamination.

Think about a chaotic lunch rush. Without a dedicated station, a cook might pull out big containers of toppings and leave them on the counter for an hour. By the end of the rush, a lot of what's left over is no longer fresh enough to save. A sandwich prep table just completely eliminates that problem.

Optimizing Workflow with Pizza Prep Tables

Pizza prep tables are built on a similar idea but are specifically adapted for making pizzas. They usually have a wider and deeper cutting board to handle large doughs and feature raised, refrigerated rails to hold pans of sauce, cheese, and toppings.

The key difference is the rail design. On a pizza prep table, the rails are often raised and angled toward the chef, making it easier to quickly and evenly spread toppings across a pizza base. This ergonomic design speeds things up and helps keep ingredient usage in check.

For a pizzeria, this is huge. Over-topping pizzas doesn't just mess with the final product's quality—it drives up food costs like crazy. A well-organized pizza station makes it simple for your team to follow recipes precisely, ensuring consistency and preventing the casual overuse of expensive ingredients like pepperoni or mozzarella.

Choosing the Right Prep Table for Your Kitchen

Selecting the right prep table is a foundational decision that impacts everything from workflow speed to waste reduction. To make the best choice, consider your menu, kitchen volume, and specific prep needs. This table breaks down the most common options to help you decide.

| Table Type | Primary Use Case | Key Features for Waste Reduction | Best For |

|---|---|---|---|

| Standard Stainless Steel | General chopping, mixing, and assembly. | Open, easy-to-clean surface. Can be positioned for optimal workflow. | All kitchens for versatile, multi-purpose prep space. |

| Sandwich/Salad Prep Table | Assembling sandwiches, salads, and wraps. | Cooled top wells for ingredient pans; refrigerated base. | Delis, cafes, and restaurants with a high volume of cold menu items. |

| Pizza Prep Table | Preparing pizzas from dough to toppings. | Wide cutting board; raised, angled refrigerated rail for toppings. | Pizzerias and restaurants serving flatbreads or made-to-order pizzas. |

| Work Table with Sink | Washing and prepping produce in one location. | Integrated sink reduces movement and potential for spills. | Kitchens that handle large quantities of fresh produce. |

Ultimately, a more organized kitchen is a more profitable one, and a well-structured layout is fundamental. You can learn more by exploring our detailed guide on commercial kitchen layout planning to see how every piece of equipment fits into the bigger picture. By investing in the right type of prep table for your specific menu, you create an environment where efficiency is baked right in.

Using Your Menu to Minimize Food Waste

Your menu is so much more than a list of what you sell—it's one of your most powerful tools for reducing food waste in restaurants. When you get it right, a thoughtfully engineered menu acts as a strategic blueprint, guiding everything from purchasing and prep to the final plate that goes out to the customer. Moving beyond basic inventory checks and into smart menu design is where you can find some serious savings and build a much more resilient kitchen.

The process starts when you stop seeing your menu as a static document and start treating it as a dynamic tool that responds to what your customers are actually buying. By digging into your Point of Sale (POS) system's data, you can quickly see which dishes are stars and which are just taking up space. This information is pure gold for predictive ordering, letting you stock up on ingredients for your bestsellers while scaling back on the slow-movers. That shift alone directly prevents overstocking and spoilage.

Engineering Your Menu for Cross-Utilization

The real magic behind a waste-efficient menu is cross-utilization. This is simply the art of designing dishes that share common ingredients, making sure that everything you buy gets used up quickly and completely across multiple different items. It’s a simple concept, but the impact it can have on your bottom line is massive.

Think about it this way: instead of buying a specialty ingredient for just one unpopular dish, you design your menu so that your high-quality (and often expensive) ingredients appear in several popular places. This simple strategy increases their turnover rate and drastically cuts down the risk of anything spoiling in the walk-in.

Here’s what this looks like in a real kitchen:

- Prime Rib Special: The high-quality trim from your weekend prime rib doesn't hit the bin. Instead, it becomes the star of a premium steak sandwich or some killer beef tacos on your weekday lunch menu.

- Roasted Chicken: The same chicken you roast for a dinner entrée can be pulled for chicken salad sandwiches, tossed into a creamy pasta, or used to make a hearty chicken noodle soup.

- Fresh Vegetables: A fresh bell pepper can be diced for an omelet at brunch, sliced for a fajita platter at dinner, and roasted for a side dish.

This approach ensures you get maximum value from every single ingredient that comes through your back door. You're not just selling food; you're selling every usable part of it in a smart, profitable way.

Leveraging POS Data for Predictive Ordering

Your POS system is an absolute treasure trove of data that can drive much smarter purchasing decisions. When you get into the habit of regularly analyzing sales reports, you can start to spot clear trends in what your customers are ordering. That insight lets you forecast demand with much greater accuracy, helping you move from "just-in-case" ordering to data-driven purchasing.

For example, if your data shows that fish tacos fly out of the kitchen on Fridays but barely move on Tuesdays, you can adjust your fresh fish order accordingly. This simple shift prevents you from having expensive, highly perishable seafood just sitting there with no chance of being sold.

The goal is to align your inventory perfectly with your sales velocity. By letting your POS data guide your purchasing, you create a direct link between what customers want and what you have on your shelves, which is a cornerstone of an effective waste reduction strategy.

The Financial Sense of Smart Portion Control

One of the biggest, and often overlooked, sources of food waste happens after the food leaves the kitchen: plate waste. While piling on generous portions might feel like good customer service, it often leads to unfinished meals and perfectly good food ending up in the trash. Fine-tuning your portion sizes is a delicate balance, but getting it right can slash your waste without making customers feel short-changed.

The scale of this issue is immense. In the United States, consumers waste nearly 35 million tons of food every year, costing a staggering $261 billion. The fact that waste has surged even with high food prices shows that cost alone isn't enough to change behavior. This highlights just how critical it is for restaurants to implement precise portioning. You can dig deeper into this challenge in ReFED's comprehensive report on U.S. food waste.

Start by using your waste audit data. If you notice a particular dish consistently comes back half-eaten, that’s a flashing red light that the portion is too large. Even a slight reduction—like serving five ounces of protein instead of six—can make a huge difference when you multiply that across hundreds of orders a week.

To roll this out without getting backlash, train your front-of-house team to communicate the change in a positive way. They can frame it as offering a more refined dining experience or mention that smaller, shareable plates are available. A lot of the time, customers won't even notice a small adjustment, but your food costs and your waste bin definitely will.

Getting Your Team on Board with Waste Reduction

A great strategy for reducing food waste in restaurants is only as good as the team putting it into practice. You can optimize your equipment and menu all day long, but if your staff isn't bought in, waste will keep eating into your profits. The real secret to a successful waste reduction plan is the people—you need to build a culture where every team member feels like they own a piece of the process.

This all starts with practical, hands-on training that connects directly to what your staff does every single day. For your kitchen crew, it's about showing them how their specific skills have a real impact on the bottom line.

Empowering Your Kitchen Crew

Your back-of-house team is on the front lines of waste prevention. Giving them the right skills and knowledge empowers them to make smarter decisions that cut down on needless loss.

- Advanced Knife Skills: This is more than just basic chopping. Run a workshop on "root-to-stem" cooking and show your team how to use every part of a vegetable. Demonstrate how precise protein trimming can create usable scraps for stocks or staff meals, turning what was once trash into a valuable product.

- Storage Protocol Mastery: Don't just tell them to use FIFO; explain why it’s so critical. Train them on the specific temperature and humidity needs for different types of produce to maximize shelf life. Proper storage isn’t just a rule—it's a technique for preserving the quality and value of your inventory.

These sessions show that reducing waste isn't about being cheap; it's about being a smarter, more skilled culinary pro.

Coaching Your Front-of-House Staff

Your servers and hosts are your direct connection to your customers, which puts them in a unique position to stop plate waste before it even happens. Coach them to be proactive guides who can help guests make choices they'll actually enjoy and finish.

Train your front-of-house team to be waste detectives. By asking the right questions about unfinished plates, they can gather invaluable feedback that helps you fine-tune portion sizes and recipes.

For instance, teach your servers to paint a clear picture of portion sizes. Simple phrases like, "Just so you know, our steak is a hearty 10-ounce cut, perfect for a big appetite," help manage expectations. If a plate comes back half-eaten, they should feel comfortable asking, "Was the portion size a bit too generous for you today?" That feedback is pure gold.

Building a Culture of Ownership

Real, lasting change happens when waste reduction becomes a shared team mission, not just another top-down directive. You have to make the process visible, collaborative, and even a little competitive.

A simple waste tracking sheet placed next to the bins is a great start. At the end of a shift, have a team member weigh the day's waste and jot down the numbers. This one small action makes an invisible problem tangible and creates a sense of shared accountability.

Want to take it to the next level? Introduce a team-based incentive. Set a clear, achievable goal—say, a 15% reduction in total food waste weight over one month. If the team hits the target, reward them. It could be a shared bonus, a team lunch, or even an extra paid day off. This transforms a chore into a challenge and unites everyone around a common goal, making waste reduction a core part of your restaurant's identity.

Common Questions on Restaurant Food Waste

Kicking off a mission to cut down on food waste in your restaurant naturally brings up a few questions. Let's tackle some of the most common ones with straightforward, practical answers so you can start making a real difference, no matter the size of your kitchen or your budget.

Where Should I Start with a Limited Budget?

You don’t need a massive budget to start slashing your waste. In fact, the most powerful first step you can take is completely free: a manual waste audit. All it takes is a simple scale and a spreadsheet to get the hard data you need to see where your biggest financial leaks are coming from.

Once you’ve identified the source of the waste, you can focus on high-impact behavioral changes that cost absolutely nothing.

- Refine Prep Techniques: Get your kitchen crew trained up on advanced knife skills. This will drastically minimize trim waste and help you use every last bit of an ingredient.

- Enforce Strict FIFO: This is a big one. Being rigorous about the "First-In, First-Out" method for your inventory costs you zero dollars but is one of the best ways to prevent older stock from spoiling.

Making these small operational tweaks can deliver a surprisingly significant return before you ever need to spend a cent on fancy new software or equipment.

How Can I Reduce Waste from a Buffet or Catering Setup?

Buffets and catered events definitely have their own unique waste challenges, but the same core principles apply. The trick is to shift your mindset from overwhelming abundance to smart, strategic replenishment. Instead of putting out giant trays of food that will sit for hours, use smaller serving dishes and simply refill them as they start to get low.

For any catered event, good forecasting is your best friend. Lean on the data from past events of a similar size and style to get a much more accurate prediction of how much food you'll actually need. Always have a clear plan in place before the event to safely donate or repurpose any untouched, safe-to-eat leftovers the moment it ends.

This more proactive approach stops you from overproducing massive amounts of food while still making sure your guests have a fantastic experience. It’s a win for your food cost, your budget, and your brand’s reputation for being sustainable.

What Is the Best Way to Handle Unavoidable Food Scraps?

Look, even the most efficient kitchens will have some scraps. It’s just part of the business. But before you toss them, get creative. Those vegetable peels and meat trimmings can be transformed into incredible, flavorful stocks for your soups and sauces. You can even use them for staff meals, adding value from something that was destined for the bin.

For the scraps that truly can't be used, start looking for local partners. You’d be surprised how many local farms would be thrilled to take your vegetable scraps for animal feed. Another great option is signing up for a commercial composting service, which diverts all that organic waste from the landfill and turns it back into nutrient-rich soil. And of course, donating any safe, surplus prepared food to local charities is an excellent way to reduce waste, give back to your community, and often get a nice tax benefit.

At PrepTables.com, we know that having the right equipment is the bedrock of a waste-efficient kitchen. From our versatile stainless steel work tables to specialized refrigerated prep stations, our products are designed to improve your workflow, keep ingredients fresher for longer, and ultimately support your bottom line. Explore our full range of professional kitchen solutions at https://preptables.com to build a smarter, more sustainable operation.