Top Inventory Management Best Practices for Commercial Kitchens

Share

In the fast-paced world of food service, what's in your walk-in cooler is just as important as what's on the menu. Effective inventory management is the unsung hero of a profitable kitchen, turning potential waste into tangible profit. It’s about more than just counting boxes; it's a strategic approach to controlling costs, ensuring quality, and streamlining operations from receiving to the final plate.

A well-organized kitchen starts with the right foundation: your equipment. Having dedicated, NSF-certified stainless steel prep tables, specialized sandwich prep tables, or expansive pizza prep tables creates defined zones for different ingredients. This is the first physical step in preventing cross-contamination and accurately tracking stock levels. When your workspace is optimized, your inventory control becomes simpler and more effective.

This guide will explore 9 essential inventory management best practices designed specifically for the unique challenges of commercial kitchens. From implementing ABC analysis to mastering demand forecasting, you will gain actionable strategies to reduce spoilage, improve cash flow, and transform your stockroom from a source of stress into a competitive advantage. These methods provide the framework needed to move beyond basic stock-taking and achieve true operational control.

1. Implement ABC Analysis for High-Value Ingredients

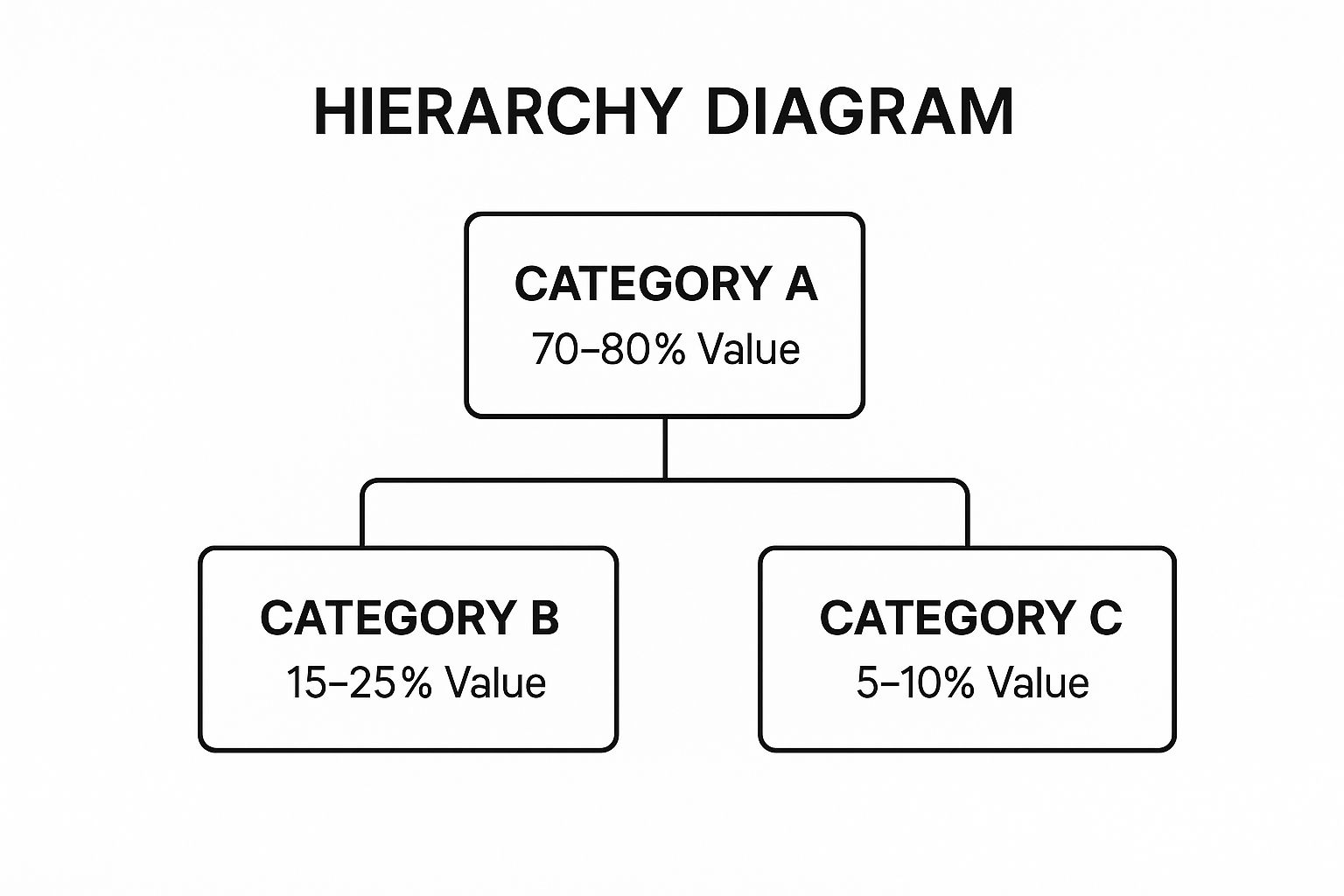

Not all inventory items carry the same financial weight. One of the most effective inventory management best practices is implementing ABC analysis, a method that applies the Pareto Principle (the 80/20 rule) to your stockroom. It involves categorizing ingredients based on their consumption value, which is the total value of an item consumed over a specific period. This strategic approach allows you to focus your most stringent control measures on the items that impact your bottom line the most.

How ABC Analysis Works in a Kitchen

The system divides your inventory into three distinct categories, ensuring you allocate time and resources efficiently:

- Category A: These are your most valuable items, typically representing 70-80% of your total food cost but only about 10-20% of your total inventory items. Think prime cuts of beef, fresh scallops, or high-end spirits. These items require frequent, rigorous tracking and secure storage.

- Category B: These are your mid-range items, accounting for 15-25% of your food cost and 20-30% of your inventory. Examples include specialty cheeses, premium produce, or house-made sauces. They need regular monitoring but less intensity than Category A.

- Category C: This category contains the bulk of your inventory items (60-70%) but represents the smallest portion of your food cost (5-10%). These are low-cost staples like flour, salt, onions, and standard spices. A more relaxed inventory control system is sufficient for these items.

This infographic illustrates the hierarchical breakdown of inventory value according to the ABC analysis method.

The visualization clearly shows that the small percentage of "A" items demands the highest level of management attention due to its significant financial impact. By focusing your efforts here, you gain better control over food costs, reduce high-value waste, and optimize purchasing for your most critical ingredients.

2. Adopt Just-In-Time (JIT) Inventory Management

Holding excess stock ties up capital and increases the risk of spoilage, a critical concern in any food-service operation. Just-In-Time (JIT) inventory management is a lean strategy that minimizes these risks by aligning raw material orders directly with production schedules. Instead of stockpiling ingredients, you receive them only as they are needed, reducing waste, lowering holding costs, and ensuring maximum freshness.

This approach, famously perfected by Toyota, requires highly reliable suppliers and precise demand forecasting to succeed. It's a powerful tool among inventory management best practices for businesses aiming to operate with maximum efficiency.

How JIT Works in a Kitchen

Implementing JIT effectively transforms your kitchen into a highly responsive and efficient operation. Rather than ordering bulk ingredients far in advance, your purchasing is triggered by immediate or near-future demand, such as daily specials or event catering needs.

- For Daily Operations: A pizzeria using a dedicated pizza prep table could schedule daily deliveries of fresh dough, mozzarella, and vegetables. This ensures ingredients for the day's service arrive just in time, minimizing the need for extensive refrigerated storage and guaranteeing peak quality.

- For Specialized Equipment: Sandwich shops with integrated sandwich prep tables rely on a steady flow of fresh bread, deli meats, and produce. JIT ensures these high-turnover items are always fresh without overstocking, which is crucial given the limited space in these units.

- For High-Volume Items: A high-end steakhouse might arrange for specific cuts of beef to be delivered just before the busy weekend service. This reduces the financial burden of holding expensive inventory and ensures the star menu items are of the highest possible quality.

By adopting JIT, you shift from a "just-in-case" to a "just-in-time" mindset, fostering a culture of efficiency and waste reduction. This requires strong supplier relationships and a deep understanding of your sales patterns but yields significant rewards in cost savings and product quality.

3. Utilize the Economic Order Quantity (EOQ) Model

Beyond knowing what to order, one of the most crucial inventory management best practices is knowing how much to order at once. The Economic Order Quantity (EOQ) model is a time-tested formula designed to identify the ideal order size that minimizes the total costs associated with purchasing and storing inventory. It strikes a perfect balance between ordering costs (labor, shipping) and holding costs (storage space, spoilage, insurance), preventing both stockouts and wasteful overstocking.

The EOQ formula considers demand rate, ordering costs, and holding costs to calculate the most cost-effective quantity of an item to purchase. For a kitchen, this means you can determine the optimal amount of non-perishable items like flour, sugar, or cooking oil to order, reducing both administrative burden and the capital tied up in excess stock. It transforms purchasing from guesswork into a data-driven strategy, directly impacting your profitability.

Applying the EOQ Model in Your Kitchen

While the underlying math can seem complex, the concept is straightforward. The goal is to find the sweet spot where you order frequently enough to avoid high storage costs but in large enough quantities to minimize the costs associated with placing each order.

- Retail and QSR Chains: Fast-food franchises use EOQ to standardize ordering for high-volume, non-perishable goods like buns, frozen patties, and condiments across multiple locations, ensuring consistency and cost control.

- Manufacturing and Commissaries: A central kitchen producing sauces or prepped ingredients for multiple outlets can use EOQ to procure raw materials like tomatoes or spices, optimizing production runs and storage.

- Institutional Kitchens: Cafeterias and hospitals apply this model to staple goods, calculating the ideal order size for items like rice, pasta, and canned goods to meet predictable demand without overtaxing limited storage space.

For specialized equipment, such as pizza prep tables or sandwich prep tables, EOQ principles can even guide decisions on stocking necessary proprietary ingredients or single-use supplies. By understanding usage patterns, a pizzeria can determine the optimal order quantity for specialty pizza boxes or a specific brand of pepperoni, minimizing costs while ensuring these essential items are always on hand. This methodical approach ensures that your inventory serves your operational needs without becoming a financial drain.

4. Real-Time Inventory Tracking and Automation

Manually counting inventory is time-consuming and prone to human error. One of the most impactful inventory management best practices for a modern kitchen is to embrace real-time tracking and automation. This approach uses technology like barcode scanners, QR codes, and integrated software to monitor stock levels continuously, providing instant, accurate data that eliminates guesswork and streamlines operations. This shift from periodic counts to a live view of your inventory allows for proactive decision-making rather than reactive problem-solving.

How Real-Time Tracking Works in a Kitchen

This system digitizes the flow of goods from receiving to service, creating a dynamic and precise inventory ledger. It ensures every ingredient is accounted for the moment it enters and leaves your storeroom.

- Barcode & QR Code Scanning: Items are scanned upon arrival and again when used for a recipe. This data is fed directly into a central inventory system, automatically updating stock counts. This is crucial for tracking ingredients used on specialized equipment like pizza prep tables and sandwich prep tables, where multiple components are used rapidly.

- POS Integration: The system connects directly to your Point-of-Sale (POS) system. When a dish is sold, the software automatically deducts the corresponding ingredients from your inventory, providing a precise, up-to-the-minute look at what you have on hand.

- Automated Alerts & Reordering: Configure the system to send automatic alerts when an item reaches its reorder point (par level). Some advanced systems can even generate purchase orders automatically, saving valuable time and preventing stockouts of critical items.

By automating these processes, you free up your team to focus on food quality and customer service. Real-time data minimizes waste from over-ordering, prevents costly service disruptions from stockouts, and provides a clear, accurate picture of your food costs at any given moment.

5. Optimize Your Safety Stock Levels

A sudden rush on a menu special or an unexpected delivery delay from a supplier can quickly lead to stockouts, disappointing customers and halting sales. This is where safety stock optimization becomes a crucial inventory management best practice. It involves maintaining a calculated buffer of key ingredients to protect against unpredictable fluctuations in demand and supply chain disruptions, ensuring you can always meet customer orders without tying up too much capital in excess inventory.

How Safety Stock Works in a Kitchen

This strategic reserve acts as a crucial insurance policy against the unknown. By analyzing historical sales data and supplier lead times, you can determine the right amount of extra stock to keep on hand. This prevents the costly scenario of 86-ing a popular dish during a busy service while also avoiding the waste and carrying costs associated with over-ordering.

- Protect Against Demand Spikes: A local event or unexpected positive review can cause a surge in demand for a specific dish. Safety stock ensures you have the ingredients, like extra salmon filets or avocados, to capitalize on the opportunity.

- Mitigate Supply Delays: If your produce delivery is delayed by a day due to weather, having a safety stock of essentials like lettuce, tomatoes, and onions means your service, especially for items made on sandwich prep tables, continues uninterrupted.

- Manage Ingredient Variability: For items with inconsistent yield, like fresh produce, a safety buffer ensures you have enough usable product to meet your pars even if a portion of the delivery is subpar.

Optimizing this buffer is a balancing act. Too little safety stock leaves you vulnerable to stockouts, while too much leads to increased storage costs and potential spoilage. By regularly reviewing sales velocity and supplier reliability, you can fine-tune these levels to protect your operations and your profits.

6. Demand Forecasting and Planning

Moving beyond reactive ordering, one of the most advanced inventory management best practices involves proactive demand forecasting. This approach uses historical sales data, market trends, and even external factors like holidays or local events to predict future customer demand. By anticipating what your customers will order, you can align your procurement and production far more accurately, preventing both stockouts of popular items and overstocking of slow-movers.

How Demand Forecasting Works in a Kitchen

This method combines data analysis with strategic planning to create a roadmap for your inventory needs. It ensures you have exactly what you need, right when you need it.

- Historical Data Analysis: The foundation of forecasting is looking back. Analyze past sales reports from your POS system to identify patterns. Which dishes sell best on weekends? Do soup sales spike when the weather gets cold? This data provides a baseline for future predictions.

- Factoring in Variables: Effective forecasting goes beyond just past sales. It incorporates upcoming promotions, marketing campaigns, seasonal menu changes, local festivals, and even weather forecasts. For example, a pizzeria might anticipate a surge in demand for pizza prep tables during a major televised sports event.

- Collaborative Planning: This process is most effective when it involves collaboration between kitchen managers, front-of-house staff, and marketing teams. Sales and marketing can provide insights into upcoming promotions that will drive demand for specific ingredients, while the kitchen team understands production capacity and supplier lead times.

By leveraging forecasting, a business can make smarter purchasing decisions, such as ordering extra ingredients for anticipated best-sellers or holding back on items for a dish that is about to be rotated off the menu. This forward-looking strategy is crucial for optimizing cash flow and minimizing waste.

7. Explore Vendor-Managed Inventory (VMI) with Key Suppliers

For high-volume, predictable inventory items, consider shifting some management responsibility directly to your suppliers through a Vendor-Managed Inventory (VMI) system. This collaborative approach involves a partnership where your supplier monitors your stock levels and automatically handles replenishment based on pre-agreed par levels and consumption data. It streamlines ordering, reduces administrative workload, and minimizes the risk of stockouts for essential items.

How VMI Works in a Kitchen

VMI turns your supplier into a proactive partner, transforming the traditional procurement process. Instead of your team manually counting and ordering, the vendor takes on that task, ensuring you always have what you need without tying up excess capital.

- Establish a Partnership: You start by selecting trusted, strategic suppliers for high-turnover goods like dairy, produce, or even specific beverages. This is one of the most effective inventory management best practices for building supply chain resilience.

- Set Clear Parameters: You and the vendor agree on minimum and maximum stock levels (par levels), delivery schedules, and performance metrics. This ensures the supplier's actions align perfectly with your kitchen’s operational needs.

- Enable Data Sharing: The supplier gains access to your inventory data, either through your POS system, inventory software, or regular physical counts they conduct themselves.

- Automate Replenishment: Based on this data, the supplier proactively schedules and executes deliveries to replenish stock before it runs low, often billing you upon delivery rather than upon order placement.

For example, a large hotel might have a VMI agreement with its primary linen provider, who ensures clean linens are always stocked without daily manual orders. Similarly, a high-volume pizzeria could partner with its flour or cheese supplier to manage these critical staple goods, ensuring the backbone of their menu is never compromised. By delegating this responsibility, your team can focus on higher-value tasks like menu development and quality control.

8. Cycle Counting and Continuous Auditing

Waiting for a massive, end-of-year physical inventory count to find discrepancies is an outdated and disruptive practice. One of the most effective inventory management best practices is to implement cycle counting, a continuous auditing procedure where you count a small subset of inventory items on a regular, rotating basis. This approach maintains high inventory record accuracy year-round without shutting down operations and allows for the quick identification and correction of issues.

How Cycle Counting Works in a Kitchen

Instead of a once-a-year scramble, cycle counting integrates inventory validation into your daily or weekly routines. By regularly verifying small portions of your stock, you create a system of perpetual inventory management that is far more accurate and less stressful.

- Prioritized Counting: Use your ABC analysis to guide your counting schedule. High-value Category A items, like prime steaks or fresh seafood, might be counted daily or weekly. Category B items, such as specialty produce or cheeses, could be counted bi-weekly, while low-value Category C staples like flour and salt might only be counted monthly.

- Discrepancy Investigation: The true power of cycle counting is in the follow-up. When a count for an item like "sirloin" doesn't match your records, you can investigate the root cause immediately. Was a delivery not logged correctly? Was there an unreported spillage? Did a prep cook use the wrong cut for a special? This real-time troubleshooting prevents small errors from becoming significant financial losses.

- Operational Efficiency: This method is far less disruptive than a full physical count. A line cook can count the fresh fish delivery in five minutes before service, or a manager can verify the liquor stock in ten minutes after closing. This turns a dreaded annual event into a simple, manageable daily task.

By adopting a cycle counting approach, you ensure your inventory data is always reliable. This leads to more accurate purchasing, reduced waste from over-ordering, and fewer stockouts of critical ingredients, ultimately strengthening your control over food costs and operational stability.

9. Enhance Supply Chain Visibility and Collaboration

Effective inventory management extends beyond the four walls of your kitchen. One of the most impactful inventory management best practices is to enhance supply chain visibility and collaboration, which involves creating transparency and coordinated planning with your key suppliers. This proactive approach ensures you have a clear view of your inventory not just on-site, but also as it moves from the source to your receiving dock.

How Supply Chain Collaboration Works in a Kitchen

This strategy moves away from a purely transactional relationship with suppliers to a more integrated partnership. By sharing data and communicating openly, you can anticipate disruptions, reduce lead times, and ensure a more reliable flow of ingredients. This is especially critical for sourcing specialized equipment like pizza prep tables or sandwich prep tables, where manufacturing and shipping delays can significantly impact operations.

- Shared Demand Data: Provide key suppliers with your sales forecasts or historical usage data. This allows them to better anticipate your needs for critical ingredients, preventing stockouts during your busiest periods.

- Coordinated Planning: Work together to plan for seasonal demand spikes, promotions, or menu changes. If you plan to feature a special dish, giving your supplier advanced notice ensures they can meet the increased demand without issue.

- Real-Time Communication: Utilize shared communication channels or platforms to quickly address potential issues, such as a delayed shipment or a quality concern. This transparency allows both parties to pivot and find solutions before problems escalate.

For instance, by collaborating closely with a local farm, a farm-to-table restaurant can align its menu with the farm's harvest schedule, guaranteeing the freshest produce and reducing waste. Similarly, coordinating with a supplier for a new stainless steel prep table ensures it arrives exactly when needed for a kitchen renovation, minimizing operational downtime. This level of partnership transforms your supply chain from a potential vulnerability into a strategic asset.

Inventory Management Best Practices Comparison

| Inventory Method | Implementation Complexity 🔄 | Resource Requirements ⚡ | Expected Outcomes 📊 | Ideal Use Cases 💡 | Key Advantages ⭐ |

|---|---|---|---|---|---|

| ABC Analysis (Pareto Analysis) | Moderate 🔄🔄 | Moderate ⚡⚡ | Prioritized inventory management, cost reduction | Inventory segmentation by value, procurement strategy | Simplifies decisions, optimizes resource allocation |

| Just-In-Time (JIT) Inventory | High 🔄🔄🔄 | High ⚡⚡⚡ | Reduced inventory costs, waste elimination | Manufacturing with reliable suppliers, demand-driven production | Minimizes holding costs, improves operational efficiency |

| Economic Order Quantity (EOQ) | Low to Moderate 🔄🔄 | Low to Moderate ⚡⚡ | Optimized order quantities, cost minimization | Stable demand environments, standard replenishment | Clear quantitative guidelines, simple implementation |

| Real-Time Inventory Tracking | High 🔄🔄🔄 | High ⚡⚡⚡ | Instant inventory visibility, fewer stock issues | Complex, large-scale operations requiring automation | Reduces errors, enables faster decisions |

| Safety Stock Optimization | Moderate 🔄🔄 | Moderate ⚡⚡ | Buffer against demand/supply uncertainty | Demand variability scenarios, critical stock protection | Prevents stockouts, improves service levels |

| Demand Forecasting and Planning | High 🔄🔄🔄 | High ⚡⚡⚡ | Accurate demand prediction, inventory cost reduction | Dynamic markets, seasonal/cyclical demand | Enables proactive planning, reduces bullwhip effect |

| Vendor-Managed Inventory (VMI) | Moderate to High 🔄🔄🔄 | Moderate ⚡⚡ | Supplier-managed stock, reduced buyer workload | Strong supplier relationships, retail/manufacturing sectors | Reduces inventory costs, improves supplier partnership |

| Cycle Counting & Continuous Auditing | Moderate 🔄🔄 | Moderate ⚡⚡ | High inventory accuracy year-round | Operations requiring ongoing accuracy without disruptions | Early discrepancy detection, less disruptive than full counts |

| Supply Chain Visibility & Collaboration | High 🔄🔄🔄 | High ⚡⚡⚡ | Coordinated supply chain, rapid disruption response | Complex multi-partner supply chains | Improves planning accuracy, reduces bullwhip effect |

Turning Best Practices into Daily Profits

The journey from a chaotic storeroom to a seamlessly managed inventory system is not a single leap but a series of deliberate, strategic steps. The inventory management best practices we've explored, from the analytical rigor of ABC analysis and the Economic Order Quantity (EOQ) model to the collaborative power of Vendor-Managed Inventory (VMI), are not just theoretical concepts. They are practical, powerful tools designed to transform your kitchen's financial health and operational efficiency. Each practice serves as a building block for a more resilient, profitable, and less stressful food service operation.

Adopting these strategies means moving beyond simple stock-taking. It’s about cultivating a new mindset where every ingredient, every supplier relationship, and every square foot of storage space is optimized for maximum value. By implementing Just-In-Time (JIT) principles, you reduce the capital tied up in perishable goods. Through accurate demand forecasting and maintaining calculated safety stock, you ensure you can always meet customer expectations without succumbing to costly overstocking or stockouts.

From Theory to Tangible Results

The true power of these systems emerges when they are integrated into the physical workflow of your kitchen. Consider the role of your equipment. A well-organized workspace, supported by the right tools, is fundamental to executing any inventory strategy. This is where specialized equipment like stainless steel prep tables becomes a critical asset. Choosing the right type is key to maximizing efficiency for specific tasks:

- Standard Work Tables: These are the versatile workhorses of any kitchen. Featuring a flat stainless steel top, often with an undershelf for storage, they provide a durable, sanitary surface for general prep, mixing, and plating.

- Sandwich Prep Tables: Designed for speed and organization, these units combine a refrigerated base with a top rail holding cold pans for ingredients like meats, cheeses, and vegetables. They often include a cutting board surface, keeping everything needed for sandwich assembly chilled and within reach, which directly supports FIFO systems and reduces waste.

- Pizza Prep Tables: A specialized version of the sandwich table, these often feature a wider, refrigerated rail to accommodate larger topping pans and a durable marble or granite top that stays cool for handling dough. The refrigerated base provides bulk storage for dough boxes and extra ingredients, streamlining the entire pizza-making process.

By investing in equipment that complements your inventory management best practices, you create an environment where efficiency becomes the default. A well-chosen table isn't just a surface; it's a station that reinforces your inventory strategy, speeds up service, and serves as a physical manifestation of your organized plan.

Your Action Plan for Inventory Mastery

The key takeaway is that mastering inventory is an ongoing process of refinement, not a one-time project. Don't feel overwhelmed by the need to implement all nine strategies at once. Start small and build momentum.

- First, choose one or two high-impact practices that address your biggest pain points. If food waste is your primary concern, begin with rigorous cycle counting and FIFO implementation. If unpredictable demand is causing stockouts, focus on improving your demand forecasting techniques.

- Next, involve your team. Train them not just on the "how" but the "why" behind each new process. When your staff understands that proper stock rotation and accurate counts directly contribute to the business's success and their job security, they become active participants in the solution.

- Finally, empower your process with the right tools. This includes leveraging technology for real-time tracking and investing in physical infrastructure that makes organization and access effortless.

By consistently applying these principles, you will do more than just cut costs. You will build a stable operational foundation that enhances food quality, improves staff morale, and ultimately frees you up to focus on culinary innovation and growing your business. The path to a healthier bottom line truly begins in your storeroom.

A well-organized kitchen is the foundation of effective inventory control. Equip your team for success with the right tools from PrepTables.com, where you can find a wide selection of stainless steel work tables, specialized sandwich prep tables, and pizza prep tables designed for efficiency. Explore our collection at PrepTables.com to find the perfect solution that turns your inventory management best practices into a physical reality.