Choosing Your Perfect Reach In Freezer

Share

Think of a reach-in freezer as your kitchen's frozen pantry. It’s a commercial-grade, upright unit built to keep your most-used ingredients perfectly frozen and right where you need them.

Why a Reach-In Freezer Is Your Kitchen's MVP

Picture a chaotic dinner rush. The grill cook is yelling for frozen burger patties, the fry station is out of fries, and the dessert station needs frozen berries for a topping—all at the same time. Making a trip to a far-off walk-in freezer kills momentum, clogs up walkways, and slows down ticket times. This is exactly where a reach-in freezer shines.

Unlike a massive walk-in freezer built for long-term bulk storage, a reach-in is all about quick access and efficiency. It’s the forward operating base for your most-used frozen goods, strategically placed right in the line of fire to keep service humming. It’s the difference between a warehouse (the walk-in) and a grab-and-go kiosk (the reach-in); one is for deep storage, the other is for what you need right now.

The Core Benefits of a Strategic Freezer

A well-placed reach-in freezer does more than just keep food cold; it’s a cornerstone of a smooth, profitable operation. By putting essential ingredients within arm's reach, it sets the entire rhythm for your kitchen.

Here’s what you gain:

- Faster Workflow: Sticking a freezer near your prep or cook stations slashes travel time. Staff can grab what they need and get back to cooking, pushing out orders faster.

- Better Food Safety and Quality: Every time someone opens the walk-in, the temperature fluctuates, which can harm sensitive ingredients. A reach-in isolates the high-traffic items, protecting the quality of everything you have in bulk storage.

- Smarter Inventory Control: When ingredients are organized on easy-to-see shelves, you can track stock levels with a quick glance. This helps prevent over-ordering and cuts down on expensive food waste.

A Critical Investment in a Growing Market

The need for top-notch cold storage isn't just a kitchen-level concern—it's a global trend. The worldwide freezer market was valued at USD 14.29 billion in 2024 and is expected to climb to USD 20.25 billion by 2032, with commercial kitchens driving much of that growth. This boom is fueled by the demand for dependable equipment in restaurants, food retail, and logistics. You can learn more about the future of commercial refrigeration and its market trends.

Ultimately, picking the right reach-in freezer is more than just buying another piece of equipment. It’s a strategic move that makes your kitchen safer, more efficient, and more profitable. It’s the unsung hero that ensures your team has what it needs, when they need it, keeping the whole operation running at its best.

Picking the Right Reach-In Freezer Model

Choosing a reach-in freezer isn't just about picking a box that gets cold. It's about finding the right fit for your kitchen's unique workflow and space. The first fork in the road is deciding between solid doors and glass doors—each one built for a totally different job.

Solid door freezers are the unsung heroes of the back-of-house. They’re built like tanks with better insulation, which means they hold their temperature like a fortress, making them incredibly energy-efficient. This is your go-to for storing bulk ingredients you don't need to show off.

Glass door models, however, are all about speed and visibility. They're perfect for your prep line or front-of-house, letting your crew see what's inside before they even open the door. That small advantage cuts down on how long the door stays open, keeping the temperature stable and saving precious seconds during a chaotic dinner rush.

Size and Capacity: The Footprint Factor

Once you’ve got your door style figured out, it's time to think about size. Reach-in freezers typically come in one, two, or three-door setups. Your choice here is a direct trade-off between how much you can store and how much floor space you're willing to give up.

A nimble single-door unit can be a lifesaver for a small café or a dedicated station in a bigger kitchen. A double-door model gives a busy restaurant a serious capacity upgrade, while a massive triple-door freezer is built for high-volume operations that need maximum storage. More doors equals more storage, but it also means a bigger footprint.

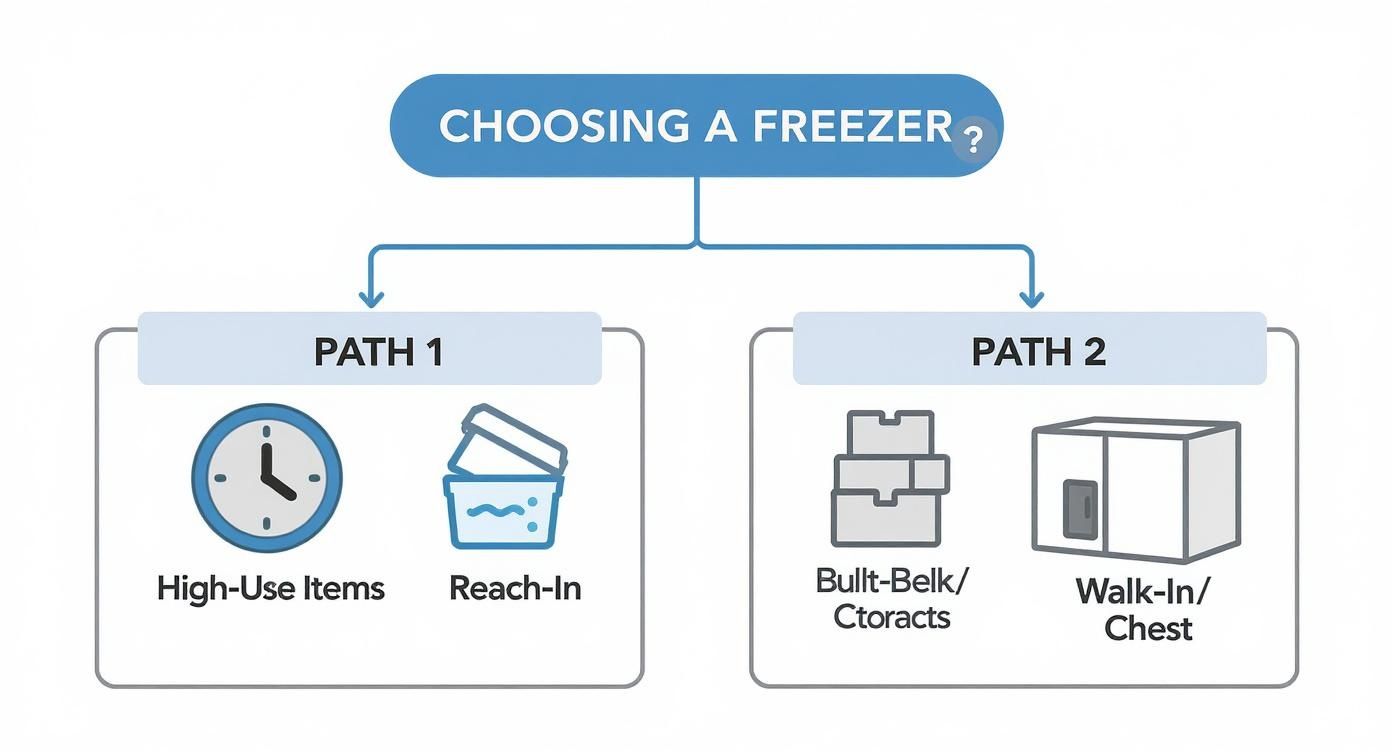

This simple chart can help you see if a reach-in is even the right place to start.

The big takeaway? Think about how you'll use it. If you need constant, quick access, a reach-in is your best bet. For stockpiling bulk items, you might need to think bigger.

The Great Compressor Debate: Top-Mount vs. Bottom-Mount

Now for the real nitty-gritty. One of the most important technical choices you'll make is where the compressor is located. This is the heart of your freezer, and whether it’s on the top or the bottom has a huge impact on performance, maintenance, and even how easy it is to use.

A reach-in freezer's compressor location isn't just a design choice; it dictates how the unit will perform in your specific environment. A top-mount unit in a bakery might struggle with flour dust, while a bottom-mount unit in a hot kitchen will work overtime.

To make it easier, let's break down the pros and cons of each style.

Top-Mount vs. Bottom-Mount Freezer Compressor Comparison

| Feature | Top-Mount Compressor | Bottom-Mount Compressor |

|---|---|---|

| Best Environment | Hot kitchens, near cook lines. | Cooler environments, prep areas. |

| Air Intake | Pulls in cleaner air from above, away from floor dust and grease. | Pulls in cooler air from floor level, which is more efficient. |

| Heat Exhaust | Vents hot air up and away from the work area. | Vents warm air into the kitchen, potentially raising the ambient temp. |

| Ergonomics | Bottom shelf is lower, requiring more bending. | Raises the bottom shelf, making it easier to access items. |

| Maintenance | Can be harder to access for cleaning and service. | Easier to access for cleaning coils and routine maintenance. |

Top-mount compressors, sitting on top of the unit, are champs in hot kitchens. Heat rises, so they avoid sucking up all the greasy, warm air from floor level that can clog up the works and kill efficiency. They're a smart pick for any space with fryers or a busy cook line.

On the flip side, bottom-mount compressors are often easier on your back. By placing the machinery at the base, the lowest shelf is lifted to a more comfortable height. No more deep squats to grab a box of fries! They also tend to run more efficiently by pulling in the cooler air that naturally settles near the floor.

Ultimately, choosing between them comes down to being honest about your kitchen. Is it a hot, greasy warzone or a cooler, cleaner prep space? Answering that question will point you to the right compressor and make sure your new freezer works hard for you, not against you.

Key Specifications That Determine Performance

When you’re looking at reach-in freezers, it’s easy to focus on the basics like size and door style. But the real workhorse features—the ones that determine how well it performs day-in and day-out—are hiding in the technical specifications. These aren't just numbers on a sheet; they're the blueprint for your unit's efficiency, reliability, and lifespan. Let's break down the jargon so you can make a smart investment.

Capacity and Cooling Power

The first spec you'll see is capacity, which is measured in cubic feet. This isn’t just about how much you can cram inside. It’s about matching storage to your kitchen's rhythm. A small café that gets daily deliveries might be perfectly fine with a 20-cubic-foot unit. A bustling restaurant, on the other hand, will probably need a 70-cubic-foot, three-door beast to keep up with inventory.

Right alongside capacity is cooling power, often shown as a BTU (British Thermal Unit) rating. Think of BTUs as the horsepower for your freezer's engine. A higher BTU number means the system can pull heat out faster. This is absolutely critical in a busy kitchen where the door is constantly opening and closing. A freezer with a weak BTU rating for its size will struggle to recover, leading to temperature spikes and serious food safety risks.

Precision Temperature Control and Insulation

Gone are the days of fiddling with a manual dial. Digital temperature controls are the industry standard for good reason: they provide pinpoint accuracy. This lets you set and monitor the exact temperature needed to comply with health codes. An external digital display is a must-have, allowing your crew to check the temp at a glance without opening the door and letting all that precious cold air out.

The single most important job of your reach-in freezer is to hold a steady temperature, usually somewhere between -10°F and 0°F. This is only possible with a combination of great insulation and precise controls, which directly impacts both food safety and your utility bills.

The unsung hero here is the insulation. Most quality commercial freezers use high-density, foamed-in-place polyurethane foam. This material is injected right into the walls, creating a solid, highly effective thermal barrier. Better insulation means the compressor runs less, saving you money on electricity and reducing wear and tear on the components. If you want to get even deeper into how cooling systems work, checking out guides on topics like understanding condenser units can be really helpful.

The Heart of the System: The Compressor

The compressor is the heart of your freezer. It’s what circulates the refrigerant to pull heat out of the cabinet. The type of compressor it uses makes a huge difference in efficiency and noise. Older models often have reciprocating compressors—they’re reliable, but they can be loud and aren't the most energy-efficient.

Today’s high-efficiency freezers are often built with variable-speed compressors. These are a game-changer. Instead of just slamming on and off at full power, they adjust their speed based on the cooling demand. They can run at a lower, steady speed, which results in:

- Significant Energy Savings: They only use the power that’s needed at the moment.

- Quieter Operation: No more jarring on-and-off cycles. Just a low, consistent hum.

- Better Temperature Stability: Continuous operation prevents the temperature swings you get with standard compressors.

Shelving and Interior Construction

Finally, don’t overlook the interior. The shelving in a reach in freezer has to be tough enough to handle heavy loads and freezing temperatures. You generally have two choices:

- Stainless Steel Shelving: This is the top-tier option. It’s incredibly strong, won't rust, and is a breeze to sanitize, making it perfect for heavy boxes or items that might leak.

- Epoxy-Coated Wire Shelving: This is the more common and budget-friendly choice. The wire design promotes better airflow around your products for more even cooling, while the epoxy coating prevents rust.

Think about what you'll be storing. If you’re dealing with heavy cases of protein, stainless steel is the way to go. For general storage where air circulation is key, epoxy-coated shelves are a fantastic, practical solution. Getting these details right ensures your freezer will be a reliable part of your kitchen for years to come.

Thinking Beyond the Price Tag: Energy Bills and Health Codes

It's tempting to fixate on the sticker price when you're buying a new reach-in freezer, but that's only part of the story. The real cost of ownership shows up on your monthly energy bill and during a surprise visit from the health inspector. Looking at the long-term value from day one is the smartest way to save money and keep your business safe.

Think of a highly efficient freezer as an investment. You're putting money into a machine that's designed to slash your operating expenses month after month.

The Power of ENERGY STAR Certification

That little blue ENERGY STAR label is more than just a sticker—it's your proof of savings. Certified freezers are, on average, 20% more energy-efficient than their standard counterparts, which means lower utility bills from the get-go. They pull this off with better hardware, like high-efficiency compressors, top-notch insulation, and tighter door seals.

Sure, you might pay a little more upfront for an ENERGY STAR model, but you'll often make that money back in just a couple of years through pure electricity savings. Over a decade or more, that's a serious return on your investment.

NSF Certification: The Non-Negotiable for Health Codes

While ENERGY STAR saves you cash, NSF (National Sanitation Foundation) certification saves your business. This is the gold standard for food safety, and it's one of the first things a health inspector looks for. The NSF mark confirms your equipment is built with non-porous materials and designed for easy, thorough cleaning to prevent bacteria from growing.

Choosing a non-NSF freezer is a gamble you just can't afford to take. One violation can lead to fines, a hit to your reputation, or even a forced shutdown. An NSF-certified freezer is your assurance that you meet or exceed public health standards.

This certification tells everyone that you're serious about running a safe, hygienic kitchen, which is the bedrock of any successful food business.

Modern Features That Drive Down Costs

Today's best freezers have a few key features that work together to keep energy use low and food safe. Understanding what they do helps you see the smart engineering at work.

- Self-Closing Doors: In the chaos of a busy kitchen, doors get left open. It happens. Self-closing doors use special hinges to automatically pull the door shut, trapping the cold air inside and giving the compressor a break.

- High-Quality Gaskets: That rubber seal around the door is your first line of defense. A tight, magnetic gasket keeps warm, humid air out, which means less frost buildup and a more efficient cooling system.

- LED Lighting: Old-school incandescent bulbs actually generate a lot of heat, making the freezer work harder to stay cold. Bright, cool-running LEDs use way less energy and light up your inventory without messing with the temperature.

Keeping your freezer at the right temperature is non-negotiable. To dive deeper into this, check out our guide on food safety temperature control and make sure your kitchen is always up to code.

Why Eco-Friendly Refrigerants Matter

The type of gas your freezer uses to stay cold is a bigger deal than ever, thanks to environmental regulations. Older refrigerants are being phased out for damaging the ozone layer. Modern, eco-friendly options like R290 (propane) are not only better for the planet but are also more efficient at doing their job.

Picking a freezer with R290 refrigerant means you won't have to worry about future regulations, and you'll get top-tier thermal performance. It's a forward-thinking choice that aligns with the industry's shift toward sustainability and safety.

Installation and Maintenance That Protects Your Investment

Buying a quality reach in freezer is a great first step, but it's only half the battle. The real secret to a long, efficient life for your unit comes down to two things: proper installation and consistent maintenance. Think of it like a high-performance car—you wouldn't skip the oil changes and expect the engine to last. Your freezer needs the same kind of attention to run smoothly for years to come.

A fantastic freezer can be brought to its knees by a bad setup. The single most critical detail during installation is ventilation clearance. Your freezer's compressor and condenser coils work hard pulling warmth out of the cabinet, and all that heat has to go somewhere.

Giving Your Freezer Room to Breathe

When you shove a freezer right up against a wall or box it in with other equipment, you’re trapping hot air. This forces the compressor to work overtime, trying to cool itself down by sucking in the same hot air it just pushed out. It's a vicious cycle that leads to overheating, insane energy bills, and eventually, a dead compressor—one of the costliest repairs you can face.

Always check the manufacturer's specs for clearance. Most units need at least 2-3 inches of space around the back and sides, and often more up top. That little bit of empty space is the cheapest insurance policy you'll ever buy for your equipment.

Your Routine Maintenance Checklist

Once your freezer is set up right, a simple maintenance routine is your best defense against common problems. To keep your unit in top shape and extend its lifespan, it helps to follow a consistent schedule, much like a good commercial HVAC maintenance checklist.

Here are the absolute essentials:

- Clean Condenser Coils (Monthly): These coils are magnets for all the dust, grease, and gunk floating around a kitchen. When they get clogged, they can't release heat, forcing the compressor to run nonstop. A quick pass with a stiff brush and a vacuum every month makes a huge difference.

- Inspect Door Gaskets (Monthly): That rubber seal around the door is what keeps the cold in. Check it for any cracks, tears, or signs of becoming brittle. An easy trick is to close the door on a dollar bill—if you can slide it out without any resistance, the seal is shot and needs replacing.

- Verify Temperature Accuracy (Weekly): Don't just trust the external display. Keep a separate, calibrated thermometer inside the freezer to make sure it’s actually holding the right temperature, which should be between -10°F and 0°F.

For more great tips on keeping all your gear in working order, check out our guide to commercial kitchen equipment maintenance.

Simple Troubleshooting Before You Call for Service

Before you dial up a technician for an expensive service call, there are a few things you can check yourself. These quick steps can save you a lot of time, money, and headaches.

Common Problems and Quick Fixes:

- Excessive Frost Buildup: This is almost always a sign of a bad door gasket or a door that's not closing properly. Check the seals for damage and make sure the door clicks shut securely every time.

- Freezer Not Cold Enough: The first place to look is the condenser coils. A good cleaning might be all it needs. Also, make sure the unit isn't packed to the gills—overstuffing a freezer blocks airflow and stops it from cooling evenly.

- Temperature Alarms Going Off: Double-check that the door is fully closed and wasn't accidentally left ajar. If the alarm keeps beeping after the door has been shut for a while, it's time to check the internal temperature with your secondary thermometer.

By making these simple installation and maintenance tasks a regular part of your kitchen's routine, you'll ensure your reach in freezer stays a reliable workhorse for its entire lifespan.

Your Final Reach-In Freezer Buying Checklist

Making that final call on a reach-in freezer can feel like a lot of pressure, but it doesn’t have to. This checklist is here to guide you through the last few critical questions, turning all that research into a confident purchase. Think of it as your final pre-flight check before you bring your kitchen's next workhorse home.

The journey to the perfect freezer starts with knowing where the industry is headed. The global deep freezer market, a huge slice of the commercial refrigeration pie, pulled in USD 2.81 billion in 2024 and is expected to rocket to USD 9.5 billion by 2030. That kind of growth just goes to show how much focus is being put on advanced freezing tech to keep food safe and high-quality.

Confirming Your Kitchen's Needs

Before you hit that "buy" button, let's run through these core questions one last time. Getting this part right is everything.

- Measure Your Space Twice: Have you double-checked the exact footprint you have available? I'm talking width, depth, and height. And don't forget to add the mandatory clearance space for ventilation—usually 2-3 inches on every side.

- Calculate Your True Capacity: Look past the simple cubic feet number. Think about your menu, how fast you turn over inventory, and your delivery schedule. Is a single-door unit going to cut it, or does your operation really need a two or three-door beast?

- Finalize Your Door Style: Is this freezer going in the back for bulk storage, where a solid door’s efficiency is king? Or is it destined for a busy prep line where seeing inside with a glass door will keep service moving fast?

Verifying Certifications and Budget

Okay, with the physical needs locked in, these final checks are all about long-term value and staying compliant. For any professional kitchen, these are non-negotiable.

A reach-in freezer isn't just an appliance; it's a long-term operational asset. Making sure it meets efficiency and sanitation standards from day one protects your investment, your inventory, and your reputation.

- Check for the Labels: Did you confirm the model you’re eyeing is both ENERGY STAR certified for efficiency and NSF certified for sanitation? These are your guarantees of smaller utility bills and a happy health inspector.

- Align with Your Budget: Does the final price, including shipping or installation, fit what you planned to spend? Don't forget to factor in the long-term energy savings you'll get from a more efficient model—it often makes up for a higher upfront cost.

Once you’ve walked through these steps, you’ll be ready to make a purchase that will serve your business for years to come. For a head-to-head comparison of top models, take a look at our guide on choosing the best commercial freezer to see how different units stack up.

Frequently Asked Questions About Reach In Freezers

Jumping into the world of commercial freezers can bring up a lot of questions. Getting clear, straightforward answers is the key to feeling confident about your investment. Here, we'll tackle the most common things business owners ask, from sizing and lifespan to long-term value.

Our goal is to give you the practical know-how you need to pick the right unit and keep it running smoothly for years.

How Do I Figure Out The Right Size Reach In Freezer For My Kitchen?

A solid rule of thumb is to plan for 1.5 to 2 cubic feet of freezer space for every seat in your restaurant. But don't stop there—think about your menu's complexity, how often you get deliveries, and the actual footprint you have available. A busy kitchen with infrequent supply drops is going to need a much bigger freezer than a small café that gets fresh stock every day.

What's The Average Lifespan Of A Commercial Reach In Freezer?

When it’s installed correctly and you stick to a maintenance schedule, a quality commercial reach in freezer can easily last 10-15 years. The single most important job is cleaning the condenser coils regularly to keep it from overheating. If you skip simple maintenance, you can drastically shorten its life and end up with costly, unexpected repairs that shut down your kitchen.

A well-maintained freezer is a reliable asset. A neglected one becomes a liability. The difference often comes down to just a few minutes of cleaning each month.

Is A More Expensive ENERGY STAR Freezer Really Worth The Extra Cost?

Absolutely. While the sticker price might be higher upfront, an ENERGY STAR certified freezer can save you hundreds of dollars a year in electricity costs alone. Those big savings on your utility bills often mean the freezer pays for its price difference in just a couple of years, making it a much smarter and more profitable investment for the long haul.

At PrepTables.com, we focus on providing top-tier commercial refrigeration built for durability and efficiency. Explore our complete collection of reach-in freezers and other essential kitchen equipment to find the perfect fit for your business at https://preptables.com.