Choosing the Best Commercial freezer for Your Business

Share

Let's get one thing straight: the best commercial freezer isn't some mythical, top-rated model that works for everyone. The right choice for a high-volume restaurant kitchen will be a terrible fit for a small coffee shop or a massive supermarket. It all comes down to finding the freezer that perfectly matches your operation's real-world demands.

How to Find the Right Commercial Freezer

Picking out a commercial freezer is a big deal. This decision directly impacts your food safety, how smoothly your kitchen runs, and, ultimately, your profits. The hard part is sorting through a sea of options, technical specs, and features to find the right one. A wrong move here can mean sky-high energy bills, spoiled inventory, and a workflow that just doesn't... flow.

This guide isn't just a list of products. We’re here to break down how to choose, so you can land a unit that feels like it was custom-made for your business. We'll give you a clear roadmap, walking you through the must-know factors before you spend a dime.

Key Decision Factors for Your Business

The search for the perfect commercial freezer starts with a good, honest look at how your business actually runs. Before you even glance at a single model, you need solid answers to some basic questions about your space, how much you need to store, and your daily kitchen rhythm.

Thinking through these points first will dramatically narrow your options. It keeps you from wasting time on units that are way too big, laughably small, or just plain impractical for your setup. Think of it as drawing up a blueprint for your ideal cold storage solution.

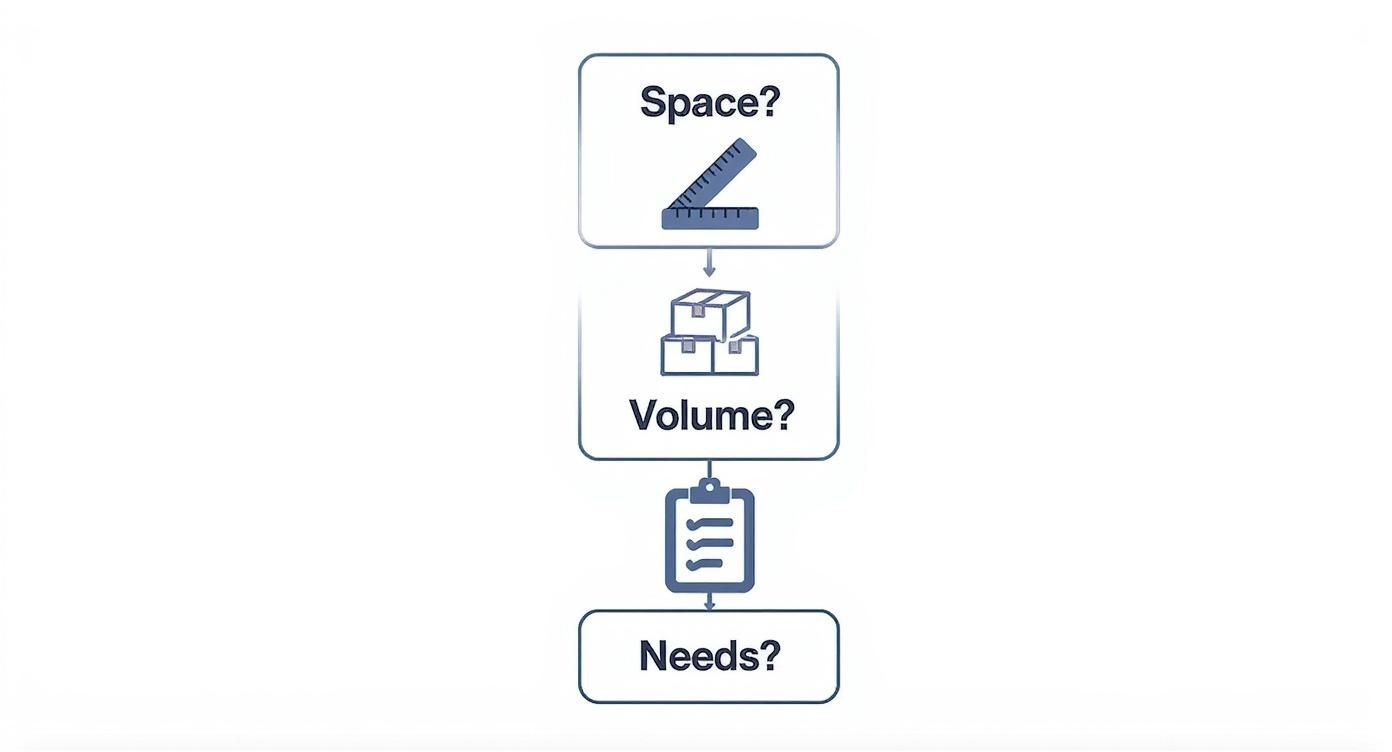

This decision tree infographic is a great visual for the key questions you should be asking right now. It guides you from the big-picture stuff, like space and volume, to your specific day-to-day needs.

As you can see, your physical layout, storage volume, and daily operational needs are the first big filters you need to apply to find the right type of freezer.

Laying the Groundwork for a Smart Purchase

Once you’ve got a handle on your core requirements, you'll be much better equipped to get into the nitty-gritty of different models. We'll explore the main types of commercial freezers out there, from common reach-in units to sprawling walk-ins. We'll also cover the make-or-break features like temperature control and the absolute non-negotiable importance of NSF certification for keeping the health inspector happy.

The 'best' freezer is never a one-size-fits-all product. It is the one that seamlessly integrates into your workflow, meets your storage capacity, and operates efficiently within your budget, turning a simple appliance into a profitable business asset.

By taking the time to understand your needs first, you're setting yourself up to make a smart, confident, and profitable decision. This foundational knowledge is what separates buying any freezer from buying the right freezer for long-term success.

Decoding Commercial Freezer Types and Door Styles

Just like a chef has specific knives for different cuts, a commercial kitchen needs the right freezer for the job. Picking the right form factor is your first real decision, and it’s all about matching the unit to your kitchen's unique space, workflow, and how much you need to store.

You wouldn't use a paring knife to break down a side of beef, right? It's the same principle here. The perfect freezer for a small coffee shop would be completely lost in a high-volume restaurant. Before you even glance at the technical specs, you need to understand these fundamental categories.

The Main Freezer Categories

Commercial freezers generally come in a few main shapes, and each one is built with a specific purpose in mind. Getting familiar with these core types will help you narrow down your search to models that actually make sense for your day-to-day operations.

- Reach-In Freezers: These are the workhorses you'll find in almost any commercial kitchen. They look like a beefed-up version of your fridge at home and are designed for intense, constant use, giving your line cooks easy access to everyday ingredients.

- Walk-In Freezers: Think of a giant, refrigerated closet. Walk-ins are an absolute must for businesses that buy in bulk. They offer massive storage for everything from cases of prime rib to big boxes of frozen fries.

- Chest Freezers: Picture a deep-storage treasure chest. Their top-loading design makes them perfect for stashing things you don't need to grab multiple times a day, like seasonal ingredients or bulk buys you’ll work through over several weeks.

- Undercounter Freezers: These are the ultimate space-savers. They tuck neatly under a prep table or countertop, putting frozen ingredients right where your team needs them. This simple move speeds up workflow and cuts down on wasted steps in a busy kitchen.

Specialty Freezers for Unique Needs

Beyond the basics, some freezers are engineered for very specific jobs, combining cold storage and prep space into one efficient workstation. For certain food service operations, these units are total game-changers.

A pizza prep table, for example, has a refrigerated rail up top that keeps toppings like pepperoni, cheese, and veggies perfectly chilled and right at the chef's fingertips. This design makes the pizza-making process dramatically faster.

In the same way, sandwich prep tables use cooled ingredient wells to hold deli meats, cheeses, and fresh toppings at safe temperatures. Integrating storage and workspace like this is the secret to maintaining both speed and food safety during a chaotic lunch rush.

Choosing a freezer type isn't just about how much it can hold; it's about designing a smarter, safer workflow. The right unit reduces steps, keeps ingredients perfectly chilled, and helps your team get plates out faster.

The Critical Role of Door Styles

The type of door on your freezer might seem like a small detail, but it has a huge impact on energy bills, how well you can showcase products, and how you move around your kitchen. Each style has clear pros and cons depending on where the freezer is and what it’s used for.

This is especially true in any area where customers are present. The retail cooler market is growing fast as consumer tastes change. Projections show the global market hitting USD 1,835.9 million in 2025 and climbing to USD 3,168.7 million by 2030, which really underscores the power of good merchandising.

Let's break down the most common door options:

- Solid Doors: These are the champions of insulation. Their solid build creates a superior seal, which is fantastic for trapping cold air and keeping your energy consumption down. They’re the best pick for back-of-house storage where you don't need to see the product.

- Glass Doors: When you want to display what you’re selling, glass doors are non-negotiable. They let customers and staff see what's inside without opening the door, cutting down on temperature swings and helping drive sales in retail spots. You can dive deeper into the benefits of commercial glass door freezers in our detailed guide.

- Sliding Doors: Perfect for cramped spaces. Sliding doors don’t swing outward, making them a great fit for narrow aisles or tight kitchen layouts. They strike a nice balance between easy access and saving space.

Essential Features and Technical Specifications

Alright, now that we've covered the basic types, it's time to pop the hood and look at the specs. Think of a spec sheet as the freezer's DNA—it tells you exactly how it’s going to perform in your kitchen, what it can handle, and whether it’s the right workhorse for your daily grind.

Learning to read these details is like understanding a blueprint. Once you know what to look for, you can see past the marketing fluff and choose a machine that truly fits your needs, without wasting money on features you’ll never use.

Capacity and Temperature Range

The first two specs you’ll always see are capacity and temperature. Capacity is listed in cubic feet, but honestly, that number can be deceiving. A 23-cubic-foot reach-in might sound huge, but what does that actually mean for your inventory? It’s better to think in real-world terms: how many 1/6-size pans, cases of fries, or tubs of gelato can you actually fit in there?

Always peek at the interior layout. A smart design with well-placed shelves can make a smaller freezer feel way more spacious and organized than a bigger one with a clunky layout.

Temperature range is just as critical. Most standard commercial freezers hum along between 0°F and -10°F. This is the sweet spot for almost everything, from frozen meats to prepped entrées. But some products are a bit more demanding.

- Standard Freezers (0°F to -10°F): This is your all-rounder, perfect for general storage in just about any restaurant, café, or commercial kitchen.

- Low-Temp Freezers (-5°F to -25°F): If you're serving ice cream or gelato, this is non-negotiable. You need those extra-cold temperatures to maintain the perfect texture and keep frustrating ice crystals from forming.

The Heart of the Machine: Refrigeration Systems

The refrigeration system is the engine of your freezer. Its design has a huge impact on performance, maintenance headaches, and even where you can place the unit in your kitchen. The compressor and condenser are the key components that pull heat out, and where they live makes all the difference.

A self-contained system is the most common, with all the cooling guts built right into the freezer cabinet. It’s essentially a plug-and-play unit, making installation a breeze. On the other hand, a remote system separates the noisy, heat-producing parts (the compressor and condenser) and puts them somewhere else, like on the roof or in a utility room. This keeps your kitchen much quieter and cooler but involves a more complex and expensive installation.

For the common self-contained units, you have another choice to make: top-mount or bottom-mount compressor?

- Top-Mount Compressors: These are fantastic for dusty spots like bakeries or prep areas with a lot of flour in the air. By pulling in cleaner air from up high, the coils don't get gunked up as quickly. The only catch is they vent hot air upwards, which can put a little extra strain on your HVAC.

- Bottom-Mount Compressors: These are a back-saver. They lift the freezer's bottom shelf to a more comfortable height, so you're not constantly bending over. They're also usually easier for service techs to access. The downside? They're sitting right on the floor, ready to suck in all the dust, grease, and debris that naturally collects there, so they need more frequent cleaning.

Choosing the right system for your kitchen is a strategic move. Here's a quick breakdown to help you decide.

Commercial Freezer Compressor and Condenser Comparison

| System Type | Best For | Pros | Cons |

|---|---|---|---|

| Self-Contained Top-Mount | Dusty kitchens (bakeries), kitchens with greasy floors. | Keeps coils cleaner by pulling air from above. | Can increase ambient kitchen temperature; harder to access for service. |

| Self-Contained Bottom-Mount | Kitchens prioritizing ergonomics and easy maintenance access. | Easy to access for cleaning/service; raises bottom shelf for less bending. | Sucks in floor dust and debris, requiring more frequent coil cleaning. |

| Remote System | High-volume kitchens, quiet dining environments, businesses wanting to reduce indoor heat. | Removes heat and noise from the kitchen; allows for larger, more powerful systems. | Higher upfront cost; complex installation requiring professional technicians. |

Ultimately, this decision hinges on your kitchen's layout, your staff's workflow, and your maintenance routine.

Your freezer’s refrigeration system dictates more than just cooling; it influences your kitchen's ambient temperature, noise level, and maintenance schedule. Choosing the right configuration is a strategic decision that affects your entire workspace.

Defrost Systems and Certifications

Finally, let's talk about defrosting and those little certification stickers. An automatic defrost system is a lifesaver. It uses a small heater to periodically melt away frost buildup on the coils, keeping air flowing and efficiency high. The only trade-off is a very slight temperature bump during the defrost cycle, but for most applications, it’s a non-issue.

A manual defrost freezer, on the other hand, is old-school. You have to shut it down, empty it out, and let the ice melt on its own. It's a pain, no doubt. But for highly sensitive products where even a tiny temperature fluctuation is a problem, the rock-solid stability of a manual defrost unit is sometimes preferred. You’re trading convenience for absolute temperature control.

And never, ever skip checking the certifications. An NSF (National Sanitation Foundation) sticker means the freezer is designed for easy cleaning and food safety—an absolute must for passing health inspections. The UL (Underwriters Laboratories) mark confirms all the electrical parts are safe and up to code. These aren’t just nice-to-haves; they’re your guarantee that you’re buying a safe, reliable, and compliant piece of professional equipment.

Calculating the True Cost of Your Freezer

The sticker price on a commercial freezer? Think of that as just the down payment. To really understand what you're getting into, you have to look past the initial price tag and calculate the freezer's Total Cost of Ownership (TCO). This isn't just a fancy acronym; it's a financial strategy that turns energy efficiency from a nice-to-have feature into a core part of your business plan.

An inefficient freezer is a silent drain on your resources, costing you money every single day it's plugged in. A high-efficiency unit, on the other hand, is a smart investment that pays you back over time with lower utility bills. Looking at the freezer's entire operational lifespan is the only way to make a truly profitable decision.

Understanding ENERGY STAR and Lifetime Savings

When you see that blue ENERGY STAR sticker, it’s not just for show. It's a certification from the U.S. Environmental Protection Agency (EPA) guaranteeing the freezer meets some pretty strict energy performance standards. On average, ENERGY STAR certified commercial freezers are 15% more efficient than their standard counterparts.

That efficiency boost comes from smarter engineering and better parts.

- Modern Compressors: Think of these like a finely-tuned car engine. They provide all the cooling power you need while sipping, not guzzling, electricity.

- High-Grade Insulation: Advanced polyurethane foam acts as a powerful thermal barrier. It keeps the cold air locked in, meaning the compressor doesn't have to kick on nearly as often.

- LED Lighting: Old-school fluorescent bulbs actually generate heat, forcing the cooling system to work harder. Bright, efficient LED lights produce almost no heat, cutting down on that extra workload.

Figuring out the potential savings is simpler than you might think. Just compare the annual energy consumption (it's listed in kWh on the EnergyGuide label) of two different models. Then, multiply the difference by your local electricity rate. Over a freezer's typical 10-year lifespan, choosing an ENERGY STAR model can easily save you thousands of dollars.

Calculating Total Cost of Ownership

The Total Cost of Ownership (TCO) formula paints the complete financial picture. It forces you to look beyond day one and account for every dollar you'll spend to keep the unit running.

TCO = Initial Purchase Price + (Annual Energy Cost x Lifespan in Years) + Estimated Maintenance Costs

This simple equation makes it crystal clear how a slightly more expensive, energy-efficient model often ends up being the cheaper option in the long run. Saving a few hundred bucks upfront can be quickly erased by years of inflated energy bills.

The entire commercial refrigeration market is shifting in this direction. Driven by new regulations to cut energy use, manufacturers are innovating with better insulation and more advanced compressors to lower operating costs for kitchens like yours. Today's best commercial freezers are built for both performance and sustainability.

This long-term mindset is critical for your bottom line. If the upfront cost is a hurdle, you can also explore B2B equipment renting and leasing options to better manage your cash flow. But whether you buy or lease, making energy efficiency a priority is a strategic move that directly protects your profits.

Pairing Your Freezer with the Right Prep Table

A great kitchen runs like a well-oiled machine, and that flow depends on how your cold storage and prep surfaces work together. Matching your commercial freezer to the right prep table isn't just about getting more counter space—it's about creating a seamless workflow that makes your team faster and keeps your food safer. Get this combination right, and you'll turn a chaotic service into a smooth operation.

Types of Stainless Steel Prep Tables

The foundation of any good prep area is a stainless steel table, but not all are created equal. Different types and grades of steel are used to balance cost, durability, and function, making it crucial to choose the right one for your needs.

- 304 Stainless Steel: This is the industry gold standard for food-contact surfaces. Its higher chromium and nickel content gives it superior resistance to rust and corrosion, making it perfect for direct contact with acidic ingredients like tomato sauce or citrus. It's the premium choice for tabletops.

- 430 Stainless Steel: A more budget-friendly option, 430 stainless steel is often used for the legs, undershelves, and frames of prep tables. While still durable and corrosion-resistant, it's not as robust as 304 and is best suited for non-food-contact parts of the table.

Beyond the grade of steel, tables come in various configurations. A simple work table offers a flat surface and an undershelf for storage. Some feature a backsplash to protect walls from splashes, while equipment stands are built lower to the ground with heavy-gauge steel to support heavy appliances like mixers or slicers.

The smartest kitchen layouts always minimize the steps between cold storage and prep. Think of a refrigerated prep table as the perfect midpoint—it ensures your ingredients stay safe and chilled from the second they're pulled from the freezer until they hit the grill.

Specialized Refrigerated Prep Tables

The real game-changer is when you integrate refrigeration directly into the prep station. These units are designed to keep ingredients within arm's reach while maintaining the crucial cold chain, preventing food from entering the temperature danger zone during service.

Sandwich and Salad Prep Tables

Designed for the fast-paced environment of delis, cafes, and salad bars, these tables are efficiency powerhouses. They combine three essential features into one unit: a refrigerated cabinet base for backup storage, a durable cutting board work surface, and a refrigerated top rail with insulated wells for holding food pans.

This setup keeps meats, cheeses, vegetables, and dressings perfectly chilled and organized. Staff can assemble orders quickly without ever leaving their station, dramatically increasing throughput during a busy lunch rush. Placing an undercounter freezer and refrigerator combo nearby can further streamline operations.

Pizza Prep Tables

For any pizzeria, the pizza prep table is mission control. These specialized units feature an extra-deep work surface to accommodate large pizza doughs and a raised, refrigerated rail to hold all the essential toppings. The rail is strategically positioned so a chef can stretch dough, apply sauce, and add cheese and toppings in one fluid motion.

This ergonomic design makes the pizza-building process incredibly fast and efficient. By keeping every ingredient organized and held at a safe temperature, a pizza prep table ensures consistency and food safety, even during the busiest Friday night service.

Proactive Maintenance to Protect Your Investment

Dropping serious cash on the best commercial freezer for your kitchen is a big move. But thinking of it as a one-and-done deal is a huge mistake. This isn't just a purchase; it's an asset that needs regular attention to give you a solid return on your investment. Proactive maintenance isn't just another task on your checklist—it's a financial strategy. It's what stands between you and catastrophic product loss, sky-high emergency repair bills, and a short lifespan for your equipment.

Skipping basic upkeep is like never changing the oil in your delivery van. It might run for a while, but eventually, a small, fixable issue is going to blow up into a massive, expensive breakdown. A consistent maintenance routine is your best defense against unexpected downtime and a cooler full of spoiled inventory.

Daily and Weekly Maintenance Checks

The most powerful maintenance habits are the small, consistent things you and your team do every single day. These quick checks are your early warning system, catching problems before they spiral out of control and keeping your freezer running efficiently.

- Monitor Temperature Logs: Check and write down the freezer's internal temperature at least once a day. This log is your first line of defense, creating a clear record that helps you spot a gradual cooling problem before it becomes a full-blown crisis.

- Wipe Down Surfaces: Clean up spills immediately, both inside and out. This simple step prevents bacteria from growing, stops ice from building up, and keeps corrosive liquids from eating away at your stainless steel.

- Inspect Door Gaskets Weekly: Take a close look at the rubber door seals. Are there any cracks, tears, or spots where they've become brittle? A bad gasket lets cold air pour out, forcing the compressor to work overtime and sending your energy bill through the roof.

Monthly and Quarterly Deep Cleaning

Deeper maintenance jobs, done on a regular monthly or quarterly schedule, are absolutely critical for the long-term health of your freezer. These tasks focus on the hardest-working parts—the ones most likely to fail if you ignore them. The condenser coil, especially, is the heart of your freezer's cooling system.

A dirty condenser coil is the number one cause of commercial freezer inefficiency and premature compressor failure. It forces the system to work harder to release heat, leading to higher energy consumption and eventual breakdown. Cleaning it every 90 days is the single most important task you can perform.

For a complete rundown of equipment upkeep, you can find more tips in our comprehensive guide to commercial kitchen equipment maintenance.

Recognizing Professional Service Warnings

While routine cleaning is your job, some signs are red flags for a bigger problem that needs a certified technician. Trying to DIY complex mechanical or electrical issues can easily void your warranty and, more importantly, create a serious safety hazard. It's time to call in a pro if you notice:

- Unusual Noises: Any grinding, clanking, or loud buzzing sounds are often a cry for help from a failing compressor motor or fan.

- Constant Motor Operation: If the freezer motor never seems to cycle off, it could be a sign of a refrigerant leak or a busted thermostat.

- Excessive Ice Buildup: A rapid or heavy frost accumulation can point to problems with the defrost system or a door seal that's given up.

Keeping your commercial freezer in top shape is a core part of smart facility management. To really optimize your kitchen's operations and protect your entire investment, think about incorporating broader facility management best practices into your overall game plan.

Your Top Questions About Commercial Freezers, Answered

When you're diving into the world of commercial freezers, a lot of questions can pop up. Getting the right answers, from installation to daily upkeep, is key to protecting your investment and keeping your kitchen running without a hitch. Let's tackle some of the most common things business owners ask.

What Is the Difference Between a Commercial and Residential Freezer?

The biggest differences boil down to three things: durability, cooling power, and health code compliance. Commercial freezers are built tough, usually with heavy-duty stainless steel, to handle the constant slam of a professional kitchen. Their compressors are much more powerful, designed to chill food fast and hold that temperature steady, even when the doors are constantly being opened.

But the most important part? The best commercial freezer models are NSF certified. This certification means they meet strict public health standards, making them easy to clean and safe for storing food. Your freezer at home doesn't have to meet this critical standard.

How Often Should I Clean the Condenser Coils?

You should plan on cleaning the condenser coils every 90 days as a general rule. But that schedule isn't set in stone; it really depends on your kitchen's environment. If you're running a busy bakery or a pizzeria with a lot of flour, grease, or dust in the air, you'll want to clean them monthly.

Neglecting the coils is the fastest way to cause problems. Dirty coils force the compressor to work much harder, which spikes your energy bills, diminishes cooling performance, and can lead to expensive, premature equipment failure.

Should I Choose a Top-Mount or Bottom-Mount Compressor?

This choice really depends on the specific conditions in your kitchen. There’s a right answer for every situation.

- Top-mount units are perfect for places with a lot of debris on the floor, like bakeries. Because they pull in cleaner air from higher up, the coils stay clean for longer.

- Bottom-mount units are easier on your staff's backs. They raise the freezer's bottom shelf, so there's less bending down. They're also usually easier for technicians to get to when it's time for service.

The main downside to a bottom-mount compressor is that it tends to suck in floor dust, which just means you'll need to be more diligent about cleaning those coils.

Can I Use an Extension Cord with My Freezer?

Absolutely not. You should never, ever use an extension cord to power a commercial freezer. These are powerful machines that draw a lot of electricity. They have to be plugged directly into a dedicated circuit that can handle their specific voltage and amperage needs.

Using an extension cord isn't just a massive fire hazard; it can also wreck the freezer's compressor. On top of that, it will almost certainly void the manufacturer's warranty, leaving you on the hook for any repair bills.

Ready to find the perfect freezer and prep table combination for your kitchen? Explore the extensive collection at PrepTables.com to discover durable, NSF-certified equipment designed for professional performance. Visit us at https://preptables.com to optimize your workflow today.